Cowboy Hat Hard Guide: Type,Cost,Material…

Introduction: Navigating the Global Market for cowboy hat hard

In the dynamic landscape of safety gear, sourcing the right cowboy hat hard is a crucial challenge for international B2B buyers. These innovative hard hats not only provide essential protection but also blend style and comfort, appealing to various industries—from construction to agriculture. As organizations in regions such as Africa, South America, the Middle East, and Europe (including Saudi Arabia and Nigeria) strive to meet safety standards while maintaining employee morale, understanding the nuances of cowboy hard hats becomes vital.

This comprehensive guide will delve into the types of cowboy hard hats available, their specific applications, and the importance of supplier vetting to ensure compliance with safety regulations such as ANSI standards. Additionally, we will cover cost considerations, helping buyers navigate budget constraints while making informed decisions. By equipping B2B buyers with actionable insights and a thorough understanding of the market, this guide aims to empower organizations to select the best cowboy hard hats that align with their operational needs and safety requirements.

As you explore the various sections, you will find valuable resources and strategies to enhance your procurement process, ensuring your workforce is both safe and stylish on the job.

Understanding cowboy hat hard Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Outlaw Cowboy Hard Hat | Stylish design resembling a ten-gallon hat; ANSI Type I compliant. | Construction, mining, and agricultural sectors. | Pros: Unique appearance, meets safety standards. Cons: May be perceived as less professional in formal settings. |

| Durango Cowboy Hard Hat | Traditional cowboy hat shape; available in various colors. | Outdoor events, ranching, and equestrian uses. | Pros: Comfortable for long wear, fashionable. Cons: Limited ventilation compared to standard hard hats. |

| Western Cowboy Hard Hat | Designed for western aesthetics; often includes ratchet suspension. | Oil and gas industry, heavy machinery operation. | Pros: Provides protection with a distinctive style. Cons: May not be suitable for all work environments. |

| Occunomix Cowboy Hard Hat | Textured finishes and multiple color options; ANSI and OSHA approved. | Construction, landscaping, and outdoor jobs. | Pros: Durable materials, customizable designs. Cons: Can be heavier than traditional hard hats. |

| Hybrid Cowboy Hard Hat | Combines traditional cowboy hat style with integrated helmet features. | Equestrian sports, recreational riding. | Pros: Offers head protection while maintaining cowboy aesthetics. Cons: Bulky and may not fit all helmets. |

What are the Key Characteristics of Outlaw Cowboy Hard Hats?

Outlaw Cowboy Hard Hats are designed to mimic the classic ten-gallon cowboy hat while ensuring compliance with ANSI Type I safety standards. This type is particularly popular in construction and agricultural industries, where a unique appearance can enhance brand identity. Buyers should consider the balance between style and safety, as these hats can stand out in a crowd but may not be viewed as traditional hard hats in more formal settings.

How Do Durango Cowboy Hard Hats Stand Out?

Durango Cowboy Hard Hats feature a traditional cowboy shape and are available in multiple colors, making them a fashionable choice for outdoor events, ranching, and equestrian uses. They are designed for comfort during extended wear, which is essential for workers who spend long hours outside. However, buyers should be aware that these hats may offer less ventilation than standard hard hats, potentially leading to discomfort in hot climates.

What Makes Western Cowboy Hard Hats Suitable for Specific Industries?

Western Cowboy Hard Hats are characterized by their western aesthetics and often come with ratchet suspension systems for a secure fit. These hats are ideal for industries such as oil and gas, where workers are exposed to heavy machinery. While they provide adequate protection, their unique design may not be suitable for all work environments, especially those requiring a more professional look.

Why Choose Occunomix Cowboy Hard Hats?

Occunomix Cowboy Hard Hats are notable for their textured finishes and variety of color options, all while being ANSI and OSHA approved. They are commonly used in construction, landscaping, and outdoor jobs where durability is essential. Buyers should consider the trade-off between the weight of these hats compared to traditional hard hats, as they may be heavier, impacting comfort during long work hours.

What are the Benefits of Hybrid Cowboy Hard Hats?

Hybrid Cowboy Hard Hats blend the traditional cowboy hat style with integrated helmet features, making them an excellent choice for equestrian sports and recreational riding. They provide essential head protection while allowing riders to maintain a cowboy aesthetic. However, their bulkiness can be a drawback, and buyers must ensure compatibility with their existing gear for optimal safety and comfort.

Key Industrial Applications of cowboy hat hard

| Industry/Sector | Specific Application of cowboy hat hard | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Mining | Protective headgear for outdoor labor | Enhances worker safety while providing a unique style | Compliance with ANSI/OSHA standards, durability, comfort |

| Agriculture & Livestock | Head protection for ranchers and farm workers | Protects against falling objects while offering sun protection | Lightweight materials, ventilation, and ease of cleaning |

| Equestrian & Outdoor Sports | Safety gear for horseback riding and related activities | Combines safety with traditional aesthetics for riders | Customization options, comfort fit, and impact resistance |

| Oil & Gas | Safety helmets for field operators | Essential for compliance and protection in hazardous environments | Resistance to environmental factors, ease of maintenance |

| Event Management & Festivals | Unique branding opportunities for outdoor events | Provides an eye-catching safety solution for event staff | Bulk purchasing options, branding capabilities, and styles |

How Are Cowboy Hat Hard Applications Beneficial in Construction and Mining?

In the construction and mining sectors, cowboy hat hard serves as an innovative protective headgear option. These helmets are designed to meet ANSI/OSHA safety standards while offering a stylish alternative to traditional hard hats. By enhancing worker safety, they reduce the risk of head injuries from falling objects, a common hazard in these industries. B2B buyers should prioritize sourcing hats that combine comfort with durability, ensuring that workers can wear them for extended periods without compromising safety.

What Role Does Cowboy Hat Hard Play in Agriculture and Livestock?

In agriculture, cowboy hat hard is vital for ranchers and farm workers who face outdoor hazards. These helmets not only protect against falling objects but also provide essential sun protection, which is crucial in regions with high solar exposure. For international buyers, especially in Africa and South America, sourcing hats that are lightweight and well-ventilated is important to ensure comfort during long working hours. Buyers should also consider ease of cleaning, as agricultural environments can be dusty and dirty.

How is Cowboy Hat Hard Used in Equestrian and Outdoor Sports?

Cowboy hat hard is increasingly popular among equestrians and outdoor sports enthusiasts, where safety is paramount. These helmets combine the traditional cowboy hat aesthetic with the necessary protective features, making them ideal for horseback riding and related activities. Buyers in the equestrian sector should look for options that offer a comfortable fit and effective impact resistance. Customization options can also enhance branding for riding schools or equestrian events, making these hats a dual-purpose investment.

Why is Cowboy Hat Hard Essential in the Oil and Gas Industry?

In the oil and gas industry, cowboy hat hard serves as crucial safety gear for field operators working in potentially hazardous environments. These helmets protect against head injuries while also complying with stringent safety regulations. B2B buyers in this sector should focus on sourcing hats that are resistant to various environmental factors, including heat and chemicals, to ensure maximum protection. Additionally, ease of maintenance is a key consideration, as these hats must withstand rigorous working conditions.

How Can Cowboy Hat Hard Enhance Event Management and Festivals?

For event management and outdoor festivals, cowboy hat hard offers unique branding opportunities while ensuring staff safety. These helmets provide an eye-catching solution that can be customized with logos and designs, enhancing brand visibility. When sourcing for events, buyers should consider bulk purchasing options to accommodate large teams and ensure that the hats are comfortable and stylish to encourage staff compliance. The ability to combine safety with aesthetics makes cowboy hat hard a valuable addition to any outdoor event.

3 Common User Pain Points for ‘cowboy hat hard’ & Their Solutions

Scenario 1: Navigating Compliance and Safety Standards for Cowboy Hard Hats

The Problem: In international markets, B2B buyers face significant challenges ensuring that cowboy hard hats meet local and international safety regulations. For instance, a construction firm in Nigeria may struggle with sourcing cowboy hats that comply with ANSI or OSHA standards while also appealing to regional aesthetics. The risk of purchasing non-compliant products could lead to safety violations, resulting in potential fines, increased insurance costs, or even worksite accidents.

The Solution: To overcome this challenge, B2B buyers should conduct thorough research on the safety standards applicable in their region. They should look for suppliers that can provide documentation proving compliance with ANSI and OSHA regulations. When sourcing cowboy hard hats, it’s beneficial to request samples and certifications upfront to verify that the products meet necessary safety standards. Establishing relationships with manufacturers who specialize in cowboy hard hats can also ensure that future orders maintain compliance. Additionally, engaging with a local safety consultant can provide insights into specific requirements, helping to streamline the procurement process and ensure that safety remains a top priority.

Scenario 2: Balancing Aesthetics and Functionality in Cowboy Hard Hats

The Problem: Aesthetic appeal is critical in various industries, particularly in sectors like event management and entertainment, where image matters. A B2B buyer in the Middle East may find it challenging to source cowboy hard hats that not only offer the required safety features but also align with cultural preferences and branding needs. The wrong choice could lead to dissatisfaction among employees and clients, adversely affecting the company’s reputation.

The Solution: To address this issue, buyers should engage in a collaborative design process with their suppliers. Providing input on preferred colors, styles, and branding opportunities can yield customized cowboy hard hats that meet safety standards while appealing to the target audience. It’s advisable to explore suppliers that offer a range of designs and the option for branding through logos or custom colors. Additionally, conducting surveys or focus groups with employees can help gauge preferences, ensuring that the chosen hats are both functional and well-received. This approach not only enhances employee morale but also strengthens brand identity.

Scenario 3: Managing Inventory and Cost-Effectiveness for Cowboy Hard Hats

The Problem: Cost management is a critical concern for B2B buyers, particularly when sourcing cowboy hard hats in bulk. Companies in South America may struggle with inflated costs due to poor supplier relationships or overstocking issues, leading to budget overruns and inefficient use of resources. Moreover, the challenge of maintaining appropriate inventory levels can result in either excess spending or supply shortages during peak operational periods.

The Solution: To optimize inventory management and control costs, buyers should implement a data-driven approach. Utilizing inventory management software can help track stock levels, forecast demand, and identify trends over time. Additionally, establishing long-term relationships with reliable suppliers can lead to better pricing agreements and discounts for bulk purchases. Buyers should consider setting up a just-in-time inventory system, allowing for more responsive ordering based on actual usage rather than estimates. Regular communication with suppliers about upcoming projects and potential needs can further streamline the procurement process, ensuring that the company maintains an optimal balance of inventory without incurring unnecessary costs.

Strategic Material Selection Guide for cowboy hat hard

What Materials Are Commonly Used for Cowboy Hard Hats?

When selecting materials for cowboy hard hats, it is essential to consider various properties that affect performance, durability, and compliance with safety standards. Below are analyses of four common materials used in the manufacturing of cowboy hard hats.

1. High-Density Polyethylene (HDPE)

Key Properties:

HDPE is known for its excellent impact resistance and lightweight nature. It typically withstands temperatures ranging from -40°F to 120°F (-40°C to 49°C) and offers good chemical resistance.

Pros & Cons:

HDPE is durable and cost-effective, making it a popular choice for hard hats. However, its lower temperature tolerance may not be suitable for extreme heat conditions, which can be a concern in regions like Saudi Arabia or Nigeria. Additionally, while HDPE is recyclable, its manufacturing process can be more complex compared to other materials.

Impact on Application:

HDPE is compatible with various industrial applications, including construction and agriculture, where impact protection is crucial. Its lightweight nature ensures comfort during prolonged use.

Considerations for International Buyers:

For buyers in Africa and the Middle East, compliance with ANSI and ISO standards is vital. HDPE hard hats are widely accepted, but local regulations may vary, necessitating thorough research.

2. Polycarbonate

Key Properties:

Polycarbonate is known for its high impact resistance and ability to withstand extreme temperatures, ranging from -40°F to 265°F (-40°C to 129°C). It also has excellent UV resistance.

Pros & Cons:

The primary advantage of polycarbonate is its superior strength and durability, making it suitable for high-risk environments. However, it is generally more expensive than HDPE and may require specialized manufacturing processes, which can increase lead times.

Impact on Application:

Polycarbonate hard hats are ideal for industries with high exposure to falling objects or extreme weather conditions. Their UV resistance makes them suitable for outdoor applications in sunny regions.

Considerations for International Buyers:

For buyers in Europe and South America, polycarbonate hard hats must comply with EN and ANSI standards. The higher cost may be a consideration for budget-sensitive projects.

3. Fiberglass

Key Properties:

Fiberglass offers excellent strength-to-weight ratios and can withstand high temperatures, making it suitable for environments where heat resistance is critical. It is also resistant to corrosion from chemicals.

Pros & Cons:

While fiberglass is exceptionally durable and provides good insulation, it can be heavier than other materials, which may affect comfort during extended wear. Additionally, its manufacturing process can be more complex, leading to higher costs.

Impact on Application:

Fiberglass hard hats are often used in electrical and chemical industries due to their non-conductive properties. They provide reliable protection in harsh environments.

Considerations for International Buyers:

International buyers should ensure that fiberglass hard hats meet local safety standards, such as ASTM or DIN. The higher price point may limit its use in cost-sensitive markets.

4. ABS Plastic

Key Properties:

Acrylonitrile Butadiene Styrene (ABS) is known for its impact resistance and toughness. It can withstand temperatures from 0°F to 140°F (-18°C to 60°C) and is resistant to various chemicals.

Pros & Cons:

ABS is lightweight and cost-effective, making it a popular choice for hard hats. However, it has a lower temperature tolerance compared to polycarbonate and fiberglass, which may limit its use in hotter climates.

Impact on Application:

ABS hard hats are suitable for general construction and manufacturing environments where impact protection is necessary but extreme temperatures are not a concern.

Considerations for International Buyers:

Buyers in regions like Nigeria and South America should verify that ABS hard hats comply with local safety regulations. The affordability of ABS makes it an attractive option for bulk purchases.

Summary Table of Material Properties

| Material | Typical Use Case for cowboy hat hard | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Density Polyethylene (HDPE) | Construction, agriculture | Lightweight and cost-effective | Limited temperature tolerance | Low |

| Polycarbonate | High-risk environments | Superior strength and UV resistance | Higher cost and complex manufacturing | High |

| Fiberglass | Electrical, chemical industries | Excellent durability and heat resistance | Heavier and more expensive | High |

| ABS Plastic | General construction | Lightweight and affordable | Lower temperature tolerance | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for cowboy hat hard

What Are the Main Stages of Manufacturing Cowboy Hat Hard?

The manufacturing process for cowboy hard hats involves several key stages: material preparation, forming, assembly, and finishing. Each stage is critical to ensuring the final product meets safety and quality standards.

-

Material Preparation: The primary material for cowboy hard hats is high-density polyethylene (HDPE) or polycarbonate, which are both lightweight and provide excellent impact resistance. During this stage, raw materials are sourced and tested for compliance with safety standards such as ANSI Z89.1. Suppliers often conduct material inspections and certifications to guarantee quality before moving to the forming stage.

-

Forming: In this stage, the prepared materials are shaped into the desired hard hat form. This is typically done through injection molding, where heated plastic is injected into molds that create the cowboy hat’s distinct shape. The molds are engineered to ensure uniformity and consistency in the product. Advanced technologies, such as computer-aided design (CAD), help in precision shaping, which is crucial for both aesthetic appeal and functional performance.

-

Assembly: After forming, components such as suspension systems, chin straps, and any decorative elements are assembled. The suspension system is particularly important as it provides comfort and stability while wearing the hard hat. Quality assurance checks are conducted throughout this phase to ensure that all parts fit properly and function as intended.

-

Finishing: The finishing stage includes painting, coating, or applying decals to the hard hats. This not only enhances aesthetics but also provides additional layers of protection. For instance, UV-resistant coatings can be applied to prevent fading in sunlight. Final inspections are conducted to ensure that the hard hats meet both visual and functional standards before packaging.

How Is Quality Assurance Implemented in Cowboy Hat Hard Manufacturing?

Quality assurance (QA) is vital in the manufacturing of cowboy hard hats to ensure compliance with international standards and customer expectations. Key QA processes include:

-

International Standards Compliance: Many manufacturers adhere to ISO 9001, which outlines the criteria for a quality management system. This ensures consistent quality in products and services. Additionally, industry-specific standards such as ANSI Z89.1 (for head protection) and CE certification (for products sold in Europe) must be met.

-

Quality Control Checkpoints: Various checkpoints are established throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify they meet specified requirements.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to ensure conformity to specifications.

– Final Quality Control (FQC): A thorough inspection of the finished products to confirm they meet safety and quality standards before shipping. -

Common Testing Methods: Cowboy hard hats undergo several testing methods, including:

– Impact Tests: To assess the helmet’s ability to withstand blunt force.

– Penetration Tests: To evaluate resistance to sharp objects.

– Electrical Tests: To ensure that the hard hats are non-conductive and safe for electrical workers.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers, especially those in regions such as Africa, South America, the Middle East, and Europe, should implement several strategies to verify the quality control practices of their suppliers:

-

Supplier Audits: Conducting on-site audits can provide insight into the supplier’s manufacturing processes, quality control measures, and adherence to international standards. Audits help identify potential risks and ensure compliance with safety regulations.

-

Quality Reports: Requesting detailed quality assurance reports from suppliers can help buyers understand the QC measures in place. These reports should outline testing results, compliance certifications, and any corrective actions taken in case of non-conformance.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control systems. These inspections can be conducted at various stages of the manufacturing process, providing additional assurance of product quality.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers must be aware of specific nuances in quality control and certification when sourcing cowboy hard hats:

-

Regional Standards Variability: Different regions may have varying safety standards and regulations. Buyers should familiarize themselves with local requirements in their target markets, such as the differences between ANSI standards in the U.S. and CE marking in Europe.

-

Cultural Considerations: Understanding cultural differences in business practices can impact negotiations and quality expectations. Buyers should engage with suppliers to establish clear communication regarding quality standards and certifications.

-

Sustainability and Ethical Sourcing: Increasingly, buyers are prioritizing sustainable practices and ethical sourcing. Suppliers who adhere to environmentally friendly manufacturing processes and fair labor practices may offer additional value and meet buyer preferences.

Conclusion

In-depth knowledge of manufacturing processes and quality assurance for cowboy hard hats is essential for B2B buyers. Understanding the stages of production, quality control measures, and verification strategies can significantly enhance buyer confidence in sourcing decisions. By ensuring compliance with international standards and engaging with suppliers proactively, buyers can secure high-quality products that meet safety requirements and market expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cowboy hat hard’

Introduction

This sourcing guide is designed for B2B buyers looking to procure cowboy hard hats, a unique blend of style and safety for various industries. By following this step-by-step checklist, you can ensure that your procurement process is efficient and aligns with both safety standards and aesthetic preferences. This guide will help you navigate the complexities of sourcing cowboy hard hats that meet your specific requirements.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s vital to outline your technical specifications. This includes understanding the safety standards required, such as ANSI certifications, and the materials that will best suit your operational environment.

– Considerations: Will the hats be used in high-temperature environments? What level of impact protection is necessary?

Step 2: Research Market Trends and Preferences

Stay informed about current market trends and buyer preferences in your target regions, such as Africa, South America, the Middle East, and Europe. Understanding the local demand for styles, colors, and features can significantly influence your purchasing decisions.

– Actions: Analyze competitors’ offerings and solicit feedback from potential users to gauge their preferences.

Step 3: Identify and Shortlist Potential Suppliers

Compile a list of potential suppliers who specialize in cowboy hard hats. Look for manufacturers with a proven track record and positive reviews from other B2B clients.

– Key Factors: Check their production capacity, delivery timelines, and whether they offer customization options to meet your specific needs.

Step 4: Verify Supplier Certifications

Ensuring that your suppliers adhere to relevant safety standards is crucial for compliance and safety. Request documentation that verifies their products meet ANSI and OSHA regulations.

– Documentation to Request: Safety certifications, product testing results, and quality assurance protocols.

Step 5: Request Samples for Evaluation

Before making a bulk order, request samples from your shortlisted suppliers. Evaluating the quality, fit, and comfort of the cowboy hard hats firsthand can help you make a more informed decision.

– Evaluation Criteria: Assess materials, weight, comfort, and overall design. Make sure the hats meet your specifications for safety and aesthetics.

Step 6: Compare Pricing and Terms

Once you have evaluated the samples, compare the pricing structures and terms from each supplier. Consider not only the base cost but also shipping fees, bulk order discounts, and payment terms.

– Negotiation Tips: Be prepared to negotiate for better pricing or terms based on your volume requirements or long-term partnership potential.

Step 7: Finalize Your Order and Establish a Relationship

After selecting your preferred supplier, finalize your order details and establish a clear communication channel for ongoing support. A strong relationship with your supplier can lead to better service and future discounts.

– Ongoing Communication: Set expectations for delivery timelines and after-sales support to ensure smooth operations.

By following these steps, you can confidently source cowboy hard hats that not only meet safety standards but also align with the aesthetic values of your organization.

Comprehensive Cost and Pricing Analysis for cowboy hat hard Sourcing

What Are the Key Cost Components in Sourcing Cowboy Hat Hard Hats?

Understanding the cost structure of cowboy hat hard hats is essential for B2B buyers aiming to make informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The primary raw material for cowboy hard hats is high-density polyethylene (HDPE) or polycarbonate, which must comply with ANSI safety regulations. The cost of these materials can fluctuate based on global supply chain issues and demand. Buyers should seek suppliers who offer transparent pricing and quality certifications.

-

Labor: Labor costs vary significantly based on the geographical location of the manufacturing facility. For example, production in regions with higher labor costs (such as Europe) may lead to increased pricing compared to sourcing from countries with lower labor costs (like some regions in Africa or Asia).

-

Manufacturing Overhead: This includes costs related to factory operations, maintenance, utilities, and administrative expenses. Efficient manufacturing processes can help minimize overhead costs, which ultimately affects the pricing of the final product.

-

Tooling: Initial setup costs for molds and production equipment are crucial for new designs or customizations. These costs can be amortized over larger production runs, making bulk orders more cost-effective.

-

Quality Control (QC): Investing in rigorous quality control measures is essential to ensure that the products meet safety standards. This can include testing materials and finished products, which adds to the overall cost but enhances buyer confidence.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. These costs can vary based on shipping methods, distances, and the chosen Incoterms. Understanding these logistics will help buyers factor total shipping costs into their purchasing decisions.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure sustainability. This margin can vary based on competition, market demand, and perceived value.

How Do Price Influencers Affect the Cost of Cowboy Hat Hard Hats?

Several factors influence the pricing of cowboy hat hard hats, including volume, specifications, materials, quality certifications, supplier factors, and Incoterms.

-

Volume/MOQ: Many suppliers offer tiered pricing based on the volume of the order. Higher quantities often lead to reduced per-unit costs, making it advantageous for buyers to consolidate their orders.

-

Specifications/Customization: Custom features, such as unique designs or additional safety features, can significantly affect the price. While customization may lead to higher costs, it can also provide a competitive edge in the market.

-

Materials: The choice of materials not only impacts safety and durability but also influences cost. For instance, high-quality materials may incur higher upfront costs but can lead to lower total costs over time through enhanced durability.

-

Quality/Certifications: Products that meet stringent safety standards (like ANSI or OSHA certifications) often command higher prices. However, these certifications can be crucial for compliance and liability protection.

-

Supplier Factors: Established suppliers with a good reputation may charge more due to their reliability and service quality. Conversely, newer or less reputable suppliers may offer lower prices but could pose risks in terms of quality and delivery.

-

Incoterms: Understanding the terms of delivery can also affect pricing. Incoterms specify the responsibilities of buyers and sellers in terms of shipping costs, insurance, and risk management. Buyers should be clear on these terms to avoid unexpected costs.

What Are the Best Practices for Negotiating Cowboy Hat Hard Hat Prices?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, negotiating effectively can lead to significant savings.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but all associated costs, including shipping, duties, and potential replacement costs. A lower initial price may not always result in the best overall value.

-

Build Relationships: Establishing a strong rapport with suppliers can lead to better terms and pricing flexibility. Long-term partnerships often yield more favorable negotiations.

-

Leverage Market Knowledge: Stay informed about market trends and competitor pricing. Knowledge of alternative suppliers can provide leverage during negotiations.

-

Be Prepared to Walk Away: If the terms don’t meet your expectations, be willing to explore other options. This can often lead to better offers from suppliers eager to secure your business.

Conclusion

Sourcing cowboy hat hard hats involves understanding various cost components and price influencers. By applying these insights, international B2B buyers can make more informed decisions, negotiate better terms, and ultimately enhance their purchasing strategies. Always consider the total cost of ownership and the long-term value of the products when making procurement decisions.

Alternatives Analysis: Comparing cowboy hat hard With Other Solutions

Introduction to Alternative Solutions for Cowboy Hat Hard

In the realm of safety gear, particularly in industries like construction and agriculture, the choice of head protection is critical. While cowboy hat hard hats offer a unique blend of style and safety, it’s essential to explore alternative solutions that meet similar safety standards without compromising on comfort or functionality. This analysis will compare cowboy hat hard hats with two viable alternatives: traditional hard hats and helmets with detachable brims.

Comparison Table

| Comparison Aspect | Cowboy Hat Hard | Traditional Hard Hat | Helmet with Detachable Brim |

|---|---|---|---|

| Performance | ANSI-certified; stylish | ANSI-certified; robust | ANSI-certified; versatile |

| Cost | $33 – $50 per unit | $20 – $40 per unit | $60 – $100 per unit |

| Ease of Implementation | Easy to wear; no setup | Ready to use | Requires assembly of components |

| Maintenance | Low; clean with damp cloth | Low; clean with damp cloth | Moderate; components may need replacement |

| Best Use Case | Outdoor work environments; style-conscious users | General construction; industrial settings | Equestrian sports; versatile outdoor activities |

Detailed Breakdown of Alternatives

Traditional Hard Hats

Traditional hard hats are a staple in construction and industrial environments. They are designed to provide maximum protection against falling objects and impact, adhering to ANSI standards. The primary advantage of traditional hard hats is their affordability and ease of use. They are often available in various colors and styles, providing options for branding. However, they lack the aesthetic appeal of cowboy hats, which may deter some users seeking a more fashionable look.

Helmet with Detachable Brim

Helmets with detachable brims combine the safety features of a standard helmet with the sun protection of a wide-brimmed hat. This option is particularly popular in outdoor activities like equestrian sports. The primary benefit is versatility; users can switch between a standard helmet for maximum protection and a stylish hat for sun coverage. However, these helmets can be more expensive and may require additional maintenance, as the brims can wear out or detach over time. This solution is ideal for users who need both safety and comfort in outdoor settings.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate head protection ultimately depends on the specific needs of your workforce and the environments in which they operate. If style and aesthetic appeal are paramount, cowboy hat hard hats provide a unique solution without compromising safety. For those prioritizing cost-effectiveness and robustness, traditional hard hats remain a reliable choice. Conversely, if versatility and sun protection are critical, helmets with detachable brims offer an excellent alternative. Assess your operational requirements, budget constraints, and user preferences to make an informed decision that best suits your business’s safety needs.

Essential Technical Properties and Trade Terminology for cowboy hat hard

What Are the Key Technical Properties of Cowboy Hat Hard?

When considering cowboy hard hats for industrial or construction use, several critical specifications must be evaluated to ensure safety, comfort, and compliance with regulatory standards. Here are the essential properties:

1. Material Composition

Cowboy hard hats are typically made from high-density polyethylene (HDPE) or fiberglass. HDPE is lightweight, resistant to impact, and offers superior durability, making it suitable for various environments. Fiberglass, while heavier, provides excellent impact resistance and thermal insulation. B2B buyers must assess the material to ensure it meets specific industry requirements and local safety regulations.

2. Impact Rating

Cowboy hard hats are classified according to ANSI (American National Standards Institute) standards. Type I hard hats are designed to protect against vertical impacts, while Type II can handle lateral impacts as well. Understanding the impact rating is crucial for ensuring worker safety in hazardous environments, particularly in construction and mining sectors where head injuries are a risk.

3. Suspension System

The suspension system inside a cowboy hard hat is vital for comfort and safety. Most models feature a 4-point or 6-point suspension system that helps distribute the weight of the hat evenly across the head. This feature not only enhances comfort during extended wear but also improves the hat’s overall stability and effectiveness in absorbing shocks.

4. Weight

The weight of a cowboy hard hat can significantly affect user comfort, especially for those required to wear them for extended periods. Lighter materials can reduce fatigue, making them more suitable for long shifts. B2B buyers should consider the balance between protection and comfort when selecting a hard hat model.

5. Ventilation

Ventilation is another crucial property, particularly in hot climates. Many cowboy hard hats are designed with ventilation holes or channels that promote airflow, reducing heat buildup and enhancing user comfort. This feature is especially important for outdoor work environments common in regions like Africa and South America.

6. Color and Visibility

While cowboy hard hats are often styled to resemble traditional cowboy hats, the color can also play a role in visibility. Bright colors like orange or yellow are typically preferred for outdoor work to ensure that workers are easily seen. B2B buyers should consider the specific visibility requirements of their work environment when selecting colors.

What Are Common Trade Terms in the Cowboy Hat Hard Industry?

Understanding the terminology used in the cowboy hard hat industry can facilitate better communication and decision-making. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of cowboy hard hats, this term is crucial for buyers seeking customized designs or specific branding options. Engaging with OEMs allows for tailored solutions that meet unique business needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This is a critical consideration for B2B buyers, as it affects inventory management and budget planning. Understanding the MOQ can help businesses gauge their purchasing strategy and avoid excess stock.

3. RFQ (Request for Quotation)

An RFQ is a formal document issued by a buyer to request pricing information from suppliers for specified products. In the cowboy hat hard industry, an RFQ can help buyers compare different suppliers’ prices, terms, and delivery schedules, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in global trade. Understanding these terms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), is essential for B2B buyers engaged in international transactions, as they dictate shipping responsibilities and risk management.

5. ANSI (American National Standards Institute)

ANSI sets safety standards for hard hats in the United States. Familiarity with ANSI regulations is essential for B2B buyers to ensure compliance with safety laws and to protect their workforce effectively.

6. Certification

Certification refers to the process through which a product is tested and verified to meet specific standards. For cowboy hard hats, certification ensures that the products have been evaluated for safety and performance. B2B buyers should prioritize certified products to ensure they are investing in quality and compliant safety equipment.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when purchasing cowboy hard hats, ensuring they meet both safety requirements and the unique needs of their workforce.

Navigating Market Dynamics and Sourcing Trends in the cowboy hat hard Sector

What Are the Key Market Drivers for Cowboy Hat Hard Products?

The cowboy hat hard sector is witnessing significant growth driven by a convergence of safety regulations and cultural fashion trends. As industries expand in regions such as Africa, South America, the Middle East, and Europe, the demand for protective headgear that marries safety with style is on the rise. The need for compliance with ANSI and OSHA safety standards is prompting international B2B buyers to seek hard hats that not only offer protection but also resonate with local cultural aesthetics.

Emerging sourcing trends indicate a growing reliance on digital platforms for procurement, enabling buyers to compare products across different suppliers efficiently. Innovations in materials and design are also influencing market dynamics. For instance, advancements in lightweight, durable plastics and ergonomic designs have enhanced the appeal of cowboy hard hats. This trend is particularly relevant for buyers in sectors such as construction, agriculture, and outdoor recreation, where comfort during extended wear is critical.

Moreover, the rise of e-commerce platforms is facilitating easier access to diverse product lines, allowing international buyers to source unique designs that align with their branding. As the market evolves, suppliers must remain agile, adapting to shifting buyer preferences and the increasing importance of customization.

How Is Sustainability Shaping B2B Sourcing of Cowboy Hat Hard Products?

Sustainability has become a pivotal consideration in the sourcing of cowboy hat hard products. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical practices, including the use of environmentally friendly materials and transparent supply chains. The environmental impact of manufacturing processes is under scrutiny, prompting buyers to seek products that minimize carbon footprints and waste.

The demand for ‘green’ certifications and sustainable materials is rising. Hard hats made from recycled plastics or sourced through ethical means not only appeal to environmentally conscious companies but can also enhance brand reputation and customer loyalty. Furthermore, sourcing from suppliers that engage in responsible production practices can mitigate risks related to regulatory compliance and corporate social responsibility.

Buyers should actively inquire about certifications such as ISO 14001 (Environmental Management) and look for suppliers committed to sustainable practices. This trend towards ethical sourcing not only supports environmental goals but also aligns with the growing consumer demand for corporate accountability, making it a crucial consideration for international buyers in the cowboy hat hard sector.

What Is the Historical Context of Cowboy Hat Hard Products in B2B Markets?

The evolution of cowboy hat hard products is rooted in a rich history that blends functionality with cultural significance. Traditionally, cowboy hats were designed for outdoor labor and protection from the elements, reflecting the rugged lifestyle of ranchers and farmers. As safety regulations in industrial sectors became more stringent, the need for protective headgear that embodied the cowboy spirit emerged.

In the late 20th century, manufacturers began to innovate, creating hard hats that not only met safety standards but also catered to the aesthetic preferences of their users. This fusion of safety and style has led to the popularity of cowboy hard hats in various industries, particularly in regions where cowboy culture is prominent. The modern cowboy hat hard product serves as a testament to the balance between heritage and contemporary safety needs, making it a unique offering in the B2B marketplace.

Understanding this historical context can provide buyers with insights into the cultural significance and potential marketability of these products, allowing them to make informed sourcing decisions that resonate with their target audiences.

Frequently Asked Questions (FAQs) for B2B Buyers of cowboy hat hard

-

How do I ensure the cowboy hat hard I purchase meets safety standards?

To ensure that the cowboy hat hard you purchase complies with safety regulations, look for products that are ANSI-certified. Check the specifications on the supplier’s website or product documentation, which should explicitly state compliance with ANSI Z89.1 standards for Type I hard hats. It’s also beneficial to request a certificate of compliance from the supplier, which confirms that their products have passed necessary safety tests. Partnering with reputable suppliers known for quality assurance can also mitigate risks. -

What is the best cowboy hat hard for construction environments?

The best cowboy hat hard for construction environments is one that combines style with safety features. Look for hats that offer a robust outer shell made from high-density polyethylene or fiberglass to withstand impact. Additionally, ensure they have a comfortable suspension system, such as a ratchet or pin-lock, for secure fit and stability. Brands like Jackson Safety and Occunomix are well-regarded for their durable and stylish cowboy hard hats, making them ideal for various work settings. -

How can I customize my cowboy hat hard for branding purposes?

Customization options for cowboy hat hard typically include adding your company logo or specific color schemes. Most suppliers offer branding services, such as screen printing or embroidery, for bulk orders. It’s advisable to discuss your branding requirements with the supplier upfront, including minimum order quantities for customization. Ensure that the materials used for printing or embroidery do not compromise the hat’s safety standards, as durability and visibility are paramount in work environments. -

What are the minimum order quantities (MOQ) for cowboy hat hard?

Minimum order quantities (MOQ) for cowboy hat hard can vary significantly based on the supplier and the type of customization requested. Typically, MOQs range from 50 to 200 units for customized products. However, some suppliers may offer lower MOQs for standard items. It’s essential to inquire directly with potential suppliers to get specific MOQ details, as this will help you plan your procurement strategy effectively, especially for large-scale projects or events. -

What payment terms should I expect when sourcing cowboy hat hard internationally?

Payment terms for international purchases of cowboy hat hard can vary based on the supplier’s policies and your negotiation. Common terms include 30% upfront payment with the balance due upon shipping or delivery, or net 30-60 days after receipt of goods. It’s advisable to use secure payment methods such as letters of credit or escrow services to protect your investment. Always clarify terms before finalizing orders to avoid misunderstandings and ensure a smooth transaction. -

How do I vet suppliers for cowboy hat hard to ensure quality and reliability?

Vetting suppliers for cowboy hat hard involves several steps. Start by researching their reputation through online reviews, testimonials, and industry ratings. Request samples to assess product quality firsthand. Verify their certifications and compliance with international safety standards. Additionally, check their production capabilities and lead times to ensure they can meet your demands. Establishing a strong line of communication can also provide insights into their customer service and reliability. -

What logistics considerations should I keep in mind when importing cowboy hat hard?

When importing cowboy hat hard, consider shipping methods, delivery times, and customs regulations specific to your country. Evaluate whether air or sea freight is more suitable based on your timeline and budget. Ensure you understand the customs duties and taxes applicable to your shipment, as these can significantly impact overall costs. Partnering with a logistics provider experienced in international trade can streamline the process and help navigate regulatory requirements efficiently. -

How can I ensure quality assurance (QA) for my cowboy hat hard orders?

To ensure quality assurance (QA) for your cowboy hat hard orders, establish clear quality standards with your supplier before production begins. Implement a quality control checklist that includes inspections for material integrity, compliance with safety standards, and overall craftsmanship. Request regular updates and progress reports during the manufacturing process. Conduct a final inspection before shipment, and consider hiring third-party QA services for unbiased assessments, ensuring that the products meet your specifications and requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Cowboy Hat Hard Manufacturers & Suppliers List

1. Tasco Safety – Cowboy Hard Hats

Domain: tasco-safety.com

Registered: 1998 (27 years)

Introduction: Cowboy Hard Hats | ANSI-Certified Construction Helmets | Tasco-Safety.com

2. ASA Supplies – Cowboy Style Hard Hats

Domain: asasupplies.com

Registered: 2003 (22 years)

Introduction: Cowboy Style Hard Hats – ANSI & OSHA Approved. Price: $37.96. Made from thermoplastic material used in regular safety helmets.

3. OSHA Online Center – Cowboy Hard Hats

Domain: blog.oshaonlinecenter.com

Registered: 2021 (4 years)

Introduction: Cowboy hard hats combine the style of traditional cowboy hats with the safety features of conventional hard hats. They are made from High Density Polyethylene (HDPE), similar to other hard hats. While they are trendy, it is crucial that they meet OSHA safety standards, specifically ANSI Z89.1, which outlines guidelines for protective headgear. It is important to note that cowboy hard hats are not …

4. Rodeo King – 5x Stiff vs. Stetson – 6x Soft

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around the comparison of stiff and soft cowboy hats, specifically mentioning a 5x Rodeo King hat being much stiffer than a 6x Stetson hat, which is noted to be soft, pliable, and smooth. Users express that stiffness does not correlate with quality, as softer hats are often perceived as higher quality. The Stetson Skyline is mentioned as a potential purchase, with users noti…

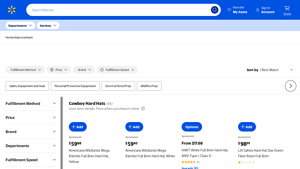

5. Walmart – Carbon Fiber Hard Hat

Domain: walmart.com

Registered: 1995 (30 years)

Introduction: This company, Walmart – Carbon Fiber Hard Hat, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Occunomix – VCB200 Cowboy Hard Hats

Domain: industrialsafetygear.com

Registered: 2004 (21 years)

Introduction: Product Name: Occunomix VCB200 Cowboy Hard Hats With Deluxe 6 Pt Ratchet Suspension

Price: $28.89 (On Sale: $34.00)

Part Number: VCB200

Bulk Pricing:

– 6 – 9 units: $28.60 each

– 10 – 19 units: $28.31 each

– 20 – 49 units: $28.02 each

– 50+ units: $26.00 each

Compliance: ANSI Z89.1-2003, Type I, Class E, G & C

Material: High-density polyethylene (made in USA)

Features:

– Extra wide brim for UV p…

7. American Hat Makers – Hollywood & Cattleman Cowboy Hats

Domain: americanhatmakers.com

Registered: 2013 (12 years)

Introduction: Cowboy Hats for Men from American Hat Makers, featuring a commitment to 50 years of craftsmanship and American authenticity. Key products include: 1. Hollywood | Mens Leather Cowboy Hat – $137.00, available in Copper Brown and Black. 2. Cattleman | Mens Felt Cowboy Hat with Western Hat Band – $139.00, available in Chocolate, Gunsmoke, Sand, Olive, White, and Black. 3. Austin | Mens Straw Cowboy Ha…

8. HorseForum – Western Riding Hat Solutions

Domain: horseforum.com

Registered: 1997 (28 years)

Introduction: Western riding hat options discussed include cowboy hats with hard helmet support, recommendations for integrating helmets with western-style hats, and alternatives like adding a brim or visor to regular helmets. Specific products mentioned include the Hell-Hat and Da Brim for shade. Users share DIY ideas for customizing helmets with straw brims or cowboy hat crowns.

Strategic Sourcing Conclusion and Outlook for cowboy hat hard

In the competitive landscape of safety equipment, cowboy hard hats represent a unique blend of functionality and style, appealing to various sectors from construction to outdoor recreation. As international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, recognizing the importance of ANSI-certified products can enhance workplace safety while aligning with regional aesthetic preferences. Strategic sourcing of cowboy hard hats not only ensures compliance with safety regulations but also allows businesses to stand out in their branding efforts.

Investing in quality cowboy hard hats can significantly impact employee morale and brand image. By prioritizing suppliers who offer a variety of designs and customization options, companies can cater to diverse market needs while maintaining safety standards. Engaging with reputable manufacturers will also facilitate better pricing and supply chain efficiency.

Looking forward, the demand for innovative and stylish safety gear is set to rise. International buyers are encouraged to explore partnerships with suppliers who can provide not just products, but also insights into market trends and consumer preferences. Embrace the opportunity to enhance your product offerings and strengthen your market position by incorporating cowboy hard hats into your sourcing strategy today.