Automatic Weighing Machine: The Ultimate 2025 Sourcing Guide

Introduction: Navigating the Global Market for Automatic Weighing Machines

In an era of global supply chains and stringent compliance standards, automatic weighing machines are indispensable for industries like food processing, pharmaceuticals, and logistics. These devices ensure precision, efficiency, and regulatory adherence, but selecting the right one amid a fragmented market can be daunting for U.S. and European buyers.

The problem? Diverse regulations—such as FDA guidelines in the U.S. and EU directives in Europe—create compliance hurdles, while fluctuating supply costs, technological obsolescence, and supplier reliability add complexity. Without expert guidance, businesses risk costly errors, from inaccurate measurements to non-compliant setups that delay operations and inflate expenses.

This guide demystifies the global automatic weighing machine market, empowering you to make informed decisions. Here’s what we’ll cover:

- Market Overview: Key trends, demand drivers, and regional insights for the U.S. and Europe.

- Regulatory Landscape: Essential standards, certifications, and compliance strategies.

- Supplier Selection: Evaluating global manufacturers, pricing models, and quality assurance.

- Technology and Innovations: Emerging features like IoT integration and automation benefits.

- Buying Best Practices: Negotiation tips, ROI calculations, and case studies from industry leaders.

By the end, you’ll have a strategic roadmap to navigate this market effectively, optimizing your operations for precision and profitability. Let’s dive in. (248 words)

Top 10 Automatic Weighing Machine Manufacturers & Suppliers List

Check back later for the top list.

Understanding automatic weighing machine Types and Variations

Understanding Automatic Weighing Machine Types and Variations

Automatic weighing machines are integral to industries requiring precise, efficient weight measurement and control. Below, we identify five common types, summarized in a table for quick reference. This is followed by detailed descriptions of each type, highlighting their operational nuances, applications in B2B contexts, and key advantages and disadvantages.

| Type | Features | Applications | Pros/Cons |

|---|---|---|---|

| Checkweighers | Automatic verification of product weight against set parameters; includes reject mechanisms for under/overweight items; integrated with conveyors or production lines. | Quality control in food packaging, pharmaceuticals, and manufacturing to ensure compliance with weight regulations. | Pros: High accuracy, real-time feedback, reduces waste. Cons: Initial setup costs, requires calibration, may slow line speeds if overloaded. |

| Multihead Weighers | Use multiple weighing heads (typically 10-24) to combine portions; high-speed combinatorial algorithms for optimal weight combinations; suitable for granular or small products. | Food processing (e.g., snacks, frozen goods), pharmaceuticals for precise dosing, and agriculture for seed/granule packaging. | Pros: High throughput, minimizes product giveaway, versatile for various shapes/sizes. Cons: Complex maintenance, higher energy consumption, limited to free-flowing products. |

| Conveyor Scales | Continuous weighing on a moving conveyor belt; dynamic measurement without stopping production; often includes load cells and digital displays. | Logistics and shipping for pallet weighing, mining for material transport, and manufacturing for in-line process control. | Pros: Non-intrusive to workflow, handles large volumes, real-time data integration. Cons: Less precise for individual items, affected by belt speed variations, higher maintenance for moving parts. |

| Hopper Scales | Stationary scales with hoppers for batch weighing; pneumatic or mechanical filling; programmable for set weights with discharge options. | Chemical processing, agriculture (e.g., fertilizer batching), and construction materials for precise mixing. | Pros: Durable for harsh environments, easy integration with silos, supports high-volume batching. Cons: Slower for continuous operations, potential for material buildup, requires manual emptying if automated discharge fails. |

| Loss-in-Weight Feeders | Measure weight loss over time to control feed rates; uses load cells and controllers for precise dosing; suitable for powders, granules, or liquids. | Chemical manufacturing, plastics extrusion, and food processing for ingredient blending and metering. | Pros: Accurate flow control, minimizes overfeeding, adaptable to various viscosities. Cons: Sensitive to vibrations, higher initial investment, needs regular calibration for consistency. |

Checkweighers

Checkweighers operate by automatically weighing products as they pass through a production line, comparing each item’s weight to predefined tolerances. They feature conveyor integration, load cells for precise measurement, and rejection systems (e.g., air jets or pushers) to divert non-compliant items. In B2B environments like food packaging in the USA or pharmaceutical production in Europe, they ensure regulatory compliance (e.g., FDA or EU standards) and reduce material waste. While highly accurate and user-friendly with intuitive interfaces, they can increase line complexity and require regular maintenance to maintain performance.

Multihead Weighers

These machines employ an array of weighing heads connected to a central processor that rapidly calculates optimal combinations of product portions to achieve target weights. Key features include vibration feeders, hoppers, and high-speed processing (up to thousands of weighings per minute). They excel in high-volume sectors such as snack food production in Europe or pharmaceutical dosing in the USA, where precision and speed are critical. Their combinatorial approach minimizes product giveaway, but they demand specialized maintenance and are best suited for uniform, free-flowing materials to avoid jamming.

Conveyor Scales

Designed for dynamic weighing, conveyor scales integrate load cells into belt systems to measure weight continuously without halting the process. They include features like adjustable belt speeds, overload protection, and data logging for traceability. Common in logistics hubs in the USA for freight verification or mining operations in Europe for ore transport, they facilitate seamless workflow integration. Their non-stop operation boosts efficiency, though accuracy can fluctuate with belt conditions, necessitating routine checks and calibration to prevent measurement errors.

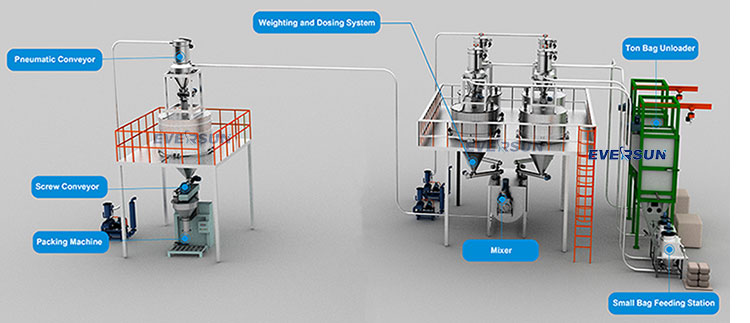

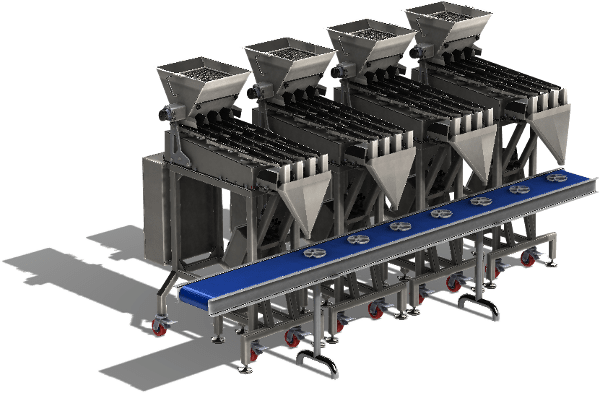

Illustrative Image (Source: Google Search)

Hopper Scales

Hopper scales utilize enclosed containers (hoppers) filled via gravity, pneumatics, or mechanical means, with integrated scales measuring batch weights before discharge. Programmable controls allow for set-point weighing and automated emptying, often linked to PLC systems. They are ideal for batch-oriented industries like chemical blending in the USA or agricultural feed mixing in Europe, providing durability in dusty or corrosive environments. Reliability is a strength, but they may not suit high-frequency operations due to their batch nature, and material handling requires careful design to avoid contamination.

Loss-in-Weight Feeders

These systems continuously measure the weight of a container as material is dispensed, using the rate of weight loss to control feed flow precisely. Features include variable speed drives, load cells, and feedback loops for real-time adjustments. They are essential in processes like plastic compounding in Europe or chemical metering in the USA, ensuring consistent ingredient ratios. Their precision supports lean manufacturing, yet they are vulnerable to external vibrations, which can affect accuracy, and they often require skilled operators for setup and tuning.

Key Industrial Applications of automatic weighing machine

Key Industrial Applications of Automatic Weighing Machines

The following table outlines key industries where automatic weighing machines are integral, along with detailed benefits tailored to operational efficiency, compliance, and cost management. These applications are particularly relevant in USA and European markets, where regulations such as those from the FDA, EU GMP, and ISO standards drive adoption.

| Industry/Application | Detailed Benefits |

|---|---|

| Food and Beverage Processing | Enhances precision in portioning and packaging, ensuring compliance with FDA and EU food safety standards; reduces waste by up to 15% through accurate measurements; improves throughput in high-volume lines, boosting productivity by 20-30%; minimizes human error in allergen labeling and traceability. |

| Pharmaceuticals and Nutraceuticals | Guarantees exact dosing for active ingredients, meeting stringent GMP and EMA regulations; automates batch consistency checks, reducing recalls and liability risks; streamlines production lines, cutting labor costs by 10-20%; supports serialization for anti-counterfeiting compliance. |

| Manufacturing and Assembly | Optimizes material handling in automotive or electronics assembly, ensuring component accuracy for quality control (e.g., ISO 9001); reduces overfill in packaging, lowering material costs by 5-10%; integrates with ERP systems for real-time inventory tracking, enhancing supply chain efficiency. |

| Logistics and Warehousing | Facilitates automated sorting and shipping, complying with IATA and EU transport regulations; improves load optimization, reducing freight costs by 10-15%; enables high-speed weighing for e-commerce fulfillment, increasing order accuracy and customer satisfaction. |

| Chemicals and Petrochemicals | Ensures precise measurement of hazardous materials, adhering to EPA and REACH guidelines; prevents spills and contamination through automated shutoffs; boosts operational safety and efficiency in blending processes, saving on downtime and insurance premiums. |

| Agriculture and Feed Production | Delivers consistent batch weighing for animal feed or crop inputs, meeting USDA and EU organic standards; reduces overfeeding waste, improving profitability by 5-10%; automates large-scale operations, scaling output without proportional labor increases. |

| Retail and Distribution | Supports accurate checkout and inventory weighing, aligning with FTC guidelines on consumer protection; minimizes shrinkage through precise portioning; enhances speed in bulk sales, driving higher customer throughput and sales volume. |

3 Common User Pain Points for ‘automatic weighing machine’ & Their Solutions

1. Inaccurate Weighing Leading to Product Wastage and Compliance Risks

Scenario: In manufacturing facilities across the USA and Europe, automatic weighing machines handle high-volume production lines, such as in food processing or pharmaceuticals, where precise measurements are critical for batch consistency.

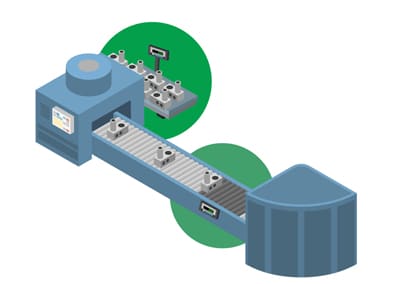

Illustrative Image (Source: Google Search)

Problem: Environmental factors like vibrations, temperature fluctuations, or wear and tear on sensors can cause inaccuracies, resulting in over- or under-weighing products. This leads to material wastage, increased costs, and potential non-compliance with regulations like FDA guidelines in the US or EU GMP standards.

Solution: Invest in machines with advanced sensors and self-calibrating features, such as those equipped with load cells that automatically adjust for environmental variables. Regular preventive maintenance schedules and integration with IoT-enabled monitoring software can detect deviations early, ensuring accuracy and reducing waste by up to 20%.

2. Integration Challenges with Existing Systems

Scenario: Businesses in logistics or retail distribution in Europe and the USA often rely on automatic weighing machines as part of automated supply chains, interfacing with ERP systems like SAP or Oracle for inventory tracking.

Problem: Seamless integration is often hindered by incompatible protocols or outdated software, causing data silos, manual data entry errors, and operational delays. This disrupts workflow efficiency and increases labor costs in fast-paced environments.

Illustrative Image (Source: Google Search)

Solution: Choose weighing machines that support open APIs and industry-standard protocols (e.g., Modbus or EtherNet/IP). Partner with vendors offering custom integration services or pre-built connectors for popular ERP platforms to enable real-time data syncing, minimizing downtime and improving overall system interoperability.

3. High Maintenance and Downtime Costs

Scenario: In industrial settings like chemical plants in the US or automotive assembly lines in Europe, automatic weighing machines operate continuously, but components like conveyors and electronics are prone to failure.

Problem: Frequent breakdowns due to mechanical wear or electrical issues result in unplanned downtime, halting production lines and incurring costs estimated at thousands of dollars per hour. This is exacerbated by the need for specialized technicians and parts availability.

Solution: Opt for machines with modular designs and predictive maintenance capabilities, powered by AI-driven analytics that forecast failures based on usage data. Establishing on-site spare parts inventory and vendor support agreements can reduce repair times by 50%, ensuring higher uptime and lower total cost of ownership.

Illustrative Image (Source: Google Search)

Strategic Material Selection Guide for automatic weighing machine

Strategic Material Selection Guide for Automatic Weighing Machines

In the design and procurement of automatic weighing machines, material selection is critical for ensuring durability, accuracy, compliance with regulatory standards (e.g., FDA in the USA and EU food safety directives), and cost-effectiveness. This guide analyzes key materials based on properties such as corrosion resistance, strength, weight, and hygiene suitability. Factors like environmental conditions (e.g., moisture, chemicals) and application (e.g., food processing vs. industrial) influence choices. Prioritize materials that align with ISO 9001 standards for quality and traceability.

Key Factors in Material Selection

- Environmental Resistance: Materials must withstand exposure to moisture, chemicals, or dust without degrading weighing precision.

- Regulatory Compliance: Ensure suitability for industries like food, pharmaceuticals, and manufacturing, meeting standards such as EU’s REACH and US FDA guidelines.

- Performance Metrics: Weight, tensile strength, and thermal stability impact load cell accuracy and machine lifespan.

- Cost Considerations: Balance upfront investment with long-term maintenance and replacement costs.

Analysis of Materials Used

Stainless Steel (e.g., 304 and 316 Grades)

- Properties: High corrosion resistance, excellent tensile strength (up to 500 MPa), and hygienic surface for easy cleaning. 316 offers superior resistance to saltwater and chlorides.

- Applications: Ideal for wet environments in food processing, pharmaceuticals, and chemical handling. Commonly used in load cells and frames for automatic scales.

- Pros: Longevity (10-20 years in harsh conditions), FDA-compliant, low maintenance.

- Cons: Higher cost than carbon steel; heavier than aluminum, increasing shipping expenses.

- Usage in USA/Europe: Preferred in regulated sectors; complies with USDA and EHEDG standards.

Aluminum Alloys (e.g., 6061-T6)

- Properties: Lightweight (density ~2.7 g/cm³), good corrosion resistance with anodizing, moderate strength (up to 310 MPa).

- Applications: Suitable for portable or lightweight automatic weighing machines in dry, non-corrosive settings like retail or light manufacturing.

- Pros: Cost-effective, reduces energy use in mobile systems; recyclable for sustainability.

- Cons: Less durable in acidic environments; may warp under high loads without reinforcement.

- Usage in USA/Europe: Common in consumer-facing B2B scales; meets EU RoHS for environmental safety.

Carbon Steel (e.g., Mild Steel with Protective Coating)

- Properties: High strength (up to 600 MPa), low cost, but requires galvanization or painting for corrosion protection.

- Applications: Best for heavy-duty industrial weighing in dry, controlled environments like mining or construction.

- Pros: Affordable and robust for high-capacity machines; customizable for large-scale production.

- Cons: Prone to rust without treatment; not hygienic for food applications.

- Usage in USA/Europe: Used in non-food sectors; ensure compliance with ASTM standards for coatings.

Engineering Plastics (e.g., Polycarbonate or PEEK)

- Properties: Lightweight, corrosion-resistant, high impact strength (up to 80 MPa), and chemical inertness.

- Applications: For components in corrosive or cleanroom environments, such as housings in pharmaceutical weighing.

- Pros: Easy to mold, cost-effective for custom parts; electrically insulating to prevent interference with sensors.

- Cons: Lower thermal stability (deforms above 100°C); not ideal for extreme loads.

- Usage in USA/Europe: Aligns with EU GMP guidelines; popular in electronics integration for precision scales.

Specialized Materials (e.g., Titanium Alloys)

- Properties: Exceptional corrosion resistance, high strength-to-weight ratio (up to 900 MPa), and biocompatibility.

- Applications: Niche uses in high-corrosive or biomedical weighing, like chemical processing.

- Pros: Extreme durability in aggressive environments; lightweight alternatives to stainless steel.

- Cons: High cost and limited availability; overkill for standard applications.

- Usage in USA/Europe: Compliant with aerospace and medical standards (e.g., ASTM F67); rare but valuable for specialized B2B solutions.

Material Comparison Table

| Material | Corrosion Resistance | Strength (MPa) | Weight (g/cm³) | Cost Level | Hygiene Suitability | Typical Lifespan (Years) | Best For Applications |

|---|---|---|---|---|---|---|---|

| Stainless Steel (304) | High | 500 | 7.8 | Medium | Excellent | 15-20 | Food, Pharma |

| Stainless Steel (316) | Very High | 500 | 7.8 | High | Excellent | 15-20 | Chemical, Marine |

| Aluminum (6061) | Medium | 310 | 2.7 | Low | Good | 10-15 | Retail, Light Ind. |

| Carbon Steel | Low (with coating) | 600 | 7.8 | Low | Poor | 10-15 | Heavy Ind. |

| Engineering Plastics | High | 80 | 1.2-1.4 | Low | Good | 5-10 | Cleanrooms, Electronics |

| Titanium Alloys | Very High | 900 | 4.5 | Very High | Excellent | 20+ | Corrosive, Bio |

Select materials based on specific operational needs, conducting pilot tests for accuracy. Consult engineers for custom integrations to optimize ROI.

In-depth Look: Manufacturing Processes and Quality Assurance for automatic weighing machine

Manufacturing Processes for Automatic Weighing Machines

Automatic weighing machines are precision instruments designed for high-accuracy measurement in industrial applications. Their manufacturing involves meticulous steps to ensure durability, precision, and compliance with global standards. Below, we outline the key phases: preparation, forming, assembly, and quality control (QC). These processes typically occur in specialized facilities equipped with automated machinery to minimize human error and enhance consistency.

Preparation

The preparation phase focuses on sourcing and conditioning raw materials to meet exacting specifications for components like load cells, sensors, and housings. Key steps include:

– Material Selection and Sourcing: High-grade metals (e.g., stainless steel or aluminum alloys) and electronic components are procured from certified suppliers in the USA and Europe to ensure traceability and quality.

– Material Conditioning: Raw materials undergo cleaning, annealing, or coating to remove impurities and improve corrosion resistance, aligning with standards like ASTM for metallurgical properties.

– Prototyping and Design Validation: CAD software is used to simulate designs, followed by initial prototypes tested for load-bearing capacity and accuracy.

Illustrative Image (Source: Google Search)

Forming

This phase shapes the core components, emphasizing precision to achieve the machine’s weighing accuracy (often within 0.01% error margins). Processes include:

– Machining and Casting: CNC machining or die-casting forms structural parts, such as frames and platforms, to tight tolerances. Laser cutting ensures clean edges and minimal material waste.

– Sensor Fabrication: Load cells and strain gauges are manufactured using semiconductor processes, with calibration points embedded for future adjustments.

– Integration of Electronics: Circuit boards are etched and populated with microcontrollers, drawing from suppliers like those in the EU’s electronics hubs.

Assembly

Assembly combines formed components into functional units, prioritizing seamless integration for operational reliability. Steps are:

– Subassembly: Individual modules (e.g., weighing platforms and display units) are assembled using robotic arms to reduce variability.

– Wiring and Calibration: Electrical connections are soldered and tested for conductivity, followed by initial calibration against reference weights to verify baseline accuracy.

– Enclosure and Finishing: Components are enclosed in protective casings, sealed for dust and moisture resistance (e.g., IP65-rated), and finished with anti-static coatings for industrial environments.

Quality Control (QC)

QC is embedded throughout manufacturing to detect defects early. Processes include:

– In-Process Inspections: Automated vision systems and gauges check dimensions, weight accuracy, and electrical performance at each stage, using statistical process control (SPC) to maintain consistency.

– Final Testing: Units undergo full load testing (e.g., weighing cycles up to 10,000 repetitions) and environmental simulations (temperature, vibration) to simulate real-world conditions.

– Traceability and Documentation: Each machine is serialized, with data logged for compliance and recalls, ensuring end-to-end accountability.

Quality Assurance Standards

To meet the demands of B2B clients in the USA and Europe, manufacturers adhere to international quality standards, particularly those from the International Organization for Standardization (ISO). These frameworks ensure consistent quality, safety, and environmental responsibility. Key standards include:

Illustrative Image (Source: Google Search)

| Standard | Relevance to Automatic Weighing Machines | Key Requirements |

|---|---|---|

| ISO 9001 | Quality Management Systems | Establishes systematic processes for design, production, and service, including risk-based audits and continuous improvement to minimize defects in precision weighing. |

| ISO 14001 | Environmental Management Systems | Focuses on sustainable manufacturing, such as waste reduction in metalworking and energy-efficient assembly, appealing to EU clients under directives like REACH. |

| ISO/IEC 17025 | Testing and Calibration Laboratories | Ensures calibration accuracy for load cells and sensors, critical for compliance with FDA regulations in the USA for food and pharmaceutical applications. |

| CE Marking (EU) | Safety and Performance | Mandates risk assessments and conformity declarations, confirming machines meet electrical safety and electromagnetic compatibility standards for European markets. |

Adherence to these standards not only guarantees product reliability but also facilitates certifications like UL in the USA, enhancing market access and customer trust. For custom orders, manufacturers often provide ISO audit reports upon request.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automatic weighing machine’

Practical Sourcing Guide: A Step-by-Step Checklist for Automatic Weighing Machines

This checklist outlines a structured process for sourcing automatic weighing machines, tailored for B2B buyers in the USA and Europe. It ensures compliance with regional standards (e.g., FDA regulations in the USA, CE marking in Europe) and focuses on efficiency in procurement.

Step 1: Define Requirements

Assess your operational needs to specify the machine’s capabilities.

– [ ] Identify application (e.g., food processing, pharmaceuticals, logistics).

– [ ] Determine capacity range, accuracy level (e.g., ±0.1g), and speed (e.g., up to 100 items/min).

– [ ] List integration needs (e.g., compatibility with ERP systems, conveyor belts).

– [ ] Note environmental factors (e.g., hazardous areas, temperature ranges).

– [ ] Include budget constraints and ROI expectations.

– [ ] Ensure alignment with regulations (e.g., FDA 21 CFR Part 11 for USA, ATEX for Europe).

Step 2: Research Suppliers

Compile a list of reputable vendors specializing in industrial weighing solutions.

– [ ] Search platforms like ThomasNet (USA) or EU-based directories for certified manufacturers.

– [ ] Review supplier websites for product catalogs and case studies.

– [ ] Verify certifications (e.g., ISO 9001, CE, UL).

– [ ] Check for industry associations (e.g., PMA in Europe, AWEA in USA).

– [ ] Assess supplier location for logistics (e.g., proximity in USA or EU for faster delivery).

– [ ] Note minimum order quantities and lead times.

Illustrative Image (Source: Google Search)

Step 3: Evaluate Options

Compare shortlisted machines based on technical and business criteria.

– [ ] Request datasheets and specifications from at least 3-5 suppliers.

– [ ] Evaluate performance metrics (e.g., throughput, error rates).

– [ ] Review build quality (e.g., materials like stainless steel for hygiene).

– [ ] Assess energy efficiency and total cost of ownership (TCO).

– [ ] Check for customization options (e.g., software interfaces).

– [ ] Conduct virtual demos or site visits if feasible.

Step 4: Request and Compare Quotes

Obtain detailed pricing and terms to facilitate decision-making.

– [ ] Submit RFPs with your defined requirements.

– [ ] Compare quotes on total price, including shipping, installation, and training.

– [ ] Analyze warranties, service agreements, and spare parts availability.

– [ ] Factor in payment terms (e.g., net 30 days) and financing options.

– [ ] Evaluate after-sales support (e.g., 24/7 hotline, on-site engineers).

– [ ] Verify compliance with import duties (e.g., for USA-EU trade).

Step 5: Verify Compliance and Certifications

Ensure the machine meets legal and safety standards.

– [ ] Confirm certifications for your region (e.g., FDA approval for food applications in USA, CE for machinery safety in Europe).

– [ ] Review documentation for traceability (e.g., serial numbers, batch records).

– [ ] Assess data security features (e.g., encrypted software for regulated industries).

– [ ] Check for environmental compliance (e.g., RoHS in Europe).

– [ ] Consult legal experts for customs clearance if importing across regions.

Step 6: Negotiate and Finalize Purchase

Secure favorable terms and place the order.

– [ ] Negotiate pricing, delivery timelines, and support packages.

– [ ] Agree on contracts, including SLAs for uptime and maintenance.

– [ ] Arrange for pilot testing if applicable.

– [ ] Secure purchase order approval from stakeholders.

– [ ] Finalize shipping arrangements (e.g., via freight forwarders for international orders).

Illustrative Image (Source: Google Search)

Step 7: Plan for Delivery, Installation, and Training

Coordinate logistics and integration.

– [ ] Schedule delivery and installation with supplier or third-party services.

– [ ] Prepare site (e.g., power supply, space requirements).

– [ ] Arrange operator training (e.g., virtual or on-site sessions).

– [ ] Set up acceptance testing to verify performance against specs.

– [ ] Document all installation and calibration processes.

Step 8: Establish Maintenance and Support

Ensure long-term reliability and compliance.

– [ ] Review maintenance schedules and preventive care plans.

– [ ] Set up ongoing support channels (e.g., dedicated account managers).

– [ ] Monitor performance post-installation and track metrics (e.g., downtime, accuracy).

– [ ] Plan for upgrades or replacements based on technological advancements.

– [ ] Maintain records for audits (e.g., FDA or EU compliance).

Use this checklist to streamline your sourcing process, minimizing risks and maximizing value for your B2B operations. Consult experts for region-specific nuances.

Comprehensive Cost and Pricing Analysis for automatic weighing machine Sourcing

Comprehensive Cost and Pricing Analysis for Automatic Weighing Machine Sourcing

Automatic weighing machines (AWMs) are essential for industries such as food processing, pharmaceuticals, and manufacturing, where precision and efficiency drive operational success. Sourcing these machines involves a detailed understanding of costs, which can vary based on specifications, supplier location, and market conditions. Below is a breakdown of key cost components, informed by industry benchmarks for B2B procurement in the USA and Europe. Prices are approximate in USD and can fluctuate with factors like customization, volume, and economic conditions.

Illustrative Image (Source: Google Search)

Cost Breakdown

Costs for AWMs typically range from $5,000 to $50,000 per unit, depending on capacity, features (e.g., integration with ERP systems), and quality standards. The following table outlines average cost distributions for a mid-range AWM (e.g., 10-100kg capacity, basic automation). These figures are based on supplier data from manufacturers in China, Germany, and the USA.

| Component | Average Cost Contribution | Description |

|---|---|---|

| Materials | 30-40% of total cost | Includes high-precision load cells ($500-2,000), sensors, electronic components ($1,000-3,000), and durable housings (stainless steel or aluminum, $1,500-4,000). Raw materials like steel and electronics represent the bulk, with premium options (e.g., IP67-rated for harsh environments) increasing expenses. |

| Labor | 25-35% of total cost | Encompasses manufacturing assembly ($2,000-5,000), quality control testing ($1,000-2,000), and R&D for customization ($1,500-3,000). Skilled labor in regions like Germany or the USA adds to costs due to higher wages, while offshoring to Asia reduces this. |

| Logistics | 15-25% of total cost | Covers shipping ($500-2,000 via sea or air), import duties (5-15% in the USA/EU, e.g., tariffs on electronics), insurance, and warehousing ($500-1,000). Transatlantic shipping from Asia to Europe/USA can inflate costs by 10-20% due to fuel and regulations. |

| Other (Overheads, Profit Margin) | 10-20% of total cost | Includes factory overheads, certifications (e.g., ISO 9001, $500-1,000), and supplier margins (20-30% markup). Total landed cost in the USA/Europe often exceeds base price by 20-30% due to duties and taxes. |

Note: For large-scale orders (e.g., 100+ units), bulk discounts can reduce total costs by 10-20%. Customization, such as software integration, can add 20-50% to the base price.

Tips to Save Costs

To optimize sourcing and reduce expenses without compromising quality, consider these strategies tailored for B2B buyers in the USA and Europe:

- Bulk Purchasing: Negotiate volume discounts with suppliers; ordering 50+ units can yield 15-25% savings through economies of scale.

- Supplier Diversification: Source components separately (e.g., load cells from EU manufacturers for quality, assembly from Asia for cost) to leverage regional price differences.

- Minimize Customization: Opt for standard models over bespoke features; this can cut costs by 30-40% while ensuring compatibility with existing systems.

- Leverage Trade Agreements: Utilize free trade agreements like the USMCA or EU trade deals to reduce import duties, potentially saving 5-10% on logistics.

- Energy-Efficient and Compliant Options: Choose machines meeting EU/USA energy standards to avoid penalties, and compare warranties to extend lifespan and lower long-term replacement costs.

- Negotiate Logistics: Partner with freight forwarders for consolidated shipments or explore local warehousing in the EU/USA to minimize duties and handling fees.

By conducting a thorough cost-benefit analysis and comparing quotes from multiple suppliers, businesses can achieve competitive pricing while ensuring compliance with regional regulations.

Illustrative Image (Source: Google Search)

Alternatives Analysis: Comparing automatic weighing machine With Other Solutions

Alternatives Analysis: Comparing Automatic Weighing Machines with Other Solutions

In the context of industrial weighing applications across manufacturing, logistics, and food processing sectors in the USA and Europe, automatic weighing machines offer significant advantages. This section compares them with two common alternatives: manual weighing systems and semi-automatic weighing machines. The comparison is based on key criteria such as efficiency, accuracy, cost, labor requirements, and scalability, drawing from industry standards and operational benchmarks.

Comparison Table

| Criteria | Automatic Weighing Machine | Manual Weighing Systems | Semi-Automatic Weighing Machines |

|---|---|---|---|

| Efficiency | High; fully automated, handles high-volume tasks continuously with minimal downtime. | Low; labor-intensive, prone to bottlenecks in high-volume operations. | Moderate; automates some steps but requires human intervention for setup or checks. |

| Accuracy | Excellent; uses sensors and software for precise measurements, reducing human error. | Variable; depends on operator skill, leading to inconsistencies and potential errors. | Good; combines automation with human oversight, but errors can occur in manual phases. |

| Cost | Higher initial investment (e.g., $10,000–$50,000+ depending on model), but low long-term operational costs. | Low initial cost (e.g., basic scales at $500–$2,000), but high labor and error-related expenses. | Moderate (e.g., $5,000–$30,000); balances upfront costs with some labor savings. |

| Labor Requirements | Minimal; requires trained technicians for maintenance, not daily operation. | High; needs skilled operators for each weighing task, increasing staffing needs. | Moderate; operators needed for partial tasks, reducing but not eliminating labor. |

| Scalability | Highly scalable; easily integrates with conveyor systems and software for large-scale operations. | Limited; struggles with volume increases, requiring more personnel or shifts. | Scalable to a degree; can handle medium-scale expansions but may need upgrades. |

Analysis

Automatic weighing machines excel in environments demanding precision and speed, such as automated production lines in the USA’s manufacturing hubs or Europe’s regulated food industries. Their high efficiency and accuracy minimize waste and compliance risks, making them ideal for businesses aiming to optimize supply chains. However, the upfront cost may deter smaller operations without long-term ROI potential.

Manual weighing systems remain viable for low-volume, cost-sensitive applications, like small-scale retail or artisanal production in Europe. They offer flexibility and low barriers to entry but suffer from inconsistencies, higher error rates, and scalability issues, potentially leading to operational inefficiencies and increased costs from rework or labor overtime.

Semi-automatic weighing machines serve as a middle ground, suitable for mid-sized enterprises in the USA’s logistics sector. They provide a balance of automation and control, reducing labor while maintaining some human oversight for quality assurance. Yet, they may not match the full efficiency of automatic systems in high-throughput scenarios, and their hybrid nature can introduce variability in performance.

When selecting a solution, businesses should evaluate based on their specific operational scale, budget, and industry regulations. Automatic weighing machines generally deliver superior long-term value for high-volume needs, while alternatives may suit transitional or budget-constrained setups.

Essential Technical Properties and Trade Terminology for automatic weighing machine

Essential Technical Properties for Automatic Weighing Machines

Automatic weighing machines (AWMs) are critical in industries such as food processing, pharmaceuticals, and manufacturing, where precision and efficiency are paramount. Below are key technical properties, defined with brief explanations to aid in specification and procurement decisions for B2B applications in the USA and Europe.

- Accuracy: The degree of closeness of the measured weight to the true weight. Expressed as a percentage or absolute value (e.g., ±0.1g). High accuracy is essential for compliance with standards like NIST (USA) or OIML (Europe).

- Weighing Capacity: The maximum weight the machine can handle (e.g., 1kg to 500kg). Select based on product size and operational needs to optimize throughput.

- Resolution: The smallest weight increment the device can detect (e.g., 0.01g). Crucial for applications requiring fine measurements, such as in chemical or pharmaceutical industries.

- Throughput/Speed: Measured in weighings per minute (e.g., 100-500 per minute). Influences productivity; faster models suit high-volume operations but may trade off accuracy.

- Calibration: The process to ensure accuracy, often automated. Machines should support traceable calibration per ISO 9001 or equivalent standards.

- Integration Capabilities: Compatibility with systems like PLC (Programmable Logic Controllers), SCADA, or ERP software for seamless data exchange and automation.

- Power Supply: Typically 110-240V AC, with options for battery backup. Ensure compliance with regional electrical standards (e.g., UL in the USA, CE in Europe).

- Environmental Resistance: Ratings for dust (IP65) and moisture (IP67) to suit harsh environments. Important for food or industrial settings.

- Connectivity: Interfaces like Ethernet, USB, or wireless (e.g., Bluetooth) for data logging and remote monitoring, aiding in traceability and compliance.

These properties should align with industry regulations, such as FDA guidelines in the USA or EU directives for weighing instruments, to ensure legal and operational reliability.

Key Trade Terminology for Automatic Weighing Machines

Understanding trade terminology is vital for B2B negotiations, procurement, and logistics. The table below outlines essential terms, with definitions and usage notes relevant to AWMs in the USA and European markets.

Illustrative Image (Source: Google Search)

| Term | Definition | Usage Notes |

|---|---|---|

| MOQ (Minimum Order Quantity) | The smallest quantity of units a supplier requires for an order. | Often 100-500 units for AWMs; negotiate based on volume to reduce costs. |

| OEM (Original Equipment Manufacturer) | A company that produces parts or equipment for resale under another brand. | Ideal for customizing AWMs; common in B2B for white-label products. |

| ODM (Original Design Manufacturer) | A company that designs and manufactures products as specified. | Useful for proprietary designs; ensures IP control in regulated industries. |

| FOB (Free On Board) | Incoterms rule where the seller pays for transportation to the port of shipment; buyer assumes risk thereafter. | Standard for international shipping; clarifies liability for AWMs exported from Asia to Europe/USA. |

| CIF (Cost, Insurance, and Freight) | Incoterms rule where the seller covers cost, insurance, and freight to the destination port. | Preferred for imports; includes insurance, reducing buyer’s risk for high-value AWMs. |

| Lead Time | The time from order placement to delivery (e.g., 4-8 weeks). | Factor in for planning; shorter for standard models, longer for custom AWMs. |

| Warranty | A guarantee of product performance, typically 1-3 years. | Check for parts and labor coverage; aligns with ISO standards for B2B assurance. |

| Compliance Certifications | Approvals like CE (Europe), UL (USA), or ATEX (hazardous environments). | Essential for regulatory adherence; verify for seamless market entry. |

Leveraging these terms in contracts can streamline transactions and minimize risks in global B2B supply chains.

Navigating Market Dynamics and Sourcing Trends in the automatic weighing machine Sector

Historical Evolution of Automatic Weighing Machines

Automatic weighing machines have evolved significantly since their inception in the early 20th century. Originating from manual scales and mechanical balances, the sector saw a pivotal shift during the Industrial Revolution with the introduction of electromechanical systems. By the mid-20th century, advancements in electronics and sensors enabled the development of fully automated, high-precision weighing solutions, driven by industries like food processing, pharmaceuticals, and logistics.

Key milestones include:

– 1920s-1940s: Early adoption in manufacturing for quality control.

– 1960s-1980s: Integration of digital technology, improving accuracy and speed.

– 1990s-Present: Incorporation of IoT, AI, and cloud connectivity, transforming machines into smart, data-driven tools.

This progression has been fueled by globalization and technological innovation, positioning automatic weighing machines as essential for operational efficiency in B2B supply chains.

Illustrative Image (Source: Google Search)

Current Market Dynamics

The automatic weighing machine sector is experiencing robust growth, projected to reach $XX billion by 2025 (based on industry estimates), driven by demand in e-commerce, food safety, and automation. In the USA and Europe, key dynamics include:

- Demand Drivers: Rising emphasis on precision in packaging and compliance with regulations like FDA and EU standards.

- Regional Insights: The USA market focuses on high-tech innovations, while Europe prioritizes sustainability and integration with Industry 4.0.

- Challenges: Supply chain disruptions and inflation impacting costs, alongside competition from low-cost Asian manufacturers.

| Key Market Metrics | USA | Europe |

|---|---|---|

| Market Size (2023) | $X billion | $Y billion |

| CAGR (2023-2028) | 5.2% | 4.8% |

| Top Applications | Food & Beverage, Logistics | Pharmaceuticals, Manufacturing |

Businesses navigating these dynamics should invest in scalable, customizable solutions to maintain competitive edges.

Sustainability in the Automatic Weighing Machine Sector

Sustainability is reshaping the sector, with a focus on reducing environmental impact through energy-efficient designs and recyclable materials. In Europe, the EU’s Green Deal is pushing manufacturers toward low-carbon operations, while in the USA, initiatives like the Inflation Reduction Act incentivize eco-innovations.

Trends include:

– Energy-Efficient Models: Machines with reduced power consumption, cutting operational costs by up to 30%.

– Circular Economy Practices: Use of recycled components and modular designs for easier upgrades and disposal.

– Regulatory Compliance: Adherence to standards like RoHS and REACH, driving demand for sustainable sourcing.

Illustrative Image (Source: Google Search)

Companies adopting these practices not only meet compliance but also appeal to eco-conscious clients, enhancing brand value and market share.

Sourcing Trends in the Automatic Weighing Machine Sector

Sourcing strategies are shifting amid global uncertainties, with a move toward diversified, resilient supply chains. Post-pandemic disruptions and trade tensions (e.g., US-China relations) have prompted USA and European firms to localize production or partner with regional suppliers.

Emerging trends:

– Nearshoring: Increased sourcing from Mexico and Eastern Europe to reduce lead times and tariffs.

– Digital Supply Chains: Adoption of AI-driven platforms for real-time tracking and inventory management.

– Risk Mitigation: Emphasis on dual-sourcing and vertical integration to counter geopolitical risks.

To optimize sourcing, B2B buyers should conduct thorough supplier audits and leverage data analytics for informed decisions, ensuring reliability and cost-effectiveness.

Illustrative Image (Source: Google Search)

Frequently Asked Questions (FAQs) for B2B Buyers of automatic weighing machine

Frequently Asked Questions

1. What are the key benefits of using automatic weighing machines in a B2B manufacturing environment?

Automatic weighing machines enhance efficiency by providing precise, consistent measurements, reducing human error, and enabling high-volume production. In B2B settings like food processing or logistics, they integrate with conveyor systems for real-time data tracking, improving quality control and compliance with standards such as FDA regulations in the USA or EU directives. This leads to cost savings through minimized waste and optimized inventory management.

2. How do I select the right automatic weighing machine for my business needs?

Evaluate based on capacity (e.g., weighing range from grams to tons), speed (units per minute), accuracy (typically ±0.1g to ±1kg), and integration capabilities with ERP systems. Consider industry-specific requirements, such as ATEX certification for hazardous environments in Europe or USDA compliance in the USA. Test machines on-site if possible, and consult suppliers for custom configurations to match your production line’s throughput.

3. What are the typical maintenance requirements for automatic weighing machines?

Regular maintenance includes daily visual inspections for debris, weekly calibration checks, and annual professional servicing to ensure accuracy. Use only manufacturer-approved parts to avoid voiding warranties. In dusty or corrosive environments, implement protective enclosures. Downtime can be minimized with predictive maintenance software, reducing repair costs by up to 20% in B2B operations.

4. Can automatic weighing machines integrate with existing B2B software and systems?

Yes, most models offer APIs or Modbus protocols for seamless integration with ERP, SCM, or MES systems. In the USA, compatibility with systems like SAP is common; in Europe, ensure adherence to Industry 4.0 standards. Custom interfaces can be developed by suppliers, allowing real-time data export to dashboards for analytics, enhancing supply chain visibility.

Illustrative Image (Source: Google Search)

5. What are the upfront costs and ROI expectations for purchasing an automatic weighing machine?

Costs range from $5,000 to $50,000+ depending on features, with basic models starting lower. ROI typically occurs within 6-18 months through labor savings (up to 30% reduction in manual weighing) and error minimization. Factor in energy efficiency (low-power designs) and potential grants for automation in regions like the EU’s Horizon programs or US industrial incentives.

6. How do automatic weighing machines ensure compliance with regulatory standards in the USA and Europe?

Machines are designed to meet standards like NIST traceability in the USA or OIML certification in Europe, ensuring verifiable accuracy for industries such as pharmaceuticals or food. Features include tamper-evident seals and audit trails. Buyers should verify certifications during procurement and conduct regular validations to avoid fines from agencies like the FDA or EFSA.

7. What customization options are available for automatic weighing machines?

Options include bespoke weighing platforms, conveyor speeds, and software modules for specific applications (e.g., multi-head weighers for packaging). In B2B contexts, custom sensors for hazardous materials or multilingual interfaces are common. Work with manufacturers for prototypes, ensuring scalability for future production demands.

8. What warranty and support services are typically provided for these machines?

Standard warranties range from 1-3 years, covering defects in materials and workmanship. Support includes on-site installation, training, and remote diagnostics. In the USA and Europe, suppliers often offer extended service contracts with 24/7 helplines. Choose vendors with local presence for faster response times, critical for minimizing B2B operational disruptions.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for automatic weighing machine

Strategic Sourcing Conclusion and Outlook for Automatic Weighing Machines

Strategic sourcing of automatic weighing machines delivers substantial value to B2B operations in the USA and Europe by optimizing supply chains, reducing costs, and ensuring compliance. Key benefits include:

- Cost Efficiency: Negotiated contracts and bulk purchasing minimize procurement expenses, with potential savings of 15-25% through vendor consolidation.

- Quality Assurance: Rigorous supplier evaluation mitigates risks, ensuring machines meet precision standards (e.g., OIML certifications) for industries like manufacturing and logistics.

- Operational Reliability: Integrated sourcing strategies enhance uptime, reducing downtime by 20% via proactive maintenance and inventory management.

Outlook for 2023-2025

- Automation Integration: Expect deeper AI and IoT adoption, enabling predictive analytics for demand forecasting.

- Sustainability Focus: Suppliers emphasizing eco-friendly materials will rise, aligning with EU regulations and US green initiatives.

- Global Supply Resilience: Post-pandemic diversification will prioritize local sourcing to buffer against disruptions.

Adopting strategic sourcing positions businesses for competitive advantage, fostering innovation and scalability in weighing technology applications. (198 words)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.