Cat 308 Guide: Type,Cost,Material…

Introduction: Navigating the Global Market for cat 308

In an increasingly competitive global market, sourcing the right equipment, such as the Cat 308 mini excavator, can be a daunting task for B2B buyers. The challenge lies not just in finding a reliable supplier, but also in understanding the machine’s specifications, applications, and overall value proposition. This guide aims to demystify the complexities surrounding the Cat 308, a powerful yet compact excavator designed for various applications—from urban construction to landscaping and utility work.

Within these pages, international buyers, particularly those in Africa, South America, the Middle East, and Europe, will discover a wealth of information. We will delve into the diverse types of Cat 308 models available, their unique features, and practical applications tailored to regional needs. Moreover, we will provide actionable insights on vetting suppliers, evaluating costs, and understanding after-sales support, ensuring that you can make informed purchasing decisions.

By equipping you with comprehensive knowledge, this guide empowers businesses to navigate the global market with confidence, maximizing their investment in the Cat 308 mini excavator. Whether you are a contractor seeking efficiency or a fleet manager aiming for reliability, understanding the nuances of this equipment will position you for success in your projects.

Understanding cat 308 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cat 308 CR Mini Excavator | Compact size, versatile attachments, and hydraulic performance | Construction, landscaping, utility work | Pros: High maneuverability, ideal for tight spaces. Cons: Limited digging depth compared to larger models. |

| Cat 308 CR Variable Angle Boom | Adjustable boom for enhanced reach and flexibility | Demolition, excavation, and grading | Pros: Greater flexibility in operations. Cons: Potentially higher maintenance costs due to complex mechanics. |

| Cat 308 CR with Steel Tracks | Increased durability and traction for challenging terrains | Mining, heavy-duty construction | Pros: Improved stability and ground pressure. Cons: Heavier, which can limit transportability. |

| Cat 308 CR with Long Stick | Extended reach and digging depth | Deep trenching, utility installation | Pros: Enhanced reach for deep excavation. Cons: May require more space for operation. |

| Cat 308 CR with Enhanced Hydraulics | Advanced hydraulic system for superior lifting and digging force | Heavy lifting, material handling | Pros: Increased productivity and efficiency. Cons: Higher upfront investment. |

What are the key characteristics of the Cat 308 CR Mini Excavator?

The Cat 308 CR Mini Excavator is designed for versatility and compactness, making it suitable for various applications, including construction, landscaping, and utility work. Its robust hydraulic system allows for efficient operation with a range of attachments. Buyers should consider the machine’s maneuverability in tight spaces, although its digging depth may be limited compared to larger excavators.

How does the Cat 308 CR Variable Angle Boom enhance operational flexibility?

The Variable Angle Boom feature of the Cat 308 CR allows operators to adjust the boom’s angle for maximum reach and flexibility. This capability is particularly beneficial in demolition and grading applications, where precision is crucial. While it enhances operational efficiency, potential buyers should be aware of the increased maintenance requirements associated with this advanced feature.

In what scenarios are Cat 308 CR models with Steel Tracks advantageous?

Models equipped with steel tracks are designed for heavy-duty applications, providing enhanced durability and traction in challenging terrains, such as mining and rough construction sites. The increased stability and reduced ground pressure are significant advantages. However, buyers should consider the added weight, which may affect transport and maneuverability.

What benefits does the Cat 308 CR with Long Stick offer for deep excavation?

The Cat 308 CR with Long Stick configuration is tailored for applications requiring extended reach and deeper digging capabilities, such as utility installations and trenching. This model is particularly effective in situations where space is limited but depth is required. Buyers should note that the extended reach may necessitate additional space for operation.

Why might a buyer choose the Cat 308 CR with Enhanced Hydraulics?

The Enhanced Hydraulics option provides superior lifting and digging force, making it ideal for heavy lifting and material handling tasks. This model can significantly boost productivity and efficiency on job sites. However, buyers should weigh the benefits against the higher initial investment required for these advanced hydraulic features.

Key Industrial Applications of cat 308

| Industry/Sector | Specific Application of cat 308 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Site Preparation and Excavation | Enhanced productivity and precision in earthmoving | Availability of parts and after-sales service |

| Landscaping | Grading and Landscaping Projects | Improved aesthetics and land usability | Local terrain adaptability and attachment options |

| Infrastructure | Utility Installation (water, gas, electricity) | Efficient trenching and minimal disruption | Compliance with local regulations and safety standards |

| Agriculture | Land Clearing and Soil Preparation | Increased arable land and crop yield potential | Versatility in attachments for various agricultural tasks |

| Mining | Material Handling and Site Development | Streamlined operations and cost-effectiveness | Robustness for harsh environments and maintenance support |

How is the Cat 308 Used in Construction Projects?

In the construction industry, the Cat 308 is primarily utilized for site preparation and excavation tasks. Its compact size allows it to maneuver in tight spaces, making it ideal for urban construction sites. The excavator’s powerful digging force (up to 13,946 lbs) enables efficient earthmoving, which is crucial for laying foundations and other preliminary work. Buyers should consider sourcing options that ensure availability of spare parts and reliable after-sales service, especially in regions where support may be limited.

What Role Does the Cat 308 Play in Landscaping?

The landscaping sector benefits significantly from the Cat 308, particularly in grading and project execution. With its variable angle boom, the excavator can perform precise cuts and fills, enhancing the aesthetics and usability of outdoor spaces. This versatility is essential for creating slopes, planting beds, and decorative features. Buyers should focus on the adaptability of the machine to local terrain and the availability of compatible attachments to maximize its landscaping potential.

How is the Cat 308 Used in Utility Installation?

In infrastructure projects, particularly utility installations for water, gas, and electricity, the Cat 308 excels in trenching operations. Its compact design allows for minimal disruption to existing landscapes, crucial for urban areas. The machine’s hydraulic capabilities ensure efficient digging while maintaining high operational pressures. Buyers must ensure compliance with local regulations and safety standards, as this is critical for project approval and operational safety.

Why is the Cat 308 Valuable for Agricultural Applications?

The agricultural sector utilizes the Cat 308 for land clearing and soil preparation, which significantly enhances arable land and crop yields. The excavator’s robust performance allows farmers to clear fields efficiently, creating optimal conditions for planting. Buyers in this sector should consider the versatility of attachments available for various agricultural tasks, ensuring that the machine can adapt to different farming methods and crop types.

How Does the Cat 308 Enhance Mining Operations?

In mining operations, the Cat 308 is employed for material handling and site development tasks. Its durability and high traction force enable it to operate effectively in harsh environments, streamlining operations and reducing costs. Businesses should evaluate the machine’s robustness against environmental challenges and ensure that there is adequate maintenance support to maximize uptime and productivity.

3 Common User Pain Points for ‘cat 308’ & Their Solutions

Scenario 1: Navigating Tight Spaces in Urban Projects

The Problem: Many B2B buyers in construction and landscaping face the challenge of maneuvering heavy machinery in tight urban environments. The Cat 308, while compact, can still present difficulties when navigating narrow streets, limited job sites, and congested work areas. Buyers often worry about the risk of damaging property or incurring penalties due to space restrictions. This can lead to delays and increased costs, undermining project timelines and profitability.

The Solution: To effectively use the Cat 308 in confined spaces, it’s essential to leverage its Variable Angle Boom feature. This functionality allows for greater flexibility and precision in operation, enabling operators to work efficiently in tight spots. B2B buyers should invest in training for their operators to maximize the machine’s capabilities. Additionally, incorporating attachments that enhance the excavator’s versatility—like narrow buckets or grapples—can significantly improve performance in restricted areas. Establishing clear communication with project managers to assess site conditions before deployment will also help in planning the best approach, ensuring that the Cat 308 is used optimally without compromising safety or efficiency.

Scenario 2: Managing Fuel Efficiency for Long-Term Projects

The Problem: Fuel costs are a significant concern for B2B buyers managing long-term projects, especially in regions where fuel prices can fluctuate dramatically. The Cat 308, with its robust engine and hydraulic systems, requires careful attention to fuel consumption to maintain budget integrity. Buyers often struggle to balance operational efficiency with cost-effectiveness, leading to potential budget overruns.

The Solution: To enhance fuel efficiency while operating the Cat 308, B2B buyers should focus on regular maintenance and proper operator training. Implementing a routine maintenance schedule, including checking hydraulic fluid levels and ensuring optimal tire pressure, can prevent unnecessary fuel consumption. Additionally, training operators on efficient operating techniques—such as avoiding rapid movements and utilizing idle time effectively—can lead to significant fuel savings. Buyers should also consider using telematics systems to monitor fuel usage and machine performance in real-time, allowing for adjustments that can lead to improved efficiency and lower operational costs.

Scenario 3: Ensuring Compliance with Safety Regulations

The Problem: In many regions, safety regulations for construction equipment are stringent, and non-compliance can lead to costly fines and project delays. B2B buyers of the Cat 308 often find themselves grappling with the need to ensure that their machinery meets local safety standards, which can vary significantly across different countries and regions. This can create additional administrative burdens and complicate project planning.

The Solution: To ensure compliance with safety regulations, B2B buyers should familiarize themselves with the specific legal requirements in their operating regions before purchasing or deploying the Cat 308. Investing in equipment that comes with a ROPS (Roll Over Protective Structure) and additional safety features, such as the ISO-certified top guard, is crucial. Furthermore, buyers should implement a comprehensive safety training program for all operators, emphasizing the importance of using safety equipment and conducting regular safety checks on the machinery. Maintaining thorough documentation of safety inspections and operator training sessions can help demonstrate compliance during audits and inspections, ultimately safeguarding the business against potential liabilities.

Strategic Material Selection Guide for cat 308

What Are the Key Materials Used in the Cat 308 Excavator?

When selecting materials for the Cat 308 Mini Excavator, various factors come into play, including performance, durability, cost, and compliance with international standards. Here, we analyze four common materials used in the construction of the Cat 308, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Steel: The Backbone of Structural Integrity

Key Properties: Steel is known for its high tensile strength and durability, making it ideal for structural components. It can withstand high temperatures and pressures, with a melting point around 1,500°C (2,732°F). Additionally, steel can be treated for corrosion resistance.

Pros & Cons: Steel offers excellent durability and strength, which is crucial for the excavator’s frame and undercarriage. However, it is relatively heavy, which can impact fuel efficiency. The cost of high-quality steel can be significant, and manufacturing processes such as welding can add complexity.

Impact on Application: Steel’s strength ensures that the Cat 308 can handle demanding tasks, including heavy digging and lifting. However, it may require protective coatings in corrosive environments, such as coastal regions.

Considerations for International Buyers: Compliance with standards like ASTM A36 or EN 10025 is essential. Buyers in regions like Europe and South America should consider local steel grades and availability.

Aluminum: Lightweight and Corrosion-Resistant

Key Properties: Aluminum is lightweight and has a high strength-to-weight ratio. It is naturally corrosion-resistant due to a protective oxide layer and can operate effectively in a wide temperature range.

Pros & Cons: The primary advantage of aluminum is its weight reduction, which can enhance fuel efficiency and overall performance. However, it is less durable than steel and may not withstand high-impact forces as effectively. The cost of aluminum is generally higher than that of standard steel.

Impact on Application: Aluminum is particularly beneficial for components that require reduced weight, such as the cab and certain hydraulic components. Its corrosion resistance makes it suitable for humid or coastal environments.

Considerations for International Buyers: Buyers should ensure that aluminum used complies with standards like ASTM B221. In regions like the Middle East, where humidity is high, aluminum’s properties can be particularly advantageous.

Rubber: Essential for Traction and Vibration Damping

Key Properties: Rubber is flexible and provides excellent traction, along with good vibration damping properties. It can operate effectively in a wide range of temperatures, although extreme heat can degrade its performance.

Pros & Cons: Rubber tracks enhance the Cat 308’s ability to navigate various terrains while minimizing ground pressure. However, they may wear out faster than steel tracks, especially in abrasive conditions, and replacement costs can be significant.

Impact on Application: The use of rubber tracks is crucial for applications in sensitive environments, such as landscaping or urban construction, where ground damage needs to be minimized.

Considerations for International Buyers: Compliance with local environmental regulations regarding material disposal is important. In regions like Africa, where terrain can be challenging, the choice of rubber can significantly impact operational efficiency.

Composite Materials: Innovative Solutions for Weight and Strength

Key Properties: Composites, often made from a combination of materials like fiberglass and resins, offer a balance of strength and lightweight properties. They are resistant to corrosion and can be tailored for specific performance needs.

Pros & Cons: Composites can significantly reduce weight while maintaining strength, making them suitable for various applications on the excavator. However, they can be more expensive and may require specialized manufacturing processes.

Impact on Application: Composites are ideal for non-structural components, such as panels and covers, where weight reduction is critical without compromising safety.

Considerations for International Buyers: Buyers should be aware of the standards for composite materials, such as ASTM D638. In regions with stringent safety regulations, like Germany, compliance with these standards is essential.

Summary Table of Material Selection for Cat 308

| Material | Typical Use Case for cat 308 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frame and undercarriage | High strength and durability | Heavy, impacting fuel efficiency | Medium |

| Aluminum | Cab and hydraulic components | Lightweight and corrosion-resistant | Less durable than steel | High |

| Rubber | Tracks for traction and vibration damping | Excellent traction and ground protection | Can wear out quickly in abrasive conditions | Medium |

| Composites | Non-structural components | Lightweight with tailored performance | Higher cost and complex manufacturing | High |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on performance, cost, and compliance considerations specific to their regions.

In-depth Look: Manufacturing Processes and Quality Assurance for cat 308

What Are the Key Stages in the Manufacturing Process of the Cat 308 Mini Excavator?

The manufacturing process of the Cat 308 Mini Excavator involves several critical stages designed to ensure precision and durability. Understanding these stages can help B2B buyers assess the quality and reliability of the equipment.

Material Preparation

The first step in the manufacturing process is material preparation, where high-quality steel and other alloys are selected for their strength and resilience. The materials undergo rigorous testing to ensure they meet specific mechanical properties and standards. This is crucial for the long-term performance of the excavator, especially in demanding environments such as construction sites in Africa and South America, where durability is paramount.

Forming Techniques

Once the materials are prepared, they are subjected to various forming techniques. Advanced techniques such as laser cutting, CNC machining, and stamping are employed to create components with high precision. For example, the steel plates that form the chassis and boom are cut and shaped using CNC machines, ensuring they fit perfectly during assembly. Additionally, forming techniques like welding and bending are used to create robust structures that can withstand heavy loads and stresses.

Assembly Process

The assembly stage is where the mini excavator takes shape. Skilled technicians assemble components such as the engine, hydraulic systems, and undercarriage. The assembly line is designed for efficiency and includes multiple checkpoints for quality control. Each component is meticulously fitted, ensuring that the final product operates smoothly and meets performance specifications. The integration of advanced robotics in some stages of assembly further enhances precision and reduces the risk of human error.

Finishing Touches

The final stage in manufacturing involves finishing processes, including painting and protective coating. These processes not only enhance the aesthetic appeal of the Cat 308 but also provide essential protection against corrosion and wear. A thorough inspection is conducted after finishing to ensure that the surface quality meets international standards, preparing the excavator for its operational environment.

How Is Quality Assurance Implemented in Cat 308 Manufacturing?

Quality assurance is a critical aspect of the manufacturing process for the Cat 308 Mini Excavator. Various international standards and industry-specific certifications guide the quality control measures implemented throughout production.

What International Standards Are Relevant for Cat 308?

The manufacturing of the Cat 308 adheres to ISO 9001 standards, which outline the requirements for a quality management system. Compliance with ISO 9001 ensures that processes are consistent, efficient, and continually improving, ultimately leading to higher customer satisfaction. Additionally, certifications such as CE (Conformité Européenne) ensure that the excavator meets European safety and environmental standards.

What Are the Key Quality Control Checkpoints?

Quality control is conducted at various checkpoints throughout the manufacturing process, including:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they are used in production. Suppliers must provide documentation and certification that their materials meet specified standards.

-

In-Process Quality Control (IPQC): During assembly, continuous monitoring is conducted to ensure that components are assembled correctly and that any issues are addressed immediately. This includes checking tolerances, alignment, and functionality of the hydraulic systems.

-

Final Quality Control (FQC): Once the excavator is fully assembled, it undergoes a comprehensive inspection and testing phase. This includes performance testing, where the excavator is operated under simulated conditions to ensure it meets all operational specifications.

What Testing Methods Are Commonly Used in Quality Assurance?

Several testing methods are employed to validate the quality and performance of the Cat 308 Mini Excavator:

-

Hydraulic Testing: Ensures that the hydraulic systems operate within designated pressure ranges and perform efficiently under load.

-

Load Testing: The excavator is subjected to load tests to verify its lifting and digging capabilities, ensuring it meets the specified digging force and stability parameters.

-

Durability Testing: Components are tested under extreme conditions to assess their longevity and resilience, simulating real-world applications that the excavator will face.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of suppliers manufacturing the Cat 308:

-

Supplier Audits: Conducting on-site audits of the manufacturing facilities can provide insight into the quality control processes in place. Buyers should evaluate whether the supplier adheres to international standards and best practices.

-

Documentation Review: Requesting quality assurance documentation, including certificates of compliance with ISO standards and test reports, can help buyers assess the reliability of the supplier’s quality control measures.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing process and the final product. This is particularly important for international buyers who may not have direct access to the manufacturing site.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances:

-

Regulatory Compliance: Different countries have unique regulatory requirements. For instance, EU buyers must ensure that the excavator meets CE standards, while buyers in the U.S. may need to verify compliance with EPA emissions regulations.

-

Supply Chain Transparency: Understanding the entire supply chain is vital for international buyers. This includes knowing where components are sourced and how they are processed, as this can impact the overall quality of the final product.

-

Cultural Considerations: Cultural differences may affect communication and expectations regarding quality assurance. Establishing clear and open lines of communication can help mitigate misunderstandings.

By understanding the manufacturing processes and quality assurance standards for the Cat 308 Mini Excavator, B2B buyers can make informed purchasing decisions that align with their operational needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cat 308’

In the competitive landscape of construction and excavation equipment, sourcing the right Cat 308 mini excavator is crucial for maximizing operational efficiency and ensuring project success. This checklist serves as a practical guide for B2B buyers, particularly in international markets, to navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Understanding your project requirements is the foundation of a successful procurement process. Clearly outline the specifications you need from the Cat 308, including net power (69.5 hp), operating weight (up to 20,385 lb), and digging depth (up to 182.8 inches). These details will help you identify models that best suit your operational needs and ensure compatibility with existing equipment.

Step 2: Research Suppliers and Manufacturers

Diligently research potential suppliers to find reputable sources for the Cat 308. Look for manufacturers with a strong presence in your region, as they are more likely to understand local regulations and market conditions. Check online reviews, industry forums, and social media for feedback from other buyers to gauge supplier reliability.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that your chosen suppliers hold necessary certifications. Look for ISO certifications, which indicate adherence to international standards for quality management systems. Additionally, confirm compliance with environmental regulations relevant to your region, as this can affect your project’s sustainability goals.

Step 4: Request Detailed Quotations

After narrowing down potential suppliers, request detailed quotations that include pricing, delivery timelines, and warranty options. Compare these quotations not only on price but also on the value offered, such as after-sales support and maintenance services. This comprehensive comparison will help you make an informed decision.

Step 5: Inspect Equipment and Conduct Trials

If possible, arrange for an inspection of the Cat 308 units before finalizing your purchase. This step is critical to assess the equipment’s condition, verify specifications, and evaluate any attachments or accessories. Conducting a trial can provide insight into the machine’s performance in real-world conditions, ensuring it meets your operational standards.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, engage in negotiations to finalize the terms and conditions of your purchase. Discuss payment terms, delivery schedules, and any potential discounts for bulk orders. Clear communication at this stage can prevent misunderstandings later and foster a positive relationship with your supplier.

Step 7: Plan for Logistics and Support

Finally, develop a logistics plan for the delivery and installation of your Cat 308. Coordinate with your supplier to ensure timely delivery and consider any local regulations regarding equipment transportation. Additionally, inquire about training for your operators to ensure they are equipped to handle the machinery safely and effectively.

By following this checklist, B2B buyers can streamline the procurement process for the Cat 308 mini excavator, ensuring a successful purchase that meets their operational needs and contributes to project success.

Comprehensive Cost and Pricing Analysis for cat 308 Sourcing

When sourcing the Cat 308 mini excavator, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. This analysis will focus on the various cost components, price influencers, and practical tips for negotiating effectively.

What Are the Key Cost Components in Sourcing Cat 308 Excavators?

The cost structure for the Cat 308 involves several components that contribute to the final price:

-

Materials: The primary materials include high-grade steel for the chassis and components, advanced hydraulic systems, and engine parts. The quality of these materials significantly impacts the durability and performance of the excavator.

-

Labor: Labor costs encompass wages for skilled workers involved in assembly, quality control, and maintenance. Skilled labor is particularly crucial in ensuring that the equipment meets stringent industry standards.

-

Manufacturing Overhead: This includes the costs associated with factory operations, such as utilities, equipment maintenance, and facility depreciation. Efficient manufacturing processes can help reduce these overheads.

-

Tooling: The development and maintenance of specialized tools for assembly and production are essential. These costs can be significant, especially for customized versions of the Cat 308.

-

Quality Control (QC): Rigorous quality control measures are necessary to ensure that every unit meets compliance standards and customer expectations. This involves both testing and inspection processes, which contribute to overall costs.

-

Logistics: Transportation and shipping costs vary based on the destination. International buyers must consider freight costs, insurance, and potential tariffs, which can influence the total landed cost.

-

Margin: Suppliers typically include a profit margin in their pricing, reflecting their operational costs and market positioning. Understanding the typical margin for excavators can aid in negotiations.

How Do Volume and Specifications Affect Pricing?

Pricing for the Cat 308 is influenced by factors such as volume and customization:

-

Volume/MOQ: Ordering in larger quantities often leads to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to maximize their purchasing power.

-

Specifications/Customization: Custom features or specific configurations may increase costs. Buyers should clearly define their requirements and understand how these specifications impact the base price.

-

Materials and Quality Certifications: Higher quality materials and certifications (such as ISO standards) may lead to increased costs but can provide long-term savings through enhanced reliability and performance.

What Buyer Tips Can Enhance Cost Efficiency?

To navigate the complexities of sourcing the Cat 308, buyers should consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially if purchasing in bulk. Leverage market knowledge to negotiate better terms and conditions.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, fuel, and potential downtime. A lower initial price may lead to higher TCO if quality is compromised.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa and South America should be aware of currency fluctuations and international trade regulations that can affect pricing. Additionally, understanding Incoterms can clarify responsibilities regarding shipping costs and risks.

-

Supplier Factors: Assess the supplier’s reputation, reliability, and service capabilities. A well-established supplier may offer better after-sales support, which can be a crucial factor in the overall cost efficiency of the equipment.

Disclaimer on Indicative Prices

Pricing for the Cat 308 mini excavator can vary significantly based on the aforementioned factors and market conditions. It is advisable to obtain multiple quotes from different suppliers and consider the total cost implications before making a purchasing decision.

Alternatives Analysis: Comparing cat 308 With Other Solutions

Exploring Alternatives to the Cat 308 Mini Excavator

In the competitive landscape of construction and excavation machinery, the Cat 308 Mini Excavator stands out for its robust performance and versatility. However, various alternatives exist that may better fit specific operational needs or budget constraints. Understanding these options can help international B2B buyers make informed decisions tailored to their project requirements.

Comparison Table

| Comparison Aspect | Cat 308 | Alternative 1: Bobcat E165 | Alternative 2: Kubota KX057-4 |

|---|---|---|---|

| Performance | 69.5 hp, 13,946 lb digging force | 62 hp, 10,000 lb digging force | 57.5 hp, 11,200 lb digging force |

| Cost | Moderate (approx. $70,000) | Lower (approx. $55,000) | Moderate (approx. $60,000) |

| Ease of Implementation | User-friendly controls | Compact, easy to maneuver | Slightly heavier, but stable |

| Maintenance | Low with easy access components | Moderate, some parts harder to reach | Low, good parts availability |

| Best Use Case | Urban construction, landscaping | Tight spaces, residential work | Utility work, heavy-duty tasks |

Detailed Breakdown of Alternatives

Bobcat E165

The Bobcat E165 is a compact excavator that excels in tight working conditions. With a slightly lower horsepower and digging force than the Cat 308, it is particularly suited for residential projects and urban environments where space is a premium. Its cost advantage makes it appealing for budget-conscious buyers. However, its maintenance can be moderately challenging due to some components being less accessible, which could affect downtime.

Kubota KX057-4

The Kubota KX057-4 offers a strong balance between power and size, making it ideal for utility work and heavier-duty applications. While it has a lower horsepower rating than the Cat 308, its digging force is commendable and suitable for a variety of tasks. It is slightly heavier, which contributes to stability but may hinder mobility in extremely tight spaces. Maintenance is straightforward, and Kubota’s robust parts network ensures that replacement components are readily available.

Conclusion: How to Choose the Right Excavator for Your Needs

When selecting an excavator, B2B buyers should assess their specific operational requirements, including the nature of the projects, budget constraints, and the working environment. The Cat 308 is an excellent choice for those needing a powerful and versatile machine for urban construction. However, alternatives like the Bobcat E165 and Kubota KX057-4 provide compelling options for different needs, such as tighter spaces or budget considerations. By carefully evaluating performance, cost, ease of implementation, and maintenance, buyers can confidently choose the most suitable solution for their projects.

Essential Technical Properties and Trade Terminology for cat 308

What Are the Key Technical Properties of the Cat 308 Mini Excavator?

Understanding the technical specifications of the Cat 308 Mini Excavator is crucial for B2B buyers to make informed purchasing decisions. Here are some essential properties:

-

Net Power (69.5 hp / 51.8 kW)

This specification indicates the engine’s power output available for performing work. In a mini excavator, adequate power is vital for tasks such as digging, lifting, and moving materials. A higher net power allows for more efficient operation in diverse applications, making it a key consideration for buyers assessing performance needs. -

Operating Weight (18,493 lb / 8,387 kg)

The operating weight encompasses the machine’s total weight when in use. This measurement affects the machine’s stability and ground pressure, which is particularly important in soft soil conditions. Understanding the weight helps buyers determine the suitability of the Cat 308 for specific job sites, especially where soil compaction and load-bearing capacity are concerns. -

Digging Force (13,946 lb / 62 kN for bucket)

Digging force refers to the maximum force exerted by the excavator’s bucket while digging. A higher digging force indicates better performance in challenging excavation tasks, allowing contractors to complete jobs more quickly and efficiently. This specification is critical for buyers in construction and earthmoving industries who require robust performance. -

Travel Speed (High: 3.2 mph / 5.1 km/h)

The travel speed indicates how quickly the excavator can move between job sites or across the work area. A higher travel speed can lead to reduced downtime and increased productivity on larger projects. B2B buyers should consider this specification when assessing the machine’s efficiency in terms of transportation and maneuverability. -

Hydraulic System (Pump Flow at 2,400 rpm: 44 gal/min / 167 l/min)

This measurement details the hydraulic fluid flow rate, which is crucial for the performance of attachments and implements. A robust hydraulic system enables the excavator to power various attachments effectively, enhancing its versatility. Buyers should evaluate this property to ensure the machine meets their operational requirements.

What Common Trade Terms Should B2B Buyers Know for the Cat 308?

Familiarity with industry jargon can enhance communication between buyers and suppliers. Here are some common terms relevant to the Cat 308:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce equipment or components that are sold under another company’s brand name. For buyers, working with an OEM ensures that they receive high-quality, compatible parts and equipment, essential for maintaining the longevity and performance of the Cat 308. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is important for B2B buyers to manage their budgets and inventory effectively. It helps in planning purchases, especially for parts or attachments for the Cat 308. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. In the context of the Cat 308, submitting an RFQ can help buyers compare prices and terms from different suppliers, ensuring they secure the best deal. -

Incoterms (International Commercial Terms)

These are standardized international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is crucial for B2B buyers engaged in international transactions for the Cat 308, as it clarifies costs and risks associated with transportation. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Knowing the lead time for the Cat 308 or its parts can help buyers plan their projects more effectively, reducing the risk of delays in construction or other operations.

By grasping these technical specifications and trade terms, B2B buyers can make more informed decisions regarding the Cat 308 Mini Excavator, ensuring they select the right equipment for their business needs.

Navigating Market Dynamics and Sourcing Trends in the cat 308 Sector

What Are the Key Market Drivers and Trends Impacting the Cat 308 Sector?

The global market for mini excavators, particularly the Cat 308 series, is experiencing significant growth driven by urbanization, infrastructure development, and increased demand for efficient machinery in construction and landscaping projects. Regions such as Africa and South America are witnessing rapid urban growth, necessitating advanced construction equipment to meet the needs of expanding urban areas. In Europe, particularly in Germany, there is a strong push for sustainable construction practices, leading to an increased preference for machines that enhance productivity while minimizing environmental impact.

Emerging technologies are reshaping the sourcing landscape for B2B buyers. The adoption of telematics is revolutionizing how equipment is monitored and maintained, providing real-time data on performance and operational efficiency. This technological shift allows businesses to optimize their fleets and reduce downtime, crucial for maintaining competitive advantage. Furthermore, the rise of e-commerce platforms has made it easier for international buyers to access equipment specifications and pricing, streamlining the procurement process.

Key market dynamics also include fluctuating commodity prices and supply chain disruptions, which have led many companies to rethink their sourcing strategies. Buyers are increasingly looking for suppliers who can offer reliable delivery timelines and consistent quality, as these factors have become critical in maintaining project schedules.

How Is Sustainability Reshaping B2B Sourcing for the Cat 308?

Sustainability is no longer a peripheral concern; it has become a central tenet of business strategy in the construction equipment sector. For the Cat 308, environmental considerations are paramount, particularly as regulations tighten and public demand for greener practices rises. The excavator’s design incorporates advanced fuel-efficient engines that comply with stringent emissions standards, such as the U.S. EPA Tier 4 Final and EU Stage V regulations. These features not only reduce the carbon footprint but also enhance operational efficiency.

Ethical sourcing is equally vital. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices throughout their supply chains. This includes using materials sourced from certified suppliers who adhere to environmental and ethical standards. Certifications such as ISO 14001 for environmental management systems and adherence to the Global Reporting Initiative (GRI) can significantly influence purchasing decisions. Companies that can showcase their commitment to sustainability are more likely to build trust and long-term relationships with international buyers.

Moreover, the move towards circular economy principles is gaining traction, prompting manufacturers to design products that are easier to recycle and maintain. This trend is reflected in the Cat 308’s design, which emphasizes durability and ease of maintenance, thereby contributing to a longer lifecycle and reduced waste.

What Is the Historical Context Behind the Development of the Cat 308 Excavator?

The Cat 308 series has evolved significantly since its inception, reflecting advancements in engineering and changing market demands. Initially launched as a compact excavator for small to medium-sized projects, the Cat 308 has continually adapted to incorporate the latest technologies and sustainability measures. Over the years, it has integrated features such as advanced hydraulic systems and improved operator ergonomics, aligning with the industry’s shift towards more user-friendly and efficient machinery.

This evolution mirrors broader trends in construction and excavation, where the emphasis has shifted from merely size and power to precision, efficiency, and environmental responsibility. The Cat 308’s ability to perform in tight spaces while offering robust performance makes it a preferred choice for B2B buyers looking for versatility and reliability in their equipment investments. As the market continues to evolve, the Cat 308 remains at the forefront, showcasing the balance between innovation and practical application in the construction sector.

Frequently Asked Questions (FAQs) for B2B Buyers of cat 308

-

1. How do I ensure the Cat 308 meets my project requirements?

To ensure the Cat 308 Mini Excavator aligns with your project specifications, assess its key features such as operating weight, dig depth, and engine power. Review the equipment’s capabilities in relation to your specific applications, whether they are construction, landscaping, or utility work. Additionally, consult with suppliers for detailed specifications and field performance data, and consider requesting a demo or trial period to evaluate the machine’s functionality in real-world conditions. -

2. What is the best payment method for purchasing Cat 308 equipment?

The best payment method for acquiring a Cat 308 typically depends on your financial strategy and the supplier’s terms. Common options include bank transfers, letters of credit, and financing options through the supplier. Ensure you understand the payment terms, including any deposits required and payment timelines. It may also be beneficial to negotiate for favorable terms that align with your cash flow and project timelines, especially for larger purchases. -

3. How can I vet suppliers of the Cat 308 in international markets?

To effectively vet suppliers, start by researching their reputation through reviews and testimonials from previous customers. Verify their certifications and compliance with international standards, such as ISO certifications. Additionally, consider their experience in your region and their ability to provide localized support, spare parts, and service. Engaging with local industry associations or trade groups can also offer insights into reliable suppliers. -

4. What are the customization options available for the Cat 308?

Customization options for the Cat 308 can include various attachments like buckets, grapples, and augers, which can enhance its versatility for specific tasks. You can also explore different track types (rubber vs. steel) depending on your working environment. Discuss your specific needs with the supplier to understand the available configurations and any implications for lead times and costs. -

5. What are the typical lead times for ordering a Cat 308?

Lead times for ordering a Cat 308 Mini Excavator can vary based on factors like supplier inventory, customization options, and shipping logistics. Typically, expect a lead time of 4 to 12 weeks from order placement to delivery. For international buyers, factor in additional time for customs clearance and transportation. It’s advisable to communicate directly with suppliers for precise timelines and to plan your procurement accordingly. -

6. What are the logistics considerations when importing a Cat 308?

When importing a Cat 308, consider logistics factors such as shipping methods, customs duties, and local regulations. Choose a reliable freight forwarder experienced in heavy equipment to facilitate the transportation process. Familiarize yourself with the import regulations in your country, including any necessary permits or inspections. Additionally, plan for the delivery logistics to your site, ensuring you have the appropriate machinery and personnel available for unloading. -

7. How do I assess the quality assurance processes of suppliers for the Cat 308?

Assessing a supplier’s quality assurance processes involves reviewing their manufacturing practices and compliance with industry standards. Request documentation on their quality control procedures, including inspections and testing protocols for the Cat 308. Inquire about warranties and after-sales support, which are indicators of a supplier’s commitment to quality. Visiting the supplier’s facility or requesting references from previous clients can also provide further insights into their quality assurance practices. -

8. What are the minimum order quantities (MOQs) for the Cat 308?

Minimum order quantities for the Cat 308 may vary by supplier and region. While some suppliers may allow individual unit purchases, others may require bulk orders for better pricing. It’s advisable to discuss your specific needs with suppliers to determine their MOQ policies. Additionally, consider negotiating for more flexible terms if you are looking to purchase a smaller quantity, especially if you plan to establish a long-term relationship for future needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Cat 308 Manufacturers & Suppliers List

1. Cat – 308 CR Mini Excavator

2. Caterpillar – 308 CR Mini Excavator

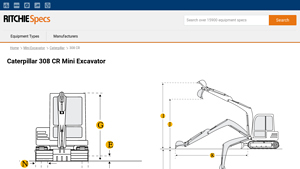

Domain: ritchiespecs.com

Registered: 2008 (17 years)

Introduction: {“model”:”Caterpillar 308 CR Mini Excavator”,”engine_power”:”55.4 kW (74.3 hp)”,”operating_weight”:”8,500 lbs (3,856 kg)”,”digging_depth”:”12 ft 6 in (3.81 m)”,”bucket_capacity”:”0.25 cu yd (0.19 m³)”,”transport_length”:”20 ft 2 in (6.15 m)”,”transport_width”:”7 ft 6 in (2.29 m)”,”transport_height”:”8 ft 1 in (2.46 m)”,”tail_swing_radius”:”4 ft 10 in (1.47 m)”,”max_reach”:”19 ft 8 in (5.99 m)”,”ma…

3. Cat – 308 CR Mini Excavator

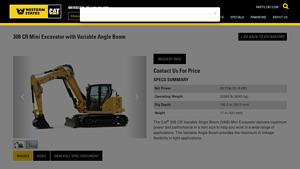

Domain: westernstatescat.com

Registered: 2005 (20 years)

Introduction: {‘name’: ‘Cat 308 CR Mini Excavator with Variable Angle Boom’, ‘net_power’: ‘69.5 hp (51.8 kW)’, ‘operating_weight’: ‘20385 lb (9245 kg)’, ‘dig_depth’: ‘150.2 in (3815 mm)’, ‘height’: ’17 in (431 mm)’, ‘displacement’: ‘203 in³ (3.33 l)’, ‘bore’: ‘3.7 in (94 mm)’, ‘gross_power’: ‘74.3 hp (55.4 kW)’, ‘stroke’: ‘4.7 in (120 mm)’, ‘engine_model’: ‘Cat® C3.3B’, ‘minimum_operating_weight’: ‘19084 lb (86…

4. Peterson – Mini Hydraulic Excavator 308 CR

Domain: petersoncat.com

Registered: 2004 (21 years)

Introduction: {‘model’: ‘308 CR’, ‘type’: ‘Mini Hydraulic Excavator’, ‘engine_net_power’: ‘69.50 hp (51.80 kW)’, ‘operating_weight’: ‘18493.00 lb (8387.00 kg)’, ‘dig_depth’: ‘182.80 in (4643.00 mm)’, ‘engine_model’: ‘Cat C3.3B’, ‘blade_height’: ‘17.00 in (431.00 mm)’, ‘machine_swing_speed’: ‘10.60 r/min’, ‘maximum_dig_height’: ‘277.10 in (7039.00 mm)’, ‘digging_force_bucket’: ‘13946.00 lb (62.00 kN)’, ‘operatin…

5. Cat – 308 Excavator

Domain: blog.rbauction.com

Registered: 1995 (30 years)

Introduction: Cat 308 excavator is a compact excavator known for its power and performance. It features a 69.5 horsepower engine and has an operating weight of approximately 20,385 lbs (9,245 kg). The maximum digging depth is about 185 inches (4,687 mm), with a robust hydraulic system for smooth operations. Sub-models include Cat 308 CR and Cat 308 E2 CR. The Cat 308 CR specs include a net power of 70.3 hp, ope…

6. Caterpillar – 308 Equipment

Domain: equipmenttrader.com

Registered: 1998 (27 years)

Introduction: This company, Caterpillar – 308 Equipment, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Holt – 308 CR Mini Hydraulic Excavator

Domain: holtca.com

Registered: 1999 (26 years)

Introduction: {“model”:”308 CR Mini Hydraulic Excavator (CAB)”,”price”:”$156,070″,”engine”:{“net_power”:”69.5hp”,”model”:”Cat C3.3B”,”gross_power”:”74.3hp”,”displacement”:”203in³”,”rated_net_power”:”69.5hp at 2200 rpm”},”operating_weight”:{“maximum”:”18493lb”,”minimum”:”16542lb”},”dimensions”:{“dig_depth”:”182.8in”,”boom_height_transport”:”89in”,”boom_height_working”:”120.1in”,”overall_shipping_length”:”270.6in…

Strategic Sourcing Conclusion and Outlook for cat 308

What Are the Key B2B Insights for Sourcing the Cat 308 Mini Excavator?

The Cat 308 Mini Excavator stands out as a versatile and powerful solution for various construction and excavation projects. With a net power of 69.5 hp and an operating weight of up to 20,385 lb, this machine delivers exceptional performance and efficiency. Its compact design and advanced hydraulic system facilitate operations in tight spaces, making it ideal for urban environments and intricate job sites. Strategic sourcing of the Cat 308 not only ensures access to a reliable piece of equipment but also offers long-term value through enhanced productivity and reduced downtime.

How Can International Buyers Leverage Strategic Sourcing for Cat 308?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing the Cat 308 is crucial. Evaluating local suppliers, considering logistics, and assessing after-sales support can significantly impact the overall investment. This strategic approach enables buyers to secure competitive pricing and favorable terms while ensuring that they have the necessary support for maintenance and parts.

What’s Next for Your Excavation Needs?

As the construction industry evolves, the demand for efficient and reliable machinery will only grow. Investing in the Cat 308 Mini Excavator positions businesses to meet these challenges head-on. Now is the time to engage with trusted suppliers and explore how the Cat 308 can enhance your operational capabilities. Embrace the future of excavation and make informed sourcing decisions that drive success in your projects.