Discover the Benefits of Nano Ceramic Tint for Your Business (2025)

Introduction: Navigating the Global Market for nano ceramic tint

In today’s competitive landscape, sourcing high-quality nano ceramic tint can be a daunting task for international B2B buyers. With a plethora of options available, understanding the nuances of this innovative product is crucial for making informed decisions. Nano ceramic tint offers unparalleled benefits, including superior heat rejection, UV protection, and enhanced durability, making it an attractive choice for automotive, architectural, and industrial applications. However, the challenge lies in identifying reliable suppliers and ensuring that the products meet specific regional requirements and standards.

This comprehensive guide is designed to empower B2B buyers from Africa, South America, the Middle East, and Europe by providing valuable insights into the global market for nano ceramic tint. We will explore various types of nano ceramic films, their applications across different industries, and the key factors to consider when vetting suppliers. Additionally, we will discuss pricing structures and cost considerations to help you optimize your purchasing strategy.

By leveraging the information in this guide, you will be better equipped to navigate the complexities of the nano ceramic tint market. Our aim is to facilitate smarter purchasing decisions that align with your business needs and regional compliance, ultimately enhancing your product offerings and customer satisfaction. Whether you’re looking to enhance vehicle aesthetics or improve energy efficiency in buildings, this guide serves as your essential resource for success in the evolving world of nano ceramic tint.

Understanding nano ceramic tint Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Nano Ceramic Tint | Basic UV protection, moderate heat rejection | Automotive, residential, commercial | Pros: Cost-effective, widely available. Cons: Limited performance compared to premium options. |

| High-Performance Nano Ceramic Tint | Enhanced heat rejection, superior clarity, and durability | High-end automotive, luxury buildings | Pros: Exceptional performance, long-lasting. Cons: Higher price point. |

| DIY Nano Ceramic Tint | User-friendly application, less professional skill needed | Small businesses, individual consumers | Pros: Lower labor costs, easy to apply. Cons: May not achieve professional finish. |

| Specialty Nano Ceramic Tint | Designed for specific applications (e.g., safety, privacy) | Security firms, healthcare, specialized industries | Pros: Tailored solutions, addresses unique needs. Cons: Limited availability, potentially higher costs. |

| Eco-Friendly Nano Ceramic Tint | Made with sustainable materials, low environmental impact | Green building projects, eco-conscious brands | Pros: Appeals to eco-friendly markets. Cons: May lack some performance features of traditional tints. |

What are the Characteristics of Standard Nano Ceramic Tint?

Standard nano ceramic tint is designed to provide basic UV protection and moderate heat rejection. This type is particularly suitable for general automotive applications and residential installations. B2B buyers should consider the cost-effectiveness of this option, as it is widely available and provides adequate performance for most standard needs. However, it may not meet the demands of high-performance applications, making it essential to evaluate specific project requirements.

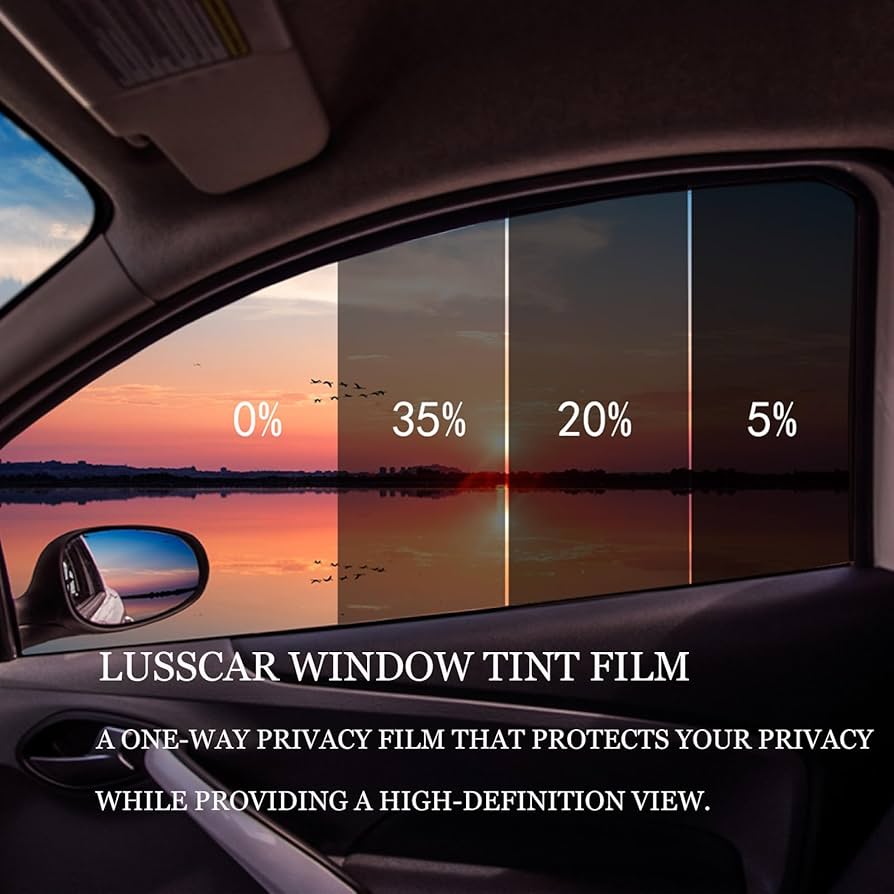

A stock image related to nano ceramic tint.

How Does High-Performance Nano Ceramic Tint Stand Out?

High-performance nano ceramic tint is characterized by its enhanced heat rejection capabilities and superior optical clarity. This type is ideal for high-end automotive markets and luxury buildings where aesthetics and comfort are paramount. B2B buyers should weigh the exceptional benefits against the higher price point. While it represents a significant investment, the long-lasting durability and premium performance can justify the cost, especially in competitive markets.

What Makes DIY Nano Ceramic Tint a Viable Option for Small Businesses?

DIY nano ceramic tint is designed for easy application, allowing businesses and individual consumers to install it without professional assistance. This type can be particularly advantageous for small businesses looking to minimize labor costs. However, B2B buyers must consider that while it offers ease of use, the final finish may not match that of professionally applied tints. It is crucial to assess the skill level of the applicators and the expected quality of the installation.

What are the Benefits of Specialty Nano Ceramic Tint for Niche Markets?

Specialty nano ceramic tint is formulated for specific applications, such as safety or privacy, making it an excellent choice for security firms and healthcare institutions. This type addresses unique market needs, providing tailored solutions that standard tints may not fulfill. Buyers should evaluate the availability and pricing of specialty products, as they may be less common and come at a premium. However, the ability to meet distinct requirements can make this investment worthwhile.

Why Choose Eco-Friendly Nano Ceramic Tint for Sustainable Projects?

Eco-friendly nano ceramic tint is produced using sustainable materials and aims to reduce environmental impact. This type is particularly relevant for green building projects and brands that prioritize sustainability. B2B buyers should consider the growing market demand for environmentally friendly products, as this can enhance brand reputation and appeal to eco-conscious consumers. Nonetheless, it is essential to verify that eco-friendly options do not compromise on performance compared to traditional tints.

Related Video: Ceramic Tint vs NANO Ceramic Tint (NEW!)

Key Industrial Applications of nano ceramic tint

| Industry/Sector | Specific Application of nano ceramic tint | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Window tinting for passenger and commercial vehicles | Enhances passenger comfort, reduces glare, and protects interiors from UV damage. | Look for suppliers with certifications for heat rejection and UV protection. |

| Architecture & Construction | Building window films for commercial and residential properties | Improves energy efficiency and occupant comfort while reducing cooling costs. | Ensure compliance with local building codes and energy efficiency standards. |

| Electronics | Protective coatings for electronic devices | Increases durability and lifespan of devices while minimizing heat buildup. | Seek suppliers with expertise in nano-coating technologies and quality assurance processes. |

| Aerospace | Window and cockpit tinting for aircraft | Enhances visibility and reduces cockpit glare, improving pilot comfort and safety. | Prioritize suppliers that meet aerospace industry standards and regulations. |

| Marine | Tinting for yacht and boat windows | Protects interiors from sun damage and enhances privacy, improving passenger experience. | Consider sourcing from manufacturers with marine-grade certifications and experience. |

How is Nano Ceramic Tint Used in the Automotive Sector?

In the automotive industry, nano ceramic tint is primarily used for window tinting in both passenger and commercial vehicles. This application addresses common problems such as excessive heat buildup, glare, and UV exposure, which can degrade interior materials over time. For international B2B buyers, particularly from regions with varying climate conditions like Africa and the Middle East, it is crucial to source tints that offer high heat rejection and UV protection. Certifications and performance data are essential for ensuring the product meets local regulations and customer expectations.

What Role Does Nano Ceramic Tint Play in Architecture and Construction?

In architecture and construction, nano ceramic tint is applied as window films for commercial and residential buildings. These films significantly enhance energy efficiency by reducing heat transfer, leading to lower cooling costs and improved occupant comfort. For buyers in Europe and South America, sourcing these films requires a focus on compliance with local building codes and energy efficiency standards. It is vital to choose manufacturers who can provide detailed product specifications and performance testing results to ensure optimal building performance.

How Does Nano Ceramic Tint Benefit Electronics?

Nano ceramic tint serves as a protective coating for electronic devices, addressing issues related to heat buildup and durability. This application is particularly relevant for B2B buyers in the electronics sector, as it extends the lifespan of devices while maintaining optimal performance. Buyers should prioritize suppliers that specialize in nano-coating technologies and can demonstrate robust quality assurance processes. This ensures that the coatings are not only effective but also compatible with various electronic materials.

Why is Nano Ceramic Tint Important in Aerospace Applications?

In the aerospace industry, nano ceramic tint is utilized for window and cockpit tinting, enhancing visibility while reducing glare for pilots. This application is critical for ensuring safety and comfort during flight operations. International B2B buyers, especially in regions with strict aviation regulations, must prioritize suppliers that adhere to aerospace industry standards. It is essential to evaluate the tint’s performance under various environmental conditions and ensure that it meets all necessary certifications.

How is Nano Ceramic Tint Applied in the Marine Industry?

In the marine sector, nano ceramic tint is used for tinting yacht and boat windows, providing protection against sun damage and enhancing passenger privacy. This application improves the overall onboard experience by reducing heat and glare. For buyers in regions like South America and Europe, sourcing from manufacturers with marine-grade certifications is vital. It is also important to consider the specific needs of the marine environment, such as resistance to saltwater and UV exposure, when selecting the appropriate product.

Related Video: LABORATORY APPARATUS AND THEIR USES

3 Common User Pain Points for ‘nano ceramic tint’ & Their Solutions

Scenario 1: Inconsistent Product Performance Across Regions

The Problem:

B2B buyers from diverse regions, such as Africa and South America, often encounter challenges with the consistency of nano ceramic tint performance. Factors such as climate, UV exposure, and application methods can significantly affect how well the tint works in different environments. For instance, a product that performs excellently in temperate climates may underperform in hotter, more humid regions. This inconsistency can lead to customer dissatisfaction, increased returns, and reputational damage for businesses that rely on these products for their service offerings.

The Solution:

To mitigate these risks, international buyers should prioritize sourcing nano ceramic tints from manufacturers who provide detailed performance specifications tailored to various climatic conditions. It’s crucial to request test data that demonstrates how the tint performs under different environmental stresses, such as UV resistance, heat rejection, and glare reduction. Additionally, consider establishing partnerships with local distributors who understand regional challenges and can offer insights into the best application techniques suited for the local climate. Training sessions for application teams, focusing on best practices for tint installation based on local conditions, can also enhance product performance and customer satisfaction.

Scenario 2: Difficulty in Ensuring Quality Control During Installation

The Problem:

One significant pain point for B2B buyers is the variability in installation quality, which can lead to customer complaints and product failure. Inconsistent application techniques and lack of skilled labor can result in issues such as bubbling, peeling, or improper adhesion of the nano ceramic tint. This is particularly relevant in regions where training resources for installers are limited, leading to a reliance on untrained personnel who may not understand the nuances of the product.

The Solution:

To address this issue, businesses should invest in comprehensive training programs for their installation teams. Partnering with manufacturers who offer certification programs can ensure that installers are well-versed in the proper application techniques for nano ceramic tint. Furthermore, providing detailed installation manuals and video tutorials can serve as ongoing resources for installers, reinforcing best practices. Implementing a quality control checklist during the installation process can also help in identifying and rectifying issues before they become a problem for end-users. Regular follow-ups and feedback sessions with the installation teams can foster a culture of continuous improvement.

Scenario 3: High Costs of Nano Ceramic Tint Products

The Problem:

B2B buyers often struggle with the high upfront costs associated with nano ceramic tint products, which can deter potential customers, especially in cost-sensitive markets such as parts of Africa and South America. The perception that these tints are a luxury rather than a necessity can limit market reach, resulting in lost opportunities for businesses looking to expand their offerings.

The Solution:

To overcome this financial barrier, B2B buyers should focus on demonstrating the long-term value and return on investment (ROI) of nano ceramic tints. This can be achieved by creating case studies that showcase how these products contribute to energy savings, enhance vehicle longevity, and improve comfort for occupants. Offering flexible financing options or bundling products with services can also make the initial investment more palatable for customers. Additionally, consider targeting specific market segments, such as commercial fleet operators, who may recognize the cost-saving benefits of lower fuel consumption and reduced interior wear over time. By effectively communicating the benefits and providing tailored financing solutions, businesses can enhance their value proposition and expand their customer base.

Strategic Material Selection Guide for nano ceramic tint

A stock image related to nano ceramic tint.

When selecting materials for nano ceramic tint, international B2B buyers must consider various factors that impact product performance, cost, and application suitability. Below is an analysis of common materials used in nano ceramic tint formulations, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What are the Key Properties of Silicon Dioxide (SiO₂) in Nano Ceramic Tints?

Silicon dioxide is a primary component in many nano ceramic tints, known for its exceptional thermal stability and UV resistance. It can withstand high temperatures, making it suitable for automotive and architectural applications. Its low thermal conductivity also contributes to energy efficiency, reducing heat transfer into vehicles and buildings.

Pros & Cons:

– Pros: High durability and scratch resistance, excellent UV protection, and good optical clarity.

– Cons: Higher manufacturing complexity and cost compared to traditional tints, which may deter budget-conscious buyers.

Impact on Application:

Silicon dioxide’s compatibility with various surfaces, including glass and plastics, makes it versatile. However, it may require specific adhesion promoters to ensure optimal bonding.

Considerations for International Buyers:

Buyers must ensure compliance with local regulations regarding UV protection and heat rejection. Standards like ASTM and EN can guide product selection, especially in regions with strict building codes.

How Does Titanium Dioxide (TiO₂) Enhance Nano Ceramic Tint Performance?

Titanium dioxide is often added to nano ceramic tints to improve opacity and enhance the tint’s reflective properties. It is known for its high refractive index, which helps in reducing glare and improving visibility.

Pros & Cons:

– Pros: Excellent light reflection and UV blocking capabilities, contributing to interior comfort and longevity of materials.

– Cons: Can be more expensive than other pigments, and its performance can be affected by environmental factors like humidity.

Impact on Application:

Titanium dioxide is particularly effective in regions with high sunlight exposure, making it ideal for automotive and architectural applications in sunny climates.

Considerations for International Buyers:

Buyers should be aware of the environmental regulations surrounding titanium dioxide, especially in Europe, where REACH compliance is crucial. Understanding local preferences for tint darkness and reflectivity can also guide material selection.

What Role Does Polyurethane Play in Nano Ceramic Tint Formulations?

Polyurethane is used as a binder in nano ceramic tints, providing flexibility and adhesion. Its properties allow for the creation of films that are both durable and resistant to environmental stressors.

Pros & Cons:

– Pros: High durability, excellent adhesion to various substrates, and resistance to chemicals and abrasion.

– Cons: Can be sensitive to UV degradation over time, which may necessitate additional protective layers.

Impact on Application:

Polyurethane’s flexibility makes it suitable for applications requiring conformability, such as curved glass surfaces in vehicles. However, its performance may vary with temperature fluctuations.

Considerations for International Buyers:

Buyers should ensure that the polyurethane used meets local environmental regulations. Additionally, understanding the typical climate conditions in their region can influence the selection of polyurethane grades.

What are the Advantages of Using Polyvinyl Butyral (PVB) in Nano Ceramic Tints?

Polyvinyl butyral is often used in the lamination process of nano ceramic tints, providing excellent adhesion and impact resistance. It is particularly valued for its safety features, as it holds glass fragments together in case of breakage.

Pros & Cons:

– Pros: Excellent safety features, high adhesion properties, and good optical clarity.

– Cons: May require additional processing steps, which can increase manufacturing time and costs.

Impact on Application:

PVB is particularly beneficial in automotive applications where safety is paramount. Its ability to enhance shatter resistance is a significant advantage in regions with high accident rates.

Considerations for International Buyers:

Compliance with safety standards, such as those set by the International Organization for Standardization (ISO), is essential for buyers in various regions. Understanding local market demands for safety features can also guide material selection.

| Material | Typical Use Case for nano ceramic tint | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Dioxide (SiO₂) | Automotive and architectural applications | High durability and scratch resistance | Higher manufacturing complexity | High |

| Titanium Dioxide (TiO₂) | Automotive and architectural applications | Excellent light reflection and UV blocking | More expensive than other pigments | Medium |

| Polyurethane | Flexible applications requiring adhesion | High durability and chemical resistance | Sensitive to UV degradation | Medium |

| Polyvinyl Butyral (PVB) | Automotive safety applications | Excellent safety features and adhesion | Requires additional processing | Medium |

In conclusion, selecting the right materials for nano ceramic tint involves evaluating performance characteristics, cost implications, and compliance with regional standards. By understanding these factors, international B2B buyers can make informed decisions that align with their specific application needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for nano ceramic tint

What Are the Key Stages in the Manufacturing Process of Nano Ceramic Tint?

The manufacturing of nano ceramic tint involves several critical stages that ensure the production of high-quality products suitable for various applications, from automotive to architectural uses. Understanding these stages can help B2B buyers assess potential suppliers effectively.

1. Material Preparation

The first step in producing nano ceramic tint is the careful selection and preparation of raw materials. This typically includes high-grade ceramic nanoparticles, polymers, and solvents. The quality of these materials directly affects the tint’s performance, durability, and clarity.

- Sourcing Quality Materials: Buyers should ensure that suppliers provide detailed specifications of their raw materials, including origin and certification. This is particularly vital for international buyers who may have different standards and regulations.

- Material Characterization: Techniques such as X-ray diffraction (XRD) and scanning electron microscopy (SEM) are often used to analyze the material properties before they are processed. B2B buyers can request documentation of these tests to verify material quality.

2. Forming

Once the materials are prepared, the next stage is forming, which involves mixing the ceramic nanoparticles with the polymer matrix. This process is crucial as it determines the uniformity and consistency of the tint.

- Mixing Techniques: High-shear mixing and ultrasonic dispersion are commonly employed to ensure even distribution of nanoparticles. Buyers should inquire about the equipment used and the mixing process to understand how it impacts the final product.

- Pilot Runs: Suppliers often conduct pilot runs to refine the formulation. This is an excellent opportunity for B2B buyers to request samples for evaluation before placing larger orders.

3. Assembly

After forming, the material is applied to a substrate, which can vary depending on the intended use (e.g., glass, plastic). The application technique can significantly influence the performance characteristics of the tint.

- Application Methods: Common methods include spray coating, roll coating, or laminating. Each method has its advantages and is suited to different applications. Buyers should understand the implications of each method on the final product’s quality and performance.

4. Finishing

The finishing stage is where the product is cured, dried, or otherwise treated to achieve the desired properties. This may include heat treatment or UV curing, which enhances the durability and performance of the nano ceramic tint.

- Quality Assurance in Finishing: It is critical to monitor curing times and temperatures to ensure optimal performance. B2B buyers should ask suppliers about their finishing processes and any relevant certifications.

How Is Quality Assurance Implemented in Nano Ceramic Tint Production?

Quality assurance (QA) is an integral part of the manufacturing process for nano ceramic tint, ensuring that the products meet international standards and customer expectations.

1. What International Standards Should B2B Buyers Be Aware Of?

For international B2B buyers, familiarity with relevant standards is crucial. Compliance with standards such as ISO 9001 ensures that manufacturers maintain a consistent quality management system. Additionally, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be necessary depending on the application.

- ISO 9001 Certification: This standard focuses on meeting customer and regulatory requirements and enhancing customer satisfaction. Buyers should confirm that their suppliers are certified and regularly audited.

2. What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival to ensure they meet specified standards. B2B buyers should ask for IQC reports from suppliers to verify material quality.

- In-Process Quality Control (IPQC): During manufacturing, samples are taken at various stages to ensure adherence to specifications. Understanding how suppliers conduct IPQC can provide insights into their quality commitment.

- Final Quality Control (FQC): This final inspection ensures that the finished product meets all quality standards before shipping. Buyers can request FQC reports to confirm the quality of the products they receive.

What Testing Methods Are Commonly Used in Nano Ceramic Tint Quality Assurance?

Various testing methods are employed to ensure that nano ceramic tints meet performance standards. These can include:

- Spectrophotometry: This method measures the tint’s light transmission and absorption, essential for assessing performance in applications like window films.

- Adhesion Tests: These tests evaluate how well the tint adheres to different substrates, which is crucial for durability.

- Durability Testing: B2B buyers should inquire about tests for UV resistance, scratch resistance, and chemical stability, as these factors influence the long-term performance of the tint.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is essential for B2B buyers, especially when sourcing internationally. Here are some actionable steps:

- Conduct Supplier Audits: Regular audits can help assess the manufacturing processes and quality control measures in place. Buyers should develop a checklist based on international standards and best practices.

- Request Documentation: Suppliers should provide detailed reports of their quality control processes, including IQC, IPQC, and FQC records. Documentation can serve as a proof of compliance with international standards.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s quality assurance processes, ensuring that products meet the required standards before shipment.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers face unique challenges regarding quality control, particularly concerning varying regulations and standards across regions.

- Understanding Regional Standards: Buyers must familiarize themselves with the specific regulations applicable in their regions, such as REACH in Europe or local standards in Africa and South America.

- Communication: Clear communication regarding quality expectations and standards is critical. Buyers should establish comprehensive agreements with suppliers that outline quality expectations, testing protocols, and recourse in case of non-compliance.

- Cultural Considerations: Recognizing and respecting cultural differences in business practices can enhance collaboration and ensure that quality standards are upheld.

In conclusion, understanding the manufacturing processes and quality assurance practices for nano ceramic tint is vital for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and rigorous quality control measures, buyers can ensure they partner with reliable suppliers who deliver high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nano ceramic tint’

In the competitive landscape of B2B procurement, sourcing high-quality nano ceramic tint is crucial for businesses looking to enhance their product offerings. This guide provides a structured checklist to help international buyers, especially from Africa, South America, the Middle East, and Europe, navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Understanding your specific needs is the foundation of successful sourcing. Clearly outline the technical specifications of the nano ceramic tint required for your application, including:

– Thickness: Determine the optimal thickness for performance and aesthetics.

– UV Protection: Specify the level of UV protection necessary for your target market.

– Heat Rejection: Identify the required heat rejection percentage based on climate considerations.

Step 2: Research the Market Landscape

Conduct thorough market research to identify potential suppliers and understand pricing trends. Analyze market reports, trade publications, and online platforms to gather insights on:

– Supplier Reputation: Look for reviews and testimonials from other B2B buyers.

– Competitive Pricing: Compare prices to ensure you are getting value for your investment.

Step 3: Verify Supplier Certifications

Before making a commitment, it’s essential to confirm that potential suppliers have the necessary certifications. This step ensures compliance with industry standards and local regulations. Check for:

– ISO Certifications: Look for ISO 9001 for quality management systems.

– Environmental Compliance: Verify adherence to environmental regulations, particularly if you operate in regions with strict guidelines.

Step 4: Request Product Samples

Always request samples before finalizing your purchase. Testing samples allows you to evaluate the tint’s quality and performance in real-world conditions. Consider:

– Color Accuracy: Ensure the tint matches your desired aesthetic.

– Durability Tests: Assess resistance to scratches, fading, and peeling.

Step 5: Assess Supply Chain Reliability

Evaluate the supplier’s ability to meet your delivery timelines consistently. A reliable supply chain is vital for maintaining your business operations. Consider the following:

– Lead Times: Discuss and agree on lead times for production and delivery.

– Logistical Capabilities: Ensure the supplier can handle international shipping and customs clearance effectively.

Step 6: Negotiate Terms and Conditions

Once you’ve narrowed down your options, it’s time to negotiate the terms of your purchase. Clear agreements help prevent misunderstandings later on. Focus on:

– Payment Terms: Discuss upfront payments, deposits, and credit options.

– Warranty and Support: Ensure there is a clear warranty policy and after-sales support in place.

Step 7: Establish a Long-Term Partnership

Building a long-term relationship with your supplier can yield significant benefits, such as better pricing, priority service, and collaborative opportunities for product development. Engage in:

– Regular Communication: Maintain open lines of communication for feedback and support.

– Performance Reviews: Schedule periodic reviews to assess the supplier’s performance and address any concerns.

By following this checklist, B2B buyers can streamline the sourcing process for nano ceramic tint and ensure that they are making informed decisions that align with their business objectives.

Comprehensive Cost and Pricing Analysis for nano ceramic tint Sourcing

What Are the Key Cost Components of Nano Ceramic Tint Sourcing?

When analyzing the cost structure for sourcing nano ceramic tint, several key components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The primary cost driver in nano ceramic tint production is the raw materials used, which include nanoparticles and high-quality resins. Prices for these materials can fluctuate based on global supply chains, so it is crucial to establish reliable suppliers.

-

Labor: Skilled labor is necessary for the manufacturing process. Labor costs can vary significantly depending on the region, with higher wages in developed countries compared to emerging markets.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient production processes can help mitigate these costs.

-

Tooling: Initial tooling costs can be substantial, especially for custom tints. It’s essential to factor in these costs when determining the overall price.

-

Quality Control: Ensuring that products meet required specifications incurs additional costs. Investing in rigorous QC processes can prevent expensive returns and enhance customer satisfaction.

-

Logistics: Shipping and handling fees can vary based on the destination and shipping method. For international buyers, understanding Incoterms can help manage and minimize these costs effectively.

-

Margin: Finally, the supplier’s profit margin must be included in the pricing. This can vary widely based on the supplier’s market position and the competitive landscape.

How Do Price Influencers Impact Nano Ceramic Tint Sourcing?

Several factors influence the final price of nano ceramic tint, making it essential for buyers to be aware of these dynamics:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for larger orders. Understanding the MOQ and negotiating terms can significantly affect pricing.

-

Specifications and Customization: Customized tints tailored to specific requirements can increase costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, ASTM) can raise costs but may be necessary for compliance and performance. Evaluate the trade-off between cost and quality carefully.

-

Supplier Factors: The supplier’s reputation, experience, and reliability can affect pricing. Established suppliers may charge a premium but often provide better service and product consistency.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial as they define the responsibilities of buyers and sellers regarding shipping costs and risks. This knowledge can help negotiate better terms.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Nano Ceramic Tint?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, here are some actionable tips to enhance cost-efficiency:

-

Negotiation Strategies: Leverage your purchasing power by negotiating terms. Consider bundling orders or establishing long-term relationships for better pricing.

-

Total Cost of Ownership (TCO): Assess the TCO instead of just the upfront price. This includes considering longevity, warranty, and potential maintenance costs associated with the product.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and potential tariffs when importing products. It’s advisable to work with suppliers who can provide fixed pricing agreements or currency hedging options.

-

Market Research: Conduct thorough market research to identify competitive pricing and understand regional differences in sourcing costs. This knowledge can empower buyers during negotiations.

-

Build Relationships with Suppliers: Strong relationships can lead to better service, pricing, and priority during supply chain disruptions.

Disclaimer on Pricing

Prices for nano ceramic tint can vary widely based on the aforementioned factors and market conditions. Buyers are encouraged to conduct thorough research and consult multiple suppliers to obtain indicative pricing tailored to their specific needs and circumstances.

Alternatives Analysis: Comparing nano ceramic tint With Other Solutions

Understanding Alternatives to Nano Ceramic Tint for B2B Buyers

When considering window tinting solutions, it’s essential for B2B buyers to evaluate various options beyond just nano ceramic tint. Each alternative offers distinct advantages and disadvantages depending on the specific application and requirements. This section will compare nano ceramic tint with other viable solutions, allowing buyers to make informed decisions.

Comparison of Nano Ceramic Tint with Alternative Solutions

| Comparison Aspect | Nano Ceramic Tint | Traditional Window Film | Laminated Glass |

|---|---|---|---|

| Performance | Superior heat rejection; blocks UV rays; scratch-resistant | Moderate heat rejection; offers UV protection | Excellent thermal insulation; sound dampening properties |

| Cost | Higher upfront investment; long-term savings on energy | Lower initial cost; potential for shorter lifespan | Higher cost due to manufacturing; durable investment |

| Ease of Implementation | Requires professional installation; specific techniques needed | Easier to install; DIY options available | Requires custom manufacturing and installation |

| Maintenance | Low maintenance; resistant to wear | Moderate maintenance; may discolor over time | Minimal maintenance; durable and long-lasting |

| Best Use Case | High-end residential and commercial applications needing aesthetics and performance | Budget-conscious projects; short-term needs | Buildings needing enhanced security and thermal properties |

What Are the Pros and Cons of Traditional Window Film?

Traditional window film is a more established option in the market, often chosen for its lower initial cost. It provides a reasonable level of UV protection and can enhance privacy. However, it generally offers moderate heat rejection compared to nano ceramic tint and may not be as durable. Over time, traditional films can fade or discolor, requiring replacement. This makes them less ideal for long-term investments, particularly in regions with intense sunlight.

A stock image related to nano ceramic tint.

How Does Laminated Glass Compare to Nano Ceramic Tint?

Laminated glass represents another alternative that combines two or more layers of glass with a plastic interlayer, providing enhanced security and sound insulation. It performs exceptionally well in terms of thermal insulation and is highly durable. However, laminated glass is typically more expensive and requires custom manufacturing, making it less accessible for smaller projects. While it offers long-term benefits, the initial investment may be prohibitive for some businesses.

Conclusion: How Can B2B Buyers Choose the Right Solution?

Choosing the right window tinting solution requires a careful assessment of specific needs and project goals. Nano ceramic tint stands out for its performance and longevity, making it suitable for high-end applications. In contrast, traditional window film may appeal to budget-conscious buyers seeking quicker solutions, while laminated glass is ideal for those prioritizing security and thermal efficiency. By analyzing the performance, costs, and maintenance requirements of each option, B2B buyers can select the most suitable tinting solution that aligns with their project objectives and financial considerations.

Essential Technical Properties and Trade Terminology for nano ceramic tint

What Are the Key Technical Properties of Nano Ceramic Tint?

When considering nano ceramic tint for automotive or architectural applications, understanding its technical properties is crucial for making informed purchasing decisions. Here are some of the most critical specifications:

1. Material Grade

Material grade refers to the classification of the tint based on its composition and manufacturing process. Higher grades typically indicate better performance in terms of heat rejection, UV protection, and durability. For B2B buyers, selecting the right material grade ensures that the product meets the specific needs of their markets, whether for luxury vehicles or commercial buildings.

2. Visible Light Transmission (VLT)

VLT is a measure of how much visible light passes through the tinted film. It is expressed as a percentage; for example, a 70% VLT allows 70% of visible light to enter. Understanding VLT is essential for compliance with local regulations, which often dictate permissible levels of tinting for vehicles. B2B buyers must ensure they procure products that align with these standards to avoid legal issues.

3. Infrared Rejection (IRR)

Infrared rejection measures the percentage of infrared radiation blocked by the tint. High IRR values are crucial for improving energy efficiency in buildings and enhancing comfort in vehicles by reducing heat buildup. For international buyers, especially in hotter climates like those in Africa and the Middle East, selecting tints with high IRR can significantly impact energy costs and customer satisfaction.

4. Durability and Scratch Resistance

Durability is a critical property that indicates how well the tint can withstand environmental factors, including UV rays, weather conditions, and physical abrasion. Scratch resistance is particularly important for automotive applications, where tints are exposed to frequent cleaning and wear. For B2B buyers, sourcing durable products minimizes the risk of replacement and enhances customer loyalty.

5. Adhesion Properties

The adhesion property of nano ceramic tint affects how well the film sticks to the glass surface. Poor adhesion can lead to bubbling or peeling over time, which can result in costly replacements. B2B buyers should inquire about the adhesion standards of the tint, ensuring they choose products that offer long-lasting performance.

What Common Trade Terms Should B2B Buyers Understand?

Navigating the world of nano ceramic tint involves familiarizing oneself with industry-specific terminology. Here are some key terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that can be rebranded and sold by another company. For nano ceramic tint, working with OEMs can provide access to high-quality products that meet specific requirements, allowing businesses to offer customized solutions to their clients.

2. MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage inventory costs and ensure that they can meet their own market demands without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a standard business process wherein buyers request pricing and terms from suppliers for specific products or services. Issuing an RFQ for nano ceramic tint can help buyers compare offers and negotiate better deals, ensuring they maximize their procurement budget.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, insurance, and duties. Familiarity with these terms is essential for B2B buyers to avoid misunderstandings and ensure smooth logistics when importing nano ceramic tint from various regions.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is crucial for B2B buyers to manage their project timelines effectively, ensuring they can deliver products to their customers on schedule.

By grasping these essential technical properties and trade terminology, B2B buyers can make informed decisions when sourcing nano ceramic tint, ensuring they meet both regulatory standards and customer expectations.

Navigating Market Dynamics and Sourcing Trends in the nano ceramic tint Sector

What Are the Key Market Trends Affecting the Nano Ceramic Tint Sector?

The nano ceramic tint market has experienced significant growth, driven by increased consumer awareness of UV protection, energy efficiency, and aesthetic appeal. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe navigate this sector, understanding the global drivers is crucial. The demand for high-performance window films is being propelled by industries such as automotive, commercial real estate, and residential applications, where energy conservation and privacy are paramount.

Emerging technologies are also shaping sourcing trends in the nano ceramic tint market. Innovations in manufacturing processes are leading to the production of thinner, lighter films with enhanced durability and performance characteristics. For B2B buyers, this means sourcing opportunities that not only fulfill regulatory standards but also offer superior product features. Additionally, the rise of online platforms for procurement is streamlining the sourcing process, allowing buyers to access a wider range of suppliers and products, compare prices, and read reviews, fostering more informed purchasing decisions.

How Does Sustainability Influence Sourcing in the Nano Ceramic Tint Industry?

Sustainability is becoming a cornerstone of sourcing strategies in the nano ceramic tint sector. The environmental impact of production and disposal practices has prompted buyers to prioritize ethical supply chains. For instance, sourcing from manufacturers who utilize eco-friendly materials and processes can significantly reduce the carbon footprint associated with the production of nano ceramic tints.

B2B buyers should look for suppliers that possess green certifications, such as ISO 14001, which indicates a commitment to environmental management practices. Additionally, the use of recycled materials in the production of nano ceramic films is gaining traction, appealing to environmentally conscious consumers and businesses alike. By aligning procurement strategies with sustainability goals, B2B buyers can not only enhance their brand reputation but also meet the growing consumer demand for environmentally responsible products.

What Is the Historical Context of the Nano Ceramic Tint Market?

The evolution of the nano ceramic tint market can be traced back to advancements in material science and manufacturing technologies. Initially, window films were predominantly made from dyed polyester, which offered limited performance in terms of UV protection and heat rejection. The introduction of ceramic particles into the tint formulation marked a significant shift, providing enhanced thermal insulation and clarity without compromising visibility.

Over the years, as technological advancements continued, nano ceramic tints emerged as a preferred choice for both commercial and residential applications. The ability to block up to 99% of UV rays while maintaining optical clarity has made these films a popular option for international B2B buyers seeking high-quality solutions for their clients. Understanding this historical context allows buyers to appreciate the innovation behind the products they source and the growing demand for superior window film solutions in various markets.

Frequently Asked Questions (FAQs) for B2B Buyers of nano ceramic tint

-

How do I choose the right nano ceramic tint supplier for my business?

When selecting a nano ceramic tint supplier, consider their manufacturing capabilities, product range, and industry experience. Conduct thorough due diligence by checking their certifications, client testimonials, and case studies. Engage in direct communication to assess their responsiveness and customer service. Additionally, request samples to evaluate the quality of their products firsthand. This will not only ensure the supplier meets your specifications but also builds a foundation for a strong business relationship. -

What are the key benefits of using nano ceramic tint for automotive applications?

Nano ceramic tint offers superior heat rejection, UV protection, and glare reduction compared to traditional tints. Its advanced technology provides durability and resistance to fading, ensuring long-lasting performance. For automotive applications, this translates to enhanced comfort for passengers and protection for the vehicle’s interior. Additionally, nano ceramic tint can contribute to energy savings by reducing the need for air conditioning, making it an eco-friendly option for businesses focused on sustainability. -

What customization options are available for nano ceramic tint products?

Many suppliers offer customization options such as varying degrees of tint darkness, specific color hues, and special formulations for unique applications. Before placing an order, discuss your specific requirements with the supplier to ensure they can accommodate your needs. Customization can also extend to packaging and branding, allowing businesses to align the product with their corporate identity. This flexibility can be crucial for gaining a competitive edge in local markets. -

What is the minimum order quantity (MOQ) for nano ceramic tint, and how does it affect pricing?

The MOQ for nano ceramic tint can vary significantly between suppliers, typically ranging from 100 to 1,000 square meters. Higher MOQs often result in better pricing per unit due to economies of scale. However, it’s essential to assess your business’s demand and storage capabilities before committing to a large order. Negotiate with suppliers to find a balance between MOQ and cost-effectiveness that suits your operational needs. -

What payment terms should I expect when sourcing nano ceramic tint internationally?

Payment terms can vary widely based on the supplier’s policies and your negotiation skills. Common terms include a deposit upfront (typically 30% to 50%) with the balance due before shipment. Some suppliers may offer flexible payment options such as letters of credit or payment upon delivery, especially for established relationships. Always clarify payment terms early in the negotiation process to avoid misunderstandings and ensure a smooth transaction. -

How can I ensure quality assurance for nano ceramic tint products?

Implementing a robust quality assurance (QA) process is vital when sourcing nano ceramic tint. Request detailed product specifications and test reports from suppliers, including certifications that demonstrate compliance with international standards. Conduct on-site inspections or third-party audits if possible. Additionally, establish a clear returns policy and warranty terms to safeguard your investment and ensure that any defective products can be addressed promptly. -

What logistical considerations should I keep in mind when importing nano ceramic tint?

Logistics play a crucial role in the successful import of nano ceramic tint. Factors to consider include shipping methods (air vs. sea), lead times, customs regulations, and import duties applicable in your country. Work with a reliable freight forwarder who understands the nuances of international shipping for your specific region. Proper planning will minimize delays and ensure that your products arrive safely and on time. -

What are the trends in the nano ceramic tint market that I should be aware of?

Current trends in the nano ceramic tint market include increased demand for eco-friendly products and advancements in tint technology that enhance performance. Additionally, there is a growing focus on customization and personalization, as businesses seek unique solutions to meet customer preferences. Staying informed about these trends can help you position your offerings effectively and tap into emerging market opportunities, particularly in regions like Africa and South America where demand is rising.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for nano ceramic tint

What Are the Key Takeaways for B2B Buyers in the Nano Ceramic Tint Market?

In the rapidly evolving landscape of nano ceramic tint, strategic sourcing emerges as a critical component for international B2B buyers. By prioritizing partnerships with reputable suppliers who adhere to quality standards, businesses can secure high-performance products that enhance both aesthetic appeal and energy efficiency. Understanding regional market dynamics, particularly in Africa, South America, the Middle East, and Europe, is essential for making informed procurement decisions.

How Can Buyers Leverage Strategic Sourcing for Competitive Advantage?

Investing in strategic sourcing not only streamlines operations but also fosters long-term supplier relationships that can lead to cost savings and innovation. Buyers should actively seek out suppliers who offer comprehensive support, including technical assistance and custom solutions tailored to specific market needs. This proactive approach can significantly improve product adoption rates and customer satisfaction.

What Should B2B Buyers Consider for Future Success?

Looking ahead, the demand for nano ceramic tint is expected to grow as sustainability becomes a priority across various industries. By aligning sourcing strategies with emerging trends in energy efficiency and eco-friendly materials, international B2B buyers can position themselves advantageously in competitive markets. Now is the time to evaluate sourcing practices and explore partnerships that will drive future growth and innovation in this dynamic sector.