Discover Fluted Glass: The Ultimate Sourcing Guide (2025)

Introduction: Navigating the Global Market for fluted glass

Navigating the global market for fluted glass presents unique challenges for international B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With applications ranging from architectural design to interior décor, sourcing high-quality fluted glass can be daunting. Buyers often face hurdles in identifying reliable suppliers, understanding the varying types of fluted glass available, and accurately assessing costs. This guide aims to simplify that process, providing a comprehensive overview of fluted glass, including its types, applications, and best practices for supplier vetting.

As you delve into this guide, you will discover actionable insights that empower you to make informed purchasing decisions. We will explore the different applications of fluted glass, from decorative elements to functional uses in construction and design. Additionally, we will discuss effective strategies for evaluating suppliers, ensuring that you partner with reputable manufacturers who meet your specific quality and service standards.

By focusing on the unique needs and challenges faced by international buyers in regions like Colombia and Nigeria, this guide will help you navigate the complexities of sourcing fluted glass, ultimately enhancing your procurement strategies and driving business success. Whether you are a seasoned buyer or new to the market, the insights provided here will facilitate your journey towards securing the best fluted glass solutions for your projects.

Understanding fluted glass Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Clear Fluted Glass | Transparent with vertical grooves | Windows, partitions, decorative items | Pros: Enhances light diffusion; aesthetically pleasing. Cons: Less privacy compared to frosted options. |

| Frosted Fluted Glass | Opaque finish with fluted texture | Shower doors, privacy screens | Pros: Provides privacy; easy to clean. Cons: Limited light transmission. |

| Colored Fluted Glass | Available in various colors, often translucent | Architectural features, lighting | Pros: Adds design versatility; can match branding. Cons: Color fading potential over time. |

| Laminated Fluted Glass | Two or more glass layers with a fluted design | Safety applications, glass facades | Pros: Enhanced strength and safety; sound insulation. Cons: Heavier and may require specialized installation. |

| Patterned Fluted Glass | Unique patterns in the fluted design | Interior design, furniture | Pros: Customizable aesthetics; unique visual appeal. Cons: Higher cost for bespoke designs. |

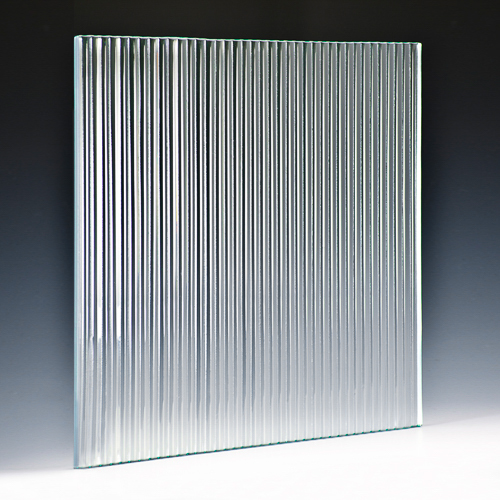

What Are the Characteristics of Clear Fluted Glass?

Clear fluted glass is characterized by its transparent surface with vertical grooves, which allows natural light to diffuse beautifully while providing a degree of texture. It is commonly used in windows, partitions, and decorative items, making it an attractive choice for modern architectural designs. When purchasing, buyers should consider the balance between aesthetic appeal and the level of privacy desired, as clear fluted glass offers minimal obscurity.

How Does Frosted Fluted Glass Provide Privacy?

Frosted fluted glass features an opaque finish that obscures visibility while maintaining a stylish appearance. This type is ideal for applications where privacy is paramount, such as shower doors and office partitions. Buyers should note that while frosted glass is easy to clean and offers significant privacy, it does limit the amount of natural light that can pass through, which might not be suitable for all environments.

What Are the Advantages of Colored Fluted Glass?

Colored fluted glass comes in various hues, allowing for creative architectural solutions and branding opportunities. This type of glass is often used in decorative applications, such as lighting fixtures and architectural features. Buyers should be aware of the potential for color fading over time, depending on the quality of the glass and exposure to sunlight, but the design flexibility it offers can be a significant advantage in marketing and aesthetics.

Why Choose Laminated Fluted Glass for Safety?

Laminated fluted glass consists of multiple layers of glass fused together, providing enhanced strength and safety. Its fluted design makes it suitable for high-traffic areas, glass facades, and safety applications where durability is critical. Buyers should consider the added weight and potential installation challenges, but the benefits of sound insulation and security make laminated fluted glass a compelling option for commercial and residential projects.

What Makes Patterned Fluted Glass Unique?

Patterned fluted glass features distinctive designs that can be customized to fit specific aesthetic needs, making it a popular choice for interior design and furniture applications. This type allows for creative expression and can transform ordinary spaces into visually appealing environments. However, buyers should be prepared for potentially higher costs associated with bespoke designs, which can impact budget considerations for larger projects.

Related Video: slim line profile section Telescopic sliding door with 5+1 , Fluted glass

Key Industrial Applications of fluted glass

| Industry/Sector | Specific Application of Fluted Glass | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Architecture and Construction | Facade Design and Glazing | Enhances aesthetic appeal while providing privacy and light diffusion. | Quality of glass, thermal insulation properties, and durability. |

| Automotive | Interior Paneling and Lighting | Reduces glare and enhances interior design with a unique texture. | Compliance with safety standards and customization options. |

| Consumer Electronics | Decorative Screens for Devices | Provides a stylish finish while protecting screens from scratches. | Sourcing from reliable manufacturers with quality control. |

| Packaging | Decorative Bottles and Containers | Differentiates products on shelves and enhances brand perception. | Recyclability and sustainability of materials used in production. |

| Furniture Design | Tabletops and Decorative Elements | Offers a unique aesthetic while being easy to clean and maintain. | Custom sizes and thickness options to fit specific designs. |

How is Fluted Glass Used in Architecture and Construction?

Fluted glass is increasingly popular in architecture, particularly for facades and glazing applications. Its unique texture not only enhances the visual appeal of buildings but also plays a critical role in light diffusion, allowing natural light to permeate while maintaining privacy. For international buyers, especially from regions like Africa and South America, sourcing fluted glass that meets local climate conditions is essential. Buyers should consider the thermal insulation properties and durability of the glass to ensure it withstands environmental stresses.

What Role Does Fluted Glass Play in Automotive Applications?

In the automotive sector, fluted glass is used for interior paneling and lighting fixtures. Its textured surface reduces glare, enhancing driver and passenger comfort while also contributing to the vehicle’s overall aesthetic appeal. When sourcing fluted glass for automotive applications, compliance with safety standards is paramount. Buyers must ensure that the glass meets regulatory requirements specific to their region, such as those in the Middle East and Europe, where safety regulations can be stringent.

How is Fluted Glass Utilized in Consumer Electronics?

Fluted glass finds its application in the consumer electronics industry, particularly as decorative screens for devices like smartphones and tablets. This type of glass not only protects screens from scratches but also adds a stylish finish that appeals to consumers. For B2B buyers in this sector, sourcing from reliable manufacturers with stringent quality control is crucial. Additionally, considering the compatibility of fluted glass with various device designs can enhance product offerings and customer satisfaction.

In What Ways is Fluted Glass Used in Packaging?

In the packaging industry, fluted glass is often employed for decorative bottles and containers. Its unique texture can differentiate products on retail shelves, enhancing brand perception and attracting consumers. Buyers should prioritize sourcing fluted glass that is recyclable and sustainable, as environmental considerations are increasingly important in global markets. Additionally, ensuring that the glass meets food safety standards is critical for companies operating in the food and beverage sector.

How Does Fluted Glass Enhance Furniture Design?

Fluted glass is a favored material in furniture design, particularly for tabletops and decorative elements. Its aesthetic appeal, combined with ease of cleaning and maintenance, makes it an attractive choice for both residential and commercial furniture. Buyers should consider custom sizes and thickness options to ensure that the fluted glass fits specific design requirements. Moreover, sourcing from manufacturers who can provide a range of finishes can help businesses cater to diverse market demands, particularly in Europe where design trends are continuously evolving.

Related Video: SOLOS Glass – How Float Glass is Made

3 Common User Pain Points for ‘fluted glass’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent Aesthetic Quality

The Problem: B2B buyers often encounter challenges with the aesthetic quality of fluted glass products. Variability in texture, thickness, and clarity can lead to mismatched appearances in large-scale projects, especially in architectural applications where consistency is crucial. This inconsistency may not only impact the visual appeal of the final product but can also lead to costly rework or rejection of the materials, causing delays in project timelines and increased expenses.

The Solution: To mitigate these issues, it is essential to establish clear specifications and quality standards before sourcing fluted glass. Buyers should collaborate closely with manufacturers, detailing the desired texture, thickness, and optical clarity in their purchase orders. Requesting samples from multiple suppliers can also help in evaluating the aesthetic quality upfront. Additionally, employing a third-party quality assurance service to inspect the glass before it is shipped can ensure that the final products meet the established standards, reducing the risk of discrepancies and ensuring a uniform look across all installations.

Scenario 2: Limited Availability of Custom Sizes and Designs

The Problem: Many international B2B buyers find that fluted glass products available in the market do not meet their specific project requirements, particularly when it comes to custom sizes and unique designs. This limitation can hinder creativity and functionality in design projects, making it challenging to achieve the desired architectural or decorative effects. Buyers may also face longer lead times when trying to source custom solutions, leading to project delays.

The Solution: To address this challenge, buyers should proactively communicate their custom needs to manufacturers early in the procurement process. Engaging with suppliers who specialize in bespoke fluted glass solutions can provide more options for unique sizes and designs. It’s beneficial to explore partnerships with manufacturers that offer advanced fabrication capabilities and are willing to collaborate on design innovations. Establishing long-term relationships with a select few suppliers can also streamline the customization process, ensuring that future projects can be executed more efficiently and with greater flexibility.

Scenario 3: Concerns About Durability and Maintenance of Fluted Glass

The Problem: Durability and maintenance are common concerns for B2B buyers when selecting fluted glass, especially in regions with harsh climates or high-traffic environments. Buyers worry about the potential for scratches, fading, and the overall lifespan of the glass. The need for regular maintenance can also lead to increased operational costs and potential disruptions in service, especially for businesses that rely heavily on the aesthetic and functional integrity of their glass installations.

The Solution: Buyers can alleviate these concerns by selecting fluted glass products that are treated with protective coatings designed to enhance durability and ease of maintenance. When sourcing fluted glass, look for options that offer scratch-resistant surfaces and UV protection to prevent fading. Additionally, educating the maintenance staff on best practices for cleaning and caring for fluted glass can significantly extend its lifespan. Implementing a regular inspection and maintenance schedule can also help identify issues early, ensuring that the glass remains in optimal condition and reducing the likelihood of costly repairs or replacements in the future.

Strategic Material Selection Guide for fluted glass

What Are the Key Materials Used in Fluted Glass Production?

Fluted glass, known for its aesthetic appeal and functional properties, can be manufactured from various materials. Each material offers unique characteristics that can significantly influence the performance and application of fluted glass in different industries. Below are analyses of four common materials used in the production of fluted glass.

A stock image related to fluted glass.

Which Glass Types Are Commonly Used for Fluted Glass?

1. Soda-Lime Glass

Key Properties: Soda-lime glass is the most widely used type of glass due to its excellent transparency and ease of fabrication. It has a temperature resistance of up to 300°C and is relatively resistant to corrosion.

Pros & Cons: This material is cost-effective and readily available, making it suitable for mass production. However, it is less durable compared to other glass types and can break easily under stress.

Impact on Application: Soda-lime glass is compatible with various media but is not ideal for high-pressure applications. It is commonly used in decorative applications, such as windows and partitions.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local safety standards, as soda-lime glass may not meet certain durability requirements in high-impact environments.

2. Borosilicate Glass

Key Properties: Borosilicate glass is known for its high thermal resistance (up to 500°C) and low thermal expansion, making it ideal for applications that involve temperature fluctuations.

Pros & Cons: Its durability and resistance to thermal shock make it suitable for laboratory and industrial applications. However, it is more expensive than soda-lime glass and may require specialized manufacturing processes.

Impact on Application: This type of glass is particularly effective in environments where chemical exposure is a concern, such as in laboratories. It is less prone to cracking and is often used in scientific glassware.

Considerations for International Buyers: Compliance with international standards like ASTM and DIN is crucial, especially for buyers in Europe and the Middle East, where quality assurance is paramount.

3. Acrylic (PMMA)

Key Properties: Acrylic is a lightweight, shatter-resistant material that offers high clarity and UV resistance. It can withstand temperatures up to 80°C.

Pros & Cons: Acrylic is highly versatile and can be molded into complex shapes, making it suitable for various decorative applications. However, it is less scratch-resistant than glass and can yellow over time when exposed to UV light.

Impact on Application: Acrylic fluted glass is often used in signage and displays due to its lightweight nature and ease of handling. It is not suitable for high-temperature applications.

Considerations for International Buyers: Buyers should consider the environmental impact of acrylic, especially in regions with strict regulations on plastic use, such as parts of Europe.

4. Tempered Glass

Key Properties: Tempered glass is heat-treated to enhance its strength, withstanding temperatures of up to 300°C. It is also more resistant to impact and thermal stress compared to standard glass.

Pros & Cons: Its durability makes it ideal for safety applications, such as in buildings and vehicles. However, it is more expensive and requires specialized processing.

Impact on Application: Tempered glass is commonly used in high-traffic areas where safety is a concern. Its ability to break into small, blunt pieces reduces the risk of injury.

Considerations for International Buyers: Compliance with safety standards is crucial, especially in construction applications. Buyers from regions like Nigeria and Colombia should ensure that the tempered glass meets local building codes.

Summary Table of Material Selection for Fluted Glass

| Material | Typical Use Case for fluted glass | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Soda-Lime Glass | Decorative windows and partitions | Cost-effective and widely available | Less durable, prone to breakage | Low |

| Borosilicate Glass | Laboratory glassware | High thermal resistance | More expensive, complex to manufacture | High |

| Acrylic (PMMA) | Signage and displays | Lightweight and versatile | Less scratch-resistant, UV degradation | Medium |

| Tempered Glass | Safety applications in buildings | Enhanced strength and safety | Higher cost, requires special processing | High |

This guide provides actionable insights for international B2B buyers, ensuring they can make informed decisions regarding the selection of materials for fluted glass that align with their specific application needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for fluted glass

What Are the Key Manufacturing Processes for Fluted Glass?

A stock image related to fluted glass.

Fluted glass, characterized by its distinct ridged surface, undergoes several critical manufacturing processes to ensure its aesthetic appeal and functional integrity. Understanding these processes can help international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, make informed purchasing decisions.

How Is Material Prepared for Fluted Glass Production?

The manufacturing process begins with material preparation, primarily involving high-quality silica sand, soda ash, and limestone. These materials are carefully weighed and mixed to achieve the desired glass composition. This mixture is then melted in a furnace at temperatures exceeding 1,600 degrees Celsius. The quality of the raw materials is crucial, as impurities can lead to defects in the final product.

B2B buyers should ensure that suppliers use high-grade materials and adhere to international standards for raw material sourcing, as this directly impacts the durability and appearance of the fluted glass.

What Forming Techniques Are Used in Fluted Glass Production?

After the glass is melted, it is formed into fluted shapes using various techniques. The two most common methods are:

-

Press Molding: In this technique, molten glass is pressed into a mold that features the fluted design. This method is efficient for producing large quantities of uniform glass products, such as panels or decorative items.

-

Blow Molding: For more intricate designs, blow molding is often utilized. In this process, air is blown into a molten glass mass, allowing it to take the shape of the mold while creating the fluted patterns. This method is particularly useful for creating bottles and other hollow glass items.

Both methods require skilled artisans to ensure precision and quality in the fluted patterns. Buyers should inquire about the specific forming techniques used by suppliers, as this can affect product consistency and quality.

What Finishing Processes Are Essential for Fluted Glass?

Once formed, fluted glass undergoes several finishing processes to enhance its visual appeal and performance. These processes typically include:

-

Annealing: This is a critical step where the glass is gradually cooled in a controlled environment to relieve internal stresses. Proper annealing is vital to prevent cracking or breaking during handling and usage.

-

Surface Treatment: Depending on the application, fluted glass may receive additional treatments such as polishing, coating, or etching. These treatments improve clarity, enhance durability, and can provide UV protection.

-

Quality Inspection: After finishing, each piece of glass is inspected for defects, such as bubbles, scratches, or inconsistencies in the fluted design. This quality assurance step is crucial for maintaining high standards.

B2B buyers should verify the supplier’s finishing processes and inquire about any additional treatments that may be available for specific applications.

What Quality Assurance Measures Are Implemented in Fluted Glass Production?

Quality assurance (QA) is a crucial aspect of fluted glass manufacturing, ensuring that products meet both international and industry-specific standards. This is particularly significant for B2B buyers who require reliable and durable products.

Which International Standards Apply to Fluted Glass?

For fluted glass, adherence to international standards such as ISO 9001 is essential. This standard focuses on quality management systems and ensures that manufacturers consistently provide products that meet customer and regulatory requirements. Other relevant certifications may include:

-

CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

-

API Standards: For fluted glass used in specific industrial applications, the American Petroleum Institute (API) standards may also apply.

B2B buyers should request certification documentation from suppliers to confirm compliance with these standards.

What Are the Common Quality Control Checkpoints in Fluted Glass Manufacturing?

Quality control (QC) in fluted glass manufacturing typically involves several key checkpoints:

-

Incoming Quality Control (IQC): This initial step checks the quality of raw materials before production begins. Suppliers should have stringent criteria for material acceptance to prevent defects.

-

In-Process Quality Control (IPQC): During production, ongoing checks are performed to monitor the manufacturing process. This includes measuring temperatures in the furnace, inspecting mold conditions, and ensuring that the forming techniques are executed correctly.

-

Final Quality Control (FQC): After finishing, the final product undergoes thorough inspection and testing. Common testing methods include visual inspection, dimensional checks, and stress testing to ensure the glass meets all specifications.

B2B buyers should inquire about the QC processes employed by suppliers and how they document and address any issues that arise during production.

How Can B2B Buyers Verify Supplier Quality Control?

Ensuring that suppliers maintain high-quality standards is crucial for B2B buyers, especially in international markets. Here are actionable steps buyers can take:

-

Conduct Supplier Audits: Periodically auditing suppliers can provide insight into their manufacturing processes, quality control measures, and adherence to standards. This is particularly important for buyers from Africa, South America, the Middle East, and Europe, where supply chain reliability may vary.

-

Request Quality Reports: Buyers should ask suppliers for detailed quality reports that outline the results of IQC, IPQC, and FQC processes. These reports can highlight any recurring issues and how they are addressed.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. This is especially useful for buyers unfamiliar with local suppliers or those looking to establish trust in new partnerships.

Conclusion

Understanding the manufacturing processes and quality assurance measures for fluted glass is vital for international B2B buyers. By focusing on material preparation, forming techniques, finishing processes, and robust quality control systems, buyers can make informed decisions that ensure they receive high-quality products that meet their specific needs. Engaging in thorough supplier assessments and requesting relevant certifications can further enhance buyer confidence in their procurement choices.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fluted glass’

In this practical sourcing guide, we aim to provide international B2B buyers with a comprehensive checklist to effectively procure fluted glass. Understanding the nuances of sourcing this specialized material can facilitate better decision-making and ultimately lead to successful partnerships.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for sourcing fluted glass that meets your project requirements. Consider factors such as thickness, dimensions, fluting patterns, and intended use (e.g., architectural, decorative, or functional). Detailed specifications help suppliers understand your needs, reducing the risk of miscommunication and ensuring that the final product aligns with your expectations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of fluted glass. Look for manufacturers with a solid reputation in the industry and experience in producing the specific type of fluted glass you require. Utilize online directories, trade shows, and industry publications to gather a list of candidates.

- Tip: Check for reviews and testimonials from previous clients to gauge supplier reliability.

Step 3: Evaluate Supplier Certifications

Before committing to a supplier, verify their certifications and compliance with international quality standards. Certifications such as ISO 9001 or specific industry-related standards indicate a commitment to quality and safety.

- What to look for: Ensure that the supplier has relevant certifications for glass production, including environmental and safety regulations.

Step 4: Request Samples

Requesting samples of fluted glass is essential to assess the quality and craftsmanship of the supplier’s products. Evaluate the samples based on your defined specifications, focusing on aspects such as clarity, finish, and fluting consistency.

- Why it matters: Samples provide a tangible way to compare different suppliers and help you make an informed decision.

Step 5: Inquire About Production Capabilities

Understanding a supplier’s production capabilities is vital to ensure they can meet your volume and timeline requirements. Ask about their manufacturing processes, lead times, and flexibility in scaling production if your needs change.

- Key questions: Can they handle custom orders? What are their minimum order quantities?

Step 6: Negotiate Terms and Pricing

Once you’ve narrowed down your options, initiate discussions around pricing and payment terms. Be clear about your budget while also considering the value of quality and service.

- Considerations: Look for bulk purchase discounts and flexible payment options that can help optimize your cash flow.

Step 7: Establish a Communication Plan

Effective communication is key to a successful sourcing relationship. Establish a clear communication plan that includes regular updates, points of contact, and preferred methods of communication.

- Tip: Set expectations for response times and problem resolution to ensure a smooth procurement process.

By following this step-by-step checklist, international B2B buyers can navigate the complexities of sourcing fluted glass, ensuring they make informed decisions that align with their project goals.

Comprehensive Cost and Pricing Analysis for fluted glass Sourcing

What Are the Key Cost Components in Fluted Glass Sourcing?

When sourcing fluted glass, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The quality and type of glass used significantly affect costs. High-quality, tempered, or specialized fluted glass can be more expensive than standard options.

-

Labor: Skilled labor is often required for the precise manufacturing of fluted glass. This includes glass cutting, shaping, and finishing processes, which can vary by region and supplier.

-

Manufacturing Overhead: This encompasses the costs associated with running production facilities, including utilities, maintenance, and equipment depreciation.

-

Tooling: Custom molds or tooling for specific designs can add significant costs. This is particularly relevant for buyers requiring unique patterns or dimensions.

-

Quality Control (QC): Implementing stringent QC processes ensures the glass meets required specifications. This can add to the overall production cost but is essential for maintaining quality.

-

Logistics: Transportation costs can vary widely based on distance, shipping methods, and the volume of the order. International shipping, especially, can incur significant fees.

-

Margin: Suppliers will include a profit margin in their pricing. This can vary based on market conditions and the supplier’s positioning.

How Do Price Influencers Affect Fluted Glass Costs?

Several factors influence the pricing of fluted glass, impacting the final cost for buyers:

-

Volume/MOQ: Larger orders typically benefit from economies of scale, reducing the per-unit price. Minimum order quantities (MOQ) can also affect overall pricing.

-

Specifications and Customization: Custom designs or specific fluting patterns may incur additional costs. Providing detailed specifications can help suppliers give more accurate quotes.

-

Materials Used: The choice between standard and premium materials affects pricing. Specialty glass types will generally command higher prices.

-

Quality Certifications: Certifications such as ISO or industry-specific standards can affect costs. Suppliers with higher certifications may charge more due to the rigorous processes they adhere to.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their experience and quality assurances.

-

Incoterms: Understanding international shipping terms (Incoterms) is vital as they determine who bears the costs and risks during transportation. This can significantly affect the total cost.

What Tips Can Help Buyers Negotiate Better Prices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate Volume Discounts: Don’t hesitate to negotiate based on volume. Suppliers are often willing to provide discounts for larger orders.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, transportation, and potential waste costs. A slightly higher initial price may lead to lower overall costs in the long run.

-

Be Aware of Pricing Nuances: Understand the local market conditions and pricing practices of suppliers in your region. This knowledge can strengthen your negotiation position.

-

Request Transparent Quotes: Ask suppliers for detailed quotes that break down costs. This transparency helps in identifying areas for negotiation and understanding where value is added.

-

Build Relationships: Establishing a good relationship with suppliers can lead to better pricing and terms over time. Trust and loyalty can often result in favorable conditions.

Disclaimer on Indicative Prices

It’s important to note that prices for fluted glass can fluctuate based on market conditions, supplier capabilities, and the specifics of each order. Buyers should always seek multiple quotes and conduct due diligence to ensure they receive the best possible pricing and value for their investment.

Alternatives Analysis: Comparing fluted glass With Other Solutions

Understanding Alternatives to Fluted Glass in B2B Applications

When considering material options for various applications, it’s crucial to evaluate alternatives to fluted glass. This analysis will focus on comparing fluted glass with two viable alternatives: textured glass and polycarbonate panels. Each option has its unique characteristics, performance metrics, and suitability for specific uses, allowing B2B buyers to make informed decisions.

| Comparison Aspect | Fluted Glass | Textured Glass | Polycarbonate Panels |

|---|---|---|---|

| Performance | Good light diffusion, aesthetic appeal | Excellent light diffusion, customizable textures | High impact resistance, UV protection |

| Cost | Moderate cost | Varies (generally higher) | Lower initial cost, but may require replacements |

| Ease of Implementation | Relatively easy to install | May require specialized installation | Simple to cut and install |

| Maintenance | Low maintenance | Low maintenance | Moderate maintenance due to scratching |

| Best Use Case | Decorative partitions, windows | Privacy screens, artistic installations | Safety glazing, outdoor applications |

What Are the Pros and Cons of Textured Glass Compared to Fluted Glass?

Textured glass offers a unique aesthetic that can enhance privacy while still allowing light to enter. Its customizable textures make it suitable for various applications, including interior design and decorative elements. However, textured glass can be more expensive than fluted glass, particularly if specialized manufacturing processes are required. While both materials have low maintenance requirements, textured glass may necessitate careful handling to avoid damage to its surface patterns.

How Does Polycarbonate Compare to Fluted Glass in Terms of Performance?

Polycarbonate panels are known for their exceptional impact resistance and lightweight nature, making them ideal for applications where safety is paramount, such as in schools and public buildings. They also provide UV protection, which is beneficial for outdoor use. However, polycarbonate can be prone to scratching, which may lead to a need for more frequent maintenance compared to fluted glass. Despite the lower initial cost, polycarbonate may require periodic replacement or repairs, which can affect long-term value.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting between fluted glass and its alternatives, B2B buyers should consider their specific requirements, such as desired aesthetics, functionality, and budget constraints. Fluted glass stands out for its unique visual appeal and suitability for decorative applications, while textured glass can offer enhanced privacy. Polycarbonate may be the right choice for high-traffic environments where safety and durability are priorities. Ultimately, the decision should align with the project’s objectives, the intended use of the material, and any long-term maintenance considerations. By carefully weighing these factors, buyers can confidently choose the solution that best meets their needs.

Essential Technical Properties and Trade Terminology for fluted glass

What Are the Key Technical Properties of Fluted Glass for B2B Buyers?

When considering fluted glass for commercial applications, understanding its technical properties is essential for making informed purchasing decisions. Here are critical specifications that international B2B buyers should be aware of:

-

Material Grade

– Fluted glass is typically made from soda-lime or borosilicate glass. The material grade affects durability and thermal resistance. For instance, borosilicate glass is preferred in environments with temperature fluctuations due to its lower thermal expansion coefficient. Selecting the appropriate material grade ensures the glass meets performance requirements for specific applications. -

Thickness

– The thickness of fluted glass can vary significantly, usually ranging from 4mm to 12mm or more. Thicker glass provides better structural integrity and insulation, making it suitable for facades and interior partitions. Buyers should assess the application requirements to determine the optimal thickness for their projects. -

Tolerance

– Tolerance refers to the permissible deviation from specified dimensions. For fluted glass, standard tolerances typically range from ±1mm to ±3mm. Understanding tolerance is crucial for ensuring that the glass fits correctly within frames or other assemblies, minimizing installation issues and potential costs. -

Finish and Surface Treatment

– Fluted glass can be treated with various finishes such as acid etching or polishing. These treatments can enhance aesthetics and improve functionality by providing a non-slip surface. Buyers should consider the intended use of the glass to choose the right finish that aligns with both design and safety standards. -

Light Transmission and Thermal Performance

– The light transmission percentage indicates how much light passes through the glass, affecting energy efficiency in buildings. Additionally, thermal performance metrics, such as U-value, determine how well the glass insulates against heat loss. Buyers in regions with extreme climates should prioritize products with high thermal performance to reduce energy costs. -

Impact Resistance

– Impact resistance measures how well the glass can withstand physical stress. Fluted glass can be treated to enhance its resistance to shattering, which is particularly important in high-traffic commercial areas. Understanding this property is vital for ensuring safety and longevity in installations.

What Are Common Trade Terms Related to Fluted Glass?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are several key trade terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of fluted glass, OEMs often supply custom solutions tailored to specific architectural needs, allowing buyers to leverage specialized expertise. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers as it affects inventory management and budgeting. For fluted glass, MOQs can vary depending on the manufacturer and the complexity of the order. -

RFQ (Request for Quotation)

– An RFQ is a document used to solicit price quotes from suppliers. For fluted glass, an RFQ should include detailed specifications such as dimensions, material grade, and finish. This ensures that suppliers provide accurate pricing and enables buyers to compare offers effectively. -

Incoterms (International Commercial Terms)

– Incoterms are a set of international rules that define the responsibilities of sellers and buyers in shipping contracts. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Understanding Incoterms is essential for managing shipping costs and risk in international transactions. -

Lead Time

– Lead time is the duration from placing an order to its delivery. For fluted glass, lead times can vary based on customization and supplier capacity. Buyers should factor in lead time when planning projects to avoid delays in construction or installation. -

Certification and Compliance Standards

– Many countries have specific standards for construction materials, including glass. Certifications such as ISO or ANSI indicate compliance with safety and quality regulations. Buyers should ensure that their fluted glass suppliers meet relevant certifications to avoid legal and safety issues.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing fluted glass, ultimately ensuring that their projects meet both performance and regulatory standards.

Navigating Market Dynamics and Sourcing Trends in the fluted glass Sector

A stock image related to fluted glass.

What Are the Current Market Dynamics and Key Trends in the Fluted Glass Sector?

The fluted glass market is experiencing a significant transformation driven by several global factors. Key trends include a growing demand for decorative glass solutions in architecture and interior design, spurred by urbanization and an increased focus on aesthetics in public and private spaces. Additionally, the rise of e-commerce and digital platforms is enabling international B2B buyers from regions such as Africa, South America, the Middle East, and Europe (notably countries like Colombia and Nigeria) to access a wider array of suppliers and products.

Technological advancements in glass manufacturing, such as automated production lines and innovative glass treatments, are enhancing product quality and reducing lead times. As a result, buyers can expect a more reliable supply chain and improved customization options. The integration of digital tools in sourcing processes, including virtual showrooms and augmented reality, is also becoming prevalent, allowing buyers to visualize products before purchase.

Moreover, sustainability is becoming a pivotal factor in purchasing decisions. Buyers are increasingly looking for suppliers who adopt eco-friendly practices, such as using recycled materials and minimizing waste during production. Understanding these dynamics is crucial for B2B buyers to navigate the fluted glass market effectively.

How Important Is Sustainability and Ethical Sourcing in the Fluted Glass Sector?

Sustainability and ethical sourcing are paramount considerations in today’s fluted glass market. The environmental impact of glass production, particularly energy consumption and emissions, has led many manufacturers to adopt greener practices. This includes using renewable energy sources in production and implementing waste reduction strategies. For international B2B buyers, particularly those in regions like Africa and South America, partnering with suppliers who prioritize sustainability can enhance brand reputation and align with consumer preferences for eco-conscious products.

Moreover, ethical supply chains that ensure fair labor practices and responsible sourcing of raw materials are gaining traction. Buyers should seek suppliers with certifications that indicate adherence to environmental and social standards, such as ISO 14001 for environmental management and Fair Trade certifications. These certifications not only demonstrate a commitment to sustainability but also ensure product quality and reliability.

Incorporating ‘green’ materials, such as recycled glass, can further enhance the sustainability profile of fluted glass products. This trend resonates well with consumers and businesses alike, making it an essential factor for B2B buyers to consider in their sourcing strategies.

How Has the Fluted Glass Sector Evolved Over Time?

The fluted glass sector has evolved significantly over the decades, transitioning from traditional hand-crafted techniques to modern automated production methods. Historically, fluted glass was primarily used for decorative purposes in architecture and design, valued for its aesthetic appeal and ability to diffuse light.

With the advent of industrialization in the 20th century, production methods became more sophisticated, allowing for mass production and wider availability. The introduction of new technologies, such as glass tempering and coating, has further expanded the application of fluted glass, making it suitable for a variety of uses, from windows and doors to decorative partitions and tableware.

As the market continues to grow, the focus has shifted towards innovation and sustainability, reflecting changing consumer demands and environmental considerations. Understanding this historical context allows B2B buyers to appreciate the ongoing developments within the fluted glass sector and make informed sourcing decisions that align with current trends.

Frequently Asked Questions (FAQs) for B2B Buyers of fluted glass

-

How do I identify reliable suppliers for fluted glass?

To identify reliable suppliers for fluted glass, start by conducting thorough market research. Utilize B2B platforms such as Alibaba, Global Sources, or industry-specific directories. Look for suppliers with positive reviews, a strong track record, and certifications such as ISO. Request samples to evaluate product quality and communicate directly with suppliers to assess their responsiveness and professionalism. Additionally, consider visiting trade shows in your region to meet suppliers face-to-face and establish relationships. -

What are the common applications for fluted glass in various industries?

Fluted glass is widely used in construction and interior design, providing both aesthetic appeal and functionality. Common applications include partition walls, shower enclosures, windows, and decorative glass panels. In the automotive industry, fluted glass can be found in vehicle windows for enhanced privacy and style. Additionally, it is used in furniture design, such as tabletops and cabinets, to add texture and elegance. Understanding these applications can help B2B buyers target their purchasing efforts effectively. -

What customization options are available when sourcing fluted glass?

Most suppliers offer a range of customization options for fluted glass, including different thicknesses, colors, patterns, and sizes. When sourcing, communicate your specific requirements clearly to ensure that suppliers can meet your needs. Some manufacturers may also offer unique finishes or treatments, such as anti-reflective coatings or UV protection. Always request samples of custom designs before placing large orders to ensure the final product aligns with your expectations. -

What is the minimum order quantity (MOQ) for fluted glass products?

The minimum order quantity (MOQ) for fluted glass can vary significantly depending on the supplier and the specific product. Generally, MOQs can range from a few sheets to several hundred, especially for customized orders. It’s advisable to discuss MOQs upfront with potential suppliers to understand their terms. Some suppliers may be flexible with MOQs for first-time buyers or if you are willing to pay a premium, so don’t hesitate to negotiate. -

What payment terms should I expect when purchasing fluted glass internationally?

Payment terms for international purchases of fluted glass typically include options like advance payment, letter of credit, or payment upon delivery. Most suppliers require a deposit (usually 30%) when placing an order, with the balance due before shipment. Be sure to clarify payment methods and terms during negotiations to avoid any misunderstandings. Using secure payment platforms can also help safeguard your transaction, especially when dealing with new suppliers. -

How can I ensure quality assurance for fluted glass products?

To ensure quality assurance for fluted glass, request detailed product specifications and certifications from suppliers. Consider implementing a quality control process that includes pre-shipment inspections, where third-party agencies can verify product quality before shipment. Additionally, establish clear communication channels with suppliers to address any issues that may arise during production. Maintaining a consistent dialogue can help ensure that the final product meets your standards. -

What logistics considerations should I keep in mind when importing fluted glass?

When importing fluted glass, logistics considerations include shipping methods, costs, and transit times. Glass is fragile, so selecting appropriate packaging and handling methods is crucial to avoid damage during transport. Work with logistics providers experienced in handling glass shipments to ensure safe delivery. Additionally, be aware of customs regulations and duties in your country to prevent delays or unexpected costs upon arrival. -

How do I handle potential disputes with fluted glass suppliers?

Handling disputes with fluted glass suppliers requires clear communication and documentation. Always keep records of contracts, correspondence, and any agreements made. If an issue arises, address it promptly by reaching out to the supplier to discuss the matter. If resolution is not achieved, consider mediation or arbitration as outlined in your contract. Building strong relationships with suppliers can also help mitigate disputes before they escalate.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for fluted glass

What Are the Key Takeaways for B2B Buyers in Fluted Glass Sourcing?

Strategic sourcing of fluted glass is pivotal for international buyers seeking quality and innovation. The unique aesthetic appeal and functional advantages of fluted glass can enhance product offerings across various industries, from architecture to consumer goods. As markets in Africa, South America, the Middle East, and Europe continue to evolve, establishing strong supplier relationships will be essential. Buyers should prioritize suppliers who demonstrate reliability, sustainability, and a commitment to quality assurance.

How Can B2B Buyers Prepare for Future Trends in Fluted Glass?

Looking ahead, the demand for fluted glass is set to grow, driven by trends in eco-friendly materials and architectural design. International B2B buyers are encouraged to stay informed about technological advancements in glass manufacturing, which could lead to improved product durability and customization options. Engaging with suppliers who are at the forefront of these innovations can provide a competitive edge.

What Actions Should B2B Buyers Take Now?

To capitalize on the opportunities in the fluted glass market, buyers should initiate discussions with potential suppliers, explore bulk purchasing options, and consider long-term contracts. By doing so, they can secure favorable terms and ensure a steady supply of high-quality fluted glass. The time to act is now—position your business for success by embracing strategic sourcing practices that align with global trends and consumer demands.