Cut Costs with Logger Solar: The Ultimate Buying Guide (2025)

Introduction: Navigating the Global Market for logger solar

Navigating the complexities of the global market for logger solar solutions can be a daunting task for international B2B buyers. With a growing emphasis on renewable energy, sourcing effective logger solar products that meet specific operational needs is essential for businesses looking to enhance efficiency and sustainability. This comprehensive guide aims to simplify the purchasing process by exploring various types of logger solar technologies, their applications across different sectors, and key considerations for supplier vetting.

Buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Colombia and Nigeria, will find actionable insights on cost structures, regulatory compliance, and market trends that influence procurement decisions. By understanding the nuances of logger solar products, businesses can make informed choices that not only align with their energy goals but also contribute to long-term operational resilience.

This guide empowers B2B buyers by providing them with the knowledge necessary to navigate the global landscape effectively. Whether you are seeking to enhance your energy monitoring systems or invest in sustainable solar technology, the information contained herein will serve as a valuable resource for making strategic purchasing decisions that align with your organizational objectives.

Understanding logger solar Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Data Logger Solar System | Integrates solar panels with data logging capabilities. | Renewable energy monitoring, agriculture | Pros: Real-time data collection, energy efficiency insights. Cons: Initial investment may be high. |

| Portable Solar Loggers | Compact, battery-operated units designed for mobility. | Field research, environmental monitoring | Pros: Easy to transport, versatile usage. Cons: Limited data storage capacity. |

| Remote Solar Data Loggers | Operates wirelessly, often includes cloud connectivity. | Remote site monitoring, weather stations | Pros: Access data from anywhere, reduced maintenance. Cons: Potential connectivity issues in remote areas. |

| Industrial Solar Loggers | High-capacity systems designed for large-scale operations. | Manufacturing, large-scale energy projects | Pros: Robust data handling, tailored for industrial needs. Cons: Complexity can require specialized training. |

| Integrated Solar Monitoring Systems | Combines data logging with energy management software. | Smart buildings, energy management | Pros: Comprehensive monitoring and analytics. Cons: Higher upfront costs and integration complexity. |

What are the Key Characteristics of Data Logger Solar Systems?

Data Logger Solar Systems are designed to collect and store data from solar panels, allowing businesses to monitor performance and energy output. These systems are ideal for industries focused on renewable energy, such as solar farms and agricultural operations. When purchasing, consider the system’s data accuracy, compatibility with existing solar infrastructure, and long-term maintenance requirements. The initial investment may be higher, but the potential for improved efficiency can yield significant returns.

How Do Portable Solar Loggers Differ from Other Types?

Portable Solar Loggers are lightweight and battery-operated, making them suitable for field research and environmental monitoring. Their compact design allows for easy transportation, which is a key advantage for businesses that require data collection in various locations. However, potential buyers should be aware of their limited data storage capacity, which may necessitate more frequent data downloads or additional units for extensive projects.

What Advantages Do Remote Solar Data Loggers Offer?

Remote Solar Data Loggers are equipped with wireless capabilities, enabling businesses to access data from distant locations through cloud platforms. This feature is especially beneficial for industries that operate in remote areas, such as mining or agriculture. While these loggers provide convenience and reduced maintenance, buyers must consider potential connectivity issues that could impact data reliability.

Why Choose Industrial Solar Loggers for Large-Scale Operations?

Industrial Solar Loggers are designed for high-capacity data handling, making them suitable for large-scale energy projects and manufacturing environments. These systems can manage vast amounts of data and are tailored to meet the specific needs of industrial applications. However, buyers should be prepared for the complexity and potential need for specialized training to operate these systems effectively.

How Do Integrated Solar Monitoring Systems Enhance Energy Management?

Integrated Solar Monitoring Systems combine data logging with energy management software, offering a comprehensive solution for businesses focused on smart building technologies and energy efficiency. These systems provide detailed analytics and insights into energy consumption patterns. While they can be more expensive and complex to integrate, the long-term benefits of enhanced monitoring and optimization can justify the investment for forward-thinking organizations.

Related Video: Weather Station (EMI) System Installation with Huawei smart Logger Solar PV System.

Key Industrial Applications of logger solar

| Industry/Sector | Specific Application of logger solar | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Remote monitoring of soil and weather conditions | Improved crop yield through data-driven decisions | Reliability of data transmission and environmental durability |

| Renewable Energy | Performance tracking of solar panels | Enhanced efficiency and maintenance forecasting | Compatibility with existing systems and ease of integration |

| Transportation & Logistics | Fleet management and route optimization | Reduced fuel costs and improved delivery efficiency | Robustness in varying climates and real-time data accessibility |

| Mining and Resource Extraction | Monitoring equipment and environmental conditions | Increased safety and compliance with regulations | Accuracy of data collection and remote accessibility |

| Telecommunications | Infrastructure health monitoring | Reduced downtime and proactive maintenance | Scalability and support for multiple data types and protocols |

How is Logger Solar Used in Agriculture to Enhance Crop Management?

In the agricultural sector, logger solar devices are employed for remote monitoring of soil moisture, temperature, and weather conditions. This technology enables farmers to make data-driven decisions, optimizing irrigation schedules and crop management strategies. By providing real-time data, logger solar can significantly improve crop yields and resource efficiency. For international buyers, sourcing should focus on devices that can withstand local environmental conditions, ensuring reliability and longevity in diverse climates, particularly in regions like Africa and South America.

What Role Does Logger Solar Play in Renewable Energy Monitoring?

In renewable energy, specifically solar power, logger solar systems are vital for tracking the performance of solar panels. These devices collect data on energy production, system efficiency, and potential maintenance needs. By analyzing this data, companies can enhance their operational efficiency and reduce downtime, leading to cost savings. When sourcing these systems, buyers must consider compatibility with existing solar setups and the ease of integration into current energy management systems, especially in Europe and the Middle East.

How Can Logger Solar Improve Fleet Management in Transportation?

For the transportation and logistics industry, logger solar technology is used for fleet management, allowing companies to monitor vehicle locations, fuel consumption, and maintenance needs. This data aids in route optimization and reduces operational costs. Buyers should prioritize sourcing solutions that are robust enough to function in varying climates and provide real-time data access, ensuring effective fleet management in regions like Nigeria and Colombia where logistics can be challenging.

What Benefits Does Logger Solar Offer in Mining and Resource Extraction?

In mining and resource extraction, logger solar applications focus on monitoring equipment performance and environmental conditions. By utilizing these systems, companies can enhance safety protocols and ensure compliance with environmental regulations. The data collected can also lead to more informed operational decisions. When sourcing, buyers should emphasize the accuracy of data collection and the ability for remote accessibility, which are crucial for operations in remote areas.

How is Logger Solar Utilized in Telecommunications for Infrastructure Monitoring?

Telecommunications companies leverage logger solar for health monitoring of their infrastructure, such as cell towers and communication systems. By continuously tracking performance metrics, these systems help reduce downtime and enable proactive maintenance strategies. For B2B buyers, sourcing considerations should include scalability to support various data types and protocols, ensuring the solution can grow with the company’s needs, particularly in diverse markets across Europe and the Middle East.

Related Video: How to add a data logger on Solarman Smart App?

3 Common User Pain Points for ‘logger solar’ & Their Solutions

Scenario 1: Navigating Inaccurate Data Readings from Logger Solar Devices

The Problem:

B2B buyers often encounter significant issues with inaccurate data readings from logger solar devices, particularly in regions like Africa and South America where environmental conditions can fluctuate dramatically. These inaccuracies can lead to poor decision-making regarding energy management and project planning. For instance, a company relying on solar energy for agricultural operations may misinterpret energy production data, resulting in either underutilization of resources or unexpected surges in energy costs. Such discrepancies not only strain operational budgets but can also jeopardize project timelines and profitability.

The Solution:

To mitigate this issue, it’s crucial to invest in high-quality logger solar devices equipped with advanced sensors and calibration features. When sourcing these devices, look for models that offer real-time data analytics and have a proven track record in similar environmental conditions. Additionally, establishing a routine calibration schedule can help ensure data accuracy. Partnering with manufacturers or service providers who offer support and training in data interpretation can also empower your team to make more informed decisions based on accurate readings. Utilizing software that integrates with your logger solar device can enhance visibility and provide actionable insights that facilitate better energy management.

Scenario 2: Managing Maintenance and Downtime of Logger Solar Systems

The Problem:

For international buyers, particularly in the Middle East and Europe, maintaining logger solar systems can be a daunting task due to the complexity of the technology and the need for regular upkeep. Unexpected downtime can lead to significant revenue losses, especially for businesses that depend heavily on solar energy for their operations. This is further complicated by the availability of local technicians trained to handle specific logger solar technologies, which can be scarce in remote areas.

The Solution:

To address maintenance challenges, it is advisable to implement a proactive maintenance strategy. This includes selecting logger solar devices that come with comprehensive warranties and support packages from reputable manufacturers. Buyers should also invest in training programs for local technicians to ensure they are well-equipped to handle routine checks and repairs. Developing a maintenance log and scheduling regular check-ups can prevent unexpected failures. Additionally, utilizing remote monitoring systems can provide real-time alerts for any performance issues, allowing for timely interventions before they escalate into costly downtime.

Scenario 3: Ensuring Compliance with Local Regulations and Standards

The Problem:

In regions such as Europe and Africa, compliance with local regulations surrounding renewable energy and technology use can be a significant hurdle for B2B buyers. Navigating the various standards and certifications required for logger solar devices can be complex and time-consuming. Non-compliance can result in hefty fines, project delays, or even the inability to operate legally, which poses a considerable risk for businesses investing in solar technology.

The Solution:

To ensure compliance, buyers should thoroughly research local regulations and engage with legal or regulatory experts who specialize in renewable energy. When selecting logger solar devices, prioritize those that are certified and have undergone rigorous testing to meet local standards. Establishing a relationship with local regulatory bodies can provide insights into upcoming changes in legislation. Additionally, consider joining industry associations that focus on renewable energy, as they often provide resources and updates regarding compliance standards. Regular audits and compliance checks should also be integrated into your operational protocols to ensure ongoing adherence to the latest regulations.

Strategic Material Selection Guide for logger solar

What Are the Best Materials for Logger Solar Applications?

When selecting materials for logger solar applications, it is crucial to consider the specific requirements of the environment and the performance characteristics of the materials. Below are analyses of four common materials used in logger solar devices, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Aluminum Perform in Logger Solar Applications?

Key Properties: Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity. It can withstand a range of temperatures and is often used in outdoor applications.

Pros & Cons: The primary advantage of aluminum is its durability and resistance to corrosion, making it suitable for harsh environments. However, it can be more expensive than other materials, and its manufacturing process may be complex, especially when forming intricate shapes.

Impact on Application: Aluminum is compatible with various media, including water and various chemicals, which is essential for logger solar systems that may be exposed to diverse environmental conditions.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the aluminum used meets local standards, such as ASTM or DIN, to guarantee quality and performance.

What Are the Benefits of Using Stainless Steel in Logger Solar Devices?

Key Properties: Stainless steel is known for its high strength, corrosion resistance, and ability to withstand extreme temperatures and pressures.

Pros & Cons: The key advantage of stainless steel is its longevity and robustness, making it ideal for demanding applications. However, it is heavier than aluminum and can be more costly, which may affect the overall budget for projects.

Impact on Application: Stainless steel is particularly effective in applications where exposure to saltwater or other corrosive environments is a concern, ensuring the logger solar systems maintain functionality over time.

Considerations for International Buyers: Buyers should verify that the stainless steel complies with international standards to ensure reliability, especially in regions with varying environmental conditions.

Why Choose Polycarbonate for Logger Solar Applications?

Key Properties: Polycarbonate is a thermoplastic material known for its high impact resistance, transparency, and lightweight nature.

Pros & Cons: The primary advantage of polycarbonate is its ability to withstand significant impacts without breaking, making it ideal for protective casings. However, it can be less durable than metals in extreme heat and may require UV stabilization to prevent degradation.

Impact on Application: Polycarbonate is suitable for applications requiring visibility, such as protective covers for solar panels, allowing for sunlight penetration while protecting internal components.

Considerations for International Buyers: It is essential for buyers to consider the UV resistance of polycarbonate products, particularly in sunny regions like Africa and the Middle East, where prolonged exposure can affect performance.

What Role Does ABS Plastic Play in Logger Solar Systems?

Key Properties: Acrylonitrile Butadiene Styrene (ABS) is a strong, lightweight plastic known for its toughness and resistance to impact and heat.

Pros & Cons: ABS is cost-effective and easy to manufacture, making it a popular choice for various applications. However, it is less resistant to UV radiation and may degrade faster in outdoor settings unless treated.

Impact on Application: ABS can be used in non-structural components of logger solar systems, such as housings, where impact resistance is needed but not necessarily high-temperature resistance.

Considerations for International Buyers: Buyers should ensure that ABS products are UV-stabilized for outdoor use, particularly in regions with high sun exposure, to prolong their lifespan.

Summary Table of Material Selection for Logger Solar Applications

| Material | Typical Use Case for Logger Solar | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Structural frames and casings | Lightweight and corrosion-resistant | Higher cost and complex mfg. | Medium |

| Stainless Steel | Components exposed to harsh environments | High strength and longevity | Heavier and more expensive | High |

| Polycarbonate | Protective covers for solar panels | High impact resistance | Less durable in extreme heat | Medium |

| ABS Plastic | Non-structural components like housings | Cost-effective and easy to mold | Less UV resistance | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on material properties, application suitability, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for logger solar

What Are the Key Manufacturing Processes for Logger Solar Products?

The manufacturing of logger solar products involves several critical stages that ensure functionality, durability, and efficiency. Understanding these processes is essential for international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe.

Material Preparation: What Materials Are Used in Logger Solar Manufacturing?

The first step in the manufacturing process is material preparation. This involves sourcing high-quality raw materials that are essential for the performance of logger solar products. Common materials include:

- Solar Cells: Typically made from silicon, these cells convert sunlight into electrical energy.

- Enclosures: Durable materials such as aluminum or polycarbonate are used for protective casings to withstand environmental conditions.

- Wiring and Connectors: Copper and other conductive materials are essential for efficient energy transfer.

Suppliers should prioritize sourcing materials that meet international quality standards to ensure product reliability.

How Is the Forming Process Executed in Logger Solar Manufacturing?

Once materials are prepared, the next stage is forming. This involves several techniques to shape components for logger solar systems:

- Cutting and Shaping: Advanced machinery is used to cut solar panels and enclosures to precise dimensions.

- Laminating: This technique involves layering materials to enhance durability and efficiency, particularly for solar cells.

- Molding: Plastic components may be molded to create custom shapes that fit specific design requirements.

Effective forming techniques are vital to ensure that components fit together seamlessly, which is critical for optimal performance.

What Does the Assembly Process Entail for Logger Solar Products?

The assembly stage integrates all components into a cohesive unit. Key steps include:

- Soldering: Solar cells are soldered together to form panels, ensuring electrical connections are secure.

- Wiring: Proper wiring techniques are essential to facilitate energy flow and minimize losses.

- Final Assembly: All components, including electronic controls and enclosures, are assembled into the final product.

Buyers should inquire about the assembly methods used by suppliers, as precision in this stage directly impacts the product’s performance.

How Does Finishing Enhance Logger Solar Products?

The finishing process applies protective coatings and final touches to enhance durability and aesthetics. This may include:

- Coating: UV-resistant coatings can protect against environmental degradation.

- Quality Inspection: Each unit undergoes a thorough inspection to identify any defects before packaging.

Finishing not only improves the product’s lifespan but also its market appeal.

What Quality Assurance Practices Should B2B Buyers Expect?

Quality assurance (QA) is crucial in the manufacturing of logger solar products, as it ensures that the final products meet both safety and performance standards.

What International Standards Should Be Considered for Logger Solar Products?

For international B2B buyers, it’s essential to understand the relevant quality standards, such as:

- ISO 9001: This standard focuses on quality management systems and ensures consistent product quality.

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with safety, health, and environmental protection standards.

- API Standards: For products used in specific industries, such as oil and gas, adherence to American Petroleum Institute (API) standards may be necessary.

Understanding these standards helps buyers assess the credibility of suppliers.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integral to maintaining product standards throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This checks the quality of raw materials upon arrival at the facility.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, this ensures that any deviations are identified and corrected immediately.

- Final Quality Control (FQC): This is the last line of defense before products are shipped, ensuring that all specifications are met.

Buyers should ask suppliers about their QC processes to ensure they align with international best practices.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers maintain high-quality standards, buyers can take several steps:

- Conduct Audits: Regular audits can provide insights into a supplier’s manufacturing processes and adherence to quality standards.

- Request Quality Reports: Suppliers should provide documentation of their quality control processes and results, including any certifications.

- Engage Third-Party Inspectors: Utilizing independent inspectors can offer an unbiased evaluation of the supplier’s quality assurance practices.

These measures can help mitigate risks associated with sourcing from international suppliers.

What Testing Methods Are Commonly Used in Logger Solar Quality Assurance?

Quality assurance for logger solar products involves rigorous testing methods to ensure reliability and performance. Some common testing methods include:

- Performance Testing: Evaluating the efficiency of solar cells under various conditions.

- Environmental Testing: Assessing the product’s resilience against extreme temperatures, humidity, and UV exposure.

- Electrical Testing: Ensuring that the electrical systems function correctly and safely.

By understanding these testing methods, B2B buyers can make informed decisions about potential suppliers.

What Nuances Should International B2B Buyers Be Aware Of?

When sourcing logger solar products, international B2B buyers should be aware of several nuances:

- Regulatory Compliance: Different regions may have specific regulations that affect product design and certification.

- Cultural Considerations: Understanding local business practices and negotiation styles can facilitate smoother transactions.

- Logistical Challenges: Consideration of shipping, tariffs, and local infrastructure is essential for timely delivery.

By being informed about these factors, buyers can navigate the complexities of international sourcing more effectively.

By focusing on these manufacturing processes and quality assurance practices, international B2B buyers can enhance their procurement strategies for logger solar products, ensuring they select reliable suppliers that meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘logger solar’

In the fast-evolving market for logger solar technology, B2B buyers must navigate a complex landscape of suppliers, specifications, and regulatory requirements. This practical sourcing guide provides a step-by-step checklist to help international buyers, particularly from Africa, South America, the Middle East, and Europe, make informed purchasing decisions.

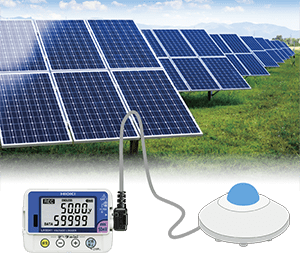

A stock image related to logger solar.

Step 1: Define Your Technical Specifications

Establishing precise technical specifications is crucial to ensure that the logger solar products meet your operational needs. Consider factors such as data storage capacity, connectivity options (like cellular or Wi-Fi), and compatibility with existing systems. Clearly defined specifications will help streamline the selection process and reduce the risk of procurement errors.

Step 2: Research Regulatory Compliance Requirements

Understanding the regulatory landscape in your region is essential for compliance and to avoid costly penalties. Investigate local laws regarding energy sourcing, data privacy, and environmental impact. Check if the suppliers adhere to international standards such as ISO certifications, which can enhance reliability and trustworthiness.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough due diligence. Request company profiles, case studies, and references from buyers in similar industries or regions. Assess their experience in delivering logger solar solutions and their ability to provide post-purchase support. A reliable supplier should demonstrate a strong track record in your specific market context.

Step 4: Request Product Samples or Demonstrations

Whenever possible, request samples or product demonstrations from potential suppliers. This hands-on approach allows you to evaluate the logger solar technology in action and assess its usability and performance. Pay attention to the user interface and data accuracy, as these factors are vital for effective operation.

Step 5: Compare Pricing and Total Cost of Ownership (TCO)

While price is an important factor, it is essential to consider the total cost of ownership, which includes installation, maintenance, and operational costs. Obtain detailed quotations from multiple suppliers and analyze the long-term value each option provides. Look for warranties and service agreements that can mitigate future expenses.

Step 6: Verify Supplier Certifications and Quality Assurance

Confirm that your shortlisted suppliers hold relevant certifications that validate their quality assurance processes. Certifications such as CE, UL, or specific industry standards can indicate a commitment to quality and safety. This verification step can significantly reduce risks associated with product failure or non-compliance.

Step 7: Establish Clear Communication Channels

Effective communication is key to a successful procurement process. Set up clear lines of communication with suppliers to ensure that any questions or issues can be addressed promptly. Regular updates and open dialogue will facilitate a smoother transaction and foster a strong business relationship moving forward.

By following this checklist, B2B buyers can enhance their sourcing strategy for logger solar technologies, ensuring that they select the most suitable products and partners to meet their business needs.

Comprehensive Cost and Pricing Analysis for logger solar Sourcing

What Are the Key Cost Components in Logger Solar Sourcing?

When sourcing logger solar systems, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The type and quality of materials directly impact costs. High-performance solar panels, batteries, and connectors can significantly vary in price. Opting for locally sourced materials can reduce costs while supporting regional economies.

-

Labor: Labor costs can differ widely based on the region. For instance, labor in South America may be cheaper than in Europe. It’s essential to consider both direct labor for assembly and indirect labor for design and engineering.

-

Manufacturing Overhead: This includes costs associated with running the manufacturing facility, such as utilities, equipment depreciation, and administrative expenses. Buyers should inquire about the manufacturer’s efficiency to gauge overhead costs.

-

Tooling: Custom tooling for specific logger solar designs can be a significant upfront cost. Understanding whether the supplier has existing tools that can be utilized can lead to substantial savings.

-

Quality Control (QC): Implementing strict QC measures ensures product reliability but adds to the overall cost. Buyers should assess the supplier’s QC processes and how they impact pricing.

-

Logistics: Shipping costs can be a hidden expense, especially for international transactions. Factors include distance, shipping method, and customs duties. Understanding Incoterms can help clarify who bears these costs.

-

Margin: Supplier margins can vary based on competition and market conditions. It’s beneficial to compare multiple suppliers to ensure competitive pricing.

How Do Price Influencers Affect Logger Solar Costs?

Several factors influence the pricing of logger solar products. Understanding these can aid in negotiating better deals:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for larger orders. Buyers should assess their needs to find a balance between inventory costs and savings from bulk purchasing.

-

Specifications and Customization: Custom solutions tailored to specific needs can increase costs. Buyers should evaluate whether standard products could meet their requirements to save money.

-

Materials: The choice of materials impacts both performance and price. Higher-quality materials may cost more initially but can lead to lower maintenance and replacement costs over time.

-

Quality and Certifications: Products that come with certifications (e.g., ISO, CE) may carry higher price tags due to the assurance of quality and compliance. Buyers should consider the long-term benefits of investing in certified products.

-

Supplier Factors: The reputation and reliability of the supplier can influence costs. Well-established suppliers may charge more but offer better service and reliability, reducing risks.

-

Incoterms: Understanding the agreed Incoterms is vital. They define who is responsible for shipping, insurance, and tariffs, directly impacting total costs.

What Are the Best Negotiation Tips for International Buyers?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to better pricing:

-

Research and Benchmarking: Conduct thorough market research to understand standard pricing. This information can empower buyers during negotiations.

-

Build Relationships: Developing a rapport with suppliers can lead to better terms and pricing. Long-term partnerships often yield discounts and favorable terms.

-

Consider Total Cost of Ownership (TCO): Evaluate the TCO rather than just the upfront price. This includes maintenance, energy efficiency, and lifespan, which can all impact long-term expenses.

-

Flexibility in Specifications: If possible, be flexible with product specifications. Adjusting minor details can lead to significant cost reductions.

-

Timing of Orders: Place orders during off-peak seasons to take advantage of lower prices and better availability.

What Should Buyers Keep in Mind Regarding Indicative Prices?

Prices for logger solar systems can fluctuate due to various factors, including market demand, changes in material costs, and geopolitical influences. It is essential for buyers to request indicative prices from multiple suppliers and remain aware of the potential for price changes throughout the sourcing process. Regularly reviewing and updating contracts can also safeguard against unexpected costs.

By understanding the intricate cost components and price influencers, international B2B buyers can make informed decisions that align with their operational budgets and long-term goals.

Alternatives Analysis: Comparing logger solar With Other Solutions

In the quest for sustainable energy solutions, businesses are increasingly considering various technologies. Logger solar systems, designed for efficient energy capture and management, are among the leading options. However, understanding alternatives can help B2B buyers make informed decisions. This section compares logger solar with other viable solutions, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table of Logger Solar and Alternatives

| Comparison Aspect | Logger Solar | Wind Turbines | Diesel Generators |

|---|---|---|---|

| Performance | High energy efficiency; ideal for sunny regions | Variable performance; dependent on wind availability | Reliable; consistent power output |

| Cost | Moderate initial investment; low operational costs | High upfront costs; long-term savings possible | Low initial cost; high fuel and maintenance costs |

| Ease of Implementation | Requires specific site analysis; straightforward installation | Complex installation; requires regulatory approvals | Simple to set up; minimal site preparation |

| Maintenance | Low maintenance needs; periodic checks | Moderate maintenance; requires regular inspections | High maintenance; frequent servicing needed |

| Best Use Case | Suitable for remote locations with high solar exposure | Effective in areas with consistent wind patterns | Ideal for backup power or in regions without grid access |

What Are the Advantages and Disadvantages of Wind Turbines?

Wind turbines harness the kinetic energy of wind to generate electricity. They can be a great alternative in regions where wind is abundant. The main advantages include high energy output potential and renewable energy generation. However, they have significant drawbacks, such as high initial costs, complex installation, and dependence on wind availability. Additionally, they may face regulatory challenges, making them less accessible for some businesses.

How Do Diesel Generators Compare to Logger Solar?

Diesel generators are traditionally used for backup power and in areas lacking reliable electricity access. They are relatively easy to set up and provide consistent power. However, the cost of fuel can add up quickly, leading to high operational expenses over time. Furthermore, they emit greenhouse gases, making them less favorable for companies focused on sustainability. In contrast, logger solar systems offer a cleaner, more sustainable solution with lower long-term costs, despite the initial investment.

Conclusion: How to Choose the Right Energy Solution for Your Business

When selecting an energy solution, B2B buyers should consider their specific operational needs, budget constraints, and sustainability goals. Logger solar systems are an excellent choice for businesses in sunny regions looking for a reliable, low-maintenance energy source. Conversely, wind turbines may be more suitable for areas with consistent winds, while diesel generators could serve as a backup option. By evaluating these factors, businesses can make informed decisions that align with their energy requirements and environmental commitments.

Essential Technical Properties and Trade Terminology for logger solar

What Are the Key Technical Properties of Logger Solar Products?

When evaluating logger solar products, international B2B buyers should consider several critical technical properties that impact performance, durability, and overall value. Understanding these specifications ensures informed purchasing decisions, particularly for businesses in regions like Africa, South America, the Middle East, and Europe.

1. Material Grade

The material grade of a logger solar unit often dictates its longevity and resistance to environmental factors. Common materials include aluminum, stainless steel, and high-grade plastics. Buyers should look for corrosion-resistant materials, especially in coastal or humid regions, to ensure that the product withstands harsh conditions.

2. Tolerance Levels

Tolerance levels refer to the permissible limits of variation in the dimensions of components. High precision in tolerances is crucial for ensuring that logger solar units fit seamlessly into existing systems and operate efficiently. Buyers should prioritize products with tight tolerances to minimize maintenance issues and enhance performance reliability.

3. Operating Temperature Range

The operating temperature range is vital for understanding how well a logger solar unit can function under extreme conditions. Solar loggers should be capable of operating in a wide range of temperatures, typically from -20°C to 60°C. This specification is especially important for buyers in regions with significant temperature fluctuations, as it impacts both performance and durability.

4. Data Storage Capacity

Data storage capacity is essential for loggers that collect and transmit solar energy data. Higher storage capacity allows for more extensive data logging, which can be crucial for businesses that require detailed analytics for performance assessment. Buyers should evaluate the storage specifications to ensure they meet their data logging needs.

5. Power Consumption

Power consumption indicates how much energy the logger solar unit uses during operation. Lower power consumption is advantageous as it can lead to longer operational periods without needing frequent maintenance or battery replacements. Buyers should compare power consumption across different models to optimize energy efficiency.

What Are Common Trade Terms in Logger Solar Procurement?

Navigating the procurement process for logger solar products involves familiarizing oneself with industry jargon. Here are several common terms that buyers should understand:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reputable suppliers and ensure that they are sourcing high-quality components for their solar logging solutions.

2. MOQ (Minimum Order Quantity)

A stock image related to logger solar.

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers, as it affects inventory management and overall cost. Businesses should negotiate MOQs based on their operational needs and budget constraints.

A stock image related to logger solar.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and availability for specific products. It is an essential step in the procurement process, allowing buyers to compare options and make informed purchasing decisions based on cost and supplier reliability.

4. Incoterms (International Commercial Terms)

Incoterms are a series of international sales terms that define the responsibilities of buyers and sellers in a transaction. Familiarity with Incoterms is vital for international B2B buyers as it clarifies shipping costs, risk management, and delivery obligations, thereby minimizing misunderstandings.

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. Understanding lead times helps businesses plan their operations effectively, ensuring that they have the necessary inventory when needed without incurring excess storage costs.

By grasping these technical properties and trade terms, B2B buyers can enhance their procurement strategies for logger solar products, facilitating smoother transactions and better alignment with their business needs.

Navigating Market Dynamics and Sourcing Trends in the logger solar Sector

What Are the Key Market Dynamics and Trends in the Logger Solar Sector?

The logger solar sector is witnessing significant growth driven by various global factors, including the increasing demand for renewable energy solutions and the urgent need for sustainable practices. Countries in Africa, South America, the Middle East, and Europe are particularly focused on leveraging solar technology to meet energy needs and reduce carbon footprints. The rising costs of fossil fuels and the falling prices of solar technology are encouraging international B2B buyers to invest in logger solar systems.

Emerging technologies such as IoT integration and advanced data analytics are reshaping how solar energy systems are monitored and managed. This trend is particularly relevant for buyers seeking to enhance operational efficiency and performance monitoring. Additionally, the adoption of smart grid technologies is becoming a common practice, enabling better energy distribution and real-time data collection.

B2B buyers should also be aware of regional market dynamics, which can vary significantly. For instance, while European markets may prioritize regulatory compliance and technological innovation, African buyers might focus more on affordability and accessibility. Understanding these nuances can help international buyers tailor their sourcing strategies effectively.

How Is Sustainability Influencing B2B Sourcing in the Logger Solar Sector?

Sustainability is a critical consideration for B2B buyers in the logger solar sector. As environmental concerns become more pressing, businesses are increasingly scrutinizing their supply chains for ethical sourcing practices. Buyers are urged to consider the environmental impact of the materials used in logger solar systems, from manufacturing to disposal.

The importance of ethical supply chains cannot be overstated. Businesses are now expected to adhere to sustainability certifications and standards, which not only enhance their brand reputation but also ensure compliance with international regulations. Certifications like ISO 14001 for environmental management and LEED (Leadership in Energy and Environmental Design) are becoming essential for companies aiming to establish credibility in the market.

Moreover, sourcing ‘green’ materials—such as recyclable components or those produced using renewable energy—can significantly reduce the carbon footprint associated with logger solar systems. B2B buyers should proactively seek suppliers who can provide transparency in their sourcing practices and demonstrate a commitment to sustainability. This not only aligns with global trends but also meets the growing demand from consumers for environmentally responsible products.

What Is the Historical Context of the Logger Solar Sector’s Development?

The logger solar sector has evolved significantly over the past few decades. Initially, solar technology was seen primarily as a niche market, with limited applications and high costs. However, technological advancements and increased awareness of climate change have catalyzed its growth.

In the early 2000s, government incentives and subsidies in various regions, particularly in Europe and North America, began to drive investment in solar technology. This led to a surge in research and development, resulting in more efficient solar panels and data logger systems. By the 2010s, the global shift towards renewable energy gained momentum, prompting countries in Africa and South America to adopt solar solutions as a viable alternative to traditional energy sources.

Today, the logger solar sector stands at the intersection of technological innovation and sustainability, making it an attractive option for B2B buyers worldwide. Understanding this historical context can help buyers appreciate the current landscape and anticipate future trends in the sector.

Frequently Asked Questions (FAQs) for B2B Buyers of logger solar

-

How do I solve compatibility issues with logger solar products?

To address compatibility issues with logger solar products, first confirm that the specifications of the logger match the solar system’s voltage and current ratings. Review the manufacturer’s documentation for compatibility guidelines. If problems persist, consider consulting with the supplier to determine if firmware updates or specific configurations are required. Additionally, testing the logger with a similar system can help isolate the issue. -

What is the best logger solar solution for off-grid applications?

The best logger solar solution for off-grid applications typically includes a logger with robust data storage capabilities, reliable wireless communication, and compatibility with various sensor types. Look for loggers that offer solar panel integration and low power consumption to ensure longevity. Brands like Solar-Log and Midnite Solar are often recommended for their reliability in harsh conditions, but it’s essential to assess your specific needs and environmental conditions. -

How can I vet suppliers of logger solar products?

To effectively vet suppliers of logger solar products, start by reviewing their certifications and compliance with international standards such as ISO and IEC. Request references from previous clients and assess their experience in your specific market, particularly in regions like Africa, South America, and the Middle East. Additionally, evaluate their financial stability, customer support, and after-sales service to ensure a reliable partnership. -

What customization options are available for logger solar solutions?

Many suppliers offer customization options for logger solar solutions, including specific data logging intervals, sensor types, and communication protocols. Some manufacturers allow for tailored software solutions that integrate with existing systems or provide unique reporting formats. When considering customization, communicate your specific requirements clearly and inquire about associated costs and lead times. -

What are typical minimum order quantities (MOQs) for logger solar products?

Minimum order quantities (MOQs) for logger solar products can vary significantly between suppliers. Generally, MOQs can range from as few as 10 units to several hundred, depending on the manufacturer and product type. It’s advisable to discuss your needs with potential suppliers to negotiate MOQs, especially if you are a smaller enterprise or just entering the market. -

What payment terms should I expect when sourcing logger solar products internationally?

Payment terms for international sourcing of logger solar products can vary widely. Common arrangements include upfront payments, letters of credit, and payment upon delivery. Ensure to clarify these terms in advance and consider using secure payment methods such as PayPal or escrow services to protect your investment. Discussing terms openly can help establish trust and facilitate smoother transactions. -

How do I ensure quality assurance for logger solar products?

To ensure quality assurance for logger solar products, request detailed product specifications and certifications from suppliers. Conduct factory audits if possible, or utilize third-party inspection services to verify product quality before shipment. Additionally, consider negotiating a warranty or guarantee that covers defects or performance issues, providing added security for your investment. -

What logistical considerations should I keep in mind when importing logger solar products?

When importing logger solar products, key logistical considerations include shipping methods, customs clearance, and lead times. Choose a reliable logistics partner who understands international shipping regulations, especially for regions like Africa and South America. It’s also crucial to prepare all necessary documentation, including invoices, packing lists, and certificates of origin, to facilitate smooth customs processing.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for logger solar

What Are the Key Takeaways for B2B Buyers of Logger Solar Solutions?

In conclusion, strategic sourcing of logger solar technology offers immense opportunities for international B2B buyers. By focusing on quality suppliers, understanding regional market dynamics, and leveraging technological advancements, companies can significantly enhance their operational efficiency. Buyers from Africa, South America, the Middle East, and Europe should prioritize partnerships that emphasize sustainability and adaptability, ensuring their solar solutions are not only efficient but also compliant with local regulations and market demands.

How Can Strategic Sourcing Influence Your Business Growth?

The value of strategic sourcing extends beyond cost savings; it fosters innovation and resilience in supply chains. By selecting suppliers who prioritize research and development, businesses can stay ahead in a rapidly evolving industry. This proactive approach is especially crucial in regions like Nigeria and Colombia, where renewable energy adoption is gaining momentum.

What’s Next for International B2B Buyers in the Logger Solar Market?

As we look ahead, it’s essential for buyers to remain agile and informed. Engage with industry experts, participate in trade shows, and explore emerging technologies to enhance your sourcing strategies. Now is the time to act—evaluate your current suppliers, seek out new partnerships, and invest in logger solar solutions that will drive your business forward in a sustainable manner.