Close-Fitting Part Of A Dress Guide: Type,Cost,Material…

Introduction: Navigating the Global Market for close-fitting part of a dress

In the ever-evolving landscape of fashion, sourcing the close-fitting part of a dress—the bodice—poses significant challenges for B2B buyers looking to enhance their product offerings. As the demand for stylish yet comfortable garments grows, international buyers, particularly from regions like Africa, South America, the Middle East, and Europe (including Saudi Arabia and Brazil), must navigate a complex market characterized by diverse styles, quality standards, and pricing strategies. This guide serves as a comprehensive resource, exploring various types of bodices, their applications in different dress styles, and essential criteria for supplier vetting.

By delving into the intricacies of sourcing bodices, this guide empowers B2B buyers to make informed purchasing decisions. It covers vital aspects such as material selection, design trends, and cost considerations, ensuring that buyers are equipped with the knowledge to negotiate effectively and secure the best deals. Additionally, we provide insights on how to identify reliable suppliers who can meet both quality and ethical standards, which is crucial in today’s socially conscious market.

With this resource, businesses can streamline their sourcing processes, reduce risks associated with supplier relationships, and ultimately enhance their competitive edge in the global fashion marketplace. Whether you are a retailer or a manufacturer, understanding the nuances of the bodice can significantly influence your product range and customer satisfaction.

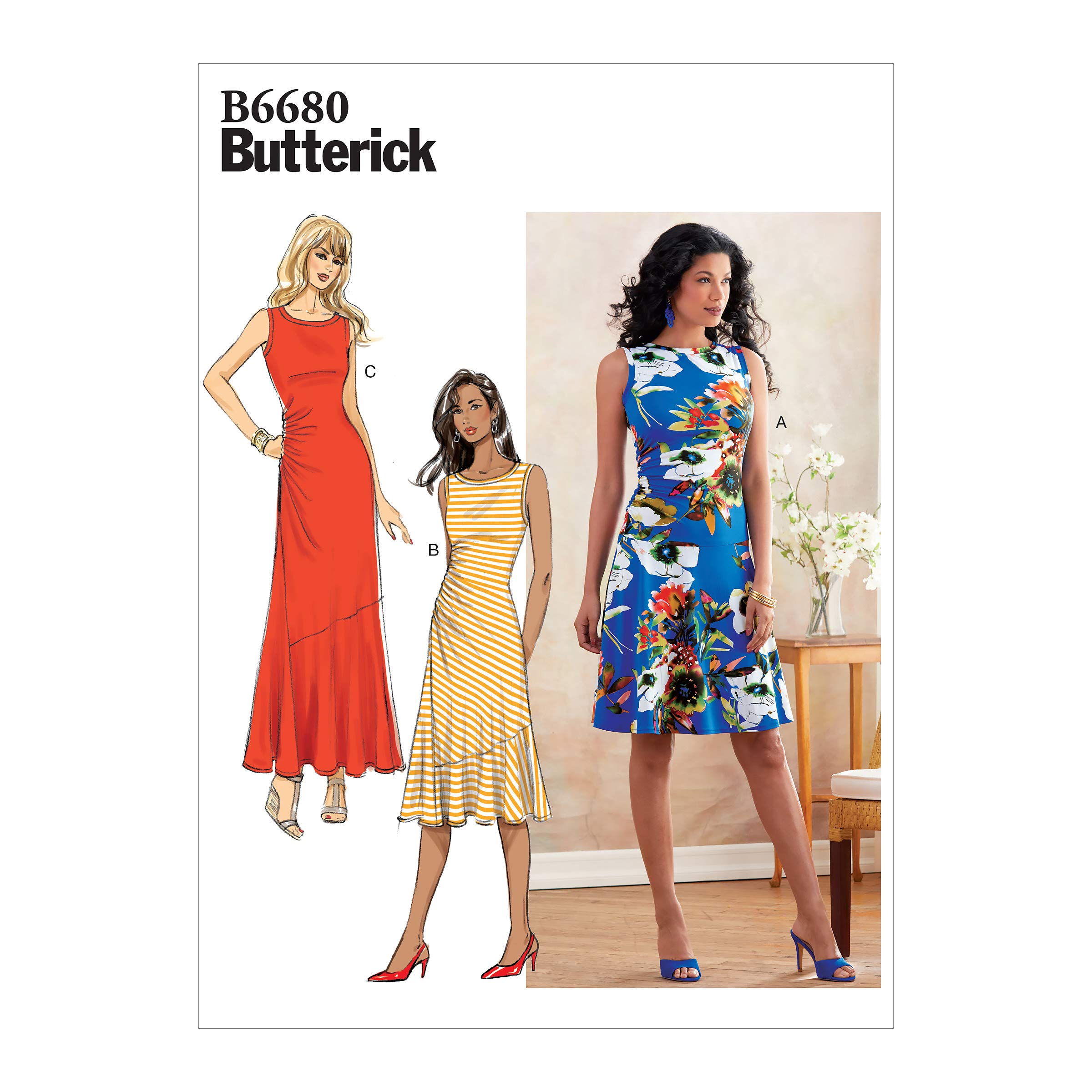

Understanding close-fitting part of a dress Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bodice | The upper part of a dress, fitted closely to the torso, often structured with boning. | High fashion, formal wear, bridal gowns | Pros: Enhances silhouette; versatile for various styles. Cons: May require alterations; can be restrictive. |

| Corset | A tightly fitted garment that shapes the waist and bust, often with laces or hooks. | Historical costumes, lingerie, fashion shows | Pros: Dramatically alters figure; supports bust. Cons: Can be uncomfortable; requires careful sizing. |

| Peplum | A short, flared ruffle attached to the waistline, creating a structured look. | Women’s business attire, evening dresses | Pros: Adds flair and style; flattering for various body types. Cons: Limited versatility; may not suit all occasions. |

| Tank Top | A sleeveless, close-fitting top that can be part of a dress or worn separately. | Casual wear, sportswear, summer collections | Pros: Comfortable and breathable; easy to layer. Cons: Less formal; may not suit professional settings. |

| Sheath Dress | A form-fitting dress that follows the body’s natural curves without additional seams. | Office wear, cocktail parties, formal events | Pros: Timeless style; emphasizes body shape. Cons: Limited movement; sizing can be tricky for diverse body shapes. |

What Are the Key Characteristics of a Bodice?

The bodice is the upper section of a dress, typically designed to fit snugly around the torso. It is often structured with materials such as boning or interfacing to provide support and shape. Bodices are prevalent in high fashion, formal wear, and bridal gowns, appealing to buyers looking for elegance and sophistication. When purchasing bodices, consider factors such as fabric choice, structural integrity, and customization options, as these can significantly impact the final garment’s fit and comfort.

How Does a Corset Differ from Other Close-Fitting Dress Types?

Corsets are unique in their ability to dramatically reshape the wearer’s figure, emphasizing the waist and bust through tight lacing and structured design. Commonly used in historical costumes and lingerie, corsets are sought after by businesses specializing in period clothing or high-fashion designs. Buyers should pay close attention to sizing, as improper fit can lead to discomfort. Additionally, the materials used in corsets can affect durability and ease of maintenance, making these considerations crucial for B2B transactions.

What Makes a Peplum Dress Attractive to Buyers?

Peplum dresses feature a distinctive ruffle at the waist that flares out, creating a visually appealing silhouette. They are popular in women’s business attire and evening wear, providing a sophisticated yet stylish option for various occasions. When considering peplum dresses, businesses should evaluate the versatility of the design and the potential for customization. While they flatter many body types, their limited versatility may restrict their use in more casual settings.

Why Are Tank Tops Popular in B2B Fashion?

Tank tops are characterized by their sleeveless design and close-fitting nature, making them ideal for casual and sportswear collections. They are lightweight and breathable, appealing to buyers looking for comfort and ease of layering. However, their informal style may not be suitable for all business contexts. B2B buyers should consider the target market’s preferences and the potential for pairing tank tops with other garments to enhance their appeal.

What Benefits Do Sheath Dresses Offer to Businesses?

Sheath dresses are known for their streamlined design that hugs the body without additional seams. This classic style is favored in office wear and cocktail settings, making it a versatile choice for formal occasions. When sourcing sheath dresses, businesses should focus on fabric quality and fit, as these elements are crucial for customer satisfaction. Although sheath dresses offer a timeless look, they can limit movement, necessitating careful attention to sizing and comfort for diverse body shapes.

Key Industrial Applications of close-fitting part of a dress

| Industry/Sector | Specific Application of close-fitting part of a dress | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | Design and manufacturing of women’s dresses | Enhances brand appeal through tailored fit | Quality of fabrics, ethical sourcing, and trend alignment |

| Costume Production | Custom costumes for theatrical productions | Provides unique, fitted designs for character portrayal | Fabric durability, design accuracy, and lead time |

| Bridal Industry | Creation of bespoke wedding gowns | Offers personalized experiences and high customer satisfaction | Customization options, fabric selection, and fitting services |

| Activewear Sector | Development of form-fitting activewear | Increases functionality and comfort for athletic performance | Material breathability, stretchability, and durability |

| Textile Manufacturing | Production of bodice components for various garments | Streamlines production processes and reduces waste | Sourcing sustainable materials, production capacity, and compliance with regulations |

How is the close-fitting part of a dress utilized in the fashion retail sector?

In the fashion retail sector, the close-fitting part of a dress, commonly known as the bodice, is crucial for designing and manufacturing women’s dresses. Retailers focus on creating garments that enhance the silhouette and provide a flattering fit, which is essential for attracting customers. Key considerations for international buyers include sourcing high-quality fabrics that align with current fashion trends and ensuring ethical production practices to meet consumer demand for sustainability. Additionally, understanding regional preferences can aid in tailoring designs to suit diverse markets, particularly in Africa, South America, the Middle East, and Europe.

What role does the close-fitting part of a dress play in costume production?

In costume production, the bodice serves as a foundational element for creating custom costumes for theatrical performances. The close fit allows for movement and comfort while ensuring that the costume accurately represents the character. This application often requires high-quality, durable fabrics that can withstand wear and tear during performances. Buyers in this sector must prioritize design accuracy and timely delivery, as productions operate on strict schedules. International buyers should also consider local customs and cultural nuances when designing costumes for specific performances.

How is the bodice significant in the bridal industry?

The bridal industry extensively utilizes the close-fitting part of a dress to create bespoke wedding gowns that cater to individual preferences. A well-fitted bodice enhances the bride’s silhouette, making it a focal point of the gown. This personalization leads to high customer satisfaction and brand loyalty. For international buyers, sourcing options must include a range of fabrics, customization capabilities, and fitting services to accommodate different body types and cultural expectations, especially in diverse markets like Saudi Arabia and Brazil.

Why is the close-fitting part of a dress important in the activewear sector?

In the activewear sector, the bodice is integral to developing form-fitting garments that enhance athletic performance. A close-fitting design provides support and comfort, allowing for a full range of motion during physical activities. Buyers must focus on sourcing materials that offer breathability, stretch, and durability to meet the demands of active consumers. Additionally, understanding regional fitness trends and preferences is vital for tailoring products that resonate with customers in various international markets, including those in the Middle East and South America.

How does textile manufacturing utilize the close-fitting part of a dress?

Textile manufacturing leverages the close-fitting part of a dress by producing bodice components for various garments, streamlining the production process. Efficient manufacturing practices can reduce waste and improve turnaround times. Buyers in this sector should prioritize sustainable material sourcing, as environmental concerns increasingly influence consumer choices. Compliance with international regulations and quality standards is also essential, particularly for buyers from Europe and other regions with stringent textile regulations.

3 Common User Pain Points for ‘close-fitting part of a dress’ & Their Solutions

Scenario 1: Sizing Inconsistencies Across Markets

The Problem: One of the most prevalent challenges B2B buyers face when sourcing close-fitting parts of dresses, such as bodices, is the inconsistency in sizing standards across different regions. For example, a bodice that fits perfectly in Europe may not translate well to African or South American markets, leading to high return rates and dissatisfied customers. This sizing discrepancy can stem from variations in body shapes, cultural preferences, and local fashion trends, making it imperative for buyers to ensure the right fit for their target audience.

The Solution: To effectively address sizing inconsistencies, B2B buyers should engage in comprehensive market research to understand the specific body measurements and preferences in their target regions. Collaborating with local designers or fashion consultants can provide valuable insights into regional sizing norms. Additionally, implementing a flexible size range and offering customization options can cater to diverse body types. When placing orders, ensure to request sample sizes for testing fit and comfort before full-scale production. This proactive approach minimizes returns and enhances customer satisfaction, ultimately leading to better sales performance.

Scenario 2: Quality Control Issues in Production

The Problem: Quality control is a significant concern when procuring close-fitting parts for dresses, especially since these components require precise tailoring and fabric quality. B2B buyers often encounter issues such as fabric stretching, misalignment in seams, or poor stitching quality that affects the overall look and durability of the bodice. These quality issues can tarnish a brand’s reputation and lead to costly returns, impacting profitability and customer loyalty.

The Solution: To mitigate quality control issues, buyers should establish stringent quality assurance protocols with their manufacturers. This includes setting clear quality standards and conducting regular inspections at various stages of the production process. Consider implementing a third-party quality control service to ensure that the fabrics meet durability and comfort standards before they are shipped. Additionally, fostering a strong relationship with manufacturers through transparent communication can help address potential issues early on. Regular feedback loops will also promote continuous improvement in the production process, ensuring a superior product for end consumers.

Scenario 3: Limited Fabric Options for Close-Fitting Designs

The Problem: B2B buyers often struggle with a limited selection of fabrics suitable for close-fitting dress designs, such as bodices. Certain markets may have specific requirements for breathable, stretchable, or sustainable materials, yet suppliers may not offer diverse fabric options that meet these criteria. This limitation can hinder creativity and the ability to meet consumer demands for stylish yet functional clothing.

The Solution: To overcome the challenge of limited fabric options, buyers should diversify their supplier base by exploring international markets for sourcing materials. Engaging with textile manufacturers that specialize in performance fabrics or sustainable materials can unlock a broader range of choices. Attending fabric trade shows and exhibitions can also provide opportunities to discover innovative materials that meet the latest fashion trends and consumer preferences. Furthermore, establishing partnerships with fabric suppliers who offer custom solutions can enable buyers to create unique, close-fitting designs that stand out in a competitive market. This approach not only enhances product offerings but also appeals to a wider audience, driving sales growth.

Strategic Material Selection Guide for close-fitting part of a dress

What Are the Key Materials for Close-Fitting Parts of a Dress?

When selecting materials for the close-fitting parts of a dress, particularly the bodice, several factors come into play, including comfort, durability, and aesthetic appeal. Below are analyses of four common materials used in this application, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Cotton Blends

Key Properties: Cotton blends, often mixed with elastane or polyester, offer breathability and stretch. They maintain a comfortable temperature, making them suitable for various climates.

Pros & Cons: Cotton blends are durable and easy to care for, making them a popular choice. However, they may not provide the same level of support as more structured fabrics, which can limit their use in more formal designs. Additionally, while cotton is generally affordable, the cost can increase with higher-quality blends.

Impact on Application: Cotton blends are compatible with skin and are often used in casual and semi-formal dresses. They are less suitable for high-pressure environments but excel in everyday wear.

Considerations for International Buyers: Buyers from regions with varying climates, such as Africa and the Middle East, should consider cotton’s breathability. Compliance with local fabric standards is essential, particularly in Europe, where organic cotton certifications may be preferred.

2. Polyester

Key Properties: Polyester is known for its strength, durability, and resistance to shrinking and stretching. It also dries quickly, making it suitable for humid climates.

Pros & Cons: The primary advantage of polyester is its cost-effectiveness and ability to hold vibrant colors. However, it can be less breathable than natural fibers, which may lead to discomfort in warmer climates. Manufacturing complexity can also be higher due to the need for specialized dyeing processes.

Impact on Application: Polyester is widely used in formal dresses due to its structured finish and ability to maintain shape. It is ideal for high-pressure applications, such as evening wear, but may not be suitable for casual styles.

Considerations for International Buyers: Buyers should be aware of the varying quality standards for polyester in different regions. For instance, European buyers may look for compliance with REACH regulations regarding chemical safety in textiles.

3. Lace

Key Properties: Lace is a delicate fabric known for its intricate patterns and lightweight nature. It often combines cotton or polyester with other fibers for added strength.

Pros & Cons: Lace adds a luxurious aesthetic to dresses, making it a popular choice for formal occasions. However, its delicate nature can limit durability, and it may require more careful handling during manufacturing and washing.

Impact on Application: Lace is often used as an overlay in close-fitting parts of dresses, providing a romantic touch. It is less suitable for everyday wear due to its fragility but excels in special occasion attire.

Considerations for International Buyers: Lace quality can vary significantly, and buyers should ensure compliance with international standards for textile quality. In regions like Brazil and the Middle East, cultural preferences may dictate the use of lace in evening wear.

4. Spandex

Key Properties: Spandex is known for its exceptional elasticity and ability to stretch up to five times its original length. It is often blended with other fabrics to enhance comfort and fit.

Pros & Cons: The primary advantage of spandex is its ability to provide a snug fit, making it ideal for close-fitting designs. However, it can be more expensive than other materials and may require specialized manufacturing techniques.

Impact on Application: Spandex is frequently used in activewear and form-fitting dresses, providing both support and comfort. It is particularly effective in applications where movement is essential.

Considerations for International Buyers: Buyers should consider the varying regulations regarding synthetic materials in their respective regions. In Europe, for example, there are strict guidelines regarding the use of spandex in garments, especially concerning environmental impact.

Summary Table of Material Selection

| Material | Typical Use Case for close-fitting part of a dress | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cotton Blends | Casual and semi-formal dresses | Breathable and comfortable | Limited support | Medium |

| Polyester | Formal and structured dresses | Cost-effective and durable | Less breathable | Low |

| Lace | Special occasion dresses | Luxurious aesthetic | Delicate and less durable | Medium |

| Spandex | Activewear and form-fitting dresses | Exceptional elasticity | Higher cost and manufacturing complexity | High |

This guide aims to empower international B2B buyers with the necessary insights to make informed decisions regarding material selection for the close-fitting parts of dresses, ensuring they meet both market demands and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for close-fitting part of a dress

What Are the Main Stages in the Manufacturing Process of Close-Fitting Dress Parts?

The manufacturing of close-fitting parts of a dress, such as the bodice, involves several critical stages that ensure both quality and efficiency. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Are Fabrics Selected and Prepared?

Material preparation is the first step in the manufacturing process. For close-fitting dress parts, the choice of fabric is crucial. Common materials include cotton blends, polyester, and spandex, which provide comfort and elasticity. Suppliers often conduct fabric tests to assess characteristics such as stretchability, breathability, and durability. Pre-treatment processes, such as washing or dyeing, may also be applied to ensure the fabric is ready for cutting.

Forming: What Techniques Are Used to Shape the Bodice?

Once the materials are prepared, the next step is forming. This involves cutting the fabric into the required patterns. Techniques such as laser cutting or automated cutting tables are increasingly used for precision and efficiency. Pattern pieces are often designed using CAD (Computer-Aided Design) systems, allowing for intricate designs that fit closely to the body. This stage also includes draping and fitting trials to ensure that the bodice will conform to the desired shape.

Assembly: How Are the Components Stitched Together?

Assembly follows forming, where the individual pieces are sewn together. This process may involve various stitching techniques, such as flatlock or overlock, depending on the garment’s design and fabric. Quality control during this stage is essential, as any misalignment can affect the final fit. Skilled operators often perform this work, using sewing machines equipped with specialized attachments for close-fitting seams.

Finishing: What Final Touches Are Applied Before Packaging?

The finishing stage includes adding final details such as hems, zippers, and embellishments. Techniques like steaming and pressing are employed to remove any creases and give the garment a polished look. This stage also involves final inspections to ensure that the product meets quality standards before being packaged for shipment.

What Quality Control Standards Should B2B Buyers Be Aware Of?

Quality control (QC) is vital in the manufacturing of close-fitting dress parts to ensure that the final products meet international standards. B2B buyers should familiarize themselves with relevant standards and QC checkpoints throughout the manufacturing process.

Which International Standards Apply to Clothing Manufacturing?

One of the most recognized international standards is ISO 9001, which outlines requirements for a quality management system. Compliance with ISO 9001 indicates that a manufacturer has established processes to enhance customer satisfaction and ensure consistent quality. Other industry-specific certifications may include CE marking for safety and environmental compliance, especially relevant for buyers in Europe.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are implemented at various stages of the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the assembly process, operators conduct routine checks to identify defects early.

- Final Quality Control (FQC): This final inspection occurs before packaging and shipment, ensuring that the finished garment meets all quality standards.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying supplier quality control is essential to ensure product reliability. There are several methods to achieve this:

What Are the Best Practices for Conducting Supplier Audits?

Conducting supplier audits is a proactive approach to assess a manufacturer’s quality management practices. Buyers can perform on-site inspections to evaluate the manufacturing processes, QC checkpoints, and overall compliance with quality standards. It is advisable to utilize third-party audit services that specialize in textile manufacturing to gain an unbiased perspective.

How Can Buyers Request Quality Reports and Documentation?

Buyers should request quality reports and documentation from suppliers, which may include inspection reports, test certificates, and compliance documentation. These documents provide insights into the supplier’s quality assurance processes and can help buyers make informed decisions.

What Common Testing Methods Are Used in Quality Control?

Several testing methods are commonly used to ensure the quality of close-fitting dress parts:

- Physical Testing: This includes tensile strength tests, seam strength tests, and stretch tests to determine the durability and comfort of the fabric.

- Colorfastness Testing: Ensures that the fabric maintains its color after washing and exposure to light.

- Fit Testing: Involves wearing samples to assess comfort, movement, and overall fit, ensuring that the garment meets design specifications.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers should be aware of specific nuances related to quality control and certification, especially when dealing with suppliers from diverse regions such as Africa, South America, the Middle East, and Europe.

How Do Cultural Differences Impact Quality Standards?

Cultural differences may influence manufacturing practices and quality expectations. For example, some regions may prioritize craftsmanship over speed, while others may focus on technological advancements. Understanding these nuances can help buyers establish better communication and collaboration with suppliers.

What Should Buyers Know About Regional Compliance Regulations?

Different regions have distinct compliance regulations that may affect quality assurance. For instance, the EU has stringent regulations regarding textile safety and environmental impact. Buyers should ensure that their suppliers are compliant with local laws and international standards relevant to their markets.

Conclusion

The manufacturing process and quality assurance for close-fitting parts of a dress are intricate and multifaceted. B2B buyers must take an active role in understanding the stages of production, quality control standards, and verification methods to ensure that they source high-quality garments. By prioritizing these aspects, buyers can foster strong partnerships with suppliers and ultimately enhance their product offerings in competitive markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘close-fitting part of a dress’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring the close-fitting part of a dress, commonly known as the bodice. The bodice serves as a critical component in women’s fashion, influencing fit, comfort, and overall garment aesthetics. By following this checklist, buyers can ensure they make informed decisions, securing quality products that meet their specifications and market demands.

Step 1: Define Your Technical Specifications

Begin by outlining the technical requirements for the bodice you wish to source. This includes dimensions, fabric types, design features, and any specific finishes. Clearly defined specifications are essential for communicating your needs to potential suppliers, ensuring that the products you receive align with your expectations.

- Consider the end-user: Understand the target demographic and their preferences regarding style and fit.

- Material selection: Choose fabrics that are not only aesthetically pleasing but also durable and comfortable.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in bodices or close-fitting dress components. Utilize online directories, trade shows, and industry networks to compile a list of candidates. A well-researched supplier base increases your chances of finding reliable partners.

- Check their experience: Look for suppliers with a proven track record in the apparel industry, especially those experienced in your target market.

- Review their product range: Ensure they offer a variety of designs and materials that suit your needs.

Step 3: Evaluate Supplier Capabilities

Assess the capabilities of shortlisted suppliers to determine their ability to meet your production requirements. This includes evaluating their manufacturing processes, quality control measures, and lead times.

- Factory visits: If possible, visit the supplier’s facilities to observe their operations firsthand.

- Request samples: Obtain samples of their bodice products to evaluate quality and craftsmanship before making a commitment.

Step 4: Verify Certifications and Compliance

It is crucial to ensure that your suppliers comply with industry standards and regulations. Verify their certifications related to quality management, environmental sustainability, and labor practices.

- Look for relevant certifications: ISO certifications, ethical sourcing certifications, and compliance with local regulations can indicate a supplier’s commitment to quality and responsibility.

- Ask for documentation: Request copies of certificates and compliance reports to review their adherence to industry standards.

Step 5: Assess Pricing and Payment Terms

Negotiate pricing and payment terms with potential suppliers. Pricing should be competitive while allowing for quality assurance. Understanding payment terms will help manage cash flow and mitigate risks.

- Compare quotes: Evaluate multiple suppliers to ensure you receive the best value without compromising quality.

- Clarify payment structures: Discuss options such as deposits, progress payments, or payment upon delivery to find a mutually beneficial arrangement.

Step 6: Establish Communication Channels

Effective communication is vital for a successful sourcing relationship. Establish clear lines of communication with your chosen supplier to ensure that any issues can be addressed promptly.

- Use technology: Leverage platforms for real-time updates and project management, ensuring all parties are aligned throughout the sourcing process.

- Set regular check-ins: Schedule periodic meetings to review progress and address any concerns or adjustments needed in the production timeline.

Step 7: Finalize Contracts and Agreements

Once a supplier meets all your criteria, finalize contracts that clearly outline terms, responsibilities, and expectations. A well-drafted contract protects both parties and provides a framework for the relationship.

- Include key clauses: Ensure the contract covers delivery schedules, quality standards, dispute resolution, and confidentiality agreements.

- Review thoroughly: Have legal counsel review the contract to protect your interests and ensure compliance with local laws and regulations.

By following these steps, B2B buyers can navigate the sourcing process for the close-fitting part of a dress with confidence, ensuring they partner with the right suppliers to meet their business objectives.

Comprehensive Cost and Pricing Analysis for close-fitting part of a dress Sourcing

What Are the Key Cost Components for Sourcing Close-Fitting Dress Parts?

When sourcing the close-fitting part of a dress, commonly referred to as the bodice, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

Materials play a significant role in the overall cost. Different fabrics such as cotton, silk, or polyester can dramatically affect pricing, with silk being the most expensive option. Additionally, embellishments or linings can add to the material costs.

Labor costs vary by region and the complexity of the design. In regions like South America and parts of Africa, labor may be more affordable, but the skill level required for high-quality craftsmanship can also influence pricing.

Manufacturing overhead includes indirect costs such as utilities, rent, and equipment maintenance. This is often a fixed cost that can be spread over larger production runs, making larger orders more cost-effective.

Tooling costs are incurred when specialized equipment is required for producing specific designs or sizes. This is particularly relevant for custom or intricate bodice designs, which may necessitate unique molds or machinery.

Quality Control (QC) ensures that the products meet required specifications and certifications. Investing in thorough QC can prevent costly returns and rework, thus influencing the overall cost positively in the long run.

Logistics costs encompass shipping, handling, and customs duties, which can vary significantly based on the destination, especially for international shipments. Incoterms play a pivotal role in defining who bears these costs.

Margins for suppliers typically range from 10% to 30%, influenced by market conditions, competition, and the perceived value of the product.

How Do Price Influencers Affect the Sourcing of Dress Bodices?

Several factors can influence pricing when sourcing close-fitting parts of dresses. Volume and Minimum Order Quantity (MOQ) are paramount; larger orders can lead to bulk pricing discounts, while smaller orders may incur higher per-unit costs.

Specifications and customization also significantly impact price. Highly customized designs necessitate more time and resources, thus increasing costs. Buyers should consider whether standard designs could meet their needs to save on costs.

The quality of materials selected will greatly affect pricing. Premium fabrics will increase the cost, but they may also enhance the product’s appeal and marketability. Certifications for organic or sustainable materials can also add to the price.

Supplier factors such as reputation, reliability, and geographical location should not be overlooked. Suppliers with a proven track record may charge a premium for their products, while newer suppliers might offer lower prices to attract business.

What Buyer Tips Can Help Achieve Cost Efficiency in Sourcing?

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, negotiating effectively can lead to significant cost savings. Understanding local market conditions and supplier dynamics will empower buyers during negotiations.

Cost-efficiency can be enhanced by considering the Total Cost of Ownership (TCO), which includes not just the purchase price but also shipping, customs duties, and potential costs associated with returns or quality issues.

It’s crucial to be aware of pricing nuances in different regions. For example, the Middle East may have different expectations regarding quality and luxury, which can affect pricing strategies.

Lastly, always include a disclaimer for indicative prices when discussing costs with potential suppliers. Prices can fluctuate based on market conditions, currency exchange rates, and changes in material costs. Providing a range rather than a fixed price can help manage expectations and facilitate smoother negotiations.

By understanding these dynamics, B2B buyers can make informed decisions that balance cost with quality, ultimately leading to a successful sourcing strategy for close-fitting dress parts.

Alternatives Analysis: Comparing close-fitting part of a dress With Other Solutions

Exploring Alternatives to the Close-Fitting Part of a Dress

In the fashion industry, the close-fitting part of a dress, commonly referred to as the bodice, serves a critical role in defining the silhouette and fit of a garment. However, various alternatives can achieve similar aesthetic and functional outcomes. This analysis will compare the traditional bodice against two viable alternatives: the corset and the structured bodice.

Comparison Table

| Comparison Aspect | Close-Fitting Part Of A Dress | Corset | Structured Bodice |

|---|---|---|---|

| Performance | Provides a classic fit, enhancing shape and support. | Offers significant support and shaping, often with a dramatic silhouette. | Maintains structure while allowing for movement and comfort. |

| Cost | Generally moderate, depending on fabric and design complexity. | Can be expensive due to materials and craftsmanship. | Typically lower cost than corsets, with varied pricing based on design. |

| Ease of Implementation | Easy to sew and fit, adaptable to various designs. | Requires skilled tailoring for proper fit and comfort. | Relatively straightforward to construct, with less complexity than corsets. |

| Maintenance | Low; standard care for fabric garments. | High; requires special care and sometimes professional cleaning. | Low to moderate; depends on fabric and construction methods. |

| Best Use Case | Ideal for casual to formal dresses needing elegant shaping. | Best for historical or fashion-forward designs that demand a pronounced silhouette. | Suitable for modern, comfortable garments that still require some structure. |

What Are the Pros and Cons of Using a Corset?

Corsets have been a staple in women’s fashion for centuries, known for their ability to shape the waist and create an hourglass figure. The primary advantage of corsets is their capacity to provide strong support, enhancing body shape dramatically. However, they can be restrictive and uncomfortable for the wearer, especially if not tailored correctly. Additionally, the complexity of their construction often results in higher costs and maintenance requirements, making them less accessible for mass production.

How Does a Structured Bodice Compare?

A structured bodice is a modern alternative that provides a balance between style and comfort. This design incorporates elements like boning and interfacing to maintain form while allowing for greater mobility compared to a corset. The structured bodice is typically more cost-effective than corsets and easier to implement in garment production. However, it may not offer the same level of dramatic shaping as a corset, making it less suitable for specific high-fashion applications.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the ideal solution for a close-fitting part of a dress, B2B buyers must consider their target market and the specific requirements of their designs. The bodice remains a versatile option for a variety of dresses, while corsets and structured bodices offer unique benefits and limitations. Evaluating factors such as performance, cost, and ease of maintenance will guide buyers in making informed decisions that align with their brand identity and customer preferences. By understanding these alternatives, businesses can effectively cater to diverse fashion needs while optimizing their production processes.

Essential Technical Properties and Trade Terminology for close-fitting part of a dress

What Are the Key Technical Properties for Close-Fitting Parts of a Dress?

When it comes to close-fitting parts of a dress, particularly the bodice, several technical properties play a crucial role in ensuring quality and performance. Here are the essential specifications to consider:

1. Material Composition

The fabric used for the bodice significantly impacts both comfort and durability. Common materials include cotton, polyester, spandex, and blends. Each fabric has unique properties; for instance, spandex provides stretchability, while cotton offers breathability. Understanding material composition helps buyers select fabrics that meet the desired aesthetic and functional requirements.

2. Fit Tolerance

Fit tolerance refers to the allowable variation in measurements that ensures the bodice fits snugly without compromising comfort. Typically measured in millimeters, these tolerances ensure that the final product aligns with the intended design specifications. Accurate fit tolerance is critical for maintaining quality and consistency across production runs, which is essential for brand reputation.

3. Seam Strength

Seam strength denotes the durability of the stitching used in the bodice construction. It is measured in pounds of force required to break the seam. High seam strength is vital for close-fitting garments, as they undergo significant stress during wear. Ensuring robust seam strength minimizes returns and increases customer satisfaction, making it a key consideration for B2B buyers.

4. Breathability Index

Breathability indicates how well air can circulate through the fabric. For close-fitting dresses, particularly in warmer climates, high breathability is essential for comfort. Fabrics with a high breathability index, such as moisture-wicking materials, can enhance wearability and performance. Buyers should prioritize materials that provide adequate breathability to cater to diverse markets, especially in regions with warm climates like Africa and South America.

5. Colorfastness Rating

Colorfastness refers to a fabric’s ability to retain its color when exposed to washing, light, and other environmental factors. It is measured on a scale from 1 to 5, with 5 being the highest. High colorfastness is crucial for maintaining the aesthetic appeal of close-fitting dresses over time. Buyers should ensure that their suppliers provide fabrics with adequate colorfastness ratings to meet customer expectations.

What Trade Terms Should B2B Buyers Know When Sourcing Close-Fitting Dress Components?

Understanding trade terminology can streamline the purchasing process and enhance communication between buyers and suppliers. Here are some common terms to be familiar with:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces components or products that are used in another company’s end product. In the fashion industry, this often refers to manufacturers who create the bodice or other components for major fashion brands. Knowing the OEMs can help buyers identify reliable suppliers.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and cash flow. Understanding the MOQ helps buyers negotiate better terms and plan their purchases effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers asking for pricing on specified products or services. It is a vital step in procurement, as it allows buyers to compare costs and terms from multiple suppliers. A well-structured RFQ can lead to better pricing and quality assurance.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping costs, risk, and delivery obligations. Familiarity with Incoterms is essential for B2B buyers to mitigate risks and ensure smooth logistics.

5. Lead Time

Lead time refers to the period required from placing an order to receiving the goods. Understanding lead times is critical for effective supply chain management. Buyers should consider lead times when planning production schedules to avoid delays in launching new products.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing close-fitting parts of dresses, ensuring quality and reliability in their supply chains.

Navigating Market Dynamics and Sourcing Trends in the close-fitting part of a dress Sector

What Are the Current Market Dynamics and Key Trends in the Close-Fitting Part of a Dress Sector?

The global market for the close-fitting part of a dress, particularly the bodice, is experiencing significant transformation driven by several key factors. Increased consumer awareness regarding fashion sustainability, coupled with the rise of e-commerce platforms, is reshaping how international buyers engage with suppliers. In regions such as Africa, South America, the Middle East, and Europe, buyers are increasingly seeking versatility and adaptability in designs, as well as the ability to cater to diverse body types. This demand is pushing manufacturers to innovate, leading to the introduction of stretch fabrics and customizable options that enhance fit and comfort.

Emerging technologies are also influencing sourcing trends. Digital platforms that facilitate direct communication between manufacturers and buyers are gaining traction, allowing for more efficient transactions and supply chain transparency. Moreover, advancements in 3D modeling and virtual fitting technologies are helping brands reduce waste and improve the design process, making it easier for buyers to visualize products before committing to orders.

Furthermore, global events such as economic fluctuations and trade agreements are impacting sourcing strategies. Buyers from countries like Saudi Arabia and Brazil are increasingly looking for suppliers who can offer competitive pricing without compromising on quality. This dynamic creates opportunities for manufacturers who can streamline their operations and leverage local materials to meet international standards.

How Important Is Sustainability and Ethical Sourcing in the Close-Fitting Part of a Dress Sector?

Sustainability has become a pivotal concern for B2B buyers in the close-fitting part of the dress sector. The environmental impact of fashion production, particularly in terms of waste and pollution, has prompted businesses to rethink their sourcing strategies. Ethical supply chains that prioritize eco-friendly materials and practices are not just a trend but a necessity in maintaining brand integrity and consumer trust.

Buyers are increasingly seeking suppliers who can provide ‘green’ certifications, such as GOTS (Global Organic Textile Standard) and OEKO-TEX, which assure that the materials used in the bodice and other components are free from harmful substances and produced in environmentally friendly conditions. This demand extends to the sourcing of fabrics, with organic cotton, Tencel, and recycled polyester gaining popularity for their reduced environmental footprint.

Moreover, the emphasis on ethical labor practices is becoming paramount. Buyers are now more inclined to partner with manufacturers who ensure fair wages and safe working conditions. This shift not only aligns with consumer expectations but also mitigates risks associated with supply chain disruptions linked to unethical practices.

What Is the Brief Evolution of the Close-Fitting Part of a Dress Sector?

The evolution of the close-fitting part of a dress, particularly the bodice, reflects broader trends in fashion and textile technology. Historically, the bodice has undergone various transformations, from the rigid corsets of the Victorian era to the more relaxed silhouettes of modern designs. This evolution has been influenced by changing societal norms regarding body image and comfort, leading to a greater emphasis on fit and functionality.

In recent years, the sector has seen a surge in demand for inclusive sizing and adaptive designs, catering to a wider array of body types and preferences. This shift is driven by consumer desire for personalization and body positivity, which has prompted brands to innovate in their offerings. As a result, the close-fitting part of a dress is no longer merely a fashion statement but a reflection of individual identity and empowerment, making it a crucial area for B2B buyers to consider in their sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of close-fitting part of a dress

-

How do I ensure the quality of close-fitting parts of a dress when sourcing from suppliers?

To ensure quality, it’s vital to conduct thorough supplier vetting. Start by requesting samples to evaluate fabric, stitching, and overall craftsmanship. Check for certifications such as ISO or other relevant quality standards. Additionally, consider third-party inspections during production to maintain quality control. Building a strong relationship with your supplier can also facilitate open communication regarding quality expectations. -

What are the most important factors to consider when selecting a supplier for dress bodices?

Key factors include the supplier’s experience in the garment industry, their production capacity, and their ability to meet your specific design requirements. Research their reputation through reviews or references from previous clients. Evaluate their compliance with international trade regulations and labor standards, especially if sourcing from regions with varying practices. Lastly, assess their logistics capabilities to ensure timely delivery. -

What is the typical minimum order quantity (MOQ) for close-fitting dress parts?

MOQs can vary significantly between suppliers, often ranging from 50 to 500 units depending on the complexity of the design and the materials used. It’s advisable to discuss your needs directly with potential suppliers to negotiate favorable terms. Consider building a long-term partnership that could allow for more flexible MOQs as your relationship develops. -

How can I customize close-fitting parts of a dress to fit my brand’s style?

Customization can include fabric selection, color, and design alterations to align with your brand’s identity. Engage with your supplier early in the design process to discuss options available for customization. Providing detailed specifications, such as sketches or samples, can facilitate the development of unique products. Be aware of potential costs and lead times associated with custom orders. -

What payment terms are typically offered by suppliers in the garment industry?

Payment terms can vary, but common practices include a 30% deposit upon order confirmation with the balance due before shipment. Some suppliers may offer net 30 or net 60 terms for established customers. It’s crucial to clarify payment expectations upfront and ensure they align with your financial capabilities. Using secure payment methods can also protect your investment. -

What logistics considerations should I keep in mind when importing dress components?

Logistics considerations include shipping methods, customs clearance, and delivery timelines. Determine whether air freight or sea freight aligns better with your budget and time constraints. Ensure your supplier is familiar with export regulations in their country and import regulations in yours. Collaborating with a logistics partner can help navigate these complexities and streamline the process. -

How do I handle potential disputes with suppliers?

To minimize disputes, establish clear contracts that outline expectations for quality, delivery timelines, and payment terms. Open communication is key; address any issues promptly and professionally. If disputes arise, refer to the terms of your contract, and consider mediation or arbitration as a cost-effective resolution method. Building a positive relationship with your supplier can also aid in resolving conflicts amicably. -

What are the trends in close-fitting dress designs that I should be aware of?

Current trends include sustainable materials, versatile designs suitable for different occasions, and inclusivity in sizing. Additionally, there’s a growing demand for innovative features like adjustable bodices and integrated support structures. Staying informed about fashion trends through industry reports and attending trade shows can help you anticipate market demands and guide your purchasing decisions effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Close-Fitting Part Of A Dress Manufacturers & Suppliers List

1. Crossword Genius – Bodice

Domain: crosswordgenius.com

Registered: 1999 (26 years)

Introduction: Close-fitting part of a dress, known as a bodice, which is the upper part of a woman’s dress and can also be referred to as a spencer or basque.

2. Crossword Nexus – Fashion Solutions

3. WordFinder – BODICE

Domain: wordfinder.yourdictionary.com

Registered: 1999 (26 years)

Introduction: This company, WordFinder – BODICE, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Try Hard Guides – Crossword Solutions

Domain: tryhardguides.com

Registered: 2021 (4 years)

Introduction: Close-fitting part of a dress crossword clue; 6-letter answer: BODICE; last seen in the NYT Crossword on May 14, 2025; definition: part of a dress above the waist.

5. Crossword Tracker – Crossword Clue Insights

Domain: crosswordtracker.com

Registered: 2010 (15 years)

Introduction: Close-fitting dress is a crossword puzzle clue that has been spotted 1 time. Related crossword puzzle answer is SHEATH. Recent usage in crossword puzzles includes LA Times – Jan. 23, 2015.

6. Daze Puzzle – Bodice

Domain: dazepuzzle.com

Registered: 2018 (7 years)

Introduction: Close-fitting part of a dress: BODICE

Strategic Sourcing Conclusion and Outlook for close-fitting part of a dress

How Can Strategic Sourcing Enhance Your Procurement of Close-Fitting Dress Parts?

In conclusion, the strategic sourcing of close-fitting components, particularly the bodice of dresses, offers significant advantages for B2B buyers across various international markets, including Africa, South America, the Middle East, and Europe. By prioritizing quality, sustainability, and supplier relationships, buyers can enhance their product offerings while reducing costs and lead times. Engaging with suppliers who understand the unique cultural and market dynamics of these regions can foster innovation and improve responsiveness to consumer trends.

As the demand for customizable and high-quality garments continues to rise, strategic sourcing will be pivotal in navigating the complexities of global supply chains. This approach not only secures competitive pricing but also ensures access to the latest fabric technologies and design trends that resonate with diverse consumer bases.

We encourage international B2B buyers to actively evaluate their sourcing strategies and consider partnerships that align with their long-term business goals. By embracing a collaborative and forward-thinking approach, you can position your brand to thrive in an ever-evolving fashion landscape. Take the first step today to revolutionize your procurement processes and enhance your competitive edge in the market.