Discover çe iir: The Ultimate Sourcing Guide (2025)

Introduction: Navigating the Global Market for çe iir

In today’s fast-paced global marketplace, sourcing high-quality çe iir can present a significant challenge for international B2B buyers. With diverse needs ranging from aesthetic appeal to functional performance, understanding the nuances of çe iir can be daunting. This comprehensive guide addresses crucial aspects such as the various types of çe iir, their applications across different industries, and effective supplier vetting strategies. By exploring cost considerations and market trends, this resource equips buyers from Africa, South America, the Middle East, and Europe—including regions like Vietnam and Turkey—with the knowledge necessary to make informed purchasing decisions.

Navigating the complexities of international trade requires more than just product knowledge; it demands a strategic approach to sourcing and supplier relationships. This guide empowers B2B buyers to identify reliable manufacturers, negotiate favorable terms, and understand the logistical challenges involved in importing çe iir. Whether you are looking to enhance your product line or fulfill specific client needs, having a solid foundation in the global market for çe iir will enable you to optimize your supply chain and drive profitability.

By the end of this guide, you will have actionable insights that will not only simplify your sourcing process but also elevate your business’s competitive edge in a crowded marketplace.

Understanding çe iir Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional çe iir | Handcrafted, often locally sourced materials | Artisan markets, cultural events | Pros: Unique, high-quality products; Cons: Higher costs, limited scalability. |

| Industrial çe iir | Mass-produced, standardized designs | Retail distribution, bulk purchasing | Pros: Cost-effective, consistent quality; Cons: Less uniqueness, potential for over-saturation. |

| Eco-friendly çe iir | Sustainable materials, environmentally conscious | Green markets, eco-friendly brands | Pros: Attracts eco-conscious buyers; Cons: May have higher production costs. |

| Custom çe iir | Tailored designs based on client specifications | Corporate gifts, branding initiatives | Pros: Unique branding opportunities; Cons: Longer lead times, potentially higher costs. |

| Digital çe iir | Virtual representations, digitally designed | Online marketplaces, e-commerce | Pros: Accessible, can reach global markets; Cons: Requires tech investment, may lack tactile experience. |

What Are the Characteristics of Traditional çe iir?

Traditional çe iir is characterized by its handcrafted nature, often utilizing locally sourced materials that reflect the cultural heritage of the region. This type typically features unique designs and craftsmanship, making each piece distinct. B2B buyers focusing on artisan markets or cultural events can benefit from offering these products, as they often command premium prices due to their authenticity. However, buyers should consider the higher costs and potential limitations in scalability when sourcing traditional çe iir.

How Does Industrial çe iir Differ from Other Types?

Industrial çe iir stands out due to its mass production and standardized designs, which allow for consistent quality and lower costs. It is particularly suitable for retail distribution and bulk purchasing, making it an attractive option for businesses looking to stock large quantities. While industrial çe iir offers cost-effectiveness, buyers should be cautious of potential over-saturation in the market, which can dilute brand uniqueness.

Why Choose Eco-friendly çe iir for Your B2B Needs?

Eco-friendly çe iir focuses on sustainable materials and environmentally conscious production methods. This type appeals to businesses targeting green markets and eco-friendly brands, tapping into the growing demand for sustainable products. While eco-friendly çe iir can attract eco-conscious buyers, it may come with higher production costs. B2B buyers should weigh the benefits of aligning with sustainability against their budget constraints.

What Are the Benefits of Custom çe iir for Branding?

Custom çe iir allows businesses to create tailored designs based on client specifications, making it ideal for corporate gifts and branding initiatives. This type provides unique branding opportunities and can enhance customer loyalty. However, buyers should be prepared for longer lead times and potentially higher costs associated with custom orders. Understanding the target audience’s preferences is essential for maximizing the impact of custom çe iir.

How Can Digital çe iir Expand Your Market Reach?

Digital çe iir involves virtual representations and digitally designed products, making it a modern solution for businesses looking to enter online marketplaces and e-commerce platforms. This type is accessible and can reach global markets, appealing to a tech-savvy audience. However, B2B buyers must consider the investment in technology and the potential lack of tactile experience when purchasing digital çe iir. Balancing these factors is crucial for successful market penetration.

Related Video: The Calculus of Variations and the Euler-Lagrange Equation

Key Industrial Applications of çe iir

| Industry/Sector | Specific Application of çe iir | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Soil Enhancement | Improves soil fertility, leading to higher crop yields. | Ensure compatibility with local soil types and regulations. |

| Manufacturing | Surface Coating | Enhances durability and corrosion resistance of products. | Verify adherence to international quality standards. |

| Construction | Structural Adhesives | Provides strong bonding for construction materials, improving safety. | Evaluate curing times and environmental impact. |

| Automotive | Fuel Additives | Increases efficiency and reduces emissions in vehicles. | Assess compatibility with various engine types and fuel standards. |

| Pharmaceuticals & Cosmetics | Active Ingredients | Serves as a crucial component in drug formulation and personal care products. | Ensure compliance with health regulations in target markets. |

How is çe iir Used in Agriculture to Enhance Soil Quality?

In the agricultural sector, çe iir is utilized as a soil enhancement agent, significantly improving soil fertility. By enhancing the nutrient retention capacity of soil, it allows for higher crop yields and better resistance to drought conditions. For international B2B buyers, particularly in regions like Africa and South America, it is essential to ensure that the product is compatible with local soil types and adheres to agricultural regulations. Buyers should also consider the long-term effects on soil health and the potential for organic certification.

What are the Benefits of Using çe iir in Manufacturing?

In manufacturing, çe iir serves as a surface coating that enhances the durability and corrosion resistance of various products. This application is particularly beneficial for companies producing metal goods or components exposed to harsh environments. By using çe iir, manufacturers can reduce maintenance costs and extend the lifespan of their products. When sourcing for this application, international buyers should verify that the coating meets international quality standards and assess the supplier’s capacity for large-scale production.

How Does çe iir Improve Safety in Construction?

In the construction industry, çe iir is employed as a structural adhesive, providing strong bonding for various materials, including metals, plastics, and wood. This application enhances the safety and integrity of structures, reducing the risk of failures over time. For buyers in the Middle East and Europe, evaluating the curing times, environmental impact, and compliance with local building codes is critical. Additionally, understanding the adhesive’s performance under different environmental conditions can influence procurement decisions.

How Can çe iir Enhance Automotive Fuel Efficiency?

For the automotive sector, çe iir is increasingly used as a fuel additive that improves engine efficiency and reduces harmful emissions. This application is vital as the industry moves towards stricter environmental regulations. International B2B buyers, especially from Europe, should assess the compatibility of çe iir with various engine types and fuel standards. Furthermore, understanding the additive’s performance under different driving conditions is essential for maximizing its benefits.

What Role Does çe iir Play in Pharmaceuticals and Cosmetics?

In the pharmaceuticals and cosmetics industries, çe iir functions as an active ingredient in formulations. It is crucial for enhancing the efficacy of drugs and personal care products, thus influencing consumer satisfaction and compliance. Buyers in these sectors must ensure that çe iir complies with health regulations in their respective markets. Additionally, sourcing should consider the purity and quality of the ingredient, as these factors significantly impact product safety and effectiveness.

Related Video: Uses and Gratifications Theory – UGT

3 Common User Pain Points for ‘çe iir’ & Their Solutions

Scenario 1: Navigating Complex Regulations for ‘çe iir’ Procurement

The Problem: B2B buyers often face the daunting task of understanding and complying with the myriad regulations surrounding the procurement of ‘çe iir’. This is particularly true for international buyers from regions such as Africa and South America, where local laws can be ambiguous and inconsistent. The challenge intensifies when considering customs regulations, import duties, and certifications required for specific markets, leading to delays in shipments and unexpected costs.

The Solution: To navigate these complexities, it’s crucial to partner with a local compliance expert or a reputable sourcing agent who specializes in ‘çe iir’. This professional can provide insights into regional regulations and ensure that all necessary paperwork is in order before the procurement process begins. Additionally, creating a checklist of required documents and certifications tailored to your specific market can streamline compliance. Regular training sessions for your procurement team on regional laws and regulations will also empower them to make informed decisions, reducing the risk of costly mistakes.

Scenario 2: Quality Assurance and Consistency Issues with ‘çe iir’

The Problem: Another significant pain point for B2B buyers is ensuring the quality and consistency of ‘çe iir’ products. Variability in quality can stem from differences in suppliers, manufacturing processes, or even raw materials used. For businesses that rely on ‘çe iir’ for production, inconsistent quality can lead to production delays, increased waste, and ultimately, customer dissatisfaction.

The Solution: Implementing a robust quality assurance process is essential. Start by conducting thorough supplier assessments to evaluate their quality control measures and certifications. Establish clear quality standards and communicate these expectations directly to suppliers. Additionally, consider utilizing third-party inspection services to perform regular quality checks on shipments before they leave the supplier’s facility. This proactive approach ensures that only products meeting your standards reach your production line, minimizing disruptions.

Scenario 3: Supply Chain Disruptions in ‘çe iir’ Sourcing

The Problem: Supply chain disruptions can significantly impact the availability of ‘çe iir’, especially for buyers in Europe and the Middle East, where geopolitical factors and logistics challenges can create bottlenecks. These disruptions can lead to delays in production timelines and increased costs, making it difficult for businesses to meet customer demands.

The Solution: To mitigate the risk of supply chain disruptions, it is advisable to diversify your supplier base. By sourcing ‘çe iir’ from multiple regions or suppliers, you can reduce dependency on a single source and enhance resilience against localized disruptions. Additionally, investing in supply chain visibility tools can provide real-time updates on inventory levels and shipment statuses, enabling you to proactively manage risks. Establishing strong relationships with logistics providers and exploring alternative shipping routes can also help ensure timely delivery, even during challenging circumstances.

Strategic Material Selection Guide for çe iir

When selecting materials for çe iir, it is crucial for international B2B buyers to understand the properties, advantages, and limitations of various materials. This guide analyzes four common materials used in çe iir applications, providing insights into their performance characteristics and considerations relevant to specific regions such as Africa, South America, the Middle East, and Europe.

What are the Key Properties of Stainless Steel for çe iir?

Stainless steel is a popular choice for çe iir due to its excellent corrosion resistance and strength. It typically has a temperature rating of up to 800°C and can withstand high pressures, making it suitable for demanding environments. The alloy composition, particularly the percentage of chromium and nickel, enhances its durability and resistance to oxidation.

Pros & Cons: The primary advantage of stainless steel is its longevity and ability to maintain integrity under harsh conditions. However, it can be more expensive than other materials, and its manufacturing complexity may lead to higher production costs. In applications where weight is a concern, stainless steel may also be less favorable compared to lighter alternatives.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances, making it ideal for various industrial applications.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN. In regions like Europe and the Middle East, specific grades of stainless steel may be preferred due to local regulations.

How Does Carbon Steel Compare for çe iir Applications?

Carbon steel offers a cost-effective alternative for çe iir applications, particularly in less corrosive environments. It typically has a lower temperature rating than stainless steel, around 400°C, and is suitable for moderate pressure applications.

Pros & Cons: The key advantage of carbon steel is its affordability and ease of manufacturing. However, it is prone to rust and corrosion, which limits its use in aggressive media. This can lead to higher maintenance costs over time.

Impact on Application: Carbon steel is best suited for applications involving non-corrosive media, where cost considerations are paramount.

Considerations for International Buyers: Buyers in Africa and South America may find carbon steel more accessible due to lower costs, but they should be aware of the need for protective coatings or treatments to enhance durability.

What are the Benefits of Polypropylene in çe iir?

Polypropylene is a thermoplastic polymer known for its excellent chemical resistance and lightweight properties. It can handle temperatures up to 100°C and is often used in applications involving acidic or alkaline substances.

Pros & Cons: The primary advantage of polypropylene is its resistance to a wide range of chemicals, making it suitable for various industrial applications. However, its lower temperature and pressure ratings limit its use in high-stress environments.

Impact on Application: Polypropylene is ideal for applications where chemical compatibility is critical, particularly in the chemical processing industry.

Considerations for International Buyers: Buyers should consider regional preferences for materials, as polypropylene may be favored in industries focused on sustainability and lightweight applications, particularly in Europe.

Why Choose PTFE for çe iir Applications?

PTFE (Polytetrafluoroethylene) is renowned for its non-stick properties and exceptional chemical resistance, making it a prime choice for çe iir applications involving aggressive chemicals. It can withstand temperatures up to 260°C and is suitable for low-pressure applications.

Pros & Cons: The major advantage of PTFE is its outstanding chemical inertness, which makes it ideal for handling corrosive substances. However, it is relatively expensive and can be challenging to fabricate, which may increase overall costs.

Impact on Application: PTFE is particularly useful in applications where media compatibility is critical, such as in the pharmaceutical and food industries.

Considerations for International Buyers: Buyers should be aware of the specific certifications required for PTFE in food-grade applications, especially in Europe and the Middle East, where compliance with health regulations is stringent.

Summary Table of Material Selection for çe iir

| Material | Typical Use Case for çe iir | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-pressure, high-temperature applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Carbon Steel | Cost-sensitive, moderate pressure applications | Affordability | Prone to rust and corrosion | Low |

| Polypropylene | Chemical processing, non-corrosive media | Chemical resistance and lightweight | Limited temperature and pressure ratings | Medium |

| PTFE | Aggressive chemical environments | Outstanding chemical inertness | Expensive and difficult to fabricate | High |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions that align with regional standards and application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for çe iir

What Are the Key Stages in the Manufacturing Process of çe iir?

The manufacturing process for çe iir involves several critical stages that ensure the product meets quality and performance standards. Understanding these stages is essential for B2B buyers to assess potential suppliers effectively.

-

Material Preparation

The initial stage involves selecting and preparing raw materials. For çe iir, this typically includes specialized polymers or rubber compounds. Suppliers often conduct material characterization tests to verify the properties of these materials, ensuring they are suitable for the intended application. Buyers should inquire about the sourcing of materials and whether they meet international specifications. -

Forming Techniques

Forming is a crucial step where the prepared materials are shaped into the desired form. Common techniques include compression molding and extrusion. Each method has its advantages; for instance, compression molding is often used for complex shapes, while extrusion is ideal for uniform cross-sections. B2B buyers should ask suppliers about their forming techniques and how they impact the final product’s performance. -

Assembly Processes

Once the parts are formed, they are assembled. This stage may involve manual labor or automated systems, depending on the production scale. Buyers should consider the supplier’s assembly methods, as these can influence product consistency and lead times. Additionally, understanding the assembly process can help buyers gauge the flexibility of suppliers to accommodate custom orders. -

Finishing Techniques

The finishing stage enhances the product’s aesthetic and functional properties. Techniques such as surface treatment, painting, or coating are applied to improve durability and resistance to environmental factors. Buyers should verify the finishing techniques used and assess whether they align with industry standards or specific requirements for their applications.

How Is Quality Assurance Implemented in the Manufacturing of çe iir?

Quality assurance (QA) is an integral part of the manufacturing process for çe iir. It encompasses various international standards and checkpoints that ensure the product’s integrity and reliability.

-

Understanding International Quality Standards

International standards like ISO 9001 set the framework for quality management systems across industries. Compliance with these standards indicates that a supplier follows systematic processes to enhance product quality. Additionally, industry-specific certifications such as CE marking for European markets and API standards for oil and gas applications are crucial. B2B buyers should prioritize suppliers that hold relevant certifications, as this demonstrates a commitment to quality. -

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically divided into three main checkpoints:

– Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet predefined specifications.

– In-Process Quality Control (IPQC): During production, continuous monitoring is performed to identify defects early. This may include real-time testing of parameters such as dimensions and material properties.

– Final Quality Control (FQC): After assembly, the final product undergoes thorough testing before shipment. This can include functional testing, visual inspections, and performance evaluations. -

What Common Testing Methods Are Used?

Various testing methods are employed to verify the quality of çe iir products. Common methods include:

– Mechanical Testing: Assessing tensile strength, elongation, and hardness.

– Thermal Analysis: Evaluating how materials respond to heat, ensuring stability under operational conditions.

– Chemical Testing: Checking for resistance to chemicals and environmental factors.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying a supplier’s quality control processes is crucial to ensure product reliability and compliance with standards. Here are actionable strategies:

-

Conducting Supplier Audits

Regular audits can provide insights into a supplier’s quality management practices. Buyers should schedule on-site audits or engage third-party auditors to evaluate the manufacturing processes, quality systems, and compliance with international standards. -

Requesting Quality Reports

Suppliers should provide documentation detailing their QC processes, including inspection records, test results, and compliance certifications. Buyers should ask for these reports to assess the supplier’s commitment to quality and identify any potential issues. -

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can offer an unbiased assessment of product quality. These services can conduct inspections at various stages of production, providing reassurance to buyers that products meet specifications before shipment.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

Navigating the complexities of quality control and certification can be challenging for international buyers, especially from regions like Africa, South America, the Middle East, and Europe. Here are some key considerations:

-

Regional Compliance Requirements

Different regions may have specific compliance requirements that affect the certification process. For example, European buyers may need to ensure that products adhere to REACH regulations, while buyers in the Middle East might require compliance with local standards. Understanding these nuances can help buyers avoid costly delays or non-compliance issues. -

Language and Documentation Barriers

Language differences can pose challenges when reviewing supplier documentation. Buyers should ensure that all quality reports, certifications, and technical documents are available in a language they understand. This can help prevent miscommunication and ensure clarity in quality expectations. -

Cultural Considerations in Quality Assurance

Cultural differences can influence how quality is perceived and managed. Buyers should be aware of the cultural context of their suppliers and engage in open communication to foster a mutual understanding of quality expectations.

By focusing on these aspects of manufacturing processes and quality assurance, international B2B buyers can make informed decisions when sourcing çe iir products, ensuring they partner with reliable suppliers that prioritize quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘çe iir’

This practical sourcing guide serves as a step-by-step checklist for international B2B buyers looking to procure ‘çe iir’. By following these actionable insights, you can streamline your sourcing process, ensuring that you find reliable suppliers while meeting your specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital to ensure that the ‘çe iir’ you are sourcing meets your operational requirements. This includes defining the dimensions, materials, quality standards, and any specific features essential for your business. Document these specifications comprehensively to communicate effectively with potential suppliers.

Step 2: Conduct Market Research

Understanding the market landscape is crucial for identifying the best suppliers. Investigate various regions that are known for producing ‘çe iir’, focusing on their market reputation and reliability. Utilize online platforms, industry reports, and trade publications to gather insights on pricing trends and supplier performance.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request detailed company profiles, including their history, client testimonials, and case studies from previous projects. It’s essential to verify that they have experience in your industry and can meet your unique requirements.

- Check References: Reach out to previous clients to gauge their satisfaction level and any challenges faced during the procurement process.

- Assess Financial Stability: Ensure the supplier has a solid financial background to mitigate risks associated with potential disruptions.

Step 4: Verify Supplier Certifications

Confirm that potential suppliers possess the necessary certifications and compliance with international quality standards. This is particularly important if you are sourcing from regions with varying regulatory practices. Certifications such as ISO or specific industry-related credentials can indicate a supplier’s commitment to quality and reliability.

Step 5: Request Samples for Testing

Before finalizing your order, request samples of the ‘çe iir’ to assess their quality firsthand. Testing samples can help you evaluate whether they meet your specifications and quality expectations. Ensure the samples are representative of the bulk order you plan to place.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, the next step is to negotiate favorable terms and conditions. Discuss pricing, payment terms, delivery schedules, and warranties. Establish clear expectations to avoid misunderstandings later on, and ensure that all agreements are documented in a formal contract.

Step 7: Plan Logistics and Shipping

Finally, coordinate logistics and shipping details to ensure timely delivery. Evaluate shipping options based on cost and reliability, and consider potential customs regulations that may apply. Developing a robust logistics plan will help you mitigate delays and ensure a smooth procurement process.

By following this comprehensive checklist, international B2B buyers can enhance their sourcing strategy for ‘çe iir’, ensuring they find reliable suppliers that meet their unique business needs.

Comprehensive Cost and Pricing Analysis for çe iir Sourcing

What Are the Key Cost Components for Sourcing çe iir?

When analyzing the cost structure of çe iir sourcing, several components play a crucial role in determining the final pricing. Understanding these elements is essential for international B2B buyers aiming to make informed decisions.

-

Materials: The choice of materials directly impacts the cost of çe iir. High-quality, durable materials might incur higher upfront costs but can lead to lower maintenance and replacement costs over time. Buyers should consider the long-term value versus initial investment.

-

Labor: Labor costs can vary significantly based on the country of manufacture. In regions like Turkey and Vietnam, labor costs are generally lower than in Europe, which can affect overall pricing. However, consider labor skill levels, as higher-skilled labor may result in better-quality products.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Understanding the manufacturing environment can help buyers gauge the efficiency and potential pricing of çe iir. Regions with advanced manufacturing capabilities may offer better quality assurance, influencing cost.

-

Tooling: Tooling costs can be substantial, especially for customized products. Buyers should inquire about the tooling requirements for their specific needs and assess whether these costs are amortized over larger production runs.

-

Quality Control (QC): Effective QC processes can add to the overall cost but are essential for ensuring product reliability. Invest in suppliers who prioritize QC, as this can save costs related to returns and defects in the long run.

-

Logistics: Shipping and handling costs can vary based on distance and the chosen Incoterms. Buyers should factor in not just the shipping fees but also potential tariffs, taxes, and delays associated with international logistics.

-

Margin: Supplier margins will vary based on market competition and supplier reputation. Understanding typical margins in the çe iir market can help buyers negotiate better pricing.

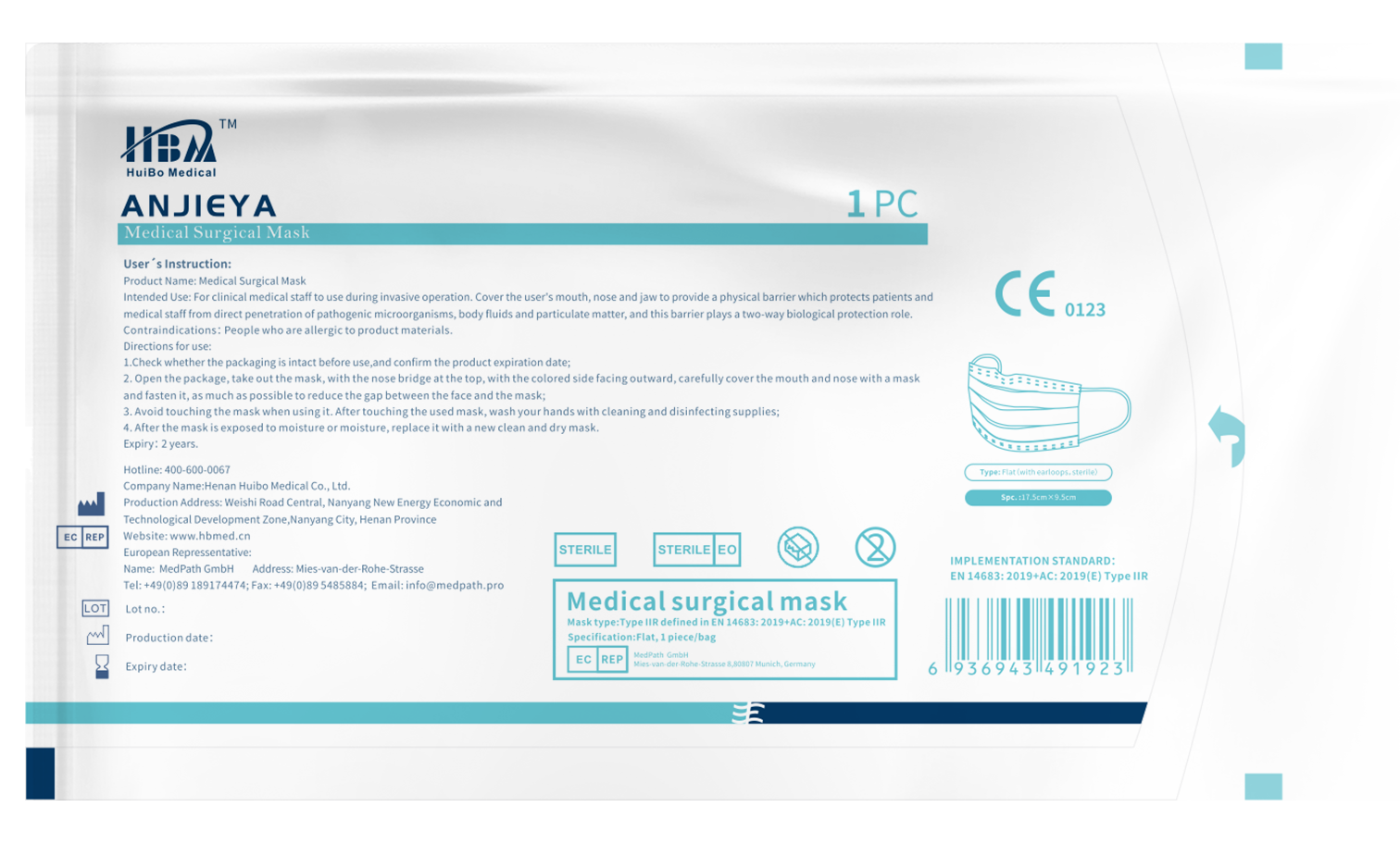

A stock image related to çe iir.

How Do Price Influencers Affect the Cost of çe iir?

Several factors can significantly influence the pricing of çe iir, particularly for international buyers.

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically lead to volume discounts. Buyers should negotiate MOQs to optimize pricing while ensuring they do not overcommit.

-

Specifications and Customization: Customized products often come with higher costs. Buyers should clearly define their specifications to avoid unexpected charges during production.

-

Material Quality and Certifications: Higher-quality materials and specific certifications (like ISO) can increase costs. Buyers must weigh the benefits of certification against potential price increases.

-

Supplier Factors: The reputation, experience, and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, but this often results in better service and product quality.

-

Incoterms: The choice of Incoterms affects the allocation of responsibilities and costs between the buyer and seller. Understanding these terms can help buyers manage logistics and avoid hidden costs.

What Buyer Tips Can Enhance Cost-Efficiency in çe iir Sourcing?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, implementing strategic practices can enhance cost-efficiency:

-

Negotiate Effectively: Leverage your buying power. Don’t hesitate to negotiate terms, prices, and payment conditions. Suppliers may be willing to adjust their pricing based on your potential for repeat business.

-

Consider Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the TCO, which includes all expenses related to procurement, usage, maintenance, and disposal. This approach can lead to better long-term decisions.

-

Understand Pricing Nuances: Different regions have distinct pricing practices and economic conditions. Familiarize yourself with these nuances to better navigate negotiations and supplier relationships.

-

Build Long-term Relationships: Cultivating strong relationships with suppliers can result in better pricing, priority service, and potential discounts on future orders.

Disclaimer on Indicative Prices

Prices for çe iir can fluctuate based on market conditions, supplier capabilities, and specific buyer requirements. It is advisable for buyers to obtain detailed quotes and perform due diligence to ensure they are receiving competitive and fair pricing.

Alternatives Analysis: Comparing çe iir With Other Solutions

When evaluating solutions in the international B2B landscape, particularly for buyers from regions like Africa, South America, the Middle East, and Europe, it’s essential to consider various alternatives to a product or method. This ensures that businesses can make informed decisions based on their specific needs, budget constraints, and operational requirements. Below, we compare ‘çe iir’ with two viable alternatives to help guide your decision-making process.

| Comparison Aspect | ‘Çe Iir’ | Alternative 1: Solution X | Alternative 2: Solution Y |

|---|---|---|---|

| Performance | High efficiency in data processing | Moderate efficiency, depends on configuration | High performance under heavy loads |

| Cost | Moderate initial investment, low ongoing costs | Low initial costs, higher maintenance expenses | High initial costs but scalable |

| Ease of Implementation | Requires specialized training | User-friendly, minimal training needed | Moderate complexity, requires some training |

| Maintenance | Low maintenance needs, updates included | Frequent maintenance required, vendor-dependent | Moderate maintenance, in-house support possible |

| Best Use Case | Ideal for large-scale data analysis | Best for small to medium enterprises | Suitable for enterprises with fluctuating demands |

What are the strengths and weaknesses of Solution X as an alternative to ‘çe iir’?

Solution X offers a user-friendly interface that is particularly appealing to small and medium enterprises. Its lower initial cost makes it accessible for businesses with limited budgets. However, its performance can fluctuate depending on configuration and usage, which may not be suitable for companies requiring consistent high-efficiency processing. Additionally, frequent maintenance is a downside, as it can lead to increased operational downtime.

How does Solution Y compare to ‘çe iir’ in terms of performance and cost?

Solution Y is designed for high-performance scenarios, making it an excellent choice for enterprises that handle large volumes of data or experience significant fluctuations in workload. While it comes with a higher initial investment, the scalability it offers can justify the cost for growing businesses. The maintenance requirements are moderate, and having in-house support can mitigate some vendor dependencies. However, organizations need to assess whether the upfront investment aligns with their budget and growth projections.

Conclusion: How should B2B buyers choose the right solution for their needs?

Selecting the right solution involves a careful analysis of your organization’s unique needs, existing infrastructure, and financial capacity. While ‘çe iir’ may offer high efficiency and low maintenance, alternatives like Solution X and Solution Y provide different advantages that might align better with specific business models. Consider conducting a thorough cost-benefit analysis and perhaps a pilot program to evaluate which solution meets your requirements in terms of performance, ease of use, and long-term viability. Ultimately, the right choice will depend on balancing immediate needs with future growth potential.

Essential Technical Properties and Trade Terminology for çe iir

What Are the Essential Technical Properties of çe iir for B2B Buyers?

Understanding the technical properties of çe iir is crucial for international B2B buyers, particularly when sourcing materials that meet specific performance and compliance standards. Here are some key specifications to consider:

1. Material Grade

Material grade refers to the classification of çe iir based on its composition and properties. Different grades can affect durability, flexibility, and resistance to environmental factors. For buyers, selecting the appropriate grade ensures that the material will perform adequately in its intended application, minimizing the risk of product failure and enhancing longevity.

2. Tolerance

Tolerance indicates the permissible limit of variation in the dimensions of çe iir products. In B2B transactions, precise tolerances are critical, especially in industries like automotive or aerospace, where even minor deviations can lead to significant operational issues. Understanding tolerance levels helps buyers ensure that the products fit seamlessly within their manufacturing processes.

3. Hardness

Hardness measures the resistance of çe iir to deformation or scratching. This property is essential for applications that require durability and wear resistance. Buyers should assess hardness ratings to ensure that the material can withstand the operational stresses it will face, which can lead to improved performance and reduced maintenance costs.

4. Thermal Stability

Thermal stability refers to the ability of çe iir to maintain its properties under varying temperature conditions. For buyers in regions with extreme climates, selecting materials with high thermal stability can prevent failures due to heat or cold. This property is particularly important in industries like construction and manufacturing, where environmental factors can significantly impact product integrity.

5. Chemical Resistance

Chemical resistance indicates how well çe iir can withstand exposure to various chemicals without deteriorating. For international buyers, especially in sectors such as agriculture and pharmaceuticals, understanding the chemical compatibility of çe iir is vital to ensure safety and efficacy in applications that involve corrosive substances.

What Trade Terminology Should B2B Buyers of çe iir Be Familiar With?

Navigating the complexities of international trade requires an understanding of specific terminology. Here are essential terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. For B2B buyers, engaging with OEMs can lead to cost-effective solutions and high-quality products that are tailored to specific requirements, making it an important term to understand when sourcing çe iir.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps B2B buyers manage inventory and cash flow effectively. By negotiating MOQs, buyers can optimize their purchasing strategy, ensuring they meet demand without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a formal process used by buyers to solicit price quotes from suppliers for specific products or services. For çe iir procurement, issuing an RFQ allows buyers to compare offers, ensuring they receive competitive pricing while maintaining quality standards. This process is essential for informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers as they clarify who bears the risks and costs at different stages of the shipping process. This knowledge helps in negotiating contracts and mitigating potential disputes.

5. Lead Time

Lead time refers to the time it takes from placing an order until the delivery of the goods. Understanding lead times for çe iir products is vital for supply chain planning. Buyers should account for lead times when scheduling production runs or project timelines to avoid delays and ensure timely delivery of their final products.

A stock image related to çe iir.

By familiarizing themselves with these technical properties and trade terminologies, B2B buyers can enhance their procurement strategies, ensuring they make informed decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the çe iir Sector

What Are the Current Market Dynamics and Key Trends in the çe iir Sector?

The çe iir sector is currently experiencing significant shifts driven by globalization, technological advancements, and changing consumer preferences. Key trends include the rise of digital platforms that facilitate B2B transactions, enhancing transparency and efficiency in sourcing processes. For international buyers from Africa, South America, the Middle East, and Europe, leveraging these platforms can streamline procurement and reduce costs.

Additionally, the ongoing emphasis on quality and traceability is reshaping supplier relationships. Buyers are increasingly seeking partners who can demonstrate compliance with international standards, ensuring that products meet both regulatory and market expectations. This trend is particularly relevant in regions like Turkey and Vietnam, where emerging manufacturers are keen to establish credibility in the global market.

Another important aspect is the growing demand for customization. Buyers are looking for suppliers who can adapt their offerings to local tastes and preferences, which necessitates a flexible and responsive sourcing strategy. As such, understanding local market conditions and cultural nuances becomes crucial for successful partnerships.

How Are Sustainability and Ethical Sourcing Changing the çe iir Sector?

A stock image related to çe iir.

Sustainability and ethical sourcing have become pivotal concerns in the çe iir sector, significantly impacting buyer decisions. The environmental impact of sourcing practices is under scrutiny, with many businesses striving to reduce their carbon footprint. International buyers must prioritize suppliers who adopt sustainable practices, such as using eco-friendly materials and minimizing waste throughout the production process.

Moreover, ethical supply chains are not just a regulatory requirement but also a competitive advantage. Certifications such as Fair Trade, ISO 14001, and other ‘green’ labels are increasingly sought after by buyers. These certifications assure consumers that the products they purchase are sourced responsibly, thereby enhancing brand loyalty and market appeal.

For buyers in Africa and South America, where local industries are often underdeveloped, partnering with suppliers committed to ethical sourcing can foster community development and create a positive brand image. As global consumers become more environmentally conscious, aligning with sustainable suppliers will not only meet regulatory demands but also resonate with end-users, enhancing the overall value proposition.

What Is the Brief Evolution of the çe iir Sector Relevant to B2B Buyers?

The çe iir sector has evolved significantly over the past few decades, transitioning from traditional, localized production methods to a more globalized approach. Initially, the industry was characterized by small-scale artisans and local suppliers. However, with the advent of technology and the internet, the sector witnessed the emergence of larger manufacturers capable of meeting international demand.

This evolution has allowed B2B buyers to access a wider range of products and suppliers, facilitating competitive pricing and innovation. As the industry matures, the focus has shifted towards quality, sustainability, and ethical practices, reflecting changing consumer values and expectations. Understanding this historical context helps buyers appreciate the importance of forging strategic partnerships that align with current trends and market dynamics.

Frequently Asked Questions (FAQs) for B2B Buyers of çe iir

-

How do I solve issues related to sourcing çe iir from international suppliers?

When sourcing çe iir, it’s crucial to conduct thorough market research to identify reputable suppliers. Utilize platforms like Alibaba or Global Sources to find manufacturers with positive reviews. Verify their credentials by requesting certifications and visiting their facilities if possible. Establish clear communication channels to address any concerns promptly. Additionally, consider working with local agents who understand the market dynamics in your region, whether it’s Africa, South America, the Middle East, or Europe. -

What is the best way to evaluate çe iir suppliers for quality assurance?

Evaluating suppliers for quality assurance requires a systematic approach. Begin by reviewing their quality management certifications, such as ISO 9001. Request samples of çe iir to assess quality firsthand. It’s also beneficial to look for suppliers with a history of compliance with international standards. Consider conducting a factory audit or hiring third-party inspection services to ensure adherence to quality benchmarks. This diligence can prevent potential issues down the line. -

What are the common payment terms when sourcing çe iir internationally?

Payment terms can vary significantly among suppliers. Common options include Letter of Credit (LC), advance payment, and net 30 or net 60 terms. It’s advisable to negotiate terms that minimize your risk, such as partial upfront payment and the remainder upon delivery. Ensure that the payment method is secure and widely accepted in your supplier’s country. Always have a clear agreement in writing to avoid misunderstandings regarding payment timelines and amounts. -

What is the minimum order quantity (MOQ) for çe iir, and how does it affect my sourcing strategy?

MOQs for çe iir can vary depending on the supplier and the type of product. Typically, manufacturers may set MOQs to cover production costs and ensure profitability. As an international buyer, understanding the MOQ is crucial for your sourcing strategy; it helps in budgeting and inventory management. If the MOQ is higher than your needs, discuss the possibility of negotiating smaller orders or consider partnering with other buyers to meet the MOQ collectively. -

How can I ensure timely logistics and delivery of çe iir?

To ensure timely logistics, establish a clear timeline with your supplier from the outset. Discuss shipping methods, lead times, and potential delays due to customs or other factors. Work with logistics companies experienced in international shipping to manage transportation effectively. Consider using Incoterms to clarify responsibilities for shipping and delivery. Regular follow-ups with your supplier can help keep the shipment on track and address any issues proactively. -

What customization options are typically available for çe iir?

Customization options for çe iir can include variations in size, color, materials, and branding. When discussing customization with suppliers, be specific about your requirements and ask for prototypes if possible. Understand that custom orders may involve additional costs and longer lead times. Always get a written agreement on the specifications and costs associated with the customization to avoid any surprises during production. -

How do I mitigate risks when sourcing çe iir from international suppliers?

Mitigating risks involves a multi-faceted approach. Start by conducting thorough due diligence on potential suppliers, including checking references and customer feedback. Utilize contracts that include clear terms regarding quality, delivery, and payment. Consider insuring your shipment and using escrow services to protect your payments. Staying informed about the political and economic conditions in your supplier’s country can also help you anticipate potential disruptions. -

What are the key considerations for compliance and regulatory requirements when importing çe iir?

Compliance with import regulations is critical for successful international trade. Research the specific regulations governing çe iir in your country, including tariffs, import licenses, and safety standards. Ensure that your supplier provides all necessary documentation, such as certificates of origin and conformity. It may be beneficial to consult with a customs broker to navigate the complexities of import compliance effectively and avoid costly penalties.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for çe iir

In today’s competitive global market, the importance of strategic sourcing for çe iir cannot be overstated. By leveraging effective sourcing strategies, international B2B buyers can enhance operational efficiency, reduce costs, and secure a reliable supply chain. It is crucial to assess potential suppliers not only on price but also on their ability to deliver quality and reliability, particularly in regions like Africa, South America, the Middle East, and Europe, where market dynamics can vary significantly.

What are the key benefits of strategic sourcing for international B2B buyers? First, it fosters long-term partnerships that can lead to better terms and conditions, which ultimately contributes to better margins. Additionally, understanding local regulations and market trends is vital in mitigating risks associated with sourcing from diverse regions.

Looking ahead, businesses should embrace technology and data analytics to refine their sourcing strategies, enabling them to adapt to changing market conditions swiftly. As you consider your sourcing decisions, remember that building a robust, sustainable supply chain is not just a necessity but a strategic advantage. Engage with local suppliers, explore innovative sourcing solutions, and position your business for success in the global marketplace. The future of sourcing is bright—are you ready to seize the opportunities?