Discover the Best Traditional Wood for a Ukulele (2025)

Introduction: Navigating the Global Market for traditional wood for a ukulele

In the world of musical instruments, sourcing traditional wood for a ukulele presents a unique set of challenges for international B2B buyers. The demand for high-quality, sustainable materials is on the rise, particularly as musicians seek instruments that offer both aesthetic appeal and superior sound quality. This guide aims to demystify the complexities of sourcing traditional wood, providing insights into various types of wood, their applications, and how to effectively vet suppliers across different regions, including Africa, South America, the Middle East, and Europe.

Understanding the nuances of wood selection is crucial; whether you’re looking to purchase mahogany for its warm tone or koa for its rich appearance, each type of wood brings distinct qualities to the table. This guide will delve into the best practices for evaluating suppliers, ensuring compliance with international trade regulations, and managing cost factors associated with importing wood.

By equipping B2B buyers with actionable insights and practical strategies, this resource empowers you to make informed purchasing decisions. With a focus on transparency and reliability, you can navigate the global market with confidence, secure high-quality materials, and ultimately enhance your product offerings in the competitive musical instrument industry. Whether you are a manufacturer in South Africa or a retailer in Poland, this guide is designed to meet your specific needs and challenges in sourcing traditional wood for ukuleles.

Understanding traditional wood for a ukulele Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Koa | Rich tonal quality, visually striking | High-end ukulele manufacturing | Pros: Excellent sound, aesthetic appeal. Cons: Expensive, sustainability concerns. |

| Mahogany | Warm sound, durability | Mid-range ukulele production | Pros: Balanced tone, readily available. Cons: Heavier, can be less resonant than others. |

| Spruce | Bright, clear tone | Entry-level to professional ukuleles | Pros: Versatile, good projection. Cons: Prone to scratches, less visually appealing. |

| Cedar | Warm, mellow tone | Custom and boutique ukuleles | Pros: Lightweight, responsive sound. Cons: Less durable, can warp with humidity. |

| Rosewood | Rich overtones, beautiful grain | Premium acoustic instruments | Pros: Excellent resonance, luxurious look. Cons: High cost, limited availability. |

What are the Characteristics and Suitability of Koa Wood for Ukuleles?

Koa wood is renowned for its stunning visual properties and rich tonal quality, making it a favored choice among high-end ukulele manufacturers. This wood type offers a unique combination of bright and warm tones, which enhances the overall sound quality of the instrument. For B2B buyers, sourcing Koa can be a significant investment due to its higher price point and limited availability, often raising sustainability concerns. However, its aesthetic appeal and sound quality justify the investment for premium products aimed at discerning customers.

How Does Mahogany Compare to Other Woods for Ukulele Manufacturing?

Mahogany is a popular choice for mid-range ukulele production due to its warm sound and durability. It offers a balanced tone that appeals to a wide range of players, making it a versatile option for manufacturers. B2B buyers looking for consistent supply can find mahogany readily available, which is a critical factor in production planning. However, its heavier nature and tendency to resonate less than other woods may limit its use in high-end models, making it essential for buyers to consider their target market’s preferences.

Why is Spruce Considered a Versatile Option for Ukulele Buyers?

Spruce wood is celebrated for its bright and clear tone, making it suitable for both entry-level and professional ukuleles. Its versatility allows manufacturers to cater to various market segments, from beginners to seasoned musicians. B2B buyers should consider spruce for its excellent projection and adaptability in different playing styles. However, its susceptibility to scratches and less visually appealing grain may deter some buyers, emphasizing the need for a balanced approach in product offerings.

What are the Benefits and Drawbacks of Using Cedar for Ukuleles?

Cedar wood is known for its warm, mellow tone and lightweight characteristics, making it an excellent choice for custom and boutique ukuleles. It responds well to fingerpicking, providing a rich sound that appeals to specific market niches. However, B2B buyers should be aware of cedar’s lower durability compared to other woods, as it can warp in high humidity environments. This necessitates careful consideration of the target market and climate conditions when sourcing cedar for ukulele production.

What Makes Rosewood a Premium Choice for Ukulele Manufacturing?

Rosewood is prized for its rich overtones and beautiful grain, often used in premium acoustic instruments. Its excellent resonance contributes to a fuller sound, appealing to high-end markets. B2B buyers should note that while rosewood offers significant aesthetic and auditory benefits, its high cost and limited availability can pose challenges in sourcing. Buyers must evaluate whether the investment aligns with their brand positioning and customer expectations, ensuring that they can effectively communicate the value of rosewood ukuleles to their clientele.

Related Video: 5 Effective Strumming Patterns for Beginners [Ukulele Lesson]

Key Industrial Applications of traditional wood for a ukulele

| Industry/Sector | Specific Application of Traditional Wood for a Ukulele | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Musical Instrument Manufacturing | Production of Ukuleles | High-quality sound and aesthetic appeal | Sustainable sourcing, wood quality, and regional regulations |

| Education and Training | Music education programs using ukuleles | Enhanced learning experiences and engagement | Bulk purchasing options, educational discounts, and delivery timelines |

| Cultural Festivals and Events | Ukulele performances and workshops | Promotion of cultural heritage and local craftsmanship | Customization options, availability of specific wood types, and logistical support |

| Retail and Distribution | Sale of traditional wooden ukuleles | High demand for quality instruments in niche markets | Supplier reliability, product certification, and import regulations |

| Artisan Craftsmanship | Custom ukulele crafting by artisans | Unique, handcrafted products that attract premium pricing | Access to rare wood types, artisan partnerships, and quality assurance |

How is Traditional Wood for a Ukulele Used in Musical Instrument Manufacturing?

In the musical instrument manufacturing sector, traditional wood is crucial for producing high-quality ukuleles. Manufacturers select specific types of wood, such as mahogany and koa, for their acoustic properties, which enhance sound quality and resonance. This sector faces challenges related to sourcing sustainable timber and ensuring compliance with international regulations. B2B buyers need to prioritize suppliers who can provide certified wood types, ensuring ethical sourcing while meeting production demands.

What Role Does Traditional Wood Play in Education and Training?

In education and training, ukuleles serve as accessible instruments for music programs. Schools and institutions utilize traditional wooden ukuleles to engage students in music education. The use of quality wood enhances the instrument’s sound, making lessons more enjoyable. Buyers in this sector should consider bulk purchasing options to reduce costs and ensure timely delivery to cater to growing student interest in music.

How is Traditional Wood Utilized in Cultural Festivals and Events?

Cultural festivals and events leverage traditional wood for ukuleles to showcase local music and craftsmanship. Performances often feature these instruments, drawing attention to cultural heritage. Buyers involved in event planning must focus on customization options to reflect local traditions and ensure availability of specific wood types that resonate with the audience. Additionally, logistical support is crucial to facilitate timely delivery for events.

What is the Importance of Traditional Wood in Retail and Distribution?

In retail and distribution, the demand for traditional wooden ukuleles is growing, particularly in niche markets. Retailers benefit from offering high-quality instruments that attract discerning customers. B2B buyers must evaluate supplier reliability and product certification to ensure they are providing authentic, high-quality instruments. Understanding import regulations is also essential for seamless market entry and compliance.

How Does Artisan Craftsmanship Incorporate Traditional Wood?

Artisan craftsmanship in ukulele production emphasizes the use of traditional wood to create unique, handcrafted instruments. Artisans often source rare wood types that enhance the instrument’s aesthetic and acoustic qualities, allowing them to command premium pricing. Buyers interested in this sector should seek partnerships with artisans who can provide quality assurance and access to exclusive wood types, ensuring their offerings stand out in the market.

Related Video: 35 Amazing Uses for Bamboo

3 Common User Pain Points for ‘traditional wood for a ukulele’ & Their Solutions

Scenario 1: Sourcing Quality Traditional Wood for Ukuleles

The Problem: One of the major challenges B2B buyers face when sourcing traditional wood for ukuleles is the inconsistency in quality. Buyers from regions like Africa and South America often encounter suppliers who either misrepresent the wood’s quality or fail to meet their specifications. This inconsistency can lead to significant production delays and quality control issues, ultimately affecting their reputation in the market.

The Solution: To overcome this challenge, B2B buyers should establish a robust vetting process for suppliers. This includes requesting samples of wood before committing to large orders, as well as verifying the supplier’s certifications and sustainability practices. Buyers can also consider partnering with local wood experts or consultants who can provide insights into the best sourcing practices in the region. Utilizing technology, such as blockchain for tracking wood provenance, can also enhance transparency and ensure that the wood meets desired quality standards. Establishing long-term relationships with reliable suppliers can further mitigate risks associated with quality inconsistency.

Scenario 2: Understanding the Properties of Different Woods

The Problem: Another pain point for international B2B buyers is the lack of understanding of how different types of traditional woods affect the sound quality and playability of ukuleles. Buyers from Europe and the Middle East may struggle to choose between options like mahogany, koa, or spruce, leading to suboptimal product offerings that do not resonate with their target market.

The Solution: To address this, buyers should invest time in understanding the acoustic properties of various woods and how they influence the sound characteristics of ukuleles. This can be achieved through workshops, online courses, or collaborations with acoustic specialists. Additionally, conducting product testing and gathering feedback from musicians can provide valuable insights into how each wood type performs. Furthermore, buyers can create a standardized comparison chart that outlines the pros and cons of each wood type, helping them make informed decisions that align with their market demands.

Scenario 3: Navigating Regulatory Compliance and Sustainability

The Problem: B2B buyers are increasingly faced with the challenge of navigating regulatory compliance and sustainability concerns when sourcing traditional wood. With growing environmental awareness, buyers from regions like South America and Africa must ensure that the wood they source is legally harvested and does not contribute to deforestation. This can be particularly daunting given the varying regulations across different countries.

The Solution: To effectively manage compliance and sustainability issues, buyers should familiarize themselves with international regulations regarding wood sourcing, such as the EU Timber Regulation and the Lacey Act in the United States. Establishing partnerships with suppliers who adhere to these regulations is crucial. Buyers can also consider obtaining certifications such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification) to ensure their wood products are sustainably sourced. Additionally, engaging in local conservation initiatives or supporting community-based forestry programs can enhance their brand image and appeal to environmentally conscious consumers. By prioritizing sustainability, buyers not only comply with regulations but also differentiate their products in a competitive marketplace.

Strategic Material Selection Guide for traditional wood for a ukulele

When selecting traditional wood for ukuleles, international B2B buyers must consider various materials that offer distinct properties and performance characteristics. This analysis focuses on four common types of wood used in ukulele construction: Mahogany, Koa, Spruce, and Cedar. Each material comes with unique advantages and limitations that can significantly impact the end product’s quality and marketability.

What are the Key Properties of Mahogany for Ukuleles?

Mahogany is a popular choice for ukulele bodies due to its warm tone and excellent resonance. It typically has a moderate density, which contributes to its durability and sound projection. Mahogany performs well under varying temperature and humidity conditions, making it suitable for diverse climates, particularly in Africa and South America.

Pros & Cons: Mahogany is relatively affordable compared to other premium woods, making it an attractive option for manufacturers. However, its susceptibility to scratches and dents can be a drawback, particularly in high-volume production environments. Additionally, while Mahogany provides a rich sound, some musicians may prefer the tonal qualities of other woods.

How Does Koa Wood Enhance the Ukulele’s Sound?

Koa wood, native to Hawaii, is renowned for its striking appearance and tonal richness. It offers a bright, clear sound with excellent projection, making it highly sought after for high-end ukuleles. Koa also exhibits good resistance to warping and cracking, which is crucial for maintaining instrument integrity over time.

Pros & Cons: The aesthetic appeal of Koa can significantly enhance the marketability of ukuleles. However, it is one of the more expensive woods, which may limit its use in budget-friendly models. Furthermore, sourcing Koa can present challenges due to environmental regulations and sustainability concerns, particularly for international buyers.

What are the Advantages of Using Spruce for Ukuleles?

Spruce is commonly used for the tops of ukuleles due to its excellent sound transmission properties. It is lightweight and has a high strength-to-weight ratio, making it an ideal choice for achieving a bright and responsive sound. Spruce is also relatively easy to work with, allowing for intricate designs and craftsmanship.

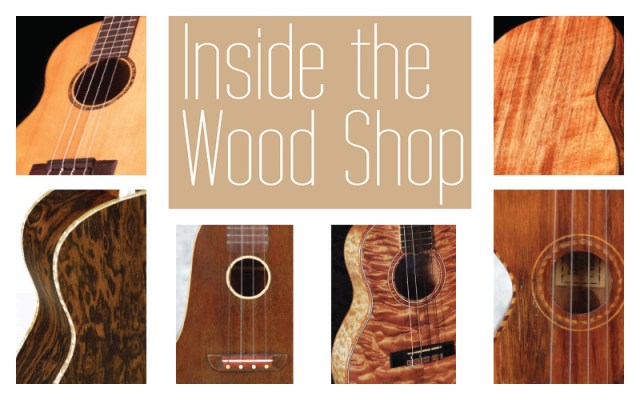

A stock image related to traditional wood for a ukulele.

Pros & Cons: While Spruce is generally cost-effective and widely available, it can be less durable than hardwoods like Mahogany or Koa. Its susceptibility to environmental changes means that it requires proper care and maintenance, which could be a consideration for buyers in humid or dry regions.

Why is Cedar a Suitable Choice for Ukuleles?

Cedar is another popular wood for ukulele tops, known for its warm, mellow tone. It has a slightly softer texture than Spruce, allowing for a more nuanced sound. Cedar also responds well to fingerpicking, making it a favorite among certain playing styles.

Pros & Cons: The primary advantage of Cedar is its rich sound quality and responsiveness. However, it is softer and can be prone to scratches and dents, which may affect its longevity in a commercial setting. Additionally, Cedar’s availability may vary by region, impacting sourcing for international buyers.

Summary Table of Traditional Woods for Ukuleles

| Material | Typical Use Case for traditional wood for a ukulele | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Mahogany | Body construction for mid-range ukuleles | Warm tone and good resonance | Susceptible to scratches and dents | Medium |

| Koa | Premium ukuleles for high-end markets | Striking appearance and rich sound | High cost and sourcing challenges | High |

| Spruce | Tops of ukuleles for bright sound | Lightweight with excellent sound transmission | Less durable than hardwoods | Low |

| Cedar | Tops for mellow sound, especially in fingerstyle | Rich sound quality and responsiveness | Softer, prone to scratches | Medium |

In conclusion, the selection of wood for ukuleles involves careful consideration of material properties, pros and cons, and market demands. International B2B buyers should prioritize compliance with local regulations and sustainability standards while also considering the preferences of their target markets. Understanding these factors will help in making informed decisions that align with both product performance and business objectives.

In-depth Look: Manufacturing Processes and Quality Assurance for traditional wood for a ukulele

What Are the Main Stages of Manufacturing Traditional Wood for a Ukulele?

The manufacturing process for traditional wood used in ukuleles involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial to ensure the quality and sound characteristics of the final product.

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of the wood. Commonly used woods for ukuleles include mahogany, koa, and spruce. Buyers should consider sourcing wood that has been properly dried and treated to prevent warping and cracking.

- Sourcing Quality Wood: Look for suppliers who can provide traceability of their wood sources. This ensures that the wood is harvested sustainably and complies with international regulations such as the Convention on International Trade in Endangered Species (CITES).

- Drying Techniques: Traditional air drying can take several months, while kiln drying speeds up the process. However, kiln drying must be done carefully to avoid damaging the wood fibers, which can affect sound quality.

2. Forming the Wood

Once the wood is prepared, it undergoes forming, where it is cut, shaped, and bent into the desired ukulele components. This stage typically involves:

- CNC Machining: Computer Numerical Control (CNC) machines provide precision cutting and shaping of wood pieces. This technology ensures consistency across multiple units, which is essential for large-scale production.

- Handcrafting Techniques: Many high-end ukuleles incorporate handcrafting techniques, especially in the shaping of the body and neck. This adds unique character to each instrument and can enhance sound quality.

How Is the Assembly Process Conducted for Ukulele Manufacturing?

The assembly phase is where all the individual components come together to form the final ukulele. This stage is vital for ensuring that the instrument not only looks appealing but also produces excellent sound.

- Joining Techniques: Various joining techniques, such as dovetail joints or mortise and tenon joints, are used to ensure durability and resonance. B2B buyers should inquire about the joining methods used by suppliers to understand the longevity of the product.

- Quality Control in Assembly: Each assembly line should have checkpoints where workers inspect the fit and finish of the components. This ensures that any flaws are caught early in the process.

What Finishing Techniques Are Used in Ukulele Production?

The finishing stage involves applying protective coatings and aesthetic finishes to the ukulele. This not only enhances the appearance but also protects the wood from moisture and wear.

- Types of Finishes: Common finishes include lacquer, oil, and polyurethane. Each type has its own set of characteristics regarding durability and appearance. Buyers should ask suppliers about the finishes used and their benefits.

- Sustainability Considerations: With increasing environmental awareness, many manufacturers are moving towards eco-friendly finishes. This could be a deciding factor for B2B buyers who prioritize sustainability in their sourcing decisions.

What Are the Key Quality Assurance Standards for Ukulele Manufacturing?

Quality assurance (QA) is crucial in ensuring that the final product meets both international standards and customer expectations. For traditional wood ukuleles, relevant QA standards include:

- ISO 9001: This international standard outlines the criteria for a quality management system. Suppliers who are ISO 9001 certified demonstrate a commitment to quality and customer satisfaction.

- CE Marking: In Europe, products must meet specific safety, health, and environmental protection requirements. B2B buyers in this region should ensure that their suppliers comply with CE marking regulations.

- API Standards: For buyers in the Middle East and North Africa, the American Petroleum Institute (API) standards may not directly apply, but they highlight the importance of industry standards in quality assurance.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying the quality control processes of suppliers is essential for B2B buyers to ensure that they are sourcing high-quality products. Here are several actionable strategies:

- Conduct Supplier Audits: Regular audits can provide insights into a supplier’s quality control processes. This includes evaluating their adherence to international standards and internal quality checks.

- Request Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including inspection reports and compliance certificates.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the quality of the products before shipment. This is particularly useful for buyers in regions where direct oversight may be challenging.

What Are the QC Checkpoints in Ukulele Manufacturing?

Quality control checkpoints are critical throughout the manufacturing process to ensure that every ukulele meets the required standards. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting the raw materials upon arrival to ensure they meet specified criteria before production begins.

- In-Process Quality Control (IPQC): During the manufacturing process, various checks are performed to monitor the quality of work and identify any defects early on.

- Final Quality Control (FQC): Before the ukuleles are packaged for shipment, a final inspection is conducted to ensure that each instrument meets the quality standards.

What Are the Common Testing Methods for Ukulele Wood Quality?

Testing methods play a vital role in assessing the quality of wood used for ukuleles. Some common testing methods include:

- Moisture Content Testing: This ensures that the wood has the correct moisture level, preventing future warping or cracking.

- Sound Testing: Acoustic testing helps determine how well the wood resonates, which directly affects the sound quality of the ukulele.

- Durability Testing: This may include impact tests to assess how well the wood withstands physical stress.

How Do Quality Control Nuances Affect International B2B Buyers?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of the nuances in quality control that can impact their purchasing decisions:

- Cultural Differences: Different regions may have varying standards and expectations for quality. Understanding these cultural differences can help in negotiating and establishing effective partnerships.

- Regulatory Compliance: Buyers must ensure that their suppliers comply with both local and international regulations, which can vary significantly between regions.

- Supply Chain Transparency: Increased transparency in the supply chain can help B2B buyers verify the quality of the wood and the manufacturing processes, which is particularly important in international transactions.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing traditional wood for ukuleles, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘traditional wood for a ukulele’

This guide provides a structured approach for international B2B buyers seeking to source traditional wood for ukuleles. Understanding the specific requirements and nuances of wood sourcing is essential to ensure quality, compliance, and sustainability. Follow this checklist to navigate the complexities of sourcing traditional ukulele woods effectively.

Step 1: Define Your Technical Specifications

Before starting your search, clearly outline the types of wood you need based on the ukulele’s design and sound requirements. Common woods include mahogany, koa, and spruce, each offering unique tonal qualities. Understanding these specifications helps you communicate effectively with suppliers and ensures you receive materials that meet your acoustic needs.

Step 2: Research Sustainable Sourcing Options

Sustainability is increasingly important in the sourcing process, particularly for wood products. Investigate suppliers who adhere to sustainable forestry practices, such as those certified by the Forest Stewardship Council (FSC). This not only ensures compliance with international environmental standards but also enhances your brand’s reputation among eco-conscious consumers.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it is crucial to conduct a thorough evaluation. Request detailed company profiles, including their production capabilities, quality assurance processes, and previous client testimonials. Focus on suppliers who have experience in the musical instrument industry, as they will understand your specific needs better.

Step 4: Request Samples for Quality Assessment

Always request samples of the wood before making bulk purchases. This allows you to assess the quality, grain, and overall characteristics of the wood, ensuring it meets your specifications. Pay attention to factors such as moisture content and finish, which can significantly affect the final product’s quality.

Step 5: Verify Supplier Certifications

Ensure that your suppliers possess the necessary certifications that validate their compliance with international trade regulations and quality standards. Certifications such as ISO 9001 for quality management systems or relevant environmental certifications can provide peace of mind regarding the supplier’s operational practices.

Step 6: Negotiate Terms and Conditions Clearly

Once you’ve identified a suitable supplier, it’s essential to negotiate clear terms and conditions. Discuss pricing, delivery schedules, payment terms, and return policies upfront to prevent misunderstandings later. A well-defined agreement can help mitigate risks associated with international shipping and customs clearance.

Step 7: Establish a Long-Term Relationship

Building a strong relationship with your wood supplier can yield long-term benefits. Regular communication and feedback can help improve the quality of future orders and foster trust. Consider establishing a partnership where both parties can collaborate on product development or explore new wood options together.

By following this practical sourcing checklist, B2B buyers can navigate the complexities of procuring traditional wood for ukuleles, ensuring they meet both quality and sustainability standards while establishing reliable supplier relationships.

Comprehensive Cost and Pricing Analysis for traditional wood for a ukulele Sourcing

What Are the Key Cost Components in Sourcing Traditional Wood for Ukuleles?

When considering sourcing traditional wood for ukuleles, understanding the cost structure is vital for international B2B buyers. The main cost components include:

-

Materials: The type of wood significantly affects the price. Common woods like mahogany, koa, and spruce each have different market values based on availability and quality. Ensure to source from reputable suppliers who can guarantee the sustainability and quality of the wood.

-

Labor: Labor costs vary by region and can significantly impact the overall pricing. In regions with a skilled workforce, such as parts of Europe, you may find higher labor costs, but the craftsmanship could justify the expense.

-

Manufacturing Overhead: This includes utilities, facility costs, and other operational expenses incurred during production. Buyers should inquire about the manufacturing location’s overhead costs, as these can vary greatly between regions.

-

Tooling: If a supplier needs to invest in specific tools or machinery to meet your requirements, this cost will be passed on to you. Understanding the tooling needs upfront can help avoid unexpected expenses later.

-

Quality Control (QC): Ensuring that the wood meets specific standards necessitates a robust QC process, which adds to the cost. Buyers should look for suppliers with established QC protocols to minimize defects and returns.

-

Logistics: Shipping costs can vary widely based on distance, shipping method, and customs duties. Given the international nature of sourcing, logistics can become a significant portion of the total cost.

-

Margin: Finally, suppliers will include their profit margin in the pricing. This can be influenced by competition and the perceived value of the product.

How Do Price Influencers Affect the Cost of Traditional Wood for Ukuleles?

Several factors can influence the pricing of traditional wood for ukuleles:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs. Buyers should assess their needs and consider consolidating orders to take advantage of economies of scale.

-

Specifications and Customization: Custom requests or specific wood grades can increase costs. Clearly define your requirements to avoid unnecessary expenditures.

-

Material Quality and Certifications: Higher-quality woods or those with certifications (like FSC) may come at a premium. However, investing in certified materials can enhance your brand’s reputation and appeal to environmentally conscious consumers.

-

Supplier Factors: The supplier’s reputation, experience, and location can all impact pricing. Established suppliers with a track record of quality may charge more, but they can also provide greater reliability.

-

Incoterms: Understanding the terms of shipment and delivery is crucial. Different Incoterms can shift costs and responsibilities, affecting the total pricing.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Traditional Wood?

For B2B buyers, particularly from Africa, South America, the Middle East, and Europe, here are several actionable tips:

-

Negotiate: Don’t hesitate to negotiate on price, especially for larger orders. Suppliers may have flexibility in pricing, particularly if they see the potential for ongoing business.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors like shipping, potential returns, and long-term quality. A cheaper option may lead to higher costs down the line.

-

Understand Pricing Nuances: Familiarize yourself with regional pricing trends and seasonal fluctuations. This knowledge can help you time your purchases for better pricing.

-

Build Relationships: Establishing a long-term relationship with suppliers can lead to better pricing and terms. Regular communication and feedback can also improve service and product quality.

-

Stay Informed: Keep abreast of market trends and wood availability. Changes in environmental policies or trade regulations can impact costs and sourcing options.

Conclusion

Sourcing traditional wood for ukuleles requires a comprehensive understanding of the cost structure and pricing influencers. By applying these insights, international B2B buyers can make informed decisions that enhance their purchasing strategies while ensuring quality and sustainability. Always consider the total cost of ownership and maintain open lines of communication with suppliers to optimize your sourcing efforts.

Alternatives Analysis: Comparing traditional wood for a ukulele With Other Solutions

Exploring Alternatives to Traditional Wood for Ukuleles

In the quest for crafting high-quality ukuleles, traditional wood has long been the standard. However, as the global market evolves, so do the materials and technologies available for instrument production. For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the alternatives to traditional wood is crucial for making informed purchasing decisions.

| Comparison Aspect | Traditional Wood For A Ukulele | Alternative 1 Name: Laminated Wood | Alternative 2 Name: Carbon Fiber |

|---|---|---|---|

| Performance | Warm, rich tone; excellent resonance | Good tone; less resonance than solid wood | Bright, clear sound; very durable |

| Cost | Higher initial investment | More affordable than solid wood | Moderate to high investment |

| Ease of Implementation | Requires skilled craftsmanship | Easier to work with; less skill needed | Specialized manufacturing required |

| Maintenance | Needs regular care and humidity control | Low maintenance; stable in various climates | Very low maintenance; resistant to environmental changes |

| Best Use Case | Professional instruments, high-end markets | Entry-level and mid-range ukuleles | Travel instruments and outdoor use |

What Are the Advantages and Disadvantages of Laminated Wood for Ukuleles?

Laminated wood is an increasingly popular alternative for ukulele construction. It consists of several thin layers of wood glued together, which enhances durability while maintaining a decent tonal quality. The primary advantage of laminated wood is its cost-effectiveness, making it accessible for entry-level and mid-range instruments. Furthermore, it is less sensitive to humidity and temperature changes, which is beneficial for buyers in regions with fluctuating climates. However, while it offers good sound quality, it may not match the rich tonal depth of solid wood, potentially limiting its appeal to professional musicians.

How Does Carbon Fiber Compare to Traditional Wood for Ukuleles?

Carbon fiber is a modern alternative that stands out due to its exceptional durability and resistance to environmental factors. Instruments made from carbon fiber often produce a bright, clear sound, making them suitable for various musical styles. The primary benefit of carbon fiber is its minimal maintenance requirements; it does not warp or crack like wood, making it ideal for travel or outdoor use. However, carbon fiber ukuleles can be more expensive than laminated wood options, and some traditionalists may find the sound lacks the warmth associated with wooden instruments. Buyers should weigh the sound preferences of their target market against the benefits of durability and low maintenance.

How Can B2B Buyers Choose the Right Ukulele Material for Their Market?

When selecting the right material for ukulele production, B2B buyers must consider multiple factors including target audience, market pricing, and environmental conditions. Buyers targeting professional musicians may lean towards traditional wood for its superior tonal qualities. In contrast, those focusing on entry-level products may find laminated wood a compelling option due to its affordability and resilience. For brands emphasizing durability and low maintenance, especially in outdoor or travel contexts, carbon fiber presents a strong case despite its higher cost.

Ultimately, understanding the unique needs of your customer base and the specific characteristics of each material will guide you in making the best choice for your ukulele offerings.

Essential Technical Properties and Trade Terminology for traditional wood for a ukulele

What Are the Essential Technical Properties of Traditional Wood for a Ukulele?

When sourcing traditional wood for ukuleles, understanding the key technical properties is crucial for ensuring high-quality production. Here are some critical specifications that B2B buyers should consider:

1. Material Grade

Material grade refers to the quality classification of wood based on its appearance and structural integrity. For ukuleles, common grades include A, B, and C, with Grade A being the highest quality, featuring minimal imperfections and optimal sound properties. Understanding material grades helps buyers assess the quality they are purchasing, impacting both the aesthetic and acoustic qualities of the ukulele.

2. Density

Density is the mass of the wood per unit volume, typically measured in kg/m³. The density of wood affects its sound projection and tonal quality. Denser woods, like mahogany or koa, often produce warmer tones, while lighter woods, like spruce, can provide brighter sounds. For manufacturers, selecting the right density is vital for achieving the desired sound profile in their instruments.

3. Moisture Content

Moisture content is a critical factor in wood selection, expressed as a percentage of water in the wood compared to its dry weight. Ideal moisture content for ukulele wood typically ranges from 6% to 10%. Excess moisture can lead to warping and cracking, while too little can cause brittleness. Buyers must ensure that their suppliers provide wood that has been properly dried to maintain quality.

4. Grain Pattern

The grain pattern of wood influences both the aesthetic appeal and the acoustic properties of the ukulele. Straight grains tend to enhance strength and sound quality, while irregular patterns may affect resonance. Buyers should consider the specific grain characteristics that align with their brand’s design and sound philosophy.

5. Tolerance Levels

Tolerance levels refer to the allowable variations in dimensions and specifications during the manufacturing process. These are crucial in ensuring that parts fit together correctly, affecting the overall quality of the ukulele. Buyers should communicate their tolerance requirements clearly to suppliers to avoid production issues.

What Trade Terminology Should B2B Buyers Know When Sourcing Ukulele Wood?

Familiarity with industry-specific terminology is essential for effective communication and negotiation in the B2B space. Here are some common terms that buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of ukuleles, an OEM may supply wood components that are branded and sold by a different company. Understanding OEM relationships can help buyers identify potential partnerships for sourcing high-quality wood.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units that a supplier is willing to sell. This term is vital for buyers as it impacts inventory management and initial investment costs. Knowing the MOQ helps businesses plan their purchases effectively, ensuring they meet production needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For ukulele wood sourcing, submitting an RFQ can help buyers compare offers from multiple suppliers, ensuring they secure the best deal in terms of price and quality.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international rules that clarify the responsibilities of buyers and sellers in global trade. Understanding Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is crucial for buyers to manage shipping costs and risks effectively.

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. In the wood sourcing context, understanding lead times is essential for managing production schedules and ensuring timely availability of materials. Buyers should communicate their timelines clearly to avoid delays in production.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing traditional wood for ukuleles, ultimately enhancing their product quality and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the traditional wood for a ukulele Sector

What Are the Key Market Dynamics and Trends in the Traditional Wood for a Ukulele Sector?

The traditional wood for ukuleles is experiencing a notable shift driven by various global factors. Increased demand for authentic musical instruments, particularly in emerging markets like South Africa and Brazil, is propelling the growth of this niche. B2B buyers are now prioritizing high-quality wood types such as mahogany, koa, and spruce, which are renowned for their tonal qualities. Additionally, the rise of e-commerce platforms has streamlined the sourcing process, enabling buyers to access a wider range of suppliers globally.

Emerging technologies, such as blockchain, are enhancing transparency in the supply chain, allowing buyers to verify the origin and quality of wood. This is particularly relevant for buyers in Europe and the Middle East, where regulatory compliance and quality assurance are paramount. Moreover, the integration of Artificial Intelligence (AI) in supply chain management is optimizing inventory levels and predicting market demands, making it easier for international buyers to plan their purchases effectively.

How Does Sustainability Influence Sourcing in the Traditional Wood Sector?

Sustainability is becoming a critical factor for B2B buyers in the traditional wood sector. As the environmental impact of deforestation and illegal logging becomes increasingly apparent, buyers are seeking ethically sourced wood that complies with international standards. Certifications such as Forest Stewardship Council (FSC) and Programme for the Endorsement of Forest Certification (PEFC) are vital indicators of sustainable practices.

Buyers from regions like Africa and South America are encouraged to partner with suppliers who can provide verified eco-friendly materials, contributing to a more sustainable industry. Moreover, the growing consumer preference for environmentally responsible products means that ethical sourcing is not just a trend but a necessity for maintaining competitive advantage.

Investing in sustainable sourcing practices can also enhance brand reputation and attract a broader customer base, particularly among environmentally-conscious consumers in Europe and the Middle East.

What Is the Historical Context of Traditional Wood for Ukuleles?

The ukulele, originally from Hawaii, has a rich history tied to the types of wood used in its construction. Traditionally, woods such as koa were favored for their resonant qualities and aesthetic appeal. Over the years, as the ukulele gained popularity globally, the demand for various wood types expanded. This evolution highlights the importance of understanding regional preferences and historical context when sourcing wood for ukuleles.

International buyers should consider how the legacy of traditional wood types influences current trends and consumer expectations. By aligning sourcing strategies with historical insights, B2B buyers can better meet market demands while honoring the cultural significance of this beloved instrument.

Frequently Asked Questions (FAQs) for B2B Buyers of traditional wood for a ukulele

-

How do I choose the right type of wood for ukulele production?

Choosing the right wood for ukulele production involves understanding the tonal qualities and durability of different wood types. Common choices include mahogany for its warm sound, koa for its bright, clear tones, and spruce for its excellent projection. Consider the specific sound characteristics desired in the final product and the climate of your target market, as humidity can affect wood performance. Request samples from suppliers to evaluate sound quality and aesthetics before making bulk purchases. -

What is the best sourcing strategy for traditional wood for ukuleles?

The best sourcing strategy involves identifying reputable suppliers who specialize in traditional woods suitable for ukulele manufacturing. Start by researching suppliers in regions known for high-quality timber, such as the USA, Canada, and parts of Europe. Attend trade shows and industry events to establish direct relationships. Utilizing platforms like Alibaba or global trade directories can also facilitate connections. Always verify supplier credentials and request references to ensure reliability and quality. -

How can I verify the quality of wood before making a bulk purchase?

To verify wood quality, request samples or small test orders to assess characteristics such as grain pattern, moisture content, and sound quality. Establish clear criteria for quality assurance, including certification for sustainable sourcing, which is crucial for international trade compliance. Consider conducting laboratory testing for wood density and structural integrity. Building a relationship with your supplier can also lead to more transparent quality assurance processes. -

What are the common minimum order quantities (MOQ) for traditional wood suppliers?

Minimum order quantities (MOQ) can vary significantly based on the supplier and the type of wood. Generally, MOQs may range from 100 to 500 board feet, depending on the species and market demand. It is advisable to discuss MOQs upfront with potential suppliers to gauge flexibility. For new buyers, consider negotiating smaller initial orders or trial purchases to establish a working relationship before committing to larger volumes. -

What payment terms should I expect when sourcing wood internationally?

Payment terms for international wood sourcing can vary widely, but common practices include upfront payments, letters of credit, or payment upon delivery. Many suppliers may require a deposit (usually 30-50%) upon order confirmation, with the balance payable before shipping. It’s crucial to clarify payment methods and terms early in negotiations to avoid misunderstandings. Consider using escrow services for larger transactions to enhance security. -

How do I handle logistics and shipping for international wood purchases?

Handling logistics for international wood purchases involves coordinating with freight forwarders who specialize in timber transport. Understand the shipping options available, including sea freight for larger orders, which is often more cost-effective. Ensure compliance with import regulations in your country, including phytosanitary certificates and customs duties. Communicate with your supplier about packing and documentation to ensure a smooth shipping process. -

What are the key quality assurance practices for traditional wood used in ukuleles?

Key quality assurance practices include establishing clear specifications for wood characteristics, conducting regular inspections during production, and ensuring proper storage to prevent warping or mold. Collaborate with suppliers who implement quality control measures such as grading systems based on tonal qualities and appearance. Additionally, consider third-party audits or certifications for sustainable sourcing to enhance your product’s marketability.

A stock image related to traditional wood for a ukulele.

- How can I customize wood products to meet specific market demands?

Customization options can include selecting specific wood types, finishes, and dimensions to align with market preferences. Engage with your target market to understand their needs, whether it’s aesthetic qualities or specific tonal characteristics. Work closely with your supplier to explore possibilities for bespoke orders or unique designs. Keep in mind that customization may impact lead times and pricing, so it’s essential to plan accordingly.

A stock image related to traditional wood for a ukulele.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for traditional wood for a ukulele

As the demand for traditional wood in ukulele manufacturing continues to rise globally, strategic sourcing has become a pivotal element for international B2B buyers. Engaging in comprehensive market research and establishing strong relationships with reliable suppliers can significantly enhance product quality while ensuring ethical sourcing practices. Buyers from regions like Africa, South America, the Middle East, and Europe should prioritize suppliers who adhere to sustainability standards, as this not only meets consumer expectations but also positions their brands favorably in the competitive landscape.

How can B2B buyers leverage strategic sourcing to optimize costs and quality? By diversifying their supplier base and exploring emerging markets, businesses can mitigate risks associated with supply chain disruptions. Additionally, investing in technology to streamline procurement processes can yield substantial long-term benefits.

Looking ahead, the outlook for traditional wood sourcing in ukulele production remains promising. By focusing on sustainability and quality, international B2B buyers can not only enhance their product offerings but also contribute positively to the environment and local economies. Now is the time to take actionable steps towards building a resilient supply chain that aligns with global trends. Embrace strategic sourcing today to ensure your business thrives in this evolving market.