Discover Cost-Saving Benefits of Flue Pipe Solutions (2025)

Introduction: Navigating the Global Market for flue pipe

Navigating the complexities of sourcing flue pipes can present significant challenges for international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. With varying regulations, material specifications, and market dynamics, making informed purchasing decisions is crucial for ensuring compliance and operational efficiency. This guide serves as a comprehensive resource, covering everything from the different types of flue pipes available and their applications to effective supplier vetting processes and cost considerations.

By delving into the nuances of the flue pipe market, this guide empowers buyers to understand key factors that influence their procurement strategies. Whether you are looking for stainless steel, aluminum, or flexible flue systems, having a clear grasp of material properties and their suitability for specific applications will enhance your decision-making process. Furthermore, we will explore the importance of identifying reputable suppliers, conducting thorough due diligence, and negotiating favorable terms to secure the best value for your investment.

This guide is tailored to equip international B2B buyers with actionable insights that not only streamline the sourcing process but also foster long-term partnerships with reliable suppliers. By addressing the unique needs of buyers across diverse markets, we aim to facilitate a smoother entry into the global flue pipe market, ultimately contributing to your business’s growth and sustainability.

Understanding flue pipe Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single Wall Flue Pipe | Lightweight, economical, and easy to install | Residential heating and small boilers | Pros: Cost-effective, easy installation. Cons: Less durable, limited insulation. |

| Double Wall Flue Pipe | Insulated design, higher temperature resistance | Industrial boilers, commercial kitchens | Pros: Enhanced safety, better insulation. Cons: Higher initial cost, requires more space. |

| Flexible Flue Pipe | Made from flexible materials, adaptable to various layouts | Tight spaces, retrofitting projects | Pros: Versatile, easy to install in complex configurations. Cons: Less rigid, potential for damage. |

| Multi-fuel Flue Pipe | Designed for multiple fuel types, such as wood and gas | Biomass heating systems, mixed fuel setups | Pros: Versatile fuel options, cost savings. Cons: More complex installation, may require specific fittings. |

| Stainless Steel Flue Pipe | Corrosion-resistant, high durability, and aesthetic appeal | High-efficiency appliances, marine applications | Pros: Long lifespan, low maintenance. Cons: Higher cost, may require professional installation. |

What Are the Characteristics of Single Wall Flue Pipes?

Single wall flue pipes are characterized by their lightweight and economical design, making them a popular choice for residential heating applications and small boilers. They are easy to install, which can significantly reduce labor costs for B2B buyers. However, they offer limited insulation and durability, which can be a concern for long-term applications. Buyers should consider the operational environment and whether the cost savings on installation outweigh potential replacements or repairs in the future.

How Do Double Wall Flue Pipes Enhance Safety?

Double wall flue pipes are designed with an insulated structure that allows them to withstand higher temperatures, making them ideal for industrial boilers and commercial kitchens. Their enhanced safety features reduce the risk of fire hazards, which is crucial for businesses operating in compliance-heavy industries. While the initial investment is higher than single wall options, the long-term benefits of safety and efficiency can justify the cost. B2B buyers should evaluate their specific operational needs and regulatory requirements when considering double wall flue pipes.

In What Situations Are Flexible Flue Pipes Most Suitable?

Flexible flue pipes are made from adaptable materials, which allow for installation in tight or complex spaces. This makes them particularly useful in retrofitting projects where existing structures may limit traditional installation methods. They provide a versatile solution, but their flexibility can also make them susceptible to damage if not handled properly. B2B buyers should assess the layout of their facilities and the potential for future modifications when considering flexible flue options.

What Advantages Do Multi-fuel Flue Pipes Offer?

Multi-fuel flue pipes are designed to accommodate various fuel types, including wood, gas, and biomass. This versatility allows businesses to adapt their heating systems to changing energy prices or availability, potentially leading to significant cost savings. However, the installation of multi-fuel systems can be more complex and may require specialized fittings. B2B buyers should carefully consider their fuel sources and operational flexibility when investing in multi-fuel flue pipes.

Why Choose Stainless Steel Flue Pipes for Durability?

Stainless steel flue pipes are renowned for their corrosion resistance and high durability, making them suitable for high-efficiency appliances and marine applications. Their aesthetic appeal and low maintenance requirements are additional advantages for businesses looking to maintain a professional appearance while ensuring functionality. Although the upfront cost is higher, the longevity and reduced need for maintenance can make stainless steel a sound investment for B2B buyers. Evaluating the total cost of ownership is essential when considering this option.

Related Video: PVC flue furnace venting

Key Industrial Applications of flue pipe

| Industry/Sector | Specific Application of Flue Pipe | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Power Generation | Exhaust systems for gas-fired power plants | Enhances efficiency and safety in energy production | Compliance with international standards and local regulations |

| Manufacturing | Ventilation in industrial furnaces | Reduces emissions and improves air quality in facilities | Material durability and heat resistance are critical factors |

| Oil and Gas | Flue gas management in refineries | Ensures regulatory compliance and operational safety | Sourcing from certified suppliers with proven track records |

| Food Processing | Exhaust systems for ovens and fryers | Maintains food safety standards and operational efficiency | Consideration of hygiene standards and ease of maintenance |

| Chemical Processing | Venting for chemical reactors and boilers | Minimizes the risk of hazardous emissions and explosions | Need for specialized materials that can withstand corrosive environments |

How Is Flue Pipe Used in Power Generation?

In the power generation sector, flue pipes are integral to the exhaust systems of gas-fired power plants. They facilitate the safe expulsion of combustion gases, which is essential for maintaining plant efficiency and ensuring compliance with environmental regulations. For international buyers, particularly in regions like Africa and the Middle East where energy demand is growing, sourcing flue pipes that meet both local and international standards is critical. Buyers should prioritize suppliers who can guarantee high-quality materials that withstand extreme temperatures and corrosive environments.

What Role Does Flue Pipe Play in Manufacturing?

Flue pipes are extensively utilized in industrial furnaces within the manufacturing sector. They are designed to vent exhaust gases, thus helping to reduce emissions and improve air quality within the facility. This is particularly important for manufacturers aiming to comply with environmental regulations while maintaining operational efficiency. International buyers, especially from Europe and South America, should focus on the durability and heat resistance of the flue pipe materials, ensuring that they can withstand the high temperatures typical in manufacturing processes.

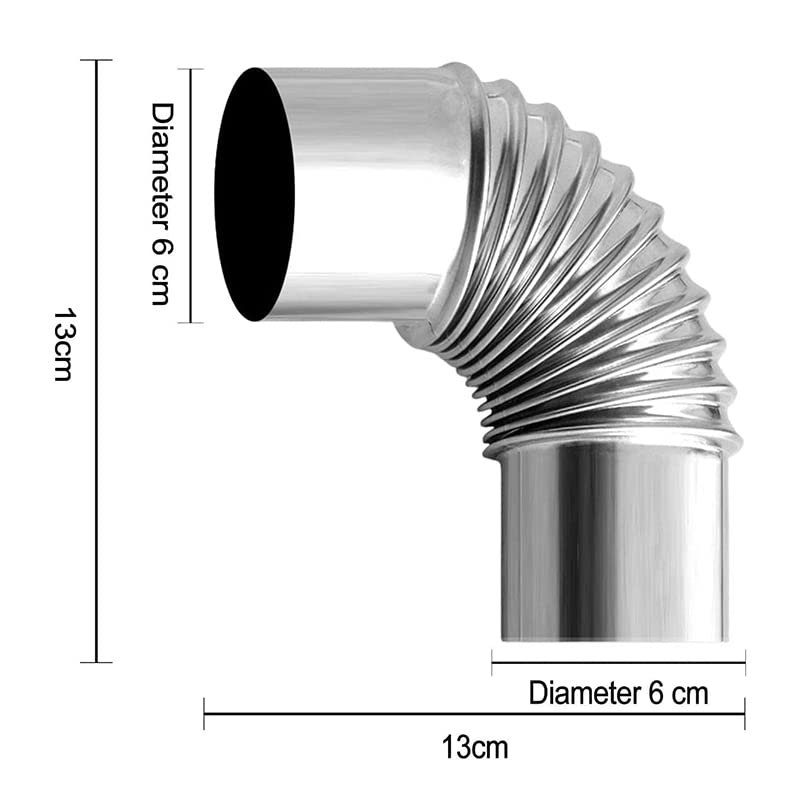

A stock image related to flue pipe.

How Is Flue Pipe Essential in Oil and Gas Industries?

In the oil and gas sector, flue pipes play a crucial role in managing flue gases within refineries. They help ensure that emissions are controlled and that the facility adheres to stringent regulatory standards. For B2B buyers in Africa and the Middle East, sourcing flue pipes from certified suppliers is essential to mitigate risks associated with operational safety and compliance. It is also important to assess the supplier’s track record in providing reliable products that meet industry-specific requirements.

Why Are Flue Pipes Important in Food Processing?

Within the food processing industry, flue pipes are vital for exhaust systems used in ovens and fryers. They ensure that combustion gases are effectively vented, maintaining food safety standards and enhancing operational efficiency. International buyers from regions like South America and Europe should consider hygiene standards when sourcing flue pipes, as well as the ease of maintenance to ensure long-term operational reliability. Selecting suppliers who specialize in food-grade materials can further enhance safety and compliance.

How Do Flue Pipes Benefit Chemical Processing?

Flue pipes are essential for venting in chemical reactors and boilers, minimizing the risk of hazardous emissions and potential explosions. This application is particularly critical in the chemical processing industry, where safety is paramount. Buyers from Africa and the Middle East must prioritize sourcing flue pipes made from specialized materials that can withstand corrosive environments. Additionally, understanding the specific requirements for pressure and temperature ratings is crucial for ensuring operational safety and compliance with local regulations.

Related Video: Double Pipe Heat Exchanger Basics Explained – industrial engineering

3 Common User Pain Points for ‘flue pipe’ & Their Solutions

Scenario 1: Inconsistent Flue Pipe Sizing Leads to Installation Issues

The Problem:

One of the most significant challenges faced by B2B buyers in the flue pipe market is ensuring that the pipe size is appropriate for their specific application. Inconsistent sizing can lead to inefficient ventilation, increased emissions, and potential safety hazards. For instance, a manufacturing facility in South Africa may purchase flue pipes that do not match the diameter required for their heating equipment, resulting in backpressure issues and poor performance. This can lead to costly downtime and a lack of compliance with local regulations.

The Solution:

To avoid sizing issues, B2B buyers should conduct a thorough analysis of their heating system’s specifications before making a purchase. Engaging with manufacturers or suppliers who offer detailed technical support can provide invaluable insights into the correct sizing. It’s also advisable to utilize software tools or consult with engineers to model the entire flue system, ensuring that every component from the flue pipe to the chimney is compatible. Additionally, opting for adjustable flue pipes can provide flexibility during installation, accommodating any last-minute changes in system design.

Scenario 2: Corrosion and Material Durability Concerns

The Problem:

Corrosion is a prevalent issue for flue pipes, especially in industries that operate under extreme temperatures or in corrosive environments, such as chemical plants or coastal regions. For instance, a company in the Middle East may face rapid deterioration of flue pipes due to high humidity and saline air, leading to leaks and unsafe conditions. This not only poses safety risks but also results in unexpected maintenance costs and operational disruptions.

The Solution:

B2B buyers must prioritize the selection of flue pipes made from corrosion-resistant materials, such as stainless steel or specially coated metals designed for harsh environments. Conducting a thorough risk assessment of the installation location can help determine the most suitable material. Furthermore, establishing a routine inspection and maintenance schedule can catch early signs of wear and tear, allowing for timely replacements before more significant issues arise. Collaborating with suppliers who provide warranties on their products can also offer peace of mind regarding long-term performance.

Scenario 3: Compliance with Local Regulations and Standards

The Problem:

Navigating the regulatory landscape can be daunting for international B2B buyers. Each region may have specific codes and standards regarding flue pipe installations, and failure to comply can result in legal penalties, increased scrutiny, and costly rework. For example, a European firm may struggle to meet the stringent environmental regulations governing emissions, risking fines or even shutdowns if their flue systems are found non-compliant.

The Solution:

To mitigate compliance issues, it is essential for buyers to conduct thorough research on local regulations before procuring flue pipes. This can involve consulting local authorities or hiring compliance experts familiar with the regional codes. Buyers should also work closely with suppliers who are knowledgeable about the regulatory landscape and offer products that meet or exceed these standards. Additionally, investing in training for installation teams on compliance requirements can further ensure that systems are installed correctly and maintain their adherence to regulations over time. Regular audits and updates to compliance practices should be integrated into the business operations to stay ahead of any changes in legislation.

Strategic Material Selection Guide for flue pipe

When selecting materials for flue pipes, international B2B buyers must consider several factors that influence performance, durability, and compliance with local regulations. Below is a detailed analysis of four common materials used in flue pipe manufacturing, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Stainless Steel for Flue Pipes?

Stainless steel is a popular choice due to its excellent corrosion resistance and high-temperature tolerance. Typically, it can withstand temperatures up to 1,200°F (650°C) and offers a pressure rating suitable for various applications. The material’s inherent strength allows it to handle thermal expansion and contraction without compromising structural integrity.

Pros & Cons: The primary advantage of stainless steel is its durability, which translates to a longer lifespan and reduced maintenance costs. However, it tends to be more expensive than other materials, which could be a limiting factor for budget-conscious projects. The manufacturing process can also be complex, requiring specialized welding techniques.

Impact on Application: Stainless steel flue pipes are compatible with a wide range of media, including flue gases from oil, gas, and solid fuels. This versatility makes them suitable for both residential and industrial applications.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A312 or EN 10217, depending on their region. In markets like Europe, certifications may be more stringent, necessitating thorough documentation.

How Does Aluminum Compare for Flue Pipe Applications?

Aluminum is another viable option for flue pipes, known for its lightweight nature and good corrosion resistance. It can typically handle moderate temperatures (up to 600°F or 315°C) and is less prone to rusting than carbon steel.

Pros & Cons: The lightweight characteristic of aluminum makes it easier to install, reducing labor costs. However, its lower temperature tolerance limits its use in high-heat applications. Additionally, aluminum may require thicker walls to maintain structural integrity under pressure, which can increase costs.

Impact on Application: Aluminum flue pipes are ideal for applications involving lower-temperature exhaust gases, such as those produced by gas-fired appliances.

Considerations for International Buyers: Compliance with standards like ASTM B221 or EN 573 is essential. Buyers in regions with high humidity, such as parts of Africa and South America, should also consider the potential for galvanic corrosion when aluminum is used in conjunction with other metals.

What Are the Benefits of Using Carbon Steel for Flue Pipes?

Carbon steel is widely used in flue pipe applications due to its strength and affordability. It can withstand high temperatures (up to 1,000°F or 538°C) and is often used in industrial settings.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness, making it a popular choice for large-scale projects. However, it is prone to corrosion, especially when exposed to moisture, which can lead to a shorter lifespan compared to stainless steel.

Impact on Application: Carbon steel flue pipes are suitable for high-temperature applications but require proper insulation and maintenance to prevent rust and degradation.

Considerations for International Buyers: Buyers should be aware of standards such as ASTM A53 or EN 10255. In regions with high humidity or corrosive environments, additional coatings or treatments may be necessary.

Why Is Polypropylene a Good Choice for Certain Flue Pipe Applications?

Polypropylene is a non-metallic option that offers excellent chemical resistance and is lightweight. It can typically handle temperatures up to 200°F (93°C), making it suitable for specific applications.

Pros & Cons: The primary advantage of polypropylene is its resistance to corrosive substances, making it ideal for flue gases from condensing boilers. However, its temperature limitations restrict its use in high-heat applications, and it may not be suitable for all types of fuels.

Impact on Application: Polypropylene flue pipes are often used in residential settings for condensing boilers, where the flue gases are cooler and more acidic.

Considerations for International Buyers: Compliance with standards such as ASTM D4101 is crucial. Buyers in Europe may also need to consider additional certifications, especially for residential installations.

Summary Table of Material Selection for Flue Pipes

| Material | Typical Use Case for flue pipe | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Industrial and residential applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Low-temperature exhaust systems | Lightweight and easy to install | Lower temperature tolerance | Medium |

| Carbon Steel | High-temperature industrial applications | Cost-effective | Prone to corrosion | Low |

| Polypropylene | Residential condensing boilers | Great chemical resistance | Limited temperature tolerance | Medium |

A stock image related to flue pipe.

In summary, the selection of the right material for flue pipes depends on various factors, including application requirements, environmental conditions, and compliance with local standards. By carefully evaluating these materials, international B2B buyers can make informed decisions that align with their project needs.

In-depth Look: Manufacturing Processes and Quality Assurance for flue pipe

What Are the Key Stages in the Manufacturing Process of Flue Pipes?

Manufacturing flue pipes involves several critical stages, each of which plays a vital role in ensuring the final product meets industry standards and customer expectations. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Flue Pipe Manufacturing?

The first step in manufacturing flue pipes is material preparation. Typically, high-quality stainless steel or other corrosion-resistant alloys are chosen for their durability and thermal resistance. The raw materials undergo stringent quality checks to ensure they meet specifications such as thickness and tensile strength. Suppliers often source materials from certified manufacturers who provide mill test reports, which are essential for verifying material quality.

What Forming Techniques Are Used in Flue Pipe Production?

Once the materials are prepared, the next stage is forming. Techniques such as roll forming and laser cutting are commonly employed to shape the raw materials into the desired pipe dimensions. Roll forming provides a continuous and uniform shape, while laser cutting allows for precise dimensions and complex designs. These techniques enhance the efficiency of production and help maintain consistency across batches.

How Is the Assembly of Flue Pipes Conducted?

After forming, the pipes are assembled. This may involve welding or mechanical fastening, depending on the design and application requirements. For instance, welded joints are often used in high-pressure applications, while mechanical joints may be suitable for lower pressure systems. Each method has its advantages and impacts the overall structural integrity of the flue pipe.

What Finishing Processes Are Important for Flue Pipes?

The final manufacturing stage is finishing, which includes processes like surface treatment, coating, and inspection. Surface treatments such as passivation can enhance corrosion resistance, while coatings can provide additional protection against environmental factors. Proper finishing is crucial to extend the lifespan of flue pipes, especially in harsh conditions.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance is paramount in the manufacturing of flue pipes, particularly given the rigorous demands of industrial applications. International standards, such as ISO 9001, provide a framework for quality management systems, ensuring consistent product quality and customer satisfaction. Additionally, industry-specific certifications like CE marking and API standards are critical indicators of compliance with safety and performance requirements.

How Are Quality Control Checkpoints Implemented in Flue Pipe Production?

Quality control (QC) involves several checkpoints throughout the manufacturing process. These typically include:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production process. It ensures that only materials meeting the specified standards are used.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor the forming and assembly processes. This helps identify any deviations from quality standards early on.

-

Final Quality Control (FQC): Once the flue pipes are completed, they undergo final inspections and testing. This stage verifies that the finished products meet all specifications and regulatory requirements.

What Testing Methods Are Commonly Used for Flue Pipes?

Testing is a critical component of quality assurance in flue pipe manufacturing. Common methods include:

-

Hydrostatic Testing: This involves filling the pipe with water and applying pressure to check for leaks and structural integrity.

-

Ultrasonic Testing: Used to detect internal flaws, this non-destructive testing method employs high-frequency sound waves.

-

Visual Inspection: Technicians conduct thorough visual inspections to identify any surface defects or irregularities.

These testing methods help ensure that the flue pipes are safe for use in their intended applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential to ensure product reliability. Here are several actionable steps:

-

Conduct Supplier Audits: Regular audits of the manufacturing facility can provide insights into their quality management systems and adherence to international standards.

-

Request Quality Control Reports: Suppliers should provide detailed QC reports that outline their testing methods, results, and compliance with relevant standards.

-

Engage Third-Party Inspectors: Hiring independent inspectors to evaluate the manufacturing process can offer an unbiased assessment of quality practices.

-

Check Certifications: Verify that the supplier holds relevant certifications (ISO, CE, API) that demonstrate compliance with international quality standards.

What Are the Quality Control and Certification Nuances for International Buyers?

For B2B buyers from diverse regions, understanding the nuances of quality control and certification is critical. Buyers from Africa, South America, the Middle East, and Europe should consider:

-

Regional Standards: Be aware that different regions may have varying requirements and certifications. For instance, European buyers may prioritize CE marking, while buyers in the Middle East might focus on local regulatory compliance.

-

Supply Chain Transparency: Ensure that your suppliers maintain transparency in their supply chain, which can affect product quality. This is particularly important when sourcing materials from different countries.

-

Cultural and Regulatory Differences: Familiarize yourself with the cultural and regulatory landscape of the supplier’s country. Understanding local practices can aid in establishing stronger partnerships and mitigating risks.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for flue pipes is essential for international B2B buyers. By focusing on material quality, manufacturing techniques, and rigorous testing, buyers can ensure they source reliable products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘flue pipe’

Introduction

Sourcing flue pipes for industrial or commercial applications can be a complex process, particularly for B2B buyers operating in diverse markets such as Africa, South America, the Middle East, and Europe. This checklist serves as a practical guide to streamline your procurement process, ensuring you make informed decisions while minimizing risks associated with quality and compliance.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful sourcing process. Determine the required materials, dimensions, and compatibility with existing systems. Consider factors like temperature ratings and corrosion resistance, which are crucial for ensuring long-term performance in varying environmental conditions.

Step 2: Research Regulatory Compliance Requirements

Understanding the regulatory landscape in your target market is essential. Different regions may have specific standards for flue pipes, such as ISO certifications or local building codes. Verify that the products you are considering meet these regulations to avoid costly delays or penalties.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct a thorough evaluation. Request detailed company profiles, case studies, and references from buyers in similar industries or regions. Assess their experience with flue pipes and inquire about their manufacturing processes, as this can significantly impact product quality.

- Look for suppliers with a proven track record in your specific market.

- Check for certifications that demonstrate adherence to international standards.

Step 4: Request Samples for Quality Assessment

Before placing a large order, request samples to evaluate the quality of the flue pipes. This step allows you to inspect the materials, finishes, and overall craftsmanship. Testing samples in real-world applications can also provide insights into performance and durability.

Step 5: Compare Pricing and Payment Terms

Pricing can vary significantly between suppliers, so it’s essential to compare quotes comprehensively. Look beyond the initial costs and consider payment terms, shipping fees, and any hidden charges. Understanding the total cost of ownership will help you make a more informed purchasing decision.

- Inquire about bulk discounts for larger orders.

- Assess the payment flexibility offered, especially for international transactions.

Step 6: Negotiate Terms and Conditions

Once you have shortlisted suppliers, enter into negotiations regarding pricing, delivery timelines, and warranty conditions. Establish clear terms that protect your interests, especially concerning product returns and replacements in case of defects. Effective negotiation can lead to better terms and a more favorable long-term partnership.

Step 7: Plan for Logistics and Delivery

Finally, consider the logistics involved in shipping and delivery. Coordinate with suppliers to establish realistic timelines and understand their shipping methods. Ensure that you have the necessary infrastructure in place for receiving and storing the flue pipes upon arrival.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing flue pipes more effectively, ensuring they secure high-quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for flue pipe Sourcing

What Are the Key Cost Components in Flue Pipe Sourcing?

Understanding the cost structure of flue pipe sourcing is crucial for B2B buyers looking to optimize their procurement strategy. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

-

Materials: The choice of materials significantly impacts the overall cost. Flue pipes are typically made from stainless steel, aluminum, or galvanized steel. Higher-grade materials with better corrosion resistance or higher heat tolerance will increase costs but can lead to longer service life and reduced maintenance.

-

Labor: Labor costs vary depending on the region of production. Areas with lower labor costs can offer competitive pricing, but it’s essential to assess the skill level and experience of the workforce, as this can affect the quality of the final product.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses associated with production. Buyers should inquire about these costs, as they can vary significantly between suppliers.

-

Tooling: Custom tooling for specific flue pipe designs can represent a substantial upfront cost. If you’re sourcing custom products, be prepared for these costs to be factored into the unit price.

-

Quality Control (QC): Implementing stringent QC processes ensures that the flue pipes meet industry standards. While this may raise initial costs, it can prevent costly failures and downtime in the long run.

-

Logistics: Shipping costs can be substantial, especially for international buyers. Factors such as distance, mode of transport, and local tariffs can influence logistics expenses.

-

Margin: Finally, suppliers will include a profit margin in their pricing. This margin can fluctuate based on market conditions, supplier reputation, and negotiation outcomes.

How Do Price Influencers Affect Flue Pipe Costs?

When sourcing flue pipes, various price influencers come into play, making it essential for buyers to consider these factors carefully.

-

Volume/MOQ: Buying in larger quantities often results in lower per-unit costs due to economies of scale. Understand the Minimum Order Quantity (MOQ) policies of your suppliers to optimize pricing.

-

Specifications and Customization: Customized flue pipes that meet specific operational requirements will typically cost more. Clearly outline your needs to avoid unexpected costs.

-

Materials and Quality Certifications: The use of higher-quality materials and adherence to international quality certifications can increase costs. Ensure that the materials selected align with your operational needs and compliance requirements.

-

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established suppliers may charge more for their products, but they often provide better service and product reliability.

-

Incoterms: Understanding Incoterms is crucial for managing logistics costs and responsibilities. Different terms can significantly impact the total landed cost of your flue pipe orders.

What Are the Best Buyer Tips for Negotiating Flue Pipe Prices?

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, effective negotiation and cost management strategies are vital.

-

Negotiate Effectively: Leverage your purchasing power to negotiate better terms. Always be prepared with market research and competitor pricing data to support your position.

-

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO) rather than just the upfront price. Higher initial costs for quality materials may lead to lower maintenance and replacement costs over time.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and local taxes that can affect pricing. Consult with local experts or logistics partners to gain insights into the best practices for your region.

-

Build Long-Term Relationships: Establishing a strong relationship with suppliers can lead to better pricing, priority service, and more favorable payment terms.

Disclaimer on Indicative Prices

Prices for flue pipes can vary widely based on the factors discussed above. Always request detailed quotes from multiple suppliers and consider all cost components to make informed purchasing decisions.

Alternatives Analysis: Comparing flue pipe With Other Solutions

Understanding Alternatives to Flue Pipe Systems

When evaluating flue pipe systems for industrial applications, it’s essential to consider alternative solutions that may offer similar functionalities. Each option presents unique advantages and drawbacks that can affect performance, cost, and overall suitability for specific projects. This analysis focuses on two viable alternatives: Chimney Systems and Direct Vent Systems. By comparing these solutions, international B2B buyers can make informed decisions tailored to their operational needs.

Comparison Table

| Comparison Aspect | Flue Pipe | Chimney Systems | Direct Vent Systems |

|---|---|---|---|

| Performance | High efficiency for gas and oil | Moderate efficiency; varies by design | High efficiency; suitable for tight spaces |

| Cost | Generally lower installation cost | Higher initial costs; requires masonry | Moderate installation costs; can be more affordable in the long run |

| Ease of Implementation | Quick installation; versatile | Complex installation; requires skilled labor | Relatively straightforward installation; fewer site restrictions |

| Maintenance | Requires periodic inspection | Regular maintenance needed; can be costly | Minimal maintenance; often self-cleaning |

| Best Use Case | Residential and commercial buildings | Large industrial operations | Small to medium-sized facilities with limited space |

In-Depth Look at Alternative Solutions

What are the Pros and Cons of Chimney Systems?

Chimney systems are traditional methods for venting combustion gases. They can be tailored for specific applications and are often built to withstand high temperatures. However, their installation can be complex and costly due to the masonry required. Maintenance is another critical factor; chimneys need regular inspections and cleaning to ensure safe operation, which can add to long-term costs. They are best suited for larger industrial operations where high volumes of exhaust need to be managed effectively.

How Do Direct Vent Systems Compare to Flue Pipes?

Direct vent systems provide a sealed combustion process, drawing air from outside for combustion and venting exhaust directly outside. This design enhances efficiency, especially in tight spaces where traditional flue pipes may not fit. The installation process is generally straightforward, making it a popular choice for many businesses. However, while the initial costs may be moderate, they can vary depending on the complexity of the installation. Additionally, direct vent systems typically require less maintenance than flue pipes, making them an attractive long-term option for small to medium-sized facilities.

Conclusion: How Can B2B Buyers Choose the Right Solution?

Selecting the right venting solution requires careful consideration of specific operational needs and conditions. Buyers should assess factors such as the scale of the operation, installation environment, and long-term maintenance capabilities. For large industrial setups, chimney systems may provide the necessary durability and performance, while flue pipes offer a cost-effective solution for smaller applications. Direct vent systems are ideal for facilities with spatial constraints, combining efficiency with ease of installation. By weighing these aspects against their unique requirements, B2B buyers can make a well-informed decision that aligns with their business objectives.

Essential Technical Properties and Trade Terminology for flue pipe

What Are the Key Technical Properties of Flue Pipe?

When sourcing flue pipes, understanding their technical properties is crucial for ensuring compliance with safety standards and operational efficiency. Here are some essential specifications to consider:

1. Material Grade: Why Does It Matter?

Flue pipes are typically made from materials such as stainless steel, carbon steel, or aluminum. The grade of the material directly impacts the pipe’s durability, resistance to corrosion, and ability to withstand high temperatures. For example, stainless steel (like grade 316) offers superior resistance to acidic flue gases, making it ideal for environments with high humidity or corrosive conditions. Buyers should prioritize material grades that meet both local regulations and application-specific requirements.

2. Wall Thickness: How Does It Affect Performance?

The wall thickness of a flue pipe influences its structural integrity and thermal insulation properties. Thicker walls provide better insulation and can handle higher pressures, which is critical for systems operating at extreme temperatures. A common standard is a minimum wall thickness of 1.5mm, but specifications may vary based on the application. Understanding the required wall thickness can prevent future operational failures and enhance the longevity of the installation.

3. Tolerance Levels: Why Are They Critical?

Tolerance levels refer to the allowable deviation from specified dimensions. In flue pipe production, maintaining tight tolerances ensures proper fit and function in installations. For instance, a tolerance of ±0.5mm might be necessary for connections to other components. Poor tolerances can lead to leaks or inefficiencies, which can compromise system performance and safety. Buyers should inquire about tolerance standards during procurement to avoid issues down the line.

4. Temperature Rating: What Should You Know?

Each flue pipe is rated for a maximum temperature it can safely handle, often specified in degrees Celsius. Understanding the temperature rating is vital for applications involving high heat, such as industrial boilers or furnaces. Exceeding the temperature rating can lead to material degradation and system failures. Buyers should match the temperature rating with their specific operational conditions to ensure reliability.

5. Connection Type: What Are the Options?

Flue pipes come with various connection types, including welded, flanged, or slip joint connections. The choice of connection affects installation ease, maintenance, and overall system performance. For example, flanged connections allow for easier disassembly, which is beneficial for regular maintenance checks. Knowing the connection type required for your installation can streamline procurement and reduce costs.

What Trade Terms Should International Buyers Understand?

Navigating the flue pipe market involves familiarizing oneself with industry jargon. Here are some common terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the flue pipe industry, working with an OEM can ensure that you receive high-quality products that meet specific operational requirements. Buyers should seek reputable OEMs to ensure compliance with industry standards.

2. MOQ (Minimum Order Quantity): How Does It Impact Purchasing?

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is critical for budgeting and inventory management. For flue pipes, MOQs can vary based on material and supplier, so it’s important for buyers to clarify this term early in negotiations to avoid unexpected costs.

3. RFQ (Request for Quotation): Why Is It Essential?

An RFQ is a document that buyers send to suppliers to solicit pricing and terms for specific products. In the context of flue pipes, submitting an RFQ helps buyers compare quotes and ensure they are getting competitive pricing. Including detailed specifications in the RFQ can lead to more accurate and tailored responses.

A stock image related to flue pipe.

4. Incoterms: What Should You Know?

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is vital for understanding shipping costs and liabilities. Buyers must clarify these terms to avoid misunderstandings regarding delivery responsibilities.

5. Lead Time: Why Is It Important?

Lead time refers to the time it takes from placing an order to receiving the product. In the flue pipe industry, lead times can vary significantly based on material availability and manufacturing processes. Understanding lead times helps buyers plan their projects more effectively and manage expectations with stakeholders.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing flue pipes, ensuring compliance, efficiency, and long-term success in their projects.

Navigating Market Dynamics and Sourcing Trends in the flue pipe Sector

What Are the Current Market Dynamics and Key Trends in the Flue Pipe Sector?

The flue pipe sector is experiencing significant shifts driven by various global factors. As industries increasingly prioritize efficiency and emissions reduction, the demand for high-quality flue pipes is on the rise. Key trends include the adoption of advanced materials that enhance durability and resistance to corrosion, which is particularly relevant in regions with harsh climates, such as parts of Africa and the Middle East. Moreover, digital transformation is reshaping sourcing strategies; B2B buyers are leveraging data analytics and IoT to optimize supply chains and improve procurement processes.

Emerging markets in South America and Africa are seeing a surge in construction and industrial activities, prompting increased investments in infrastructure. This growth is driving demand for flue pipes in both residential and commercial applications. Additionally, European buyers are focusing on compliance with stringent environmental regulations, which is influencing their purchasing decisions. As a result, suppliers are increasingly offering products that meet or exceed these standards, creating opportunities for international buyers to source innovative solutions.

How Are Sustainability and Ethical Sourcing Impacting the Flue Pipe Sector?

The importance of sustainability and ethical sourcing cannot be overstated in today’s B2B landscape. Environmental concerns related to manufacturing processes and material sourcing are prompting buyers to seek out flue pipes made from sustainable materials. This shift is not only a response to regulatory pressures but also a reflection of changing consumer preferences for environmentally friendly products.

Buyers should prioritize suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials or certified ‘green’ products. Certifications like ISO 14001 (Environmental Management) and other eco-labels can provide assurance of a supplier’s commitment to minimizing environmental impact. Moreover, establishing ethical supply chains ensures that sourcing practices are transparent and socially responsible, which is becoming increasingly important for companies looking to enhance their brand reputation in global markets.

What Is the Historical Context of the Flue Pipe Industry and Its Evolution?

The flue pipe industry has evolved significantly over the past few decades, driven by technological advancements and changing regulatory landscapes. Initially, flue pipes were primarily made from traditional materials such as clay and metal, which posed limitations in terms of durability and efficiency. However, the introduction of new materials like stainless steel and advanced composites has revolutionized the sector, allowing for improved performance and longevity.

As environmental regulations have tightened, particularly in Europe and North America, manufacturers have had to adapt by developing products that not only meet compliance standards but also contribute to energy efficiency. This historical context is crucial for B2B buyers as it underscores the importance of selecting suppliers who are not only aware of past challenges but are also proactive in addressing current and future market demands. Understanding this evolution can help buyers make informed decisions that align with both their operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of flue pipe

-

How do I choose the right flue pipe for my application?

Choosing the right flue pipe involves understanding the specific requirements of your application, including the type of fuel being used, the temperature of the flue gases, and the installation environment. Flue pipes are available in various materials such as stainless steel, aluminum, and galvanized steel, each offering different durability and thermal properties. Assessing local regulations and standards is also crucial, as compliance can affect safety and efficiency. Consulting with suppliers who specialize in your industry can provide tailored recommendations to meet your specific needs. -

What are the key factors to consider when sourcing flue pipes internationally?

When sourcing flue pipes internationally, consider the supplier’s reputation, product quality, and compliance with international standards. Verify their certifications and past performance through customer testimonials and case studies. Additionally, evaluate logistics and shipping costs, including customs regulations that may affect delivery timelines. Understanding the local market dynamics in the supplier’s country can also provide insights into potential risks and advantages. Engage in thorough due diligence to ensure a reliable and cost-effective sourcing process. -

What is the minimum order quantity (MOQ) for flue pipes from suppliers?

The minimum order quantity (MOQ) for flue pipes can vary significantly among suppliers and often depends on factors such as material, size, and customization requirements. Some manufacturers may have a low MOQ for standard products, while custom designs might require larger orders to justify production costs. It’s advisable to discuss your specific needs with potential suppliers to negotiate MOQs that align with your project scope. Understanding your demand forecast can help in effectively managing MOQ negotiations. -

What payment terms should I expect when purchasing flue pipes internationally?

Payment terms can vary widely when purchasing flue pipes internationally. Common terms include upfront payment, partial payment upon order confirmation, and balance due upon shipment. Some suppliers may offer more flexible terms, such as letters of credit or payment after delivery, depending on your relationship and transaction history. Always clarify the payment terms before finalizing the order and ensure they are documented in the purchase agreement to avoid disputes. -

How can I ensure quality assurance for flue pipes sourced from abroad?

To ensure quality assurance for flue pipes sourced internationally, request detailed product specifications and certifications from your suppliers. Consider conducting factory audits or hiring third-party inspection services to assess product quality before shipment. Implementing a clear quality control process that includes testing samples upon arrival can also mitigate risks. Collaborating with suppliers who have established quality management systems, such as ISO certification, can further enhance your assurance of receiving high-quality products. -

What are the shipping options for flue pipes, and how do they affect costs?

Shipping options for flue pipes typically include air freight, sea freight, and courier services, each varying in speed and cost. Sea freight is generally the most economical for large orders but may take longer, while air freight offers quicker delivery at a higher price. Understanding the weight and dimensions of your order is crucial for accurate shipping quotes. Additionally, factor in insurance, duties, and taxes, as these can significantly impact overall costs. Collaborating with logistics experts can help optimize shipping choices. -

How do I vet suppliers of flue pipes for reliability and quality?

Vetting suppliers for reliability and quality involves a multi-step process. Start by researching their business history, client reviews, and industry certifications. Request references from previous customers and assess their responsiveness and communication skills during initial interactions. Visiting the supplier’s facility, if feasible, can provide valuable insights into their manufacturing processes and quality control measures. Consider using platforms that specialize in supplier ratings and reviews to enhance your decision-making process. -

What customization options are available for flue pipes, and how do they affect pricing?

Customization options for flue pipes may include variations in diameter, length, material, and design features such as insulation or specific fittings. Customization can enhance performance and compatibility with existing systems but often comes at an increased cost due to additional manufacturing processes. Discussing your specific requirements with suppliers can help you understand the pricing implications of customization. It’s also beneficial to assess whether the added cost aligns with the expected performance improvements for your application.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for flue pipe

What Are the Key Takeaways for B2B Buyers in Flue Pipe Sourcing?

In conclusion, strategic sourcing of flue pipes is essential for international B2B buyers looking to optimize their supply chain and enhance operational efficiency. Key takeaways include the importance of understanding regional regulations and standards, which can significantly impact sourcing decisions. Buyers should prioritize partnerships with reliable suppliers that offer quality materials and flexible logistics solutions tailored to their specific market needs.

How Can Strategic Sourcing Enhance Your Business Operations?

Implementing a strategic sourcing approach not only reduces costs but also mitigates risks associated with supply chain disruptions. Buyers from Africa, South America, the Middle East, and Europe must leverage market intelligence to identify emerging trends and opportunities in the flue pipe industry. This proactive stance allows for better negotiation and procurement strategies, ultimately leading to improved profitability.

What Should B2B Buyers Focus on for Future Sourcing Opportunities?

As we look forward, the demand for sustainable and efficient flue pipe solutions will continue to rise. B2B buyers should focus on sourcing innovative products that meet environmental standards while ensuring compliance with local regulations. Engaging in collaborative relationships with suppliers will be crucial in navigating these changes effectively.

In closing, now is the time to reassess your sourcing strategies and position your business for success in the evolving market landscape. Embrace the opportunities that strategic sourcing presents and take actionable steps toward enhancing your procurement processes for flue pipes.