Discover Cost-Efficient Fiets Stepper Solutions for 2025

Introduction: Navigating the Global Market for fiets stepper

In the rapidly evolving fitness equipment market, sourcing high-quality fiets steppers presents a unique challenge for international B2B buyers. As businesses aim to enhance employee wellness and productivity, understanding the diverse types and applications of fiets steppers becomes crucial. This guide serves as a comprehensive resource, detailing everything from product specifications and supplier vetting processes to cost considerations and market trends.

Navigating the global landscape can be daunting, particularly for buyers from regions such as Africa, South America, the Middle East, and Europe. With varying standards and consumer preferences, it is essential to identify reliable suppliers and products that meet specific regional demands. This guide empowers international B2B buyers by providing actionable insights and expert recommendations, enabling them to make informed purchasing decisions that align with their organizational goals.

Whether you’re looking to integrate fitness solutions into your office environment or seeking to expand your product offerings in the fitness sector, understanding the nuances of the fiets stepper market will enhance your competitive advantage. By leveraging the information presented in this guide, you will be well-equipped to navigate the complexities of sourcing, ensuring that your investments yield maximum returns in employee health and productivity.

Understanding fiets stepper Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Fiets Stepper | Basic design with adjustable resistance settings | Fitness centers, rehabilitation | Pros: Affordable, easy to use. Cons: Limited advanced features. |

| Recumbent Fiets Stepper | Reclined seating position, ergonomic design | Senior fitness programs, therapy | Pros: Comfortable for users with back issues. Cons: Larger footprint. |

| Commercial Fiets Stepper | Heavy-duty construction, multi-user capability | Gyms, corporate wellness programs | Pros: Durable, high capacity. Cons: Higher initial investment. |

| Compact Fiets Stepper | Space-saving design, lightweight, portable | Home offices, small gyms | Pros: Easy to store, transportable. Cons: May lack stability. |

| Smart Fiets Stepper | Integrated technology for tracking and connectivity | High-end fitness facilities | Pros: Data analytics, user engagement. Cons: Higher maintenance costs. |

What are the Characteristics of Standard Fiets Steppers?

Standard fiets steppers feature a straightforward design with adjustable resistance settings, making them suitable for a variety of users. They are commonly found in fitness centers and rehabilitation facilities due to their affordability and ease of use. When considering a purchase, B2B buyers should evaluate the durability and warranty options, ensuring that the equipment can withstand frequent use.

How Do Recumbent Fiets Steppers Differ in Design?

Recumbent fiets steppers are designed with a reclined seating position, providing ergonomic support that is ideal for users with back problems or those undergoing rehabilitation. This type of stepper is popular in senior fitness programs and therapy sessions. Buyers should assess the dimensions and stability of the unit, as well as the ease of access for various users.

What Makes Commercial Fiets Steppers a Good Investment?

Commercial fiets steppers are built with heavy-duty materials to accommodate multiple users in a high-traffic environment. They are ideal for gyms and corporate wellness programs, where durability and performance are crucial. Buyers should consider the total cost of ownership, including maintenance and repair services, as these units typically require a higher initial investment.

Why Choose Compact Fiets Steppers for Limited Spaces?

Compact fiets steppers are designed to be lightweight and space-saving, making them perfect for home offices or small gyms. Their portability allows for easy storage and transportation. However, potential buyers should be mindful of the stability and construction quality, as these factors can affect user experience.

How Do Smart Fiets Steppers Enhance User Experience?

Smart fiets steppers integrate technology for tracking performance and connecting to fitness apps, making them a popular choice in high-end fitness facilities. These steppers provide data analytics that can enhance user engagement and motivation. B2B buyers should weigh the benefits of technological features against the potential higher maintenance costs associated with smart equipment.

Related Video: The Genius Behind Bach’s Goldberg Variations: CANONS

Key Industrial Applications of fiets stepper

| Industry/Sector | Specific Application of fiets stepper | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fitness Equipment | Integration in commercial gyms | Enhances user experience and retention | Durability, ease of maintenance, and warranty terms |

| Rehabilitation | Used in physical therapy clinics | Supports patient recovery and mobility | Compliance with medical standards and ergonomic design |

| Hospitality | Fitness amenities in hotels | Increases guest satisfaction | Compact design, aesthetic appeal, and service support |

| Education | Fitness programs in schools | Promotes student health and wellness | Safety certifications and ease of use for students |

| Corporate Wellness | Employee fitness initiatives | Boosts employee productivity and morale | Customization options and integration with health programs |

How is the fiets stepper Used in the Fitness Equipment Industry?

In commercial gyms, the fiets stepper is often integrated as a key piece of equipment that promotes cardiovascular fitness. It provides users with a low-impact workout option, which is particularly appealing to those with joint concerns. For B2B buyers in this sector, sourcing durable models that require minimal maintenance is crucial. Additionally, warranties and service agreements can influence purchasing decisions, as they ensure long-term operational efficiency.

What Role Does the Fiets Stepper Play in Rehabilitation?

In physical therapy clinics, the fiets stepper serves as an essential tool for rehabilitation programs. It aids patients recovering from injuries by improving strength and mobility while minimizing the risk of further injury. International B2B buyers in the rehabilitation sector must consider compliance with medical standards and ergonomic designs to ensure patient safety and comfort. This focus on quality can significantly enhance the effectiveness of therapy sessions.

How Does the Fiets Stepper Enhance Hospitality Offerings?

Hotels that provide fitness amenities often incorporate the fiets stepper to enhance their guest experience. By offering a high-quality fitness option, hotels can attract health-conscious travelers, leading to increased guest satisfaction and loyalty. B2B buyers in this industry should prioritize sourcing models that are compact and aesthetically pleasing, as they need to fit seamlessly into varied hotel environments. Additionally, reliable service support is essential to maintain equipment functionality.

Why is the Fiets Stepper Important in Educational Settings?

Schools are increasingly recognizing the importance of physical health, leading to the inclusion of fitness equipment like the fiets stepper in their programs. This equipment promotes student wellness and encourages an active lifestyle, which can lead to improved academic performance. Buyers from educational institutions must ensure that the equipment meets safety certifications and is user-friendly for students of all ages, thereby facilitating a safe and engaging environment for physical activity.

How Can Corporate Wellness Programs Benefit from the Fiets Stepper?

Incorporating the fiets stepper into corporate wellness initiatives can significantly boost employee productivity and morale. By providing accessible fitness options, companies can encourage a healthier workforce, which often translates to reduced healthcare costs and improved employee retention. B2B buyers in this sector should look for customizable options that align with their corporate health goals, as well as integration capabilities with existing health programs to maximize impact.

Related Video: Control a Stepper Motor with Hall Effect Switches

3 Common User Pain Points for ‘fiets stepper’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Fiets Steppers from Reliable Suppliers

The Problem:

B2B buyers, particularly in emerging markets across Africa and South America, often struggle to find reliable suppliers for high-quality ‘fiets steppers’. This challenge is compounded by the lack of local manufacturers and the presence of numerous unverified international suppliers, leading to concerns about product quality, shipping delays, and after-sales service. Buyers may face situations where they receive subpar products that do not meet their specifications, causing financial losses and customer dissatisfaction.

The Solution:

To effectively source high-quality ‘fiets steppers’, buyers should start by conducting thorough research on potential suppliers. Utilize platforms like Alibaba, TradeIndia, or specialized B2B marketplaces that feature verified suppliers. Look for suppliers with positive reviews and a history of successful transactions. Request samples before placing bulk orders to assess product quality firsthand. Additionally, consider establishing a relationship with suppliers who offer transparent communication and comprehensive after-sales support. It’s also beneficial to attend industry trade shows and expos, where buyers can meet suppliers face-to-face, negotiate terms, and inspect products directly.

Scenario 2: Inadequate Product Customization Options for Target Markets

The Problem:

Many international buyers discover that off-the-shelf ‘fiets steppers’ do not cater to the specific needs and preferences of their local markets. For instance, buyers in the Middle East may require adaptations for extreme weather conditions, while European buyers might seek designs that align with local aesthetic preferences. This lack of customization can result in poor market fit and low sales.

The Solution:

Buyers should prioritize suppliers that offer customization options. Before initiating a partnership, inquire about the supplier’s ability to modify designs, materials, and features to meet local demands. Collaborate with product designers to create prototypes that reflect the needs of your target audience. Use market research to guide these customization efforts, ensuring that the final product resonates with local consumers. Establishing a feedback loop with end-users can also provide insights into necessary adjustments, helping to refine the product before a full market launch.

Scenario 3: Challenges in After-Sales Support and Maintenance Services

The Problem:

After-sales support is critical for maintaining customer satisfaction and loyalty, yet many B2B buyers encounter challenges in this area with ‘fiets steppers’. This is particularly true in regions like Africa and South America, where access to replacement parts and maintenance services can be limited. Buyers may find themselves unable to provide adequate support to their customers, leading to increased frustration and potential loss of business.

The Solution:

To mitigate these challenges, buyers should select suppliers who have robust after-sales support systems in place. This includes ensuring the availability of replacement parts and technical assistance. Establish clear service level agreements (SLAs) that outline the expected response times and support services. Additionally, consider forming partnerships with local service providers who can offer maintenance and repair services. This can enhance customer satisfaction and retention. Investing in training programs for your staff on product maintenance can also empower your team to handle basic issues, reducing reliance on external support and improving overall customer experience.

Strategic Material Selection Guide for fiets stepper

When selecting materials for the fiets stepper, it is essential to consider the specific properties and performance requirements that will meet the needs of international B2B buyers. Below, we analyze four common materials used in the construction of fiets steppers, focusing on their key properties, advantages, disadvantages, and implications for buyers in diverse markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Aluminum for Fiets Steppers?

Aluminum is a lightweight and corrosion-resistant metal, making it a popular choice for fiets steppers. Its excellent strength-to-weight ratio allows for easy maneuverability without compromising structural integrity. Aluminum can withstand moderate temperatures and pressures, making it suitable for various environments.

Pros and Cons:

– Pros: Lightweight, good corrosion resistance, and easy to machine.

– Cons: Lower strength compared to steel, can be more expensive, and may require protective coatings for enhanced durability.

Impact on Application:

Aluminum is compatible with various media, including water and oils, but it may not be suitable for highly corrosive environments without proper treatment.

Considerations for International Buyers:

Buyers should consider compliance with international standards such as ASTM and DIN. In regions with high humidity or saline environments, additional protective measures may be necessary to prevent corrosion.

How Does Steel Compare in Terms of Performance for Fiets Steppers?

Steel is known for its exceptional strength and durability, making it a preferred material for high-stress applications. It can withstand high temperatures and pressures, which is crucial for components that experience significant wear and tear.

Pros and Cons:

– Pros: High strength, excellent durability, and cost-effective.

– Cons: Heavier than aluminum, susceptible to rust if not treated, and requires more complex manufacturing processes.

Impact on Application:

Steel is compatible with a wide range of media, including fuels and lubricants. However, it may require protective coatings or treatments in corrosive environments.

Considerations for International Buyers:

Buyers in regions with stringent regulations should ensure that the steel used meets local standards. For example, European buyers may prefer materials that comply with EN standards, while South American buyers may look for compliance with local regulations.

What Are the Benefits of Using Composite Materials in Fiets Steppers?

Composite materials, such as fiberglass or carbon fiber, are increasingly used in the manufacturing of fiets steppers due to their lightweight and high strength. These materials offer excellent corrosion resistance and can be tailored to specific performance requirements.

Pros and Cons:

– Pros: Lightweight, high strength, and excellent corrosion resistance.

– Cons: Higher manufacturing costs and complexity, limited repairability, and potential for delamination under extreme conditions.

Impact on Application:

Composite materials are suitable for various media, but their compatibility should be verified, especially in chemical applications.

Considerations for International Buyers:

Buyers should be aware of the specific certifications required for composite materials in their region. For instance, compliance with ISO standards may be necessary for certain applications in Europe.

Why Is Plastic a Viable Option for Fiets Steppers?

Plastics, particularly engineering plastics like nylon and polypropylene, are often used in fiets steppers for non-structural components. They provide good chemical resistance and are lightweight.

Pros and Cons:

– Pros: Lightweight, good chemical resistance, and low cost.

– Cons: Limited strength compared to metals, lower temperature resistance, and potential for wear over time.

Impact on Application:

Plastics are suitable for applications where weight savings and corrosion resistance are critical, but they may not withstand high loads or temperatures.

Considerations for International Buyers:

Buyers should ensure that the plastics used comply with relevant standards in their region, such as REACH in Europe, which governs the use of chemicals.

Summary Table of Material Selection for Fiets Steppers

| Material | Typical Use Case for fiets stepper | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Frame and structural components | Lightweight and corrosion-resistant | Lower strength than steel | Medium |

| Steel | High-stress components | High strength and durability | Heavier, susceptible to rust | Low |

| Composite | Lightweight parts and casings | High strength-to-weight ratio | Higher cost and complexity | High |

| Plastic | Non-structural components | Good chemical resistance | Limited strength and wear | Low |

This guide provides actionable insights for international B2B buyers, emphasizing the importance of material selection based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for fiets stepper

What Are the Key Manufacturing Processes for Fiets Steppers?

Manufacturing a fiets stepper involves several critical stages that ensure the final product meets quality and performance expectations. Understanding these stages can help international B2B buyers assess potential suppliers effectively.

How Does Material Preparation Impact Quality?

The first stage in the manufacturing process is material preparation. This involves selecting high-quality materials such as steel or aluminum for the frame, durable plastics for parts, and rubber for pedals. Suppliers often use advanced techniques like laser cutting and CNC machining to ensure precision in material dimensions. B2B buyers should inquire about the material sourcing practices of their suppliers to ensure they are using certified materials that meet international standards.

What Forming Techniques Are Commonly Used?

Once the materials are prepared, the next step is forming. Techniques such as stamping, bending, and welding are frequently employed to shape the components of the fiets stepper. For instance, the frame is typically welded together using MIG or TIG welding methods, which provide strong and durable joints. B2B buyers should ask about the specific forming techniques used and whether they comply with industry standards, as this directly impacts the structural integrity and longevity of the product.

How Is Assembly Conducted in the Manufacturing Process?

The assembly phase combines all the components into a finished product. This process often includes attaching the handlebars, pedals, and display systems. Automated assembly lines may be used for efficiency, but many manufacturers still employ skilled labor for critical assembly tasks to ensure quality control. Buyers should request information on the assembly processes, including any certifications or training that assembly staff receive, to ensure that the product is put together correctly and reliably.

What Finishing Processes Enhance the Product’s Durability?

Finishing processes such as painting, powder coating, and anodizing are vital for both aesthetic appeal and protection against corrosion. These processes not only enhance the visual aspects of the fiets stepper but also increase its durability, especially in varying climates. B2B buyers should confirm the types of finishing processes used by suppliers and whether they adhere to environmental regulations, as this can affect product quality and sustainability.

How Is Quality Assurance Implemented in Fiets Stepper Manufacturing?

Quality assurance is essential for ensuring that each fiets stepper meets the required standards before it reaches the market. This involves several checkpoints throughout the manufacturing process.

What International Standards Should Buyers Be Aware Of?

International standards such as ISO 9001 play a crucial role in quality management systems. Compliance with these standards indicates that a supplier has established processes for continuous improvement and customer satisfaction. Additionally, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) for certain mechanical components may also apply. Buyers should ensure that potential suppliers can provide documentation of these certifications as part of their quality assurance processes.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically broken down into several checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC involves inspecting raw materials and components upon arrival to ensure they meet specifications.

- IPQC focuses on monitoring the manufacturing processes to detect any issues early, thereby minimizing defects.

- FQC is the final inspection before products are shipped, ensuring that all items meet the established quality standards.

B2B buyers should inquire about the specific QC practices employed by suppliers and request access to inspection reports.

How Can B2B Buyers Verify Supplier Quality Control?

To verify the quality control measures of potential suppliers, buyers can take several steps:

- Conduct Supplier Audits: Regular audits help assess compliance with quality standards and can reveal insights into the supplier’s manufacturing processes.

- Request Quality Reports: Suppliers should provide documentation of their quality control processes, including any test results and inspection records.

- Engage Third-party Inspection Services: Utilizing third-party services can provide an unbiased assessment of the supplier’s quality control measures and product quality.

What Testing Methods Are Common in Fiets Stepper Manufacturing?

Various testing methods are employed to ensure the durability and safety of fiets steppers. Common methods include:

- Load Testing: Verifying that the structure can withstand specified weight limits.

- Fatigue Testing: Assessing the long-term durability of the materials and construction.

- Safety Testing: Ensuring that all components meet safety regulations and standards.

B2B buyers should inquire about the specific testing methods used by suppliers and request access to test results to ensure compliance with safety and quality standards.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers, especially from diverse regions like Africa, South America, the Middle East, and Europe, B2B buyers should be aware of specific nuances:

- Cultural Differences in Quality Standards: Different regions may have varying interpretations of quality and compliance, making it essential to clarify expectations upfront.

- Regulatory Compliance: Understanding local and international regulations is crucial, especially when importing goods. Buyers should ensure that suppliers are compliant with both local laws and international standards.

- Communication Barriers: Language and time zone differences can complicate communication. Establishing clear channels and regular updates can help mitigate these issues.

By understanding these manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions when sourcing fiets steppers, ensuring they partner with reliable suppliers that meet their quality and compliance needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fiets stepper’

In the competitive landscape of B2B procurement, acquiring the right fiets stepper can significantly impact your business’s operational efficiency and product offering. This step-by-step sourcing guide will help international buyers navigate the complexities of procurement and ensure they make informed decisions when sourcing this equipment.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for effective sourcing. Consider the intended use of the fiets stepper, such as commercial fitness centers or personal use. Key specifications may include dimensions, weight capacity, materials, and resistance levels.

– Example Specifications: Determine if you need a heavy-duty model for commercial use or a more lightweight option for home use.

Step 2: Research Potential Suppliers

Thorough research on potential suppliers is essential to avoid future complications. Look for suppliers with a proven track record in manufacturing and distributing fiets steppers. Use platforms like Alibaba or industry-specific directories to compile a list of potential vendors.

– Supplier Evaluation: Check for reviews, ratings, and any complaints about the suppliers’ products and customer service.

Step 3: Verify Supplier Certifications

Before finalizing a supplier, ensure they hold relevant certifications. Certifications such as ISO or CE indicate adherence to quality and safety standards, which is especially important in the fitness equipment industry.

– Importance of Certifications: These credentials not only assure product quality but also enhance your credibility when selling to end-users.

Step 4: Request Samples for Testing

Requesting product samples allows you to evaluate the quality and performance of the fiets stepper firsthand. Conduct thorough testing to ensure the product meets your specifications and quality standards.

– Testing Parameters: Assess aspects such as durability, ease of use, and user comfort during your evaluation.

Step 5: Negotiate Pricing and Terms

Negotiating favorable pricing and terms can significantly impact your bottom line. Engage with suppliers to discuss bulk order discounts, payment terms, and delivery schedules.

– Price Comparison: Don’t hesitate to compare offers from multiple suppliers to ensure you get the best deal without compromising on quality.

Step 6: Review Shipping and Import Regulations

Understanding shipping and import regulations is vital, especially for international transactions. Familiarize yourself with tariffs, customs duties, and import restrictions that may apply to your order.

– Regulatory Compliance: Ensure that the supplier is compliant with the importing country’s regulations to avoid delays and additional costs.

Step 7: Establish a Strong Communication Channel

Maintaining clear and open communication with your supplier is essential for a successful partnership. Discuss your expectations and establish regular check-ins to address any concerns that may arise during the sourcing process.

– Effective Communication: Utilize tools like email, video calls, or dedicated project management software to keep all stakeholders informed and engaged.

By following this checklist, B2B buyers can streamline their procurement process for fiets steppers, ensuring they make informed decisions that align with their business goals.

Comprehensive Cost and Pricing Analysis for fiets stepper Sourcing

What Are the Key Cost Components in Fiets Stepper Sourcing?

When sourcing fiets steppers, understanding the cost structure is crucial for effective budgeting and pricing strategy. The primary components of the cost structure include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality metals, plastics, and electronic components may raise the price, while lower-cost alternatives can reduce it. Buyers should weigh the cost against the durability and performance of the materials selected.

-

Labor: Labor costs can vary depending on the manufacturing location. Regions with higher labor costs, such as parts of Europe, may lead to increased prices. Conversely, sourcing from countries with lower labor costs, such as in parts of Africa or South America, can provide savings.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses related to the production facility. A manufacturer with advanced technology may have lower overhead due to increased efficiency, influencing the overall pricing.

-

Tooling: Custom tooling can be a significant upfront investment, especially for bespoke designs. Buyers should consider whether the tooling cost will be amortized over a large production run to minimize the impact on unit price.

-

Quality Control (QC): Ensuring that each fiets stepper meets quality standards involves costs associated with inspection and testing. Higher QC standards may increase costs but can lead to better product reliability and customer satisfaction.

-

Logistics: Shipping costs, including freight and insurance, are vital to consider, particularly for international buyers. The choice of Incoterms can significantly affect the final price, as they define the responsibilities of buyers and sellers in shipping.

-

Margin: Suppliers will typically add a profit margin to cover their costs and risks. Understanding typical margins in the fiets stepper market can help buyers gauge whether they are being offered a competitive price.

How Do Price Influencers Affect Fiets Stepper Sourcing?

Several factors can influence the pricing of fiets steppers, making it essential for buyers to understand their implications:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower unit prices. Buyers should negotiate MOQs that balance their needs with cost efficiencies.

-

Specifications and Customization: Customized designs or specific features may incur additional costs. Buyers should clearly communicate their specifications to avoid unexpected price increases.

-

Material Choices: Opting for premium materials can elevate costs but may enhance the product’s longevity and performance. Buyers must evaluate the trade-off between initial price and long-term value.

-

Quality Certifications: Products certified by recognized quality standards (e.g., ISO, CE) may command higher prices due to the associated production costs. Buyers should assess whether such certifications are necessary for their market.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can influence pricing. Engaging with well-established suppliers may offer better quality assurance but at a premium.

-

Incoterms: Understanding Incoterms is crucial for international sourcing. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) determine who bears the shipping costs and risks, impacting the total cost of ownership.

What Are the Best Buyer Tips for Cost-Efficient Fiets Stepper Sourcing?

International B2B buyers should adopt strategic approaches to optimize their sourcing processes:

-

Negotiate Effectively: Building a relationship with suppliers can facilitate better terms. Leverage volume orders or long-term contracts to negotiate discounts or favorable payment terms.

-

Focus on Total Cost of Ownership (TCO): Evaluate the TCO rather than just the upfront price. Consider factors such as maintenance, warranty, and potential replacement costs to make informed purchasing decisions.

-

Understand Pricing Nuances: Prices can vary significantly based on geography, economic conditions, and currency fluctuations. Stay informed about market trends in the supplier’s region to better assess pricing strategies.

-

Conduct Market Research: Research multiple suppliers to compare prices and terms. Understanding market standards can empower buyers during negotiations and help identify fair pricing.

-

Consider Local Regulations and Tariffs: Import duties and local regulations can impact the final cost. Buyers should be aware of these factors to avoid unexpected expenses.

By focusing on these areas, international buyers can navigate the complexities of fiets stepper sourcing, ensuring they make informed and cost-effective purchasing decisions.

Alternatives Analysis: Comparing fiets stepper With Other Solutions

Introduction: Why Consider Alternatives to the Fiets Stepper?

When evaluating the fiets stepper, it is essential to consider viable alternatives that may better suit specific operational needs, budget constraints, or performance expectations. The right choice can significantly impact overall efficiency, employee satisfaction, and return on investment (ROI). In this section, we will compare the fiets stepper with two alternative solutions: the traditional exercise bike and the treadmill desk. Each option has its unique advantages and drawbacks that can influence the decision-making process for international B2B buyers.

Comparison Table: Fiets Stepper vs. Alternatives

| Comparison Aspect | Fiets Stepper | Traditional Exercise Bike | Treadmill Desk |

|---|---|---|---|

| Performance | Moderate cardio workout, engages lower body | High-intensity cardio, adjustable resistance | Low-impact, continuous walking |

| Cost | Mid-range pricing | Affordable to mid-range | Higher initial investment |

| Ease of Implementation | Simple assembly, minimal space required | Easy to set up, requires more space than fiets | Requires more space, setup complexity |

| Maintenance | Low maintenance needs | Moderate maintenance (e.g., belt replacement) | Regular maintenance for motor and belt |

| Best Use Case | Offices focusing on lower body fitness | Fitness centers, homes, commercial gyms | Remote work environments, active offices |

What Are the Pros and Cons of Traditional Exercise Bikes?

Traditional exercise bikes are a well-known alternative that provides a robust cardiovascular workout.

Pros:

– High-Intensity Options: They offer adjustable resistance levels, making them suitable for users seeking high-intensity workouts.

– Space Efficiency: While they require some floor space, many models are designed to be compact and foldable.

Cons:

– Single Muscle Focus: Primarily engage the lower body, potentially leading to muscle imbalance if not complemented by other exercises.

– User Fatigue: Intense workouts can lead to user fatigue, which may limit the duration of use, especially in an office setting.

How Does the Treadmill Desk Compare?

The treadmill desk combines a traditional desk with a treadmill, allowing users to walk while working, promoting a more active lifestyle.

Pros:

– Increased Activity Levels: Users can maintain a steady level of activity throughout the workday, combating sedentary behavior.

– Improved Focus: Walking while working may enhance cognitive function and creativity, benefiting overall productivity.

Cons:

– Higher Cost: Treadmill desks often come with a higher price tag compared to both the fiets stepper and exercise bikes.

– Space Requirements: They require more space and may not be suitable for smaller office environments.

– Adjustment Period: Users may need time to adapt to walking and working simultaneously, which can affect initial productivity.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the ideal solution among the fiets stepper, traditional exercise bike, or treadmill desk ultimately hinges on the specific needs of your organization. If promoting lower body fitness in a compact space is a priority, the fiets stepper may be the best option. Conversely, if high-intensity workouts and varied resistance are essential, a traditional exercise bike could be more appropriate. For organizations focused on enhancing overall activity levels in a remote work environment, a treadmill desk may be the most effective investment. Consider your workforce’s preferences, available space, and budget to make an informed decision that aligns with your business objectives.

Essential Technical Properties and Trade Terminology for fiets stepper

What Are the Essential Technical Properties of a Fiets Stepper?

When considering the procurement of a fiets stepper, understanding its technical properties is vital. Here are some key specifications that international B2B buyers should be aware of:

1. Material Grade

The material grade of a fiets stepper significantly affects its durability and performance. Common materials include high-grade steel, aluminum, or composite materials. High-grade steel offers strength and longevity, while aluminum is lightweight and corrosion-resistant. Buyers should evaluate the intended use environment to select the appropriate material, as this can influence maintenance costs and lifespan.

2. Weight Capacity

Weight capacity is a critical specification that determines the maximum user weight the fiets stepper can support. Typically, this ranges from 100 kg to 200 kg. This property is essential not only for safety but also for ensuring that the equipment meets the needs of various users, particularly in commercial settings such as gyms or rehabilitation centers.

3. Tolerance Levels

Tolerance levels indicate the acceptable limits of variation in the fiets stepper’s dimensions and performance. Tight tolerances ensure precision in the stepper’s operation, which can improve user experience and safety. Buyers should pay attention to these specifications, especially when sourcing from different manufacturers, as they can impact the performance consistency of the equipment.

4. Resistance Mechanism

The resistance mechanism, whether magnetic, mechanical, or air-based, plays a crucial role in the user experience. Magnetic resistance is often preferred for its quiet operation and smooth transitions. Understanding the resistance mechanism allows buyers to select equipment that aligns with user preferences and training goals.

5. Dimensions and Footprint

The overall dimensions and footprint of the fiets stepper are important for space planning, particularly in commercial environments. Compact models may be necessary for smaller facilities, while larger models might be suitable for dedicated fitness spaces. Buyers should assess the available space before making a purchase to ensure proper fit and functionality.

What Common Trade Terminology Should B2B Buyers Know?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are several essential terms related to the procurement of fiets steppers:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reputable suppliers and assess the quality of components used in the fiets stepper.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell in a single order. For international buyers, knowing the MOQ can help in budgeting and inventory planning. It is essential to negotiate MOQs that align with your purchasing power and demand forecast.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers asking for pricing and terms for specific products or services. This document is crucial for B2B buyers as it helps in comparing offers and ensuring competitive pricing. A well-structured RFQ can lead to more favorable terms.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is essential for avoiding misunderstandings and ensuring that all parties are clear on their obligations during shipping and delivery.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. For B2B buyers, understanding lead times is crucial for inventory management and meeting customer demand. It is advisable to factor in lead times when planning purchases to ensure timely availability of the equipment.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, streamline their procurement processes, and foster successful supplier relationships in the fiets stepper market.

Navigating Market Dynamics and Sourcing Trends in the fiets stepper Sector

What Are the Key Trends Driving the Fiets Stepper Market?

The fiets stepper sector is experiencing significant growth driven by several global factors. Firstly, the increasing focus on health and fitness, particularly post-pandemic, has led to heightened demand for versatile exercise equipment. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are prioritizing innovative fitness solutions that cater to diverse markets. Emerging technologies such as smart fitness equipment, which integrates apps and IoT capabilities, are reshaping sourcing strategies, allowing buyers to meet consumer demands more efficiently.

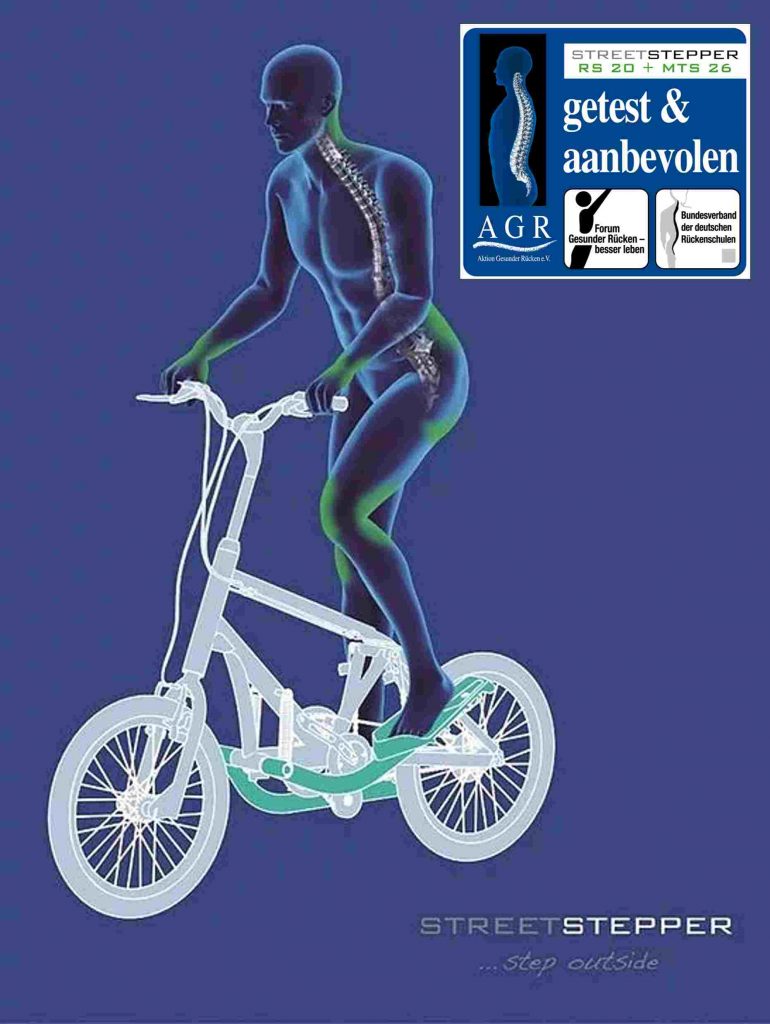

A stock image related to fiets stepper.

Another important trend is the rise of e-commerce platforms, facilitating easier access to suppliers and products. This shift is particularly beneficial for buyers in developing regions, where traditional retail options may be limited. Buyers are increasingly leveraging digital tools to compare products, assess supplier credibility, and streamline procurement processes, which enhances operational efficiency.

A stock image related to fiets stepper.

Moreover, sustainability is becoming a central concern in the sourcing process. As consumers become more environmentally conscious, international buyers are seeking suppliers who demonstrate a commitment to eco-friendly practices. This trend is leading to a surge in demand for sustainable materials and production methods within the fiets stepper market.

How Are Sustainability and Ethical Sourcing Impacting the Fiets Stepper Sector?

The environmental impact of manufacturing processes in the fiets stepper industry has garnered significant attention. B2B buyers are now prioritizing ethical sourcing as a critical criterion in their purchasing decisions. This shift is not just a response to regulatory pressures but also aligns with consumer expectations for sustainability. Buyers are increasingly looking for suppliers who use renewable resources, reduce waste, and implement energy-efficient production methods.

A stock image related to fiets stepper.

In addition, the demand for ‘green’ certifications is on the rise. Certifications such as ISO 14001 and LEED are becoming essential for suppliers seeking to establish credibility in the market. These certifications not only validate a company’s commitment to environmental stewardship but also enhance their marketability to international buyers who prioritize sustainability.

Moreover, the integration of recyclable materials in the manufacturing of fiets steppers is becoming a standard practice. Suppliers who invest in sustainable materials not only contribute to reducing the carbon footprint but also attract a growing segment of environmentally conscious consumers. For B2B buyers, partnering with such suppliers can enhance their brand reputation and align with their corporate social responsibility goals.

What Is the Historical Context of the Fiets Stepper Market?

The fiets stepper, a hybrid between traditional cycling and stepping exercises, has evolved significantly since its inception. Originally designed as a niche fitness tool, it has transitioned into a mainstream product, particularly in Europe where cycling is a prevalent mode of transportation. Over the years, advancements in design and technology have improved its functionality and appeal, making it a popular choice for both home and commercial gyms.

The market has seen a shift from basic models to sophisticated machines equipped with digital interfaces and connectivity features. This evolution is largely driven by technological advancements and a growing awareness of fitness, particularly in urban areas. As a result, the fiets stepper has not only gained traction in fitness centers but also in residential settings, reflecting a broader trend toward personalized fitness solutions. This historical context provides international B2B buyers with insights into market maturity and growth potential, guiding their sourcing strategies effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of fiets stepper

-

1. How do I ensure the quality of fiets steppers from international suppliers?

To ensure the quality of fiets steppers, start by vetting potential suppliers thoroughly. Request certifications, product samples, and references from previous clients. Conduct factory audits, if possible, to assess manufacturing practices and quality control measures. Additionally, consider using third-party inspection services to conduct quality checks before shipment. Establish clear quality expectations in your purchase agreements to hold suppliers accountable. -

2. What is the best customization option for fiets steppers to meet my business needs?

The best customization options for fiets steppers depend on your specific market demands and customer preferences. Work closely with manufacturers to discuss available features such as adjustable resistance, ergonomic designs, or unique branding elements. Ensure that the customization aligns with your target audience’s needs, whether for fitness centers, rehabilitation clinics, or home use. A well-defined customization request can enhance your competitive advantage in the market. -

3. What are the typical minimum order quantities (MOQ) for fiets steppers?

Minimum order quantities (MOQ) for fiets steppers can vary widely depending on the manufacturer and the specific model. Generally, MOQs may range from 50 to 500 units. Discuss your requirements with suppliers to negotiate favorable terms, especially if you are a new buyer. Some manufacturers may offer lower MOQs for first orders or for standard models, while custom designs may require higher quantities. -

4. What payment terms should I expect when sourcing fiets steppers internationally?

Payment terms can vary significantly among suppliers. Common practices include a 30% deposit upon order confirmation, with the remaining balance due before shipment. However, some suppliers may offer flexible terms such as net 30 or net 60 days, especially for established relationships. Always clarify payment methods accepted, such as letters of credit, bank transfers, or escrow services, to protect your investment. -

5. How do I handle logistics and shipping for fiets steppers across borders?

Handling logistics for international shipping of fiets steppers involves careful planning. Choose a reliable freight forwarder who can navigate customs regulations and provide shipping options that balance cost and delivery time. Consider using Incoterms (International Commercial Terms) to define responsibilities between you and the supplier regarding shipping, insurance, and customs duties. Always factor in lead times, especially during peak shipping seasons. -

6. What should I include in a supplier agreement for fiets steppers?

A comprehensive supplier agreement for fiets steppers should include key elements such as product specifications, pricing, delivery schedules, payment terms, and quality assurance measures. Specify penalties for delays or non-compliance and outline procedures for resolving disputes. Including clauses on intellectual property rights and confidentiality can also protect your business interests. -

7. How can I assess the reliability of a fiets stepper supplier?

To assess the reliability of a fiets stepper supplier, start by reviewing their business history, including years in operation and customer reviews. Look for certifications that demonstrate adherence to international quality standards. Request references and follow up with previous clients to understand their experiences. Additionally, consider visiting the supplier’s facility if feasible, or using third-party audits to validate their operations. -

8. What are the emerging trends in the fiets stepper market that I should be aware of?

Emerging trends in the fiets stepper market include increased demand for smart fitness equipment that integrates with mobile apps and tracks user performance. Sustainability is also becoming a focal point, with manufacturers exploring eco-friendly materials and production processes. Consider these trends when sourcing fiets steppers to align your offerings with market demands and enhance your competitive edge.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for fiets stepper

In the rapidly evolving landscape of the fitness industry, particularly for products like the fiets stepper, strategic sourcing has emerged as a critical component for international B2B buyers. By embracing a strategic sourcing approach, businesses can enhance their supply chain efficiency, ensure quality, and mitigate risks associated with cross-border transactions. This is particularly vital for buyers in regions such as Africa, South America, the Middle East, and Europe, where market dynamics and consumer preferences may differ significantly.

How Can International Buyers Leverage Strategic Sourcing?

Buyers should prioritize building strong relationships with reliable suppliers who understand local market conditions and can provide timely insights. Additionally, investing in technology to streamline procurement processes can lead to significant cost savings and improved product availability. Engaging in market research to identify trends and consumer demands is equally essential for tailoring offerings that resonate with local audiences.

What is the Future Outlook for the Fiets Stepper Market?

As the global demand for innovative fitness solutions continues to rise, the outlook for the fiets stepper remains promising. International B2B buyers are encouraged to stay ahead of the curve by actively exploring new partnerships and adopting sustainable sourcing practices. By doing so, businesses can not only enhance their competitive edge but also contribute positively to the evolving fitness landscape.

Now is the time to act; the opportunities in the fiets stepper market are ripe for those willing to invest in strategic sourcing and collaboration.