Boost Efficiency: The Ultimate Cow Milking Machine Guide (2025)

Introduction: Navigating the Global Market for cow milking machine

Navigating the global market for cow milking machines presents unique challenges for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. With the increasing demand for dairy products, sourcing the right milking equipment has become essential for optimizing production efficiency and ensuring animal welfare. This guide offers a comprehensive overview of various types of cow milking machines, their applications across different farming environments, and crucial insights into supplier vetting processes.

Understanding the intricacies of the cow milking machine market is vital for making informed purchasing decisions. This guide delves into the latest technological advancements, cost considerations, and the importance of aligning with reputable suppliers who can meet specific regional needs. By addressing these elements, we aim to empower B2B buyers with actionable insights that facilitate smarter investments.

From identifying the right machinery for your operational scale to evaluating supplier reliability and support services, this guide equips you with the knowledge needed to navigate the complexities of international sourcing. Whether you’re a dairy farmer looking to upgrade your milking operations or a distributor seeking to expand your product offerings, you will find valuable information tailored to your unique market challenges. Embrace the opportunity to enhance your dairy business with the right cow milking machines, ensuring both profitability and sustainability in a competitive landscape.

Understanding cow milking machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Milking Bucket | Portable, manual operation, easy to transport | Small to medium dairy farms | Pros: Low initial cost; Cons: Labor-intensive and less efficient. |

| Pipeline Milking System | Automated system with pipeline infrastructure | Large-scale dairy operations | Pros: High efficiency; Cons: High initial investment and maintenance. |

| Robotic Milking System | Fully automated, utilizes AI for milking | Advanced dairy farms, high production | Pros: Labor-saving; Cons: High cost and requires technical expertise. |

| Mobile Milking Unit | Self-contained unit on wheels, suitable for various locations | Grazing systems, small farms | Pros: Versatile and adaptable; Cons: Limited capacity compared to fixed systems. |

| Vacuum Milking Machine | Uses vacuum technology for milking | Diverse dairy farm sizes | Pros: Effective and fast milking; Cons: Requires regular maintenance. |

What Are the Characteristics of Milking Buckets?

Milking buckets are a traditional choice for small to medium-sized dairy farms. They are portable and easy to operate, making them ideal for farmers who prefer manual milking or have limited capital for investment. The key purchasing consideration for B2B buyers is the labor intensity involved; while the initial cost is low, the efficiency is not as high compared to automated systems. Buyers should also assess the ease of cleaning and maintenance, which can influence overall operational costs.

How Does a Pipeline Milking System Enhance Dairy Operations?

Pipeline milking systems are designed for larger dairy operations and incorporate a network of pipes connecting the milking units to a central storage tank. This automation significantly increases efficiency and reduces the time spent on milking. B2B buyers must consider the high initial investment and the need for regular maintenance. However, this system offers the advantage of scalability, allowing farms to expand without a proportional increase in labor costs. It’s essential to evaluate the existing infrastructure and the potential for future growth when considering this option.

Why Choose a Robotic Milking System for Advanced Dairy Farms?

Robotic milking systems represent the pinnacle of technological advancement in dairy farming, utilizing artificial intelligence to optimize the milking process. These systems are best suited for advanced dairy farms that prioritize high production and labor efficiency. While they offer significant savings in labor, the high initial cost and the requirement for technical expertise in operation and maintenance can be barriers for some buyers. B2B purchasers should conduct a thorough cost-benefit analysis, considering both current operations and future goals.

What Are the Advantages of Mobile Milking Units?

Mobile milking units are a flexible solution for farmers who need to milk cows in various locations, particularly in grazing systems. These self-contained units can be transported easily, making them ideal for small farms or those practicing rotational grazing. Buyers should weigh the versatility against the limited capacity, as these units may not be suitable for larger herds. Considerations should also include the ease of setup and the ability to maintain hygiene standards during operations.

How Effective Are Vacuum Milking Machines for Diverse Farm Sizes?

Vacuum milking machines are versatile and can be used across a range of dairy farm sizes. They operate by creating a vacuum that efficiently extracts milk from the cows. B2B buyers should consider the effectiveness and speed of milking, which can enhance productivity. However, these systems require regular maintenance to ensure optimal performance and longevity. Buyers must also evaluate the availability of technical support and spare parts in their region to minimize downtime and operational disruptions.

Related Video: Milking Machine in Action 🐄 INCREDIBLE Cow & Goat Automatic Milking System Processing

Key Industrial Applications of cow milking machine

| Industry/Sector | Specific Application of Cow Milking Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dairy Farming | Automated Milking Systems for Large Scale Dairy Farms | Increased efficiency and reduced labor costs | Assess compatibility with herd size and milk yield |

| Organic Dairy Production | Portable Milking Units for Organic Farms | Compliance with organic standards and flexibility | Ensure units meet organic certification requirements |

| Dairy Processing Facilities | Integration of Milking Machines with Processing Equipment | Streamlined operations and improved milk quality | Evaluate equipment compatibility and maintenance needs |

| Export-focused Dairy Operations | High-capacity Milking Machines for Export Markets | Enhanced productivity to meet international demand | Consider shipping logistics and local regulations |

| Smallholder Dairy Cooperatives | Shared Milking Machines for Cooperative Use | Cost savings and improved milk collection efficiency | Assess financing options and cooperative agreements |

How Are Cow Milking Machines Used in Dairy Farming?

In large-scale dairy farming, automated milking systems significantly enhance productivity. These machines allow farmers to milk multiple cows simultaneously, reducing the time spent on milking while increasing the overall milk yield. For B2B buyers in regions like Africa and South America, sourcing machines that can handle the specific herd sizes and local conditions is crucial. Buyers should consider the machine’s compatibility with their existing infrastructure and the potential for scalability as their operations grow.

What Are the Benefits of Cow Milking Machines in Organic Dairy Production?

For organic dairy producers, portable milking units offer the flexibility to maintain compliance with stringent organic standards while ensuring high-quality milk production. These machines can be used in various locations, allowing farmers to milk cows in the field or at different sites. International buyers from Europe, particularly those in the UK and Poland, should prioritize units that are certified organic and meet local regulations to guarantee product integrity and market acceptance.

How Do Cow Milking Machines Enhance Dairy Processing Facilities?

In dairy processing facilities, the integration of milking machines with processing equipment is vital for optimizing operations. This synergy allows for immediate transfer of fresh milk to processing lines, thereby maintaining quality and reducing spoilage. B2B buyers should evaluate the compatibility of milking machines with their existing processing systems to ensure seamless integration. Additionally, understanding maintenance requirements and service availability is essential for long-term operational efficiency.

Why Are High-Capacity Milking Machines Important for Export-focused Dairy Operations?

For dairy operations targeting export markets, high-capacity milking machines are essential to meet increasing international demand. These machines not only enhance productivity but also ensure that the quality of milk meets global standards. Buyers from regions such as the Middle East must consider local regulations and quality certifications when sourcing equipment, as these factors can significantly impact their ability to compete in the global market.

How Can Smallholder Dairy Cooperatives Benefit from Shared Milking Machines?

Smallholder dairy cooperatives can leverage shared milking machines to improve efficiency and reduce costs. By pooling resources, these cooperatives can afford higher-quality equipment that would be unattainable for individual farmers. B2B buyers involved in cooperative structures should explore financing options that facilitate shared ownership and consider the logistics of machine maintenance and training for cooperative members to maximize the benefits of their investment.

Related Video: Cow milking machine | Milking machine for cows

3 Common User Pain Points for ‘cow milking machine’ & Their Solutions

Scenario 1: Inefficient Milking Processes Leading to Lost Revenue

The Problem: Many dairy farms, particularly in regions like Africa and South America, face challenges with traditional milking processes that are time-consuming and labor-intensive. This inefficiency can result in longer milking times, increased labor costs, and ultimately, reduced milk production. In competitive markets, where margins are tight, any delay in the milking process can lead to substantial revenue loss.

The Solution: To mitigate this issue, B2B buyers should consider investing in automated cow milking machines that incorporate advanced technology such as vacuum systems and automated pulsation control. When sourcing these machines, it’s essential to evaluate models that offer adjustable settings to accommodate different breeds and milking preferences. Buyers should also look for suppliers who provide training and support on optimal machine usage. This ensures that the milking process is not only efficient but also maximizes milk yield. Furthermore, implementing a scheduled maintenance plan can prevent downtime and keep the machinery operating at peak performance.

Scenario 2: High Maintenance Costs and Downtime

The Problem: One of the significant pain points for B2B buyers in the dairy industry, especially in Europe and the Middle East, is the high maintenance costs associated with cow milking machines. Frequent breakdowns can lead to operational disruptions, causing not only financial strain but also impacting the overall productivity of the dairy farm.

The Solution: To address maintenance concerns, buyers should prioritize purchasing cow milking machines known for their reliability and durability. Conducting thorough research on manufacturers that provide comprehensive warranty plans and have a reputation for quality can significantly reduce long-term costs. Additionally, opting for machines with easily accessible parts and user-friendly designs simplifies repairs and maintenance tasks, which can be performed by in-house staff. Establishing a regular maintenance schedule and keeping spare parts on hand will also minimize downtime and ensure a steady milk supply.

Scenario 3: Difficulty in Adapting to New Technologies

The Problem: As the dairy industry evolves, many traditional farmers, particularly in regions with less technological exposure, struggle to adapt to modern milking equipment. This resistance to change can stem from a lack of understanding of the technology or fear of disrupting established workflows. Consequently, these buyers may miss out on the efficiency and productivity gains that modern cow milking machines can provide.

The Solution: For B2B buyers hesitant about adopting new milking technologies, investing in comprehensive training and support is crucial. Look for suppliers who offer hands-on training sessions, online resources, and robust customer service. This can help ease the transition and boost confidence among farm workers in using the new equipment. Additionally, consider starting with a pilot program that integrates a small number of machines before full-scale implementation. This allows the team to familiarize themselves with the technology while measuring the impact on productivity and efficiency. Engaging with industry forums and networks can also provide valuable insights and peer support during the transition phase.

By addressing these common pain points with targeted solutions, B2B buyers can enhance their operations, improve their bottom line, and remain competitive in the ever-evolving dairy market.

Strategic Material Selection Guide for cow milking machine

When selecting materials for cow milking machines, international B2B buyers must consider various factors that affect performance, durability, and compliance with regional standards. Here, we analyze four common materials used in the construction of cow milking machines, providing insights into their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Stainless Steel in Cow Milking Machines?

Stainless steel is a widely used material in cow milking machines due to its excellent corrosion resistance and strength. It can withstand high temperatures and pressures, making it suitable for the rigorous cleaning processes involved in milking operations. Additionally, stainless steel is non-reactive, ensuring that milk quality is maintained without contamination.

Pros & Cons: The durability of stainless steel is a significant advantage, as it can last for many years with proper maintenance. However, the initial cost can be relatively high compared to other materials. Manufacturing complexity may also increase due to the need for specialized welding techniques.

Impact on Application: Stainless steel is compatible with various cleaning agents and sanitizers, essential for maintaining hygiene in dairy operations.

Considerations for International Buyers: Compliance with standards such as ASTM A240 for stainless steel is crucial, especially in regions like Europe where regulations are stringent. Buyers should also consider the availability of local suppliers to minimize shipping costs.

How Does Plastic Compare as a Material for Cow Milking Machines?

Plastic, particularly high-density polyethylene (HDPE), is another material used in cow milking machines. It offers good chemical resistance and is lightweight, which can ease installation and maintenance.

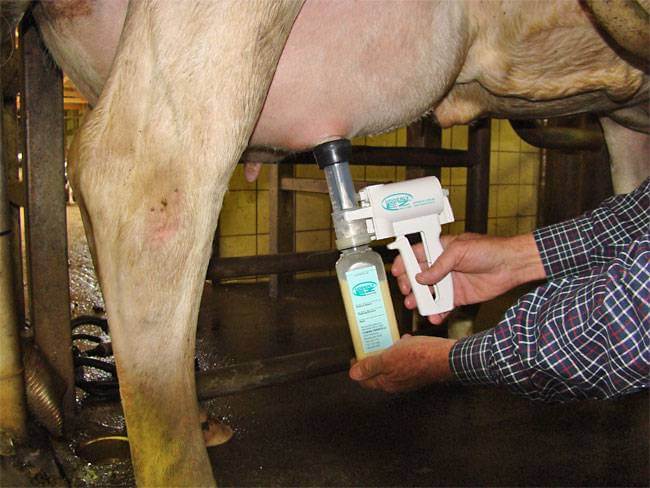

A stock image related to cow milking machine.

Pros & Cons: One of the main advantages of plastic is its lower cost compared to metals. However, it may not be as durable as stainless steel and can degrade over time when exposed to UV light or extreme temperatures.

Impact on Application: Plastic components are often used for non-structural parts of milking machines, such as tubing and containers, where high strength is not a primary concern.

Considerations for International Buyers: Buyers should ensure that the plastic used meets local food safety regulations, such as those outlined by the FDA or EU regulations. In regions with high temperatures, understanding the thermal limits of plastic is essential.

What Are the Benefits of Using Aluminum in Cow Milking Machines?

Aluminum is known for its lightweight properties and good strength-to-weight ratio, making it a popular choice for various components in cow milking machines.

Pros & Cons: Aluminum is generally less expensive than stainless steel and offers good corrosion resistance when anodized. However, it is not as durable as stainless steel and can be prone to scratching and denting.

Impact on Application: Aluminum is often used in parts that require a balance between weight and strength, such as frames and supports.

Considerations for International Buyers: Buyers should verify that the aluminum used complies with standards like ASTM B221. In regions with high humidity, additional coatings may be necessary to prevent corrosion.

Why Consider Rubber for Seals and Gaskets in Cow Milking Machines?

Rubber is commonly used for seals and gaskets in cow milking machines due to its excellent flexibility and sealing properties.

Pros & Cons: The flexibility of rubber allows it to create a tight seal, preventing leaks and ensuring efficient operation. However, rubber can wear out over time, especially when exposed to harsh cleaning chemicals or extreme temperatures.

Impact on Application: Rubber components are critical for maintaining the integrity of the milking system, as they prevent contamination and ensure a consistent milk flow.

Considerations for International Buyers: Buyers should ensure that the rubber used complies with food safety standards and is resistant to the specific cleaning agents commonly used in their region.

Summary Table of Material Selection for Cow Milking Machines

| Material | Typical Use Case for cow milking machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, tanks | Excellent durability and corrosion resistance | Higher initial cost, complex manufacturing | High |

| Plastic | Tubing, containers | Lightweight, lower cost | Less durable, can degrade over time | Low |

| Aluminum | Frames, supports | Good strength-to-weight ratio | Prone to scratching, less durable | Medium |

| Rubber | Seals, gaskets | Excellent sealing properties | Can wear out, sensitive to chemicals | Low |

This strategic material selection guide provides international B2B buyers with critical insights into the materials used in cow milking machines, enabling informed decisions that align with regional standards and operational needs.

In-depth Look: Manufacturing Processes and Quality Assurance for cow milking machine

What Are the Main Stages of Manufacturing Cow Milking Machines?

A stock image related to cow milking machine.

Manufacturing cow milking machines involves several critical stages, each designed to ensure that the final product meets the necessary performance and quality standards. Understanding these stages can help international B2B buyers make informed decisions when sourcing equipment.

1. Material Preparation

The first stage in the manufacturing process is material preparation, which involves selecting high-quality materials that meet industry standards. Common materials used include stainless steel, which is favored for its durability and resistance to corrosion, and food-grade plastics that are essential for components that come in contact with milk.

Additionally, suppliers often conduct material testing to ensure that the materials comply with international standards such as ISO 9001, which outlines quality management systems. Buyers should verify the supplier’s material certification to ensure compliance with these standards.

2. Forming Techniques

Once the materials are prepared, the next step is forming. This typically involves processes such as:

- CNC Machining: Computer Numerical Control (CNC) machining is commonly used to create precise components. This method ensures that parts fit together perfectly, which is crucial for the machine’s efficiency.

- Injection Molding: For plastic parts, injection molding is frequently employed. This process allows for high-volume production with consistent quality.

B2B buyers should inquire about the specific forming techniques used by their suppliers, as these can significantly impact the machine’s reliability and longevity.

3. Assembly Process

After the individual components are formed, they are assembled into the final product. The assembly process may involve:

- Manual Assembly: Skilled technicians assemble complex components that require careful handling.

- Automated Assembly Lines: For high-volume production, automation is often used to increase efficiency and reduce human error.

During assembly, it’s crucial that suppliers implement strict quality control measures to ensure that each machine functions as intended. Buyers can ask for documentation regarding assembly procedures and employee training programs to gauge the supplier’s commitment to quality.

4. Finishing Touches

The finishing stage includes surface treatment, cleaning, and packaging. Surface treatments may involve polishing or coating parts to enhance durability and prevent contamination. A thorough cleaning process is essential to ensure that no residues remain before the machine is packaged for shipping.

Buyers should check whether suppliers adhere to hygiene standards, particularly those set by the European Union (EU) for food safety, as this can affect the end user’s operational compliance.

How Is Quality Assurance Managed in Cow Milking Machine Production?

Quality assurance (QA) is critical in the manufacturing of cow milking machines to ensure they perform efficiently and safely. Various international standards and industry-specific certifications play a vital role in this process.

What Are the Relevant International Standards for Cow Milking Machines?

The most pertinent international standard for quality management systems is ISO 9001. This standard emphasizes the need for consistent quality and customer satisfaction. Additionally, specific certifications may include:

- CE Marking: Required for products sold within the European Economic Area (EEA), indicating conformity with health, safety, and environmental protection standards.

- API Certification: Relevant for equipment that may interact with other industrial systems, ensuring adherence to specific operational standards.

B2B buyers should ensure that their suppliers possess these certifications to guarantee that the machines comply with applicable regulations.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated into various stages of the manufacturing process to catch defects early. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Checks are conducted during the manufacturing process to monitor the quality of the assembly and forming stages.

- Final Quality Control (FQC): The final inspection occurs after assembly, where the complete machine is tested for functionality, safety, and compliance.

Buyers should ask suppliers about their QC procedures and how they document these checkpoints to ensure transparency.

What Common Testing Methods Are Used?

Testing methods can vary based on the specific requirements of the cow milking machines, but common techniques include:

- Functional Testing: Evaluating the machine’s performance under simulated operational conditions.

- Durability Testing: Assessing how well the machine withstands wear and tear over time.

- Safety Testing: Ensuring that the machine meets safety standards and does not pose any risks to users.

B2B buyers should request access to testing reports to evaluate the reliability of the machines being offered.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of suppliers is essential to ensure they receive high-quality products. Here are actionable steps buyers can take:

1. Conduct Supplier Audits

Performing on-site audits can provide valuable insights into a supplier’s manufacturing and quality assurance processes. During an audit, buyers can assess the supplier’s adherence to industry standards and their QC protocols.

2. Request Documentation

Buyers should request detailed documentation of QC processes, including inspection reports, testing results, and certifications. This documentation can help buyers evaluate the supplier’s commitment to maintaining high-quality standards.

3. Engage Third-Party Inspection Services

Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These services can conduct inspections at various stages of production and verify compliance with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, must navigate unique challenges in quality control.

- Understanding Local Regulations: Different countries have varying regulations regarding manufacturing and safety standards. Buyers should familiarize themselves with these regulations to ensure compliance.

- Cultural Differences: Communication styles and business practices can differ significantly across regions. Establishing clear expectations and open lines of communication is essential for successful partnerships.

- Logistics Considerations: Shipping and logistics can impact the delivery of quality products. Buyers should consider the supplier’s logistics capabilities to minimize delays and ensure timely delivery.

By paying close attention to these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions and foster successful partnerships in the cow milking machine industry.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cow milking machine’

The following guide provides a structured approach for international B2B buyers looking to procure cow milking machines. With the increasing demand for efficient dairy production, understanding the sourcing process is essential for making informed decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s vital to outline the technical specifications of the cow milking machines you require. Consider factors such as the number of cows to be milked, the type of milking system (e.g., bucket, pipeline, or robotic), and the desired features (such as automation and hygiene standards). Clearly defined specifications will help you narrow down options and communicate your needs effectively to suppliers.

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends in dairy technology and innovations in milking systems. Understanding advancements, such as automated milking parlors or IoT-enabled machines, can significantly impact productivity and efficiency. This knowledge will empower you to select equipment that not only meets current needs but also prepares your operation for future growth.

Step 3: Identify and Evaluate Potential Suppliers

Finding reputable suppliers is a critical step in the sourcing process. Research potential manufacturers and distributors in your target regions, paying attention to their experience and market presence. Request product catalogs, company profiles, and references from other buyers in similar markets to assess credibility and reliability.

- Look for:

- Years in operation and client testimonials.

- Certifications and compliance with international standards.

Step 4: Verify Supplier Certifications and Compliance

Ensuring that your suppliers meet industry standards is essential for quality assurance. Check for certifications such as ISO 9001 or specific agricultural machinery certifications relevant to your region. Compliance with health and safety regulations will minimize risks associated with equipment failure and operational inefficiencies.

Step 5: Request Quotes and Compare Pricing

Once you have a shortlist of potential suppliers, request detailed quotes that outline pricing, warranty terms, and additional costs (such as shipping and installation). Comparing these quotes will help you understand the market rate and identify any hidden costs. Ensure that you also consider the total cost of ownership, which includes maintenance and operational expenses over time.

Step 6: Conduct Site Visits or Virtual Tours

If possible, visit the suppliers’ facilities or arrange for virtual tours. Observing the manufacturing process can provide valuable insights into their quality control measures and production capabilities. This step is particularly beneficial for building trust and ensuring that the supplier can meet your specifications and timelines.

Step 7: Finalize Contracts and Payment Terms

After selecting a supplier, carefully review and negotiate the contract terms. Pay attention to payment schedules, delivery timelines, and after-sales support. Clear agreements will protect both parties and ensure that expectations are aligned, reducing the risk of disputes later in the process.

By following this practical sourcing checklist, B2B buyers can navigate the procurement of cow milking machines with confidence, ensuring that they invest in reliable technology that enhances their dairy operations.

Comprehensive Cost and Pricing Analysis for cow milking machine Sourcing

What Are the Key Cost Components of Cow Milking Machines?

When sourcing cow milking machines, understanding the cost structure is vital for international B2B buyers. The main cost components include:

-

Materials: The choice of materials directly influences the durability and efficiency of the milking machine. Stainless steel is often preferred for its corrosion resistance, while various plastics may be used for lightweight components. Pricing can vary significantly based on material quality and supplier relationships.

-

Labor: Labor costs can vary widely depending on the country of manufacture. Regions with lower labor costs may offer more competitive pricing, but this can sometimes come at the expense of quality. Buyers should evaluate the skill level of the workforce involved in the production process.

-

Manufacturing Overhead: This encompasses factory expenses such as utilities, rent, and administrative costs. A well-managed facility can optimize overhead, potentially lowering the overall price for buyers.

-

Tooling: The initial investment in tooling can be substantial, particularly for custom designs. Buyers may benefit from economies of scale; larger orders often lead to reduced per-unit costs.

-

Quality Control (QC): Investing in QC processes is essential for ensuring product reliability and compliance with international standards. Buyers should inquire about the QC measures in place, as this can impact both cost and quality.

-

Logistics: Transportation costs must be factored into the total cost, especially for international shipments. Consider the distance, shipping method, and potential tariffs or duties that may apply.

-

Margin: Supplier margins will vary based on market conditions and competition. Understanding the expected markup can aid in negotiations and help buyers identify value-added services.

How Do Pricing Influencers Affect Cow Milking Machine Costs?

Several factors can influence the pricing of cow milking machines, including:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to discounts. Buyers should assess their needs against supplier MOQs to maximize savings.

-

Specifications and Customization: Custom features or specific configurations can significantly affect pricing. Buyers must weigh the benefits of customization against the potential increase in cost.

-

Materials and Quality Certifications: Machines that meet specific quality certifications (such as ISO or CE) may command higher prices but provide assurance regarding performance and safety. Buyers should evaluate the importance of certifications in relation to their market requirements.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a track record of quality may charge more, but they also offer greater peace of mind.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for determining who bears the cost of shipping, insurance, and tariffs. This can significantly affect the final price.

What Are the Best Buyer Tips for Sourcing Cow Milking Machines?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, consider the following tips to enhance cost-efficiency:

-

Negotiate Wisely: Engage in discussions with multiple suppliers to compare offers. Leverage quotes to negotiate better terms, focusing on the total cost rather than just the upfront price.

-

Assess Total Cost of Ownership (TCO): Beyond the purchase price, evaluate the long-term operational costs, including maintenance, energy consumption, and potential downtime. A lower initial cost may lead to higher TCO if the machine is less reliable.

-

Understand Pricing Nuances: Be aware that pricing may fluctuate based on market demand, currency exchange rates, and geopolitical factors. Staying informed about these variables can help buyers make timely purchasing decisions.

-

Conduct Thorough Research: Invest time in researching suppliers, their product offerings, and reviews from other customers. This can provide insights into the best value options available.

Disclaimer on Indicative Prices

Prices for cow milking machines can vary greatly based on the factors mentioned above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes before making purchasing decisions. This approach will help ensure that you are getting the best value for your investment.

Alternatives Analysis: Comparing cow milking machine With Other Solutions

When considering a cow milking machine, it’s essential to evaluate alternative solutions that can also facilitate efficient milking processes. Understanding the strengths and weaknesses of each method can help international B2B buyers make informed decisions tailored to their specific operational needs.

Comparison Table of Cow Milking Machine and Alternatives

| Comparison Aspect | Cow Milking Machine | Manual Milking | Robotic Milking System |

|---|---|---|---|

| Performance | High throughput; consistent milk quality | Labor-intensive; variable output | High throughput; automated consistency |

| Cost | Moderate initial investment; low ongoing costs | Low initial cost; high labor costs | High initial investment; low labor costs |

| Ease of Implementation | Requires some training; straightforward installation | No training required; easy to implement | Complex setup; requires skilled technicians |

| Maintenance | Low; regular checks needed | Minimal; depends on equipment | Moderate; requires regular software updates |

| Best Use Case | Large-scale dairy farms | Small farms or family operations | Large farms seeking automation |

A stock image related to cow milking machine.

What Are the Pros and Cons of Manual Milking?

Manual milking is the traditional method of extracting milk from cows, often employed on small farms or family-run operations. The primary advantage of manual milking is its low initial cost; farmers do not need to invest in machinery. Moreover, this method does not require complex training, making it accessible for all laborers. However, the drawbacks include labor intensity and the potential for inconsistent milk quality. Additionally, as the farm grows, manual milking may become unsustainable due to the increasing labor demands and time constraints.

How Does Robotic Milking System Compare to Cow Milking Machines?

Robotic milking systems represent a cutting-edge solution that automates the milking process entirely. This technology offers high throughput and ensures consistent milk quality, as machines do not tire or vary in performance. While the initial investment for a robotic system is considerably high, the ongoing labor costs are significantly lower, making it a cost-effective solution for large-scale dairy operations over time. However, these systems require a complex setup and regular maintenance, including software updates and technical expertise, which may not be feasible for all farms, particularly in regions with limited access to skilled technicians.

Conclusion: How Should B2B Buyers Choose the Right Milking Solution?

When selecting the best milking solution, B2B buyers must consider their specific operational requirements, including farm size, budget constraints, and labor availability. For large dairy operations seeking efficiency and consistency, cow milking machines or robotic systems may be ideal despite their higher initial costs. In contrast, smaller farms with limited resources might find manual milking to be a more practical and economically viable option. Ultimately, understanding the pros and cons of each method will empower international buyers to make strategic decisions that enhance productivity and profitability in their dairy operations.

Essential Technical Properties and Trade Terminology for cow milking machine

When selecting a cow milking machine, understanding its essential technical properties and trade terminology is crucial for making informed purchasing decisions. This section will outline key specifications and common industry terms that will empower international B2B buyers to navigate the market effectively.

What Are the Key Technical Properties of Cow Milking Machines?

-

Material Grade

– The material used in the construction of a cow milking machine significantly impacts its durability and hygiene. Stainless steel is the preferred choice due to its corrosion resistance and ease of cleaning. For B2B buyers, selecting machines made from high-grade materials ensures long-term investment and compliance with health standards. -

Vacuum Level

– The vacuum level is crucial for efficient milking, typically measured in inches of mercury (inHg). Optimal vacuum levels generally range from 12 to 15 inHg for cow milking machines. Understanding this specification helps buyers select machines that maximize milk yield while ensuring cow comfort, thus enhancing productivity. -

Milking Capacity

– This specification refers to the volume of milk the machine can handle per hour, often expressed in liters. Machines with higher capacities are essential for larger dairy operations. B2B buyers should assess their operational scale and choose a machine that meets their specific milking requirements to avoid bottlenecks. -

Power Consumption

– The energy efficiency of a milking machine is a critical consideration, especially for operations aiming to reduce operational costs. Power consumption is generally expressed in kilowatts (kW). Buyers should compare the energy efficiency ratings of different models to ensure sustainable and cost-effective milking practices. -

Tolerance Levels

– Tolerance refers to the allowable deviation in the dimensions of the machine components. High tolerance levels ensure that parts fit together seamlessly, minimizing wear and tear. For B2B buyers, understanding tolerance specifications helps in selecting machines that offer better longevity and reduced maintenance costs.

What Are Common Trade Terms Used in the Cow Milking Machine Industry?

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the cow milking machine industry, knowing whether a machine is an OEM product can indicate its quality and reliability. Buyers should inquire about OEM status when considering equipment to ensure they are investing in reputable products. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, particularly those operating in regions like Africa or South America, where purchasing power may vary. It’s important to negotiate MOQs to align with budget constraints and operational needs. -

RFQ (Request for Quotation)

– An RFQ is a document issued by buyers to solicit price quotes from suppliers. This term is vital for B2B transactions, as it helps buyers compare costs effectively. When drafting an RFQ for cow milking machines, buyers should include specifications and quantities to receive accurate quotes. -

Incoterms (International Commercial Terms)

– Incoterms are international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is essential for B2B buyers to understand shipping costs, risk management, and delivery obligations. This knowledge can significantly affect the total landed cost of the milking machines. -

Lead Time

– Lead time refers to the amount of time it takes from placing an order to receiving the product. For dairy operations that rely on timely equipment upgrades, understanding lead times is critical. Buyers should communicate with suppliers about lead times to ensure that their milking operations remain uninterrupted.

By grasping these essential technical properties and trade terminologies, B2B buyers can make more informed decisions when purchasing cow milking machines, ultimately leading to improved operational efficiency and profitability.

Navigating Market Dynamics and Sourcing Trends in the cow milking machine Sector

What Are the Key Market Drivers and Trends in the Cow Milking Machine Sector?

The global cow milking machine market is experiencing significant growth, primarily driven by the increasing demand for dairy products and the need for efficient dairy farming practices. Technological advancements, such as automation and smart farming solutions, are reshaping the landscape. For B2B buyers in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

In Africa, the rise of agritech startups is providing innovative solutions tailored to local needs, such as affordable milking machines suitable for smallholder farmers. South American markets are leaning towards sustainable practices, with a focus on machines that reduce water and energy consumption. Meanwhile, European buyers, particularly in countries like Poland and the UK, are increasingly adopting IoT-enabled milking equipment, enhancing operational efficiency through real-time data analytics.

Emerging trends indicate a shift toward more integrated systems that combine milking, monitoring, and data management. This shift not only improves productivity but also aligns with global sustainability goals. B2B buyers must stay attuned to these trends, as they can affect product availability, pricing, and long-term partnerships with suppliers.

How Important Is Sustainability and Ethical Sourcing in the Cow Milking Machine Industry?

Sustainability and ethical sourcing are becoming paramount in the cow milking machine sector, driven by growing consumer awareness and regulatory pressures. For international B2B buyers, this means sourcing equipment that minimizes environmental impact while ensuring ethical labor practices throughout the supply chain.

The environmental impact of dairy farming is significant, with concerns around water usage and greenhouse gas emissions. Machines that employ energy-efficient technologies and sustainable materials are increasingly sought after. For instance, milking machines that utilize recyclable components or are certified by recognized environmental standards can enhance a company’s sustainability profile.

Moreover, ethical sourcing practices are gaining traction, as buyers prioritize suppliers who adhere to fair labor standards and transparent supply chains. Certifications such as Fair Trade or ISO 14001 for environmental management can provide reassurance to buyers about the ethical implications of their purchases. By aligning procurement strategies with sustainability goals, B2B buyers can not only meet regulatory requirements but also appeal to a growing segment of environmentally conscious consumers.

How Has the Cow Milking Machine Sector Evolved Over Time?

The evolution of cow milking machines reflects broader advancements in agricultural technology. Initially, milking was performed manually, which was labor-intensive and time-consuming. The introduction of mechanical milking systems in the mid-20th century revolutionized dairy farming, allowing for increased efficiency and higher milk yields.

Over the decades, advancements in automation and robotics have further transformed the sector. Today, automated milking systems (AMS) are becoming more prevalent, providing farmers with real-time monitoring capabilities and reducing the labor burden. This evolution is particularly significant for B2B buyers looking to modernize their operations, as these systems not only enhance productivity but also contribute to better animal welfare and milk quality.

As the market continues to advance, B2B buyers should consider how historical trends can inform future purchasing decisions, particularly in terms of technology adoption and supplier partnerships. Understanding the historical context can provide valuable insights into the reliability and performance of various milking technologies available in the market today.

Frequently Asked Questions (FAQs) for B2B Buyers of cow milking machine

-

How do I select the right cow milking machine for my farm?

Choosing the right cow milking machine depends on several factors, including the size of your herd, the type of milking system preferred (e.g., rotary, parallel, or herringbone), and your budget. Evaluate your farm’s specific needs by considering the efficiency, ease of use, and maintenance requirements. It’s also beneficial to consult with suppliers who can provide technical specifications and insights based on your region’s farming practices. Request product demonstrations or testimonials from other farmers to ensure the machine meets your operational goals. -

What is the best cow milking machine for small-scale farmers?

For small-scale farmers, portable or compact milking machines are often the best choice. These machines typically have lower capacity but are easier to operate and maintain. Look for models with user-friendly features, such as easy setup and cleaning processes. Brands that offer customization options can also cater to specific needs, allowing you to adapt the machine for your unique farm layout. Always consider the availability of local support and parts for maintenance. -

What are the typical minimum order quantities (MOQs) for cow milking machines?

Minimum order quantities for cow milking machines can vary significantly between suppliers. Many manufacturers may require a MOQ of 5 to 10 units, especially for customized machines. However, some suppliers may accommodate smaller orders, particularly for first-time buyers or for trial purposes. It’s advisable to negotiate with suppliers and clarify whether they can provide samples or smaller orders to test the product before committing to larger quantities. -

How can I vet suppliers of cow milking machines for reliability?

Vetting suppliers is crucial to ensure product quality and service reliability. Start by researching the supplier’s reputation through online reviews, industry forums, and references from other buyers. Request certifications and compliance documentation to verify that their products meet international standards. Additionally, consider visiting the supplier’s facility if possible, or engage in video calls to assess their production capabilities and quality control processes. Building a relationship with the supplier can also provide insights into their reliability. -

What payment terms should I expect when purchasing a cow milking machine internationally?

Payment terms can vary widely among international suppliers. Typically, you might encounter terms such as 30% upfront and 70% upon delivery, or full payment in advance. It’s essential to negotiate terms that protect your interests, especially in international transactions. Consider using secure payment methods such as letters of credit or escrow services to mitigate risks. Always clarify the currency used for transactions and any potential additional costs, like shipping or customs duties. -

How do I ensure quality assurance when buying a cow milking machine?

To ensure quality assurance, request a detailed quality control plan from the supplier, including testing processes and certifications. Ask for samples or demonstrations of the machine in operation. It’s also beneficial to review warranty terms and after-sales support, as these can indicate the supplier’s commitment to quality. Conducting a factory audit or third-party inspection can further assure you of the machine’s quality and compliance with safety standards. -

What logistics considerations should I keep in mind when importing a cow milking machine?

When importing cow milking machines, consider shipping costs, delivery timelines, and customs regulations in your country. It’s essential to work with a logistics provider experienced in agricultural equipment to navigate these complexities. Be aware of import duties and taxes that may apply, and ensure all necessary documentation is in order to avoid delays. Discuss the shipping method with your supplier, as options like air freight may offer faster delivery, albeit at a higher cost. -

What are the common maintenance requirements for cow milking machines?

Regular maintenance is vital for ensuring the longevity and efficiency of cow milking machines. Common requirements include cleaning the machine after each use, checking for wear and tear on hoses and seals, and ensuring that electrical components are functioning properly. Follow the manufacturer’s maintenance schedule and guidelines closely, and keep a record of maintenance activities. Consider training your staff on basic maintenance tasks to minimize downtime and ensure smooth operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cow milking machine

In the ever-evolving agricultural landscape, strategic sourcing of cow milking machines is crucial for optimizing dairy operations. International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should prioritize suppliers that offer advanced technology, robust support, and sustainable practices. By evaluating the total cost of ownership—including maintenance, energy efficiency, and productivity gains—buyers can make informed decisions that enhance operational efficiency and profitability.

How Can Strategic Sourcing Enhance Your Dairy Business?

Adopting a strategic sourcing approach not only mitigates risks associated with supply chain disruptions but also fosters long-term partnerships with manufacturers. This collaborative approach allows for customized solutions that cater to specific regional needs, whether it be in terms of climate adaptation or market demands.

What is the Future Outlook for Cow Milking Machines?

As the dairy industry continues to innovate, the future of cow milking machines is promising. Emerging technologies, such as automation and IoT integration, will drive efficiency and enhance milk quality. B2B buyers should stay informed about these trends and be ready to invest in next-generation solutions to remain competitive.

In conclusion, the strategic sourcing of cow milking machines presents a significant opportunity for international buyers to enhance their operations. By staying proactive and aligning with forward-thinking suppliers, businesses can ensure they are well-positioned for future success in the global dairy market. Engage with suppliers today to explore how you can leverage these advancements for your dairy operations.