Discover Cost-Saving Benefits of Props Cap Sourcing (2025)

Introduction: Navigating the Global Market for props cap

Navigating the complexities of the global market for props caps can be a daunting task for international B2B buyers, especially those looking to source high-quality products tailored to specific applications. Whether you’re in the vibrant markets of Africa, the dynamic economies of South America, or the established industrial hubs of Europe and the Middle East, understanding the nuances of props caps—ranging from their types to their applications—can significantly impact your purchasing decisions.

This comprehensive guide serves as an essential resource for B2B buyers, outlining critical factors such as supplier vetting, cost considerations, and the latest industry trends. By providing insights into various types of props caps, their functional applications in different sectors, and best practices for ensuring quality and compliance, this guide empowers buyers to make informed decisions that align with their business needs.

Furthermore, we address common challenges faced by international buyers, including navigating regulatory requirements and identifying reliable suppliers. As you delve into this guide, you will gain the knowledge necessary to effectively source props caps that meet your operational demands, enhance productivity, and ultimately contribute to your business’s success. Whether you’re in Colombia or Germany, the insights provided here are designed to equip you with the confidence and clarity needed to thrive in the global props cap market.

Understanding props cap Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Props Cap | Basic design, often made from durable materials | General construction, agriculture | Pros: Cost-effective, widely available. Cons: Limited customization options. |

| Adjustable Props Cap | Allows height and angle adjustments | Event planning, staging, photography | Pros: Versatile, adaptable to various needs. Cons: Can be more expensive than standard options. |

| Heavy-Duty Props Cap | Reinforced structure for high weight capacity | Industrial applications, film production | Pros: High durability, supports heavy loads. Cons: Bulkier, may require additional handling. |

| Eco-Friendly Props Cap | Made from sustainable materials | Eco-conscious businesses, outdoor events | Pros: Supports sustainability goals, positive brand image. Cons: Potentially higher initial costs. |

| Custom Props Cap | Tailored designs to specific client requirements | Theatrical productions, custom events | Pros: Perfect fit for unique applications. Cons: Longer lead times, higher costs. |

What Are the Characteristics of Standard Props Caps?

Standard props caps are typically designed for basic functionality and affordability. Constructed from durable materials, they are suited for a variety of applications, including general construction and agricultural use. For B2B buyers, the primary consideration is cost-effectiveness and availability, making these caps a practical choice for companies looking to manage budgets without sacrificing quality. However, the trade-off comes in the form of limited customization options, which might not meet the specific needs of specialized projects.

How Do Adjustable Props Caps Enhance Versatility?

Adjustable props caps feature mechanisms that allow for height and angle adjustments, making them ideal for applications such as event planning, staging, and photography. Their versatility can be a significant advantage for B2B buyers who require flexible solutions that adapt to varying conditions. While they provide a higher level of functionality, buyers should be aware that these caps often come at a premium price point compared to standard options, necessitating a careful evaluation of budget versus utility.

Why Choose Heavy-Duty Props Caps for Industrial Use?

Heavy-duty props caps are specifically engineered to support substantial weight, making them essential for industrial applications and film production where safety and reliability are paramount. The reinforced structure ensures that they can handle high loads without compromising stability. B2B buyers in sectors requiring robust solutions should consider the long-term durability and safety features. However, these caps may be bulkier and require more handling, which could impact logistics and storage.

What Are the Benefits of Eco-Friendly Props Caps?

Eco-friendly props caps are crafted from sustainable materials, appealing to businesses that prioritize environmental responsibility. These caps are increasingly popular for outdoor events and among eco-conscious companies. For B2B buyers, using eco-friendly options can enhance brand image and align with corporate sustainability goals. However, it is essential to note that the initial costs may be higher, which could affect budget considerations for organizations looking to implement green practices.

How Can Custom Props Caps Meet Unique Needs?

Custom props caps offer tailored designs that meet specific client requirements, making them a perfect choice for theatrical productions and bespoke events. This level of customization ensures that the props fit perfectly within the intended context, enhancing overall presentation and functionality. B2B buyers should weigh the benefits of a perfect fit against the longer lead times and higher costs associated with custom orders. This option is ideal for businesses that are willing to invest in unique solutions to stand out in competitive markets.

Related Video: The Genius Behind Bach’s Goldberg Variations: CANONS

Key Industrial Applications of props cap

| Industry/Sector | Specific Application of props cap | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Temporary support structures during construction | Ensures safety and stability of structures | Material durability, compliance with safety standards |

| Oil & Gas | Wellhead protection and equipment mounting | Protects critical equipment from environmental damage | Corrosion resistance, compatibility with harsh conditions |

| Manufacturing | Tool and equipment organization | Enhances workflow efficiency and reduces downtime | Customization options, load-bearing capacity |

| Aerospace | Component assembly and support in aircraft production | Increases precision and reliability of components | Weight considerations, adherence to aerospace standards |

| Automotive | Assembly line support and part positioning | Improves assembly speed and reduces errors | Material strength, ease of integration with existing systems |

How is ‘props cap’ Used in the Construction Industry?

In the construction sector, props caps are essential for providing temporary support to structures during the building process. They are used to stabilize scaffolding and formwork, ensuring safety and preventing structural failures. For international buyers, especially in regions like Africa and South America, sourcing props caps that meet local safety regulations and can withstand varying environmental conditions is crucial. Additionally, considering the material’s durability and weight capacity is key to ensuring that the props caps serve their intended purpose effectively.

What Role Does ‘props cap’ Play in the Oil & Gas Sector?

In the oil and gas industry, props caps are utilized primarily for wellhead protection and to mount critical equipment securely. They help prevent environmental damage by shielding sensitive components from harsh weather and operational wear. Buyers from the Middle East and Europe should prioritize sourcing props caps made from corrosion-resistant materials that can endure extreme conditions. This ensures that the equipment remains operational, reducing downtime and maintenance costs.

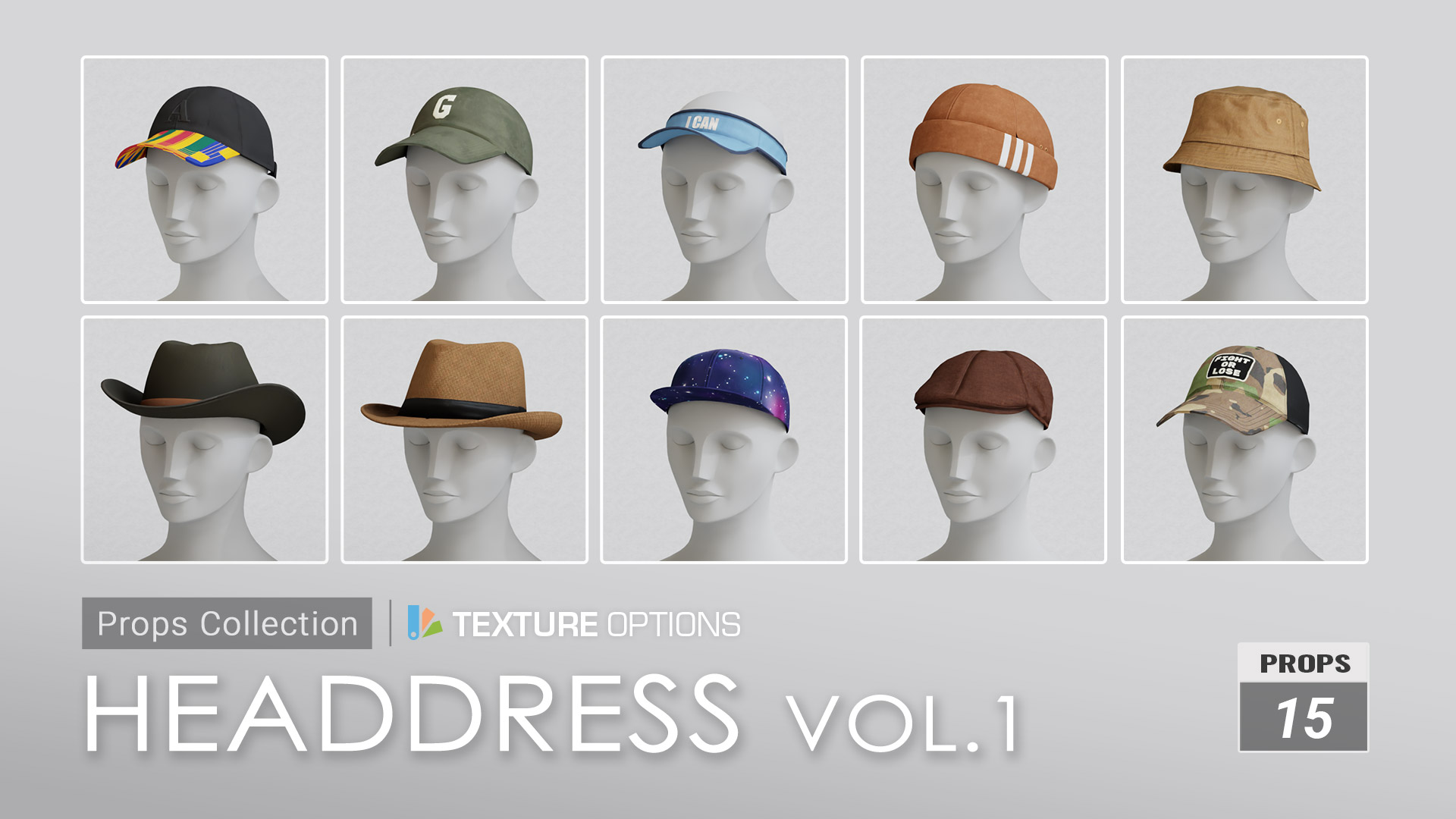

A stock image related to props cap.

How is ‘props cap’ Beneficial in Manufacturing?

In manufacturing, props caps are employed to organize tools and equipment, facilitating a more efficient workflow. They help in the precise positioning of parts, which is vital for assembly lines. For B2B buyers in Europe and South America, it is essential to consider customization options that fit specific production needs. Additionally, assessing the load-bearing capacity of props caps is vital to minimize operational disruptions and enhance productivity.

Why is ‘props cap’ Important in Aerospace Manufacturing?

In the aerospace industry, props caps are critical for the assembly and support of aircraft components. They ensure precision during the manufacturing process, thereby increasing the reliability of the final product. Buyers in this sector must focus on sourcing props caps that meet stringent aerospace standards, including weight specifications and material integrity. This attention to detail is necessary to maintain safety and performance in aviation applications.

How Does ‘props cap’ Improve Automotive Assembly Lines?

In the automotive sector, props caps are used extensively on assembly lines to support parts and tools, enhancing the efficiency of the assembly process. They help in reducing errors and improving assembly speed, which is crucial in a competitive market. For international buyers, particularly in regions like Germany and South America, it is important to evaluate the props caps for material strength and compatibility with existing systems to ensure seamless integration into their production processes.

Related Video: LABORATORY APPARATUS AND THEIR USES

3 Common User Pain Points for ‘props cap’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Props Caps for Diverse Applications

The Problem: B2B buyers often struggle to find high-quality props caps that meet specific industry standards, especially when operating in diverse markets such as Africa and South America. This challenge is exacerbated by the lack of reliable suppliers who can provide consistent quality and compliance with local regulations. Many buyers report receiving props caps that do not perform as expected, leading to operational inefficiencies and increased costs due to frequent replacements.

The Solution: To effectively source quality props caps, B2B buyers should conduct thorough market research to identify suppliers with a proven track record in their respective industries. Leveraging platforms like Alibaba or TradeIndia can provide access to a wide range of manufacturers, but it’s crucial to verify their certifications, customer reviews, and production capabilities. Additionally, consider requesting samples before making large orders to assess quality firsthand. Establishing long-term relationships with suppliers can also lead to better negotiation on quality assurance and pricing, ensuring that the props caps meet the required specifications and performance standards.

Scenario 2: Inadequate Knowledge of Props Cap Specifications and Their Impact

The Problem: Many international B2B buyers lack comprehensive knowledge about the technical specifications of props caps, leading to incorrect purchases that do not fit their applications. This often results in wasted resources and delays in project timelines, particularly in sectors like construction and manufacturing where precision is key. Buyers may not fully understand the implications of choosing the wrong material or size, which can affect the durability and effectiveness of the props caps.

The Solution: To overcome this knowledge gap, buyers should invest time in understanding the key specifications of props caps, such as material properties, size variations, and load-bearing capacities. Engaging with industry experts or attending trade shows can provide invaluable insights into the latest trends and technologies. Additionally, creating a checklist of requirements based on specific applications can guide purchasing decisions. Collaborating with engineers or technical consultants during the selection process can further ensure that the props caps chosen are optimal for their intended use, thus enhancing operational efficiency and reducing the risk of costly mistakes.

Scenario 3: Challenges in Integrating Props Caps with Existing Systems

The Problem: Another significant pain point for B2B buyers is the integration of new props caps with existing equipment or systems. Buyers often encounter compatibility issues, especially when dealing with props caps designed for specific applications or machinery. This can lead to increased downtime and additional costs associated with modifications or replacements, frustrating buyers who rely on seamless operations to maintain productivity.

The Solution: To mitigate integration challenges, buyers should conduct a thorough compatibility assessment before procurement. This involves reviewing existing systems and identifying the specific requirements for props caps, such as dimensions and connection types. Collaborating with suppliers who offer customization options can also be beneficial, as they may provide tailored solutions that fit seamlessly into existing setups. Additionally, incorporating a testing phase, where new props caps are trialed in a controlled environment, can help identify potential integration issues before full-scale implementation. By adopting a proactive approach to compatibility, buyers can ensure smoother operations and avoid unexpected costs associated with integration failures.

Strategic Material Selection Guide for props cap

When selecting materials for props caps, B2B buyers must consider various factors that influence product performance, durability, and compliance with international standards. Here, we analyze four common materials used in props caps, detailing their properties, advantages and disadvantages, application impacts, and specific considerations for international buyers.

What Are the Key Properties of Polypropylene (PP) for Props Caps?

Polypropylene (PP) is a thermoplastic polymer known for its excellent chemical resistance and lightweight nature. It typically has a temperature rating of up to 100°C and exhibits good impact strength. Its resistance to moisture and various chemicals makes it suitable for applications involving liquids and gases.

Pros & Cons:

– Pros: Lightweight, cost-effective, and resistant to a wide range of chemicals.

– Cons: Limited temperature resistance compared to other materials, which may restrict its use in high-temperature applications.

Impact on Application:

Polypropylene is compatible with many media, making it ideal for applications in the automotive and packaging industries. However, it may not be suitable for high-temperature environments.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM D638 for tensile properties. European buyers may look for compliance with REACH regulations, ensuring that the material does not contain harmful substances.

How Does Polycarbonate (PC) Perform in Props Cap Applications?

Polycarbonate (PC) is a high-performance thermoplastic known for its exceptional strength and impact resistance. It can withstand temperatures up to 120°C and offers excellent optical clarity, making it suitable for applications requiring visibility.

Pros & Cons:

– Pros: High impact resistance, good temperature tolerance, and transparency.

– Cons: Higher cost compared to polypropylene and may be prone to scratching unless treated.

Impact on Application:

Polycarbonate is ideal for applications requiring durability and clarity, such as in safety equipment or transparent enclosures. Its robustness makes it suitable for harsh environments.

Considerations for International Buyers:

B2B buyers in the Middle East should consider the material’s UV resistance if used outdoors. Compliance with international standards like ISO 7391 for polycarbonate products is also essential.

What Are the Benefits of Using Nylon (Polyamide) in Props Caps?

A stock image related to props cap.

Nylon, or polyamide, is a synthetic polymer known for its high strength, flexibility, and resistance to abrasion. It can operate effectively at temperatures up to 150°C and is resistant to many chemicals.

Pros & Cons:

– Pros: Excellent strength-to-weight ratio, good wear resistance, and flexibility.

– Cons: Can absorb moisture, which may affect dimensional stability and mechanical properties.

Impact on Application:

Nylon is often used in applications requiring high durability and flexibility, such as in automotive and industrial settings. However, moisture absorption can be a concern in humid environments.

Considerations for International Buyers:

Buyers from Europe should ensure compliance with DIN standards for mechanical properties. In South America, understanding local manufacturing capabilities for nylon components can provide a competitive edge.

Why Choose Stainless Steel for Props Caps?

Stainless steel is a corrosion-resistant alloy known for its strength and durability. It can withstand high temperatures and pressures, making it suitable for demanding applications.

Pros & Cons:

– Pros: Exceptional strength, corrosion resistance, and longevity.

– Cons: Higher cost and weight compared to plastic materials, which may affect shipping and handling.

Impact on Application:

Stainless steel is ideal for applications in harsh environments, such as chemical processing and oil and gas industries. Its durability ensures a long service life.

Considerations for International Buyers:

Buyers should be aware of compliance with international standards such as ASTM A240 for stainless steel. Understanding the local market’s preferences for stainless steel grades can also influence purchasing decisions.

Summary Table of Material Selection for Props Caps

| Material | Typical Use Case for props cap | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene (PP) | Automotive and packaging applications | Lightweight and cost-effective | Limited temperature resistance | Low |

| Polycarbonate (PC) | Safety equipment and transparent enclosures | High impact resistance and clarity | Higher cost and prone to scratching | Medium |

| Nylon (Polyamide) | Automotive and industrial applications | Excellent strength and flexibility | Moisture absorption affects properties | Medium |

| Stainless Steel | Chemical processing and oil and gas | Exceptional strength and durability | Higher cost and weight | High |

This guide provides a comprehensive overview of material selection for props caps, helping international B2B buyers make informed decisions that align with their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for props cap

What Are the Main Stages in the Manufacturing Process for Props Caps?

The manufacturing process for props caps involves several critical stages, ensuring the final product meets both functional and aesthetic standards. These stages include:

-

Material Preparation: The first step involves selecting high-quality materials that meet industry specifications. Common materials for props caps include plastics, metals, and composites. Suppliers should conduct thorough material inspections to ensure that they meet the required standards. B2B buyers should inquire about the source of materials and whether they comply with international standards.

-

Forming: This stage encompasses various techniques such as injection molding, extrusion, and stamping, depending on the material and design specifications. Injection molding is particularly favored for its efficiency and precision in producing complex shapes. Buyers should ask suppliers about the machinery used and its capacity to produce the desired volume.

-

Assembly: After forming, the individual components are assembled. This may involve mechanical fastening, adhesive bonding, or welding, depending on the design. Suppliers should utilize automated assembly lines to enhance precision and reduce labor costs. B2B buyers should consider the assembly methods used and their implications on the final product’s durability.

-

Finishing: The final stage includes surface treatments like painting, coating, or polishing to enhance the product’s appearance and resistance to wear and corrosion. Finishing processes can significantly impact the product’s performance, especially in harsh environments. Buyers should request samples of finished products to evaluate the quality of finishing before placing bulk orders.

What International Standards and Industry-Specific Certifications Should B2B Buyers Consider?

Quality assurance in the props cap manufacturing process is paramount, particularly for international B2B buyers. Key standards and certifications include:

-

ISO 9001: This internationally recognized standard focuses on quality management systems (QMS). Suppliers certified under ISO 9001 demonstrate their commitment to consistent quality and continuous improvement. B2B buyers should prioritize suppliers with ISO certification, as this indicates adherence to global quality benchmarks.

-

CE Marking: For props caps intended for the European market, CE marking signifies compliance with EU safety, health, and environmental protection standards. Buyers should ensure that suppliers can provide documentation proving CE compliance, especially if the products are to be used in consumer-facing applications.

-

API Standards: If the props caps are intended for use in the oil and gas sector, API (American Petroleum Institute) certifications are crucial. These standards ensure that products meet specific performance and safety criteria relevant to the industry.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Effective quality control (QC) is essential to ensure that props caps meet specified standards. Buyers should focus on several key QC checkpoints:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival at the manufacturing facility. Buyers should inquire about the protocols in place for IQC and how suppliers ensure that materials meet predefined specifications.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, continuous monitoring and testing should be conducted to identify any deviations from quality standards. B2B buyers should ask for details on the IPQC measures taken by suppliers to maintain product integrity during production.

-

Final Quality Control (FQC): Before products are shipped, a thorough inspection should be performed to ensure that the final products meet all specifications. Buyers should request FQC reports that detail the testing methods and results.

What Common Testing Methods Are Used in Quality Assurance for Props Caps?

Quality assurance involves several testing methods to confirm the performance and safety of props caps. Some common methods include:

-

Mechanical Testing: This includes tensile strength tests, impact resistance tests, and fatigue testing to assess how well the props caps can withstand various forces and conditions.

-

Dimensional Inspection: Utilizing calipers and gauges, this method verifies that the dimensions of the props caps meet specified tolerances. Accurate dimensional inspection is crucial for ensuring compatibility with other components.

-

Environmental Testing: This assesses how props caps perform under extreme temperatures, humidity, and chemical exposure. B2B buyers should confirm that their suppliers conduct these tests, especially if the products will be used in challenging environments.

A stock image related to props cap.

How Can International B2B Buyers Navigate Quality Control Nuances?

International B2B buyers must be aware of the nuances in quality control that may arise due to geographic and regulatory differences. Here are several strategies to navigate these complexities:

-

Conduct Supplier Audits: Regular audits of suppliers can help assess their adherence to quality standards. Buyers should consider both on-site inspections and remote audits, especially when dealing with suppliers in regions like Africa or South America where travel may be challenging.

-

Request Documentation: Suppliers should provide detailed quality control documentation, including certificates of compliance, testing reports, and inspection records. Buyers should scrutinize these documents to ensure they meet the necessary standards.

-

Engage Third-Party Inspectors: Hiring third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. This is particularly beneficial for B2B buyers unfamiliar with local regulations and standards in regions like the Middle East or Europe.

-

Understand Local Regulations: Different regions may have specific regulations impacting product quality and safety. Buyers should familiarize themselves with these regulations and ensure that their suppliers comply with local laws, especially when importing goods.

By focusing on these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing props caps, ensuring they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘props cap’

In today’s global marketplace, sourcing the right props cap is essential for businesses looking to enhance their branding and promotional efforts. This guide provides a practical checklist for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, helping them navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, it’s crucial to clearly outline your technical requirements for the props cap. Consider factors such as size, material, design, and functionality. Having a detailed specification will not only streamline the sourcing process but also ensure that suppliers understand your exact needs, reducing the risk of miscommunication.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in props caps. Use platforms like Alibaba, TradeKey, or industry-specific trade shows to compile a list of manufacturers. Pay attention to their market reputation and the range of products they offer, ensuring they align with your business objectives.

Step 3: Evaluate Supplier Credentials

Before making any commitments, it’s essential to verify the credentials of your shortlisted suppliers. Request documentation such as business licenses, certifications, and quality assurance processes. This step is vital to ensure that the suppliers adhere to industry standards and can deliver quality products consistently.

Step 4: Request Samples for Quality Assessment

Once you have identified a few potential suppliers, request samples of their props caps. This allows you to assess the quality of materials, craftsmanship, and overall design. Evaluate the samples based on your defined specifications and any additional criteria important to your brand.

Step 5: Negotiate Terms and Pricing

Effective negotiation is key to establishing a successful supplier relationship. Discuss pricing, payment terms, minimum order quantities, and delivery timelines. Be clear about your budget while remaining open to supplier suggestions that may enhance your procurement strategy.

Step 6: Establish Communication Channels

Clear communication is crucial for a successful sourcing experience. Set up regular check-ins with your supplier and establish preferred communication channels. This ensures that both parties stay aligned throughout the production process and can quickly address any issues that may arise.

Step 7: Plan for Logistics and Delivery

Finally, consider the logistics involved in transporting the props caps to your location. Assess shipping options, customs regulations, and potential delays. Proper planning in this area will help mitigate unforeseen costs and ensure timely delivery of your products.

By following these steps, international B2B buyers can ensure a smooth and effective sourcing process for props caps, ultimately leading to successful partnerships and enhanced brand visibility.

Comprehensive Cost and Pricing Analysis for props cap Sourcing

What Are the Key Cost Components in Props Cap Sourcing?

When sourcing props caps, understanding the cost structure is essential for international buyers. The primary cost components include:

- Materials: The quality and type of materials significantly impact the overall cost. Common materials for props caps include plastics and metals, each with varying price points depending on market demand and availability.

- Labor: Labor costs can vary widely based on the region where manufacturing occurs. Countries with lower labor costs may offer more competitive pricing, but this can also affect quality and lead times.

- Manufacturing Overhead: This includes costs related to utilities, rent, and administrative expenses. Overhead can vary based on the manufacturing facility’s location and operational efficiency.

- Tooling: Initial tooling costs for molds and machinery are critical for custom designs. These costs are amortized over the production volume, making them a vital consideration for large orders.

- Quality Control (QC): Ensuring product quality may involve additional inspections and testing, which can add to the overall cost. International buyers should consider suppliers with robust QC processes to minimize risks.

- Logistics: Shipping and handling costs can significantly affect the total price, especially for international shipments. Factors such as distance, transportation mode, and Incoterms can influence logistics expenses.

- Margin: Supplier profit margins can vary based on market conditions and the complexity of the product. Understanding typical margins in the industry can help buyers gauge fair pricing.

How Do Price Influencers Affect Props Cap Sourcing?

Several factors can influence the pricing of props caps:

- Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs. Suppliers may have set MOQs that buyers should be aware of, as these can affect total costs significantly.

- Specifications and Customization: Custom designs or specific specifications typically incur higher costs due to the need for unique tooling and materials. Buyers should weigh the benefits of customization against the associated costs.

- Materials Quality and Certifications: Higher-quality materials and certifications (like ISO or safety standards) can drive up costs. However, investing in quality can reduce long-term risks and enhance product durability.

- Supplier Factors: The supplier’s reputation, reliability, and financial stability can impact pricing. Established suppliers may charge more due to their proven track record and service reliability.

- Incoterms: Understanding Incoterms is crucial for international transactions. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and duties, which can affect pricing and total cost.

What Are the Best Negotiation Strategies for International Buyers?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to better pricing and terms:

- Research and Benchmarking: Conduct market research to understand average pricing and standards. This knowledge enables buyers to negotiate from an informed position.

- Leverage Volume: Use volume as a bargaining chip. Suppliers are more likely to offer discounts or favorable terms for larger orders.

- Be Open to Alternatives: If a supplier cannot meet your desired price, consider negotiating alternative terms such as payment plans or extended delivery times.

- Assess Total Cost of Ownership (TCO): Evaluate not just the initial price but also the TCO, including shipping, customs duties, and potential maintenance costs. This comprehensive view can justify higher upfront costs if long-term savings are evident.

- Cultivate Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Trust and communication can facilitate smoother negotiations and future dealings.

What Are the Pricing Nuances for Different Markets?

Pricing for props caps can vary significantly across regions:

- Africa and South America: In emerging markets, buyers may encounter fluctuating costs due to currency instability and varying import tariffs. Negotiating terms that account for these variables is essential.

- Middle East: Buyers in this region often face higher shipping costs due to geographical challenges. However, regional suppliers may offer competitive pricing due to lower labor costs.

- Europe (e.g., Germany): European buyers should consider the impact of strict regulations and standards on pricing. While this can elevate costs, compliance can also assure product quality and marketability.

Disclaimer on Indicative Prices

It is important to note that prices can fluctuate based on market conditions, supplier negotiations, and regional factors. Buyers should seek quotes from multiple suppliers to ensure competitive pricing and transparency in the sourcing process.

Alternatives Analysis: Comparing props cap With Other Solutions

When considering the implementation of a ‘props cap’, it’s essential to evaluate alternative solutions that may offer comparable benefits or enhanced functionality. For international B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe, understanding the strengths and weaknesses of different options can facilitate informed decision-making.

Comparison Table of ‘Props Cap’ Against Alternatives

| Comparison Aspect | Props Cap | Alternative 1: Dynamic Props System | Alternative 2: Static Configuration |

|---|---|---|---|

| Performance | High | Moderate | Low |

| Cost | Medium | High | Low |

| Ease of Implementation | Moderate | Difficult | Easy |

| Maintenance | Moderate | High | Low |

| Best Use Case | Complex, dynamic UIs | Applications requiring frequent updates | Simple, static applications |

What are the Benefits of Using a Dynamic Props System?

A Dynamic Props System allows for the real-time adjustment of component properties, making it suitable for applications that require frequent updates or changes. This solution excels in environments where user interactions are dynamic, such as e-commerce platforms. However, its implementation can be complex and may incur higher costs, especially for organizations with limited technical resources. While it offers moderate performance, the maintenance demands can escalate, requiring dedicated resources for ongoing adjustments.

How Does Static Configuration Compare to ‘Props Cap’?

Static Configuration is a straightforward approach, often utilized in simpler applications where the requirements do not change frequently. This method is inexpensive and easy to implement, making it attractive for businesses that prioritize cost-effectiveness over flexibility. However, the performance is generally lower than that of a ‘props cap’, especially in scenarios where user interactions and data inputs need to be dynamic. Maintenance is minimal, but the lack of adaptability may hinder growth or scaling for businesses looking to evolve their offerings.

Conclusion: How Can B2B Buyers Choose the Right Solution?

In choosing the right solution, B2B buyers should consider their specific needs and operational contexts. For organizations that require high performance and adaptability, a ‘props cap’ may be the best fit, despite its moderate cost and maintenance requirements. Conversely, companies focusing on budget and simplicity might find Static Configuration more aligned with their goals. The Dynamic Props System can be ideal for those needing real-time updates, but it comes with a higher complexity and cost. Ultimately, aligning the chosen solution with business objectives, technical capabilities, and long-term growth strategies will lead to a more effective implementation.

Essential Technical Properties and Trade Terminology for props cap

What Are the Key Technical Properties of Props Caps?

When sourcing props caps for various industrial applications, understanding specific technical properties is crucial for making informed purchasing decisions. Here are some essential specifications to consider:

1. Material Grade

Material grade indicates the quality and characteristics of the material used in the props cap. Common materials include aluminum, steel, and plastic composites. The choice of material affects the cap’s strength, durability, and resistance to environmental factors. For B2B buyers, selecting the right material ensures that the props cap can withstand operational stresses and meet industry standards.

2. Tolerance Levels

Tolerance levels refer to the allowable variations in dimensions during manufacturing. These specifications are critical, as they determine how well the props cap fits with other components. High precision in tolerances is essential for applications requiring tight fits, such as in aerospace or automotive industries. Buyers should ensure that suppliers can meet the necessary tolerance levels to avoid costly rework or failures.

3. Load Capacity

Load capacity specifies the maximum weight or force that a props cap can support without failing. This property is particularly important in construction and heavy machinery applications where safety and performance are paramount. Buyers must assess their operational requirements and ensure that the props cap’s load capacity aligns with their specific use cases.

4. Corrosion Resistance

Corrosion resistance indicates a material’s ability to withstand deterioration due to chemical exposure or environmental conditions. This property is vital for props caps used in outdoor or industrial settings where they may be exposed to moisture, chemicals, or extreme temperatures. Selecting corrosion-resistant materials can significantly extend the lifecycle of the props cap, offering long-term cost savings.

5. Finish and Coating

The finish and coating of a props cap can enhance its appearance and provide additional protection against wear and corrosion. Common finishes include anodizing, powder coating, and galvanizing. For international buyers, understanding the available finishes can help in selecting props caps that not only perform well but also meet aesthetic and branding requirements.

What Are Common Trade Terms Used in the Props Cap Industry?

Familiarity with industry jargon can streamline communication and negotiations with suppliers. Here are several key terms relevant to props caps:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of props caps, understanding OEM relationships can help buyers identify quality sources and ensure compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cost-effectiveness. Buyers should negotiate MOQs that align with their operational needs while ensuring they do not overcommit financially.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. For props caps, submitting a well-structured RFQ can lead to competitive pricing and better service terms, enabling buyers to make more informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers to clarify shipping costs, risks, and responsibilities, ensuring smooth logistics and compliance with international trade regulations.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. For props caps, understanding lead times is crucial for project planning and ensuring that production schedules are met. Buyers should communicate clearly with suppliers about lead times to avoid delays in their operations.

By understanding these technical properties and trade terms, international B2B buyers can navigate the procurement process more effectively, ensuring they select the right props caps for their applications.

Navigating Market Dynamics and Sourcing Trends in the props cap Sector

What Are the Key Market Dynamics and Trends in the Props Cap Sector for B2B Buyers?

The props cap sector is witnessing significant shifts driven by various global factors, making it essential for international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, to stay informed. One of the primary drivers is the increasing demand for customized solutions that cater to specific branding needs. Companies are leaning towards personalized props caps that reflect their brand identity, which enhances customer engagement and loyalty.

Technological advancements are also reshaping sourcing trends in the props cap market. The rise of e-commerce platforms and digital supply chain management tools has streamlined sourcing processes, making it easier for buyers to find suppliers and compare products across different markets. Additionally, the incorporation of automation and AI in manufacturing processes is leading to higher efficiency and lower costs, which can be attractive for B2B buyers looking for competitive pricing.

Emerging markets are becoming increasingly important in the props cap sector. For instance, manufacturers in Colombia and other South American countries are capitalizing on local materials and craftsmanship, appealing to buyers interested in unique and culturally resonant designs. Furthermore, geopolitical factors and trade agreements are influencing sourcing decisions, prompting buyers to consider suppliers from diverse regions to mitigate risks associated with supply chain disruptions.

How Is Sustainability and Ethical Sourcing Impacting the Props Cap Sector?

Sustainability has become a paramount consideration for B2B buyers in the props cap sector. The environmental impact of production processes, particularly in terms of waste and resource consumption, is under scrutiny. Buyers are increasingly seeking suppliers that prioritize sustainable practices, such as using recycled materials or eco-friendly manufacturing processes. This trend is not just about compliance but also about aligning with consumers’ growing preference for environmentally responsible brands.

Ethical sourcing is equally important, as buyers want to ensure that their suppliers adhere to fair labor practices and contribute positively to their local communities. Certifications such as Fair Trade and Global Organic Textile Standard (GOTS) are gaining traction, providing buyers with a reliable framework to assess the ethical standards of their suppliers. Emphasizing these certifications not only enhances a brand’s reputation but also fosters trust among consumers who are increasingly making purchasing decisions based on ethical considerations.

Moreover, the integration of ‘green’ materials into product offerings is becoming a competitive differentiator. Buyers are encouraged to explore partnerships with suppliers who utilize organic cotton, biodegradable materials, or other sustainable fabrics in their props cap production. This shift not only meets the growing consumer demand for sustainable products but also helps brands position themselves as leaders in corporate social responsibility.

What Is the Evolution of the Props Cap Sector and Its Relevance to B2B Buyers?

The props cap sector has evolved significantly over the past few decades, transitioning from basic functional items to sophisticated branding tools. Initially, caps were primarily utilitarian, designed for protection against the elements. However, as branding and marketing strategies evolved, props caps began to serve as powerful promotional items that convey brand messages and engage customers.

In recent years, the proliferation of digital marketing has further transformed the props cap landscape. Brands now leverage social media and influencer partnerships to showcase their products, leading to a surge in demand for unique and visually appealing designs. For B2B buyers, understanding this evolution is crucial as it impacts sourcing strategies; they must now consider not only the quality and cost of caps but also their potential as marketing assets.

Additionally, as the market continues to expand globally, B2B buyers must be aware of regional preferences and trends. For instance, the styles and materials favored in Europe may differ significantly from those in Africa or South America. Being informed about these nuances allows buyers to make strategic sourcing decisions that align with their target markets and enhance their competitive edge.

Frequently Asked Questions (FAQs) for B2B Buyers of props cap

-

How do I solve the issue of sourcing high-quality props caps for my business?

To ensure you source high-quality props caps, start by identifying reputable manufacturers or suppliers with proven experience in the industry. Check their certifications, customer reviews, and case studies to gauge quality standards. Request samples before placing larger orders to evaluate the product’s material, durability, and design. Additionally, leverage B2B platforms and trade shows to connect with verified suppliers, which can facilitate direct communication and negotiation. -

What is the best material for props caps in different climates?

The best material for props caps largely depends on the climate of your target market. For humid or tropical regions, such as parts of Africa and South America, consider breathable fabrics like cotton or moisture-wicking synthetic materials to enhance comfort. In colder climates, such as Germany, wool or insulated materials are preferable for warmth. Always discuss material options with your supplier to ensure suitability for your specific regional needs. -

What should I consider when customizing props caps for my brand?

When customizing props caps, focus on aspects such as design, color, and branding elements like logos or slogans. Ensure the design aligns with your brand identity and appeals to your target audience. Discuss minimum order quantities (MOQs) with suppliers, as customization often requires larger quantities. Additionally, seek input on manufacturing capabilities to ensure the supplier can deliver your desired specifications without compromising quality. -

What are common payment terms when sourcing props caps internationally?

Payment terms can vary significantly among suppliers. Common options include advance payments, letters of credit, or payment upon delivery. It’s essential to negotiate terms that protect your investment while ensuring the supplier’s commitment to quality. For larger orders, consider using escrow services or third-party payment solutions to mitigate risks. Research local regulations in your target market to comply with any currency exchange or import duties. -

How do I vet suppliers for props caps in international markets?

To effectively vet suppliers, start by checking their business credentials, including registration details and export licenses. Conduct background checks and seek testimonials from other international buyers. Utilize platforms like Alibaba or Global Sources to find verified suppliers and read reviews. Additionally, consider requesting a factory visit or a third-party inspection service to assess their production facilities and capabilities firsthand. -

What logistics should I consider when importing props caps?

Logistics plays a crucial role in importing props caps. Consider factors such as shipping methods (air vs. sea), transit times, and costs. Research customs regulations in your destination country to ensure compliance with import duties and taxes. Collaborate with a reliable freight forwarder who can manage the shipping process and provide insights into documentation requirements. Always factor in potential delays due to customs clearance when planning your inventory. -

What quality assurance measures should I implement when sourcing props caps?

Implementing quality assurance (QA) measures is vital to ensuring product consistency. Establish clear quality standards and communicate them to your supplier before production begins. Request quality inspection reports during and after manufacturing, and consider third-party inspections to verify compliance. Additionally, set up a return policy for defective items to protect your business interests and maintain customer satisfaction. -

What are the minimum order quantities (MOQs) for props caps, and how do they affect pricing?

Minimum order quantities (MOQs) for props caps can vary widely based on the supplier and customization requirements. Typically, higher MOQs lead to lower per-unit costs, making it more economical for bulk purchases. However, if you are a smaller buyer, negotiate with suppliers to see if they can accommodate lower MOQs or offer tiered pricing based on order size. Understanding your sales forecasts will help you balance inventory costs and demand effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for props cap

What Are the Key Takeaways for International B2B Buyers in Strategic Sourcing of Props Cap?

In conclusion, strategic sourcing for props cap presents a significant opportunity for international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe. The importance of aligning sourcing strategies with local market dynamics cannot be overstated. Understanding regional regulations, supplier capabilities, and market demands is crucial for maximizing procurement efficiency and minimizing risks.

Furthermore, leveraging technology and data analytics can enhance decision-making processes, enabling businesses to identify cost-effective suppliers while maintaining quality standards. Buyers should prioritize establishing long-term relationships with trusted suppliers to foster innovation and agility in their supply chains.

How Can International Buyers Prepare for Future Opportunities in Props Cap?

Looking ahead, the landscape of props cap sourcing is likely to evolve with increasing globalization and technological advancements. International buyers are encouraged to stay informed about emerging trends and adapt their strategies accordingly. Engaging in collaborative sourcing initiatives and exploring sustainable practices will not only drive operational efficiency but also enhance brand reputation.

In this dynamic environment, proactive engagement and continuous learning will be key to navigating the complexities of global supply chains. Embrace this opportunity to strengthen your sourcing strategy today and position your business for success in the future.