Discover the Risks: Your Guide to Devil Cars (2025)

Introduction: Navigating the Global Market for devil cars

In the ever-evolving landscape of international trade, sourcing devil cars—vehicles characterized by their unique design and performance—poses a significant challenge for B2B buyers. As markets in Africa, South America, the Middle East, and Europe grow increasingly interconnected, navigating the complexities of this niche automotive sector requires strategic insight and thorough knowledge of the global supply chain. This guide aims to equip international buyers with the critical information needed to make informed purchasing decisions, covering a wide array of topics including types of devil cars, their applications, effective supplier vetting processes, and cost considerations.

Understanding the multifaceted nature of devil cars is essential for businesses seeking to enhance their fleet or expand their offerings. Each market presents distinct opportunities and challenges, influenced by local regulations, consumer preferences, and economic conditions. By leveraging this comprehensive guide, B2B buyers can identify reliable suppliers, assess the viability of different models, and negotiate competitive pricing.

With actionable insights tailored specifically for buyers from regions such as the UK and Colombia, this resource is designed to demystify the process of sourcing devil cars. Whether you are a seasoned buyer or new to the industry, this guide will empower you to navigate the global market with confidence, ensuring that your investments yield maximum returns and align with your business objectives.

Understanding devil cars Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Devil Cars | Zero emissions, advanced battery technology | Urban logistics, fleet management | Pros: Low running costs, eco-friendly. Cons: Higher initial investment, charging infrastructure needed. |

| Performance Devil Cars | High horsepower, enhanced aerodynamics | Luxury transport, racing events | Pros: Exceptional speed, brand prestige. Cons: High maintenance costs, less fuel-efficient. |

| Off-Road Devil Cars | Rugged design, all-terrain capability | Mining, agriculture, remote transport | Pros: Durability, versatile use. Cons: Limited comfort features, fuel consumption. |

| Compact Devil Cars | Small footprint, agile maneuverability | Delivery services, urban commuting | Pros: Cost-effective, easy parking. Cons: Limited cargo space, less powerful. |

| Luxury Devil Cars | Premium materials, advanced technology integrations | Executive travel, high-end rentals | Pros: Comfort, status symbol. Cons: High depreciation, expensive repairs. |

What are Electric Devil Cars and Their B2B Applications?

Electric Devil Cars are characterized by their zero emissions and advanced battery technology, making them ideal for businesses focused on sustainability. Their primary B2B applications include urban logistics and fleet management, particularly in cities with stringent emissions regulations. Buyers should consider the total cost of ownership, as while the initial investment may be higher, the long-term savings on fuel and maintenance can be significant. Additionally, the availability of charging infrastructure is a crucial factor for companies planning to integrate these vehicles into their operations.

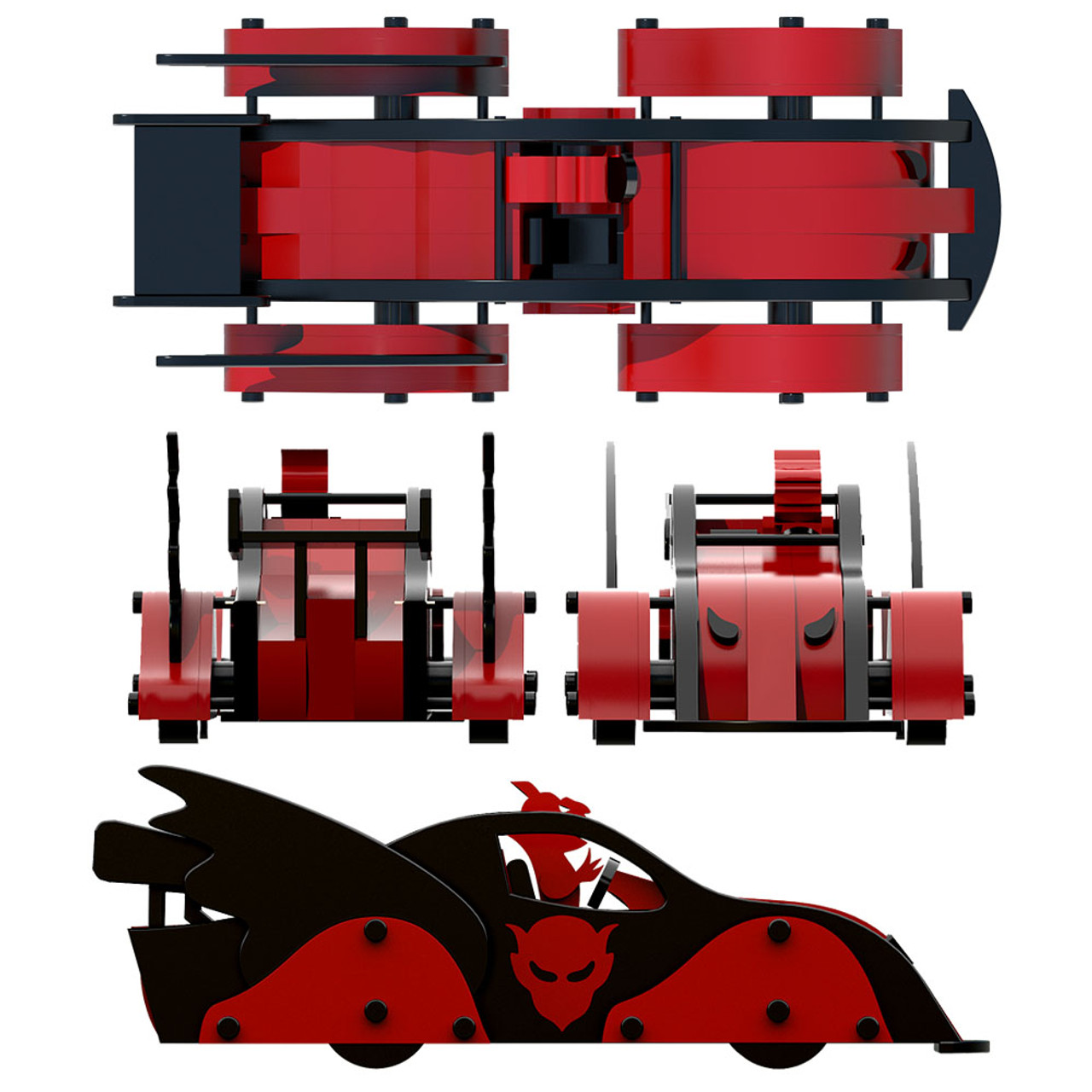

A stock image related to devil cars.

How Do Performance Devil Cars Stand Out in the Market?

Performance Devil Cars are designed for high-speed capabilities and enhanced aerodynamics, catering to luxury transport and racing events. These vehicles are often associated with premium brands and can elevate a company’s image while providing exceptional driving experiences. However, B2B buyers must weigh the benefits of brand prestige and performance against the high maintenance costs and lower fuel efficiency. For businesses that prioritize speed and luxury, investing in Performance Devil Cars can be a strategic choice, particularly for high-profile client engagements.

Why Choose Off-Road Devil Cars for Your Business Needs?

Off-Road Devil Cars are built for rugged environments, featuring all-terrain capabilities essential for industries such as mining, agriculture, and remote transport. Their durability and versatility make them suitable for challenging conditions, ensuring reliable performance. However, potential buyers should consider the trade-offs, such as limited comfort features and higher fuel consumption. For companies operating in remote areas or requiring robust transport solutions, Off-Road Devil Cars can be a valuable addition to their fleet.

What Advantages Do Compact Devil Cars Offer to Urban Businesses?

Compact Devil Cars are notable for their small footprint and agile maneuverability, making them perfect for delivery services and urban commuting. Their cost-effectiveness and ease of parking are significant advantages for businesses operating in congested city environments. However, B2B buyers should be aware of the limitations in cargo space and overall power compared to larger vehicles. For startups and small businesses focusing on last-mile delivery, Compact Devil Cars can provide an efficient and economical solution.

How Do Luxury Devil Cars Enhance Corporate Image?

Luxury Devil Cars are distinguished by their premium materials and advanced technology integrations, primarily used for executive travel and high-end rentals. They not only provide comfort but also serve as a status symbol for businesses looking to impress clients. However, the high depreciation rates and expensive repairs associated with these vehicles can be a concern for buyers. For companies that prioritize client experience and brand image, investing in Luxury Devil Cars can significantly enhance their corporate image and client relationships.

Related Video: BLACK DEVIL : MERCEDES BENZ S63 AMG

Key Industrial Applications of devil cars

| Industry/Sector | Specific Application of devil cars | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics & Transportation | Last-Mile Delivery Solutions | Enhanced delivery efficiency and reduced operational costs | Local regulations, vehicle specifications, and maintenance support |

| Mining & Heavy Industry | Off-Road Material Transport | Increased productivity in challenging terrains | Durability, fuel efficiency, and after-sales service |

| Agriculture | Remote Field Access and Crop Monitoring | Improved yield through timely intervention | Terrain adaptability, payload capacity, and technology integration |

| Construction | Site Transportation and Equipment Hauling | Streamlined operations and reduced project timelines | Load capacity, safety features, and compliance with local standards |

| Emergency Services | Rapid Response Vehicles | Critical time savings in emergency situations | Reliability, speed, and availability of spare parts |

How Are Devil Cars Used in Logistics & Transportation?

In the logistics and transportation sector, devil cars are often deployed for last-mile delivery solutions. Their robust design and agility allow them to navigate urban environments and rural areas alike, addressing the challenge of reaching remote locations. International B2B buyers, particularly from Africa and South America, must consider local regulations regarding vehicle emissions and size restrictions, as well as the need for a reliable maintenance network to ensure operational efficiency.

What Role Do Devil Cars Play in Mining & Heavy Industry?

In the mining and heavy industry sectors, devil cars are essential for off-road material transport. These vehicles are built to handle rugged terrains, making them ideal for transporting heavy materials from extraction sites to processing facilities. Buyers from the Middle East and Europe should prioritize durability and fuel efficiency when sourcing these vehicles, as these factors significantly impact operational costs and productivity in harsh environments.

How Can Devil Cars Enhance Agricultural Operations?

In agriculture, devil cars facilitate remote field access and crop monitoring. Their capability to traverse uneven landscapes allows farmers to reach isolated fields, ensuring timely interventions that can enhance crop yields. For B2B buyers in regions like Africa and South America, key considerations include terrain adaptability and payload capacity, as well as the integration of technology for precision farming practices.

Why Are Devil Cars Important for Construction Projects?

A stock image related to devil cars.

Devil cars are crucial in the construction industry for site transportation and equipment hauling. They enable the efficient movement of materials and machinery, which can significantly reduce project timelines. Buyers in Europe should focus on load capacity and safety features when sourcing these vehicles, ensuring compliance with local construction regulations and standards to minimize risks on job sites.

How Do Devil Cars Support Emergency Services?

In emergency services, devil cars serve as rapid response vehicles that can reach affected areas quickly. Their reliability and speed are vital for providing timely assistance in critical situations. B2B buyers must consider the availability of spare parts and maintenance services when sourcing these vehicles, as operational readiness is essential for effective emergency response, especially in regions prone to natural disasters.

Related Video: FANUC Industrial Robots | AUDI Case Study

3 Common User Pain Points for ‘devil cars’ & Their Solutions

Scenario 1: Navigating Regulatory Challenges in Different Markets

The Problem: For B2B buyers in sectors such as logistics or transportation, acquiring ‘devil cars’—vehicles that may not meet stringent regulatory standards—can pose significant challenges. Buyers often face difficulties understanding the varying regulations across regions, such as emissions standards in Europe versus safety regulations in Africa or South America. This lack of clarity can lead to costly delays, fines, or even the rejection of imported vehicles.

The Solution: To effectively navigate these regulatory challenges, buyers should conduct thorough research on the specific regulations in each target market. Collaborating with local compliance experts or legal advisors can provide insights into the necessary certifications and standards for ‘devil cars’. Additionally, investing in vehicles that have been pre-certified for multiple markets can reduce risk. Establishing relationships with reliable suppliers who understand local regulations can also streamline the procurement process, ensuring that vehicles meet compliance requirements before purchase.

Scenario 2: Managing Maintenance and Repair Issues

The Problem: A common pain point for B2B buyers is the ongoing maintenance and repair of ‘devil cars’, especially when these vehicles are sourced from international markets. Buyers may encounter difficulties in finding compatible parts or qualified service technicians, leading to extended downtimes and increased operational costs. For instance, a logistics company in South America might struggle with sourcing parts for a specialized vehicle that is not widely recognized in the local market.

The Solution: To mitigate maintenance challenges, B2B buyers should prioritize sourcing vehicles that are supported by a robust aftermarket network. When selecting ‘devil cars’, it is essential to evaluate the availability of spare parts and service centers in the region. Establishing agreements with local mechanics or service providers who are experienced with these vehicles can also enhance repair efficiency. Additionally, buyers can consider creating a partnership with the manufacturer or a distributor that offers guaranteed parts supply and service training, ensuring that their teams are well-equipped to handle maintenance needs promptly.

Scenario 3: Addressing Safety Concerns in the Workforce

The Problem: Safety is a paramount concern for companies utilizing ‘devil cars’ in their operations. B2B buyers may face challenges related to the safety features of these vehicles, especially if they are older models or not built to modern safety standards. For instance, a construction firm in the Middle East might worry about the potential liabilities associated with using vehicles lacking essential safety features like airbags or advanced braking systems, putting both their workers and the company’s reputation at risk.

The Solution: To address safety concerns, buyers should conduct a comprehensive safety assessment of any ‘devil cars’ they intend to purchase. This includes examining the vehicle’s safety ratings, features, and history of recalls. Investing in retrofitting vehicles with necessary safety upgrades, such as additional airbags or enhanced visibility equipment, can also be a viable solution. Furthermore, implementing a rigorous training program for drivers on safe operation practices can significantly reduce the risk of accidents. Regular safety audits and compliance checks will ensure that the fleet operates within acceptable safety parameters, ultimately protecting the workforce and the company’s bottom line.

Strategic Material Selection Guide for devil cars

What Are the Key Properties of Aluminum in Devil Cars?

Aluminum is a popular choice for devil cars due to its lightweight nature and excellent strength-to-weight ratio. It typically has a temperature rating of up to 600°F (316°C) and is resistant to corrosion, making it suitable for various environments. Additionally, aluminum’s thermal conductivity allows for effective heat dissipation, which is crucial in high-performance applications.

Pros and Cons of Using Aluminum

The primary advantage of aluminum is its durability combined with low weight, which can enhance fuel efficiency and performance. However, it can be more expensive than other materials and requires specialized manufacturing processes, which may complicate production. Furthermore, while aluminum is resistant to corrosion, it can be susceptible to galvanic corrosion when in contact with certain metals.

Impact on Application

Aluminum is compatible with a variety of media, including fuels and oils, making it an excellent choice for components that interact with these substances. However, international B2B buyers should ensure compliance with relevant standards such as ASTM B209 for aluminum alloy sheets and plates, particularly in regions like Europe and the Middle East.

How Does Steel Compare as a Material for Devil Cars?

Steel is another common material used in devil cars, known for its high tensile strength and durability. It can withstand high pressures and temperatures, with some alloys rated for up to 1,200°F (649°C). Steel also offers excellent resistance to wear and tear, making it suitable for components that experience high stress.

Pros and Cons of Using Steel

The key advantage of steel is its cost-effectiveness and availability, making it a popular choice among manufacturers. However, its heavier weight can negatively impact fuel efficiency and performance. Additionally, steel is prone to corrosion, necessitating protective coatings or treatments, which can increase manufacturing complexity.

Impact on Application

Steel is compatible with a range of media, but its susceptibility to rust and corrosion can limit its use in certain environments. Buyers from regions like Africa and South America should consider local climate conditions when selecting steel components and ensure compliance with standards such as ASTM A36 for structural steel.

What Are the Advantages of Composite Materials in Devil Cars?

Composite materials, such as carbon fiber and fiberglass, are increasingly being used in devil cars due to their high strength-to-weight ratios and design flexibility. These materials can withstand temperatures up to 500°F (260°C) and are inherently resistant to corrosion and chemical degradation.

Pros and Cons of Using Composites

The major advantage of composites is their lightweight nature, which significantly enhances performance and fuel efficiency. However, they can be expensive and require specialized manufacturing processes, which may not be feasible for all suppliers. Additionally, composites can be less durable than metals under certain conditions, such as impact or extreme temperatures.

Impact on Application

Composites are compatible with a wide range of media, including fuels and oils, and are often used in high-performance applications. International buyers should be aware of standards such as ASTM D3039 for tensile properties of composites, ensuring compliance with regional regulations.

How Does Titanium Benefit Devil Cars?

Titanium is a high-performance material known for its exceptional strength, low weight, and excellent corrosion resistance. It can withstand high temperatures (up to 1,800°F or 982°C), making it ideal for extreme conditions often encountered in devil cars.

Pros and Cons of Using Titanium

The primary advantage of titanium is its superior strength-to-weight ratio and resistance to corrosion, which can lead to longer-lasting components. However, titanium is one of the most expensive materials available, and its manufacturing processes can be complex and costly. This may deter some manufacturers from using it in standard applications.

Impact on Application

Titanium is compatible with various media, including aggressive chemicals, making it suitable for specialized applications. Buyers should ensure compliance with standards such as ASTM B348 for titanium and titanium alloy bars and rods, particularly in Europe and the Middle East.

Summary Table of Material Selection for Devil Cars

| Material | Typical Use Case for devil cars | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Engine components, body panels | Lightweight and corrosion-resistant | Higher cost, manufacturing complexity | Medium |

| Steel | Chassis, structural components | Cost-effective and durable | Heavier, prone to corrosion | Low |

| Composites | Body panels, interior components | Lightweight, design flexibility | Expensive, less durable under impact | High |

| Titanium | Exhaust systems, high-stress parts | Superior strength-to-weight ratio | Very high cost, complex manufacturing | High |

In-depth Look: Manufacturing Processes and Quality Assurance for devil cars

What Are the Key Stages in the Manufacturing Process of Devil Cars?

The manufacturing process of devil cars involves several critical stages that ensure the final product meets the highest standards of performance and reliability. Understanding these stages can empower international B2B buyers to make informed purchasing decisions.

Material Preparation

Material preparation is the first step in the manufacturing process. This involves sourcing high-quality raw materials, such as steel, aluminum, and composites. Suppliers must adhere to stringent specifications to ensure the materials can withstand the extreme conditions that devil cars are designed for. Buyers should inquire about the sourcing practices of their suppliers, including whether they utilize local materials or import components, as this can affect lead times and costs.

Forming Techniques

Once the materials are prepared, they undergo various forming techniques. Common methods include stamping, casting, and forging. Each technique has its advantages; for instance, stamping is often favored for producing complex shapes with high precision. Buyers should evaluate suppliers based on their expertise in these techniques and the technology employed, such as CNC machines or robotic automation, which can enhance precision and reduce waste.

Assembly Process

The assembly stage is where the vehicle components come together. This process typically employs both manual labor and automation, depending on the complexity and volume of production. Buyers should assess the assembly line’s efficiency, labor skills, and adherence to safety protocols. A well-structured assembly process not only enhances quality but also reduces the risk of defects.

Finishing Techniques

Finishing techniques, such as painting, coating, and polishing, are crucial in ensuring the devil car’s durability and aesthetic appeal. Advanced techniques like powder coating can provide a robust finish that resists corrosion and wear. B2B buyers should verify that their suppliers use environmentally friendly practices in their finishing processes, as regulations may differ significantly across regions, particularly in Europe.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that each vehicle meets specific standards before reaching the market. Understanding how QA is implemented can help B2B buyers mitigate risks associated with poor-quality products.

What International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 provide a framework for quality management systems. Compliance with these standards demonstrates a commitment to maintaining quality throughout the manufacturing process. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for certain components are essential for devil cars.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are critical in identifying defects at various stages of production. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early.

- Final Quality Control (FQC): A thorough inspection of the finished product ensures it complies with all quality standards.

B2B buyers should ensure that their suppliers have robust QC processes in place, as this can significantly reduce the likelihood of receiving subpar products.

Which Testing Methods Are Commonly Used in the Devil Car Industry?

Several testing methods are employed to assess the performance and safety of devil cars. Common methods include:

- Durability Testing: Evaluates the vehicle’s ability to withstand extreme conditions, including temperature fluctuations and mechanical stress.

- Crash Testing: Ensures that the vehicle meets safety standards by simulating real-world collisions.

- Emissions Testing: Verifies compliance with environmental regulations, particularly in regions with strict emissions standards.

B2B buyers should request detailed reports on these tests from suppliers, as this information is crucial for assessing the vehicle’s reliability and marketability.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control practices is essential for B2B buyers seeking to establish reliable partnerships. Here are actionable steps to consider:

Conducting Audits

Regular audits of suppliers can provide insight into their manufacturing processes and QC measures. Buyers should establish a clear audit schedule and criteria, focusing on areas such as compliance with international standards and the effectiveness of their QC checkpoints.

Reviewing Quality Reports

Requesting quality reports from suppliers can help buyers assess the consistency of product quality over time. These reports should include data on defect rates, corrective actions taken, and compliance with testing standards.

Engaging Third-Party Inspectors

Utilizing third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes. These inspectors can conduct thorough assessments of manufacturing facilities, ensuring compliance with international standards and best practices.

What Are the Quality Control Nuances for International Buyers?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding regional nuances in quality control is vital. Different regions may have varying standards and practices, which can impact the overall quality of devil cars.

Regional Standards and Compliance

Buyers should familiarize themselves with local regulations and standards in their respective markets. For instance, European buyers must comply with CE standards, while buyers in the Middle East may need to adhere to specific local regulations. Understanding these requirements can help buyers avoid potential compliance issues.

Cultural Considerations in Quality Assurance

Cultural differences can also influence quality assurance practices. For example, some regions may prioritize speed over quality, while others may take a more meticulous approach. B2B buyers should engage in open communication with suppliers to align expectations and ensure a shared commitment to quality.

Conclusion: Making Informed Decisions in the Devil Car Market

Understanding the intricacies of manufacturing processes and quality assurance is crucial for international B2B buyers in the devil car market. By focusing on material preparation, forming techniques, assembly, finishing, and robust quality control measures, buyers can make informed decisions that lead to successful partnerships and high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘devil cars’

Introduction

In the competitive landscape of B2B procurement, sourcing ‘devil cars’—a term that typically refers to high-performance vehicles or specialized automotive equipment—requires a strategic approach. This checklist provides international buyers, particularly from Africa, South America, the Middle East, and Europe, with actionable steps to ensure a successful procurement process. By following this guide, you can streamline your sourcing efforts, mitigate risks, and ultimately enhance your supply chain efficiency.

Step 1: Define Your Technical Specifications

Before you begin the sourcing process, it’s essential to establish clear technical specifications for the ‘devil cars’ you intend to procure. This includes understanding the performance requirements, safety standards, and any regional compliance regulations.

- Key Considerations:

- Engine specifications, horsepower, and torque.

- Safety features and compliance with international automotive standards.

Step 2: Conduct Market Research

Gather data on current market trends, pricing, and available models. This knowledge will empower you to make informed decisions and identify the best options for your needs.

- Research Tools:

- Industry reports and market analyses.

- Competitor benchmarking to understand pricing strategies.

Step 3: Identify Potential Suppliers

Compile a list of potential suppliers who specialize in ‘devil cars’. Focus on those with a proven track record in your target regions, as local market knowledge can greatly enhance your purchasing experience.

- Tips for Selection:

- Look for suppliers with established relationships in your region.

- Use platforms like LinkedIn and industry forums to find reputable suppliers.

Step 4: Evaluate Supplier Credentials

Before entering into negotiations, it is crucial to assess the credibility of your shortlisted suppliers. This includes reviewing their certifications, financial stability, and customer feedback.

- Verification Steps:

- Request certifications relevant to automotive manufacturing and safety.

- Check references and case studies from similar businesses to gauge supplier reliability.

Step 5: Request Detailed Proposals

Once you have narrowed down your options, reach out to suppliers for detailed proposals. This should include pricing, delivery timelines, and after-sales support.

- What to Look For:

- Transparent pricing structures that highlight all potential costs.

- Clear terms regarding warranties, maintenance, and support services.

Step 6: Negotiate Terms and Conditions

Effective negotiation can lead to favorable terms for both parties. Engage in discussions about payment terms, delivery schedules, and volume discounts to optimize your procurement strategy.

- Negotiation Strategies:

- Prepare to discuss your budget constraints openly.

- Be ready to explore flexible payment options that can benefit your cash flow.

Step 7: Finalize Contracts and Place Orders

Once negotiations are complete, ensure that all agreements are documented in a formal contract. This step is vital for protecting your interests and providing a clear framework for the transaction.

- Contract Essentials:

- Include delivery schedules, payment terms, and liability clauses.

- Ensure that all technical specifications are accurately reflected in the contract.

By following these steps, you can create a robust framework for sourcing ‘devil cars’ that aligns with your operational needs and market conditions.

Comprehensive Cost and Pricing Analysis for devil cars Sourcing

What Are the Key Cost Components in Sourcing Devil Cars?

Understanding the cost structure of devil cars is essential for international B2B buyers. The primary cost components involved include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margins.

-

Materials: The choice of materials significantly impacts the overall cost. High-quality materials may increase upfront costs but can lead to enhanced durability and performance, reducing maintenance expenses over time.

-

Labor: Labor costs vary widely depending on the region. In countries with lower wage rates, labor-intensive processes can be more cost-effective, but this may also affect quality and compliance with international standards.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment. Efficient manufacturing processes can lower overhead costs, making it crucial for suppliers to demonstrate their operational efficiencies.

-

Tooling: Custom tooling can be a significant upfront investment, especially for specialized devil cars. Buyers should assess whether the supplier’s tooling capabilities align with their customization needs.

-

Quality Control (QC): Rigorous QC processes are essential for ensuring product reliability. While higher QC standards may increase costs, they can also mitigate risks associated with defects and recalls.

-

Logistics: Transportation costs are a critical factor, especially for international shipments. Consideration of shipping methods, distances, and customs duties is necessary to calculate total logistics expenses accurately.

-

Margin: Suppliers typically include a profit margin that reflects their business model and market positioning. Understanding the margin structure can help buyers negotiate better terms.

How Do Price Influencers Affect Devil Cars Sourcing?

Several factors influence pricing in the devil cars market. These include volume or minimum order quantity (MOQ), specifications and customization, material quality and certifications, supplier factors, and Incoterms.

-

Volume/MOQ: Purchasing in larger quantities often leads to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their demand forecasts to optimize pricing.

-

Specifications/Customization: Custom features can significantly increase costs. Buyers must clearly define their specifications and understand how these will affect pricing.

-

Materials and Quality/Certifications: The quality of materials and necessary certifications can vary in cost. Buyers should prioritize suppliers who can provide the required certifications while maintaining competitive pricing.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a proven track record may command higher prices but offer better assurance of quality and service.

-

Incoterms: Understanding Incoterms is crucial for international buyers. They define the responsibilities of buyers and sellers in terms of shipping costs, risk, and insurance, directly impacting the total cost of ownership.

What Are Essential Buyer Tips for Cost-Efficiency in Devil Cars Sourcing?

To achieve cost-efficiency in sourcing devil cars, buyers should consider the following strategies:

-

Negotiation: Effective negotiation can lead to better pricing and terms. Buyers should be prepared to discuss their purchasing volume and long-term partnership potential to leverage favorable terms.

-

Total Cost of Ownership (TCO): Assessing TCO, which includes initial costs, maintenance, and operational expenses, is critical. A lower upfront cost may not always translate to lower overall expenses.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional market dynamics, currency fluctuations, and economic conditions that may affect pricing.

-

Building Relationships with Suppliers: Establishing strong relationships with suppliers can lead to better pricing, priority service, and insights into future trends or changes in the market.

-

Conducting Market Research: Stay informed about industry trends, competitor pricing, and emerging technologies that may influence costs. Regular market analysis can provide leverage during negotiations.

Disclaimer on Indicative Prices

While this analysis provides a comprehensive overview of cost components and pricing influencers in devil cars sourcing, actual prices may vary based on specific buyer requirements, market conditions, and supplier negotiations. Buyers are encouraged to conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing devil cars With Other Solutions

Understanding Alternatives to Devil Cars for B2B Buyers

In today’s competitive market, international B2B buyers must carefully evaluate their options when considering ‘devil cars’ as a solution for their needs. Understanding the strengths and weaknesses of alternative solutions is crucial for making informed decisions. This section will compare ‘devil cars’ with two viable alternatives: Electric Vehicles (EVs) and Internal Combustion Engine (ICE) vehicles, focusing on key aspects that matter to businesses.

Comparison Table of Devil Cars and Alternatives

| Comparison Aspect | Devil Cars | Electric Vehicles (EVs) | Internal Combustion Engine (ICE) Vehicles |

|---|---|---|---|

| Performance | High torque, fast acceleration | Sufficient for urban use, lower torque | Varied performance, high torque in larger engines |

| Cost | Higher initial investment | Higher upfront, lower long-term (fuel savings) | Lower initial cost, fluctuating fuel prices |

| Ease of Implementation | Requires specialized infrastructure | Growing charging infrastructure, needs planning | Widely available fueling infrastructure |

| Maintenance | High maintenance due to complex systems | Lower maintenance, fewer moving parts | Moderate to high maintenance, parts availability varies |

| Best Use Case | Urban environments, racing, and high-demand sectors | City driving, eco-conscious businesses | Long-distance travel, heavy-duty applications |

What Are the Pros and Cons of Electric Vehicles?

Electric Vehicles (EVs) are increasingly popular among businesses aiming to reduce their carbon footprint. One of the primary advantages of EVs is their lower operational costs over time, thanks to reduced fuel and maintenance expenses. They are ideal for urban environments where stop-and-go traffic is common, and they have the added benefit of being environmentally friendly.

However, EVs come with challenges, particularly in regions where charging infrastructure is still developing. The initial investment can also be higher compared to traditional vehicles, which may deter some buyers. Businesses must assess whether the long-term savings justify the upfront costs and infrastructural challenges.

How Do Internal Combustion Engine Vehicles Compare?

Internal Combustion Engine (ICE) vehicles have been the traditional choice for many businesses due to their versatility and availability. They offer a variety of performance options, making them suitable for heavy-duty applications and long-distance travel. ICE vehicles generally have a lower initial purchase cost compared to both ‘devil cars’ and EVs.

On the downside, ICE vehicles are increasingly scrutinized for their environmental impact, and fuel costs can be unpredictable due to market fluctuations. Additionally, maintenance can become costly over time, particularly for older models. Companies that prioritize sustainability may find ICE vehicles less appealing in the long run.

How to Choose the Right Solution for Your Business Needs

When deciding between ‘devil cars’, Electric Vehicles, and Internal Combustion Engine vehicles, B2B buyers should consider their specific operational requirements, budget constraints, and long-term sustainability goals. It’s essential to evaluate the total cost of ownership, including maintenance and fuel costs, against the performance needs of your business.

Additionally, assess the availability of necessary infrastructure, such as charging stations for EVs or servicing options for ICE vehicles. By carefully analyzing these factors, buyers can select the most suitable solution that aligns with their business objectives and operational demands.

Essential Technical Properties and Trade Terminology for devil cars

What Are the Essential Technical Properties of Devil Cars?

When sourcing devil cars, understanding the technical specifications is crucial for making informed purchasing decisions. Here are some critical properties that B2B buyers should consider:

1. Material Grade

The material grade refers to the composition and quality of the materials used in the manufacturing of devil cars. Common materials include high-strength steel, aluminum, and composite materials. The choice of material affects the vehicle’s durability, weight, and overall performance. For international buyers, knowing the material grade is essential for compliance with regional regulations and standards.

2. Tolerance Levels

Tolerance levels denote the allowable deviation from specified dimensions in the manufacturing process. Precision in tolerances is vital for ensuring that parts fit together correctly and function as intended. In the context of devil cars, tighter tolerances often translate to better performance and safety. B2B buyers should inquire about tolerance specifications to avoid compatibility issues during assembly.

3. Weight Capacity

Weight capacity indicates the maximum load a devil car can carry without compromising performance or safety. This property is particularly important for businesses engaged in logistics or transportation. Buyers must assess their operational requirements to ensure that the chosen vehicle meets their load-bearing needs, thus optimizing efficiency.

4. Powertrain Specifications

Powertrain specifications include details about the engine type, horsepower, torque, and transmission system. Understanding these specifications helps buyers evaluate the vehicle’s performance capabilities. For markets in Africa and South America, where terrain can vary widely, selecting a devil car with a robust powertrain is vital for operational success.

5. Fuel Efficiency

Fuel efficiency is a critical property that directly impacts operational costs. It is measured in miles per gallon (MPG) or liters per 100 kilometers (L/100km). For B2B buyers, especially in regions with fluctuating fuel prices, selecting a devil car with high fuel efficiency can lead to significant cost savings over time.

What Are Common Trade Terms in the Devil Car Industry?

Familiarity with industry terminology enhances communication and negotiation. Here are some essential trade terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the devil car industry, understanding OEM relationships can help buyers ensure they are purchasing high-quality components that meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ denotes the minimum number of units a supplier is willing to sell. For buyers, understanding MOQ is crucial for budgeting and inventory management. Negotiating lower MOQs can be advantageous for smaller businesses or those testing new markets.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. For B2B buyers, issuing an RFQ is a strategic way to gather competitive quotes and assess supplier capabilities, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping contracts. They clarify who is responsible for shipping, insurance, and tariffs, which is essential for international transactions. Understanding Incoterms helps buyers avoid unexpected costs and delays.

5. Lead Time

Lead time refers to the time it takes from placing an order until it is delivered. For B2B buyers, understanding lead times is critical for planning and inventory management. Longer lead times can impact operational efficiency, particularly in fast-paced markets.

By grasping these essential technical properties and trade terms, B2B buyers can navigate the complexities of the devil car industry more effectively, ensuring they make strategic purchasing decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the devil cars Sector

What Are the Key Market Dynamics Driving the Devil Cars Sector?

The devil cars sector is experiencing significant growth due to several global drivers. One of the most influential factors is the increasing demand for innovative automotive technology. International B2B buyers are particularly focused on integrating advanced features such as AI-assisted driving and enhanced safety systems, which are becoming standard expectations. Additionally, the rise of electric and hybrid vehicles is reshaping sourcing strategies, as manufacturers seek suppliers who can provide sustainable components.

Emerging trends in B2B technology are also affecting how buyers source devil cars. The adoption of digital platforms for procurement is on the rise, making it easier for buyers in regions like Africa, South America, the Middle East, and Europe to connect with manufacturers and suppliers worldwide. Technologies like blockchain are enhancing transparency in the supply chain, which is crucial for international buyers concerned about quality and authenticity.

Moreover, geopolitical factors, including trade agreements and tariffs, are influencing sourcing decisions. Buyers must stay informed about these dynamics to navigate the complexities of international trade effectively. Recognizing local market conditions and consumer preferences is essential for tailoring product offerings, which can vary significantly between regions.

How Is Sustainability Influencing Sourcing Decisions in the Devil Cars Sector?

Sustainability has become a critical consideration in the devil cars sector, particularly for international B2B buyers. Environmental impacts associated with automotive production, such as carbon emissions and resource depletion, are prompting manufacturers to seek greener practices. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their environmental footprint, making ethical sourcing a key factor in procurement decisions.

Incorporating sustainable materials and processes into the supply chain is no longer optional; it is a necessity. Certifications such as ISO 14001 (Environmental Management) and eco-labels for sustainable materials are becoming vital for manufacturers looking to attract B2B buyers. These certifications not only enhance brand reputation but also align with the growing consumer demand for environmentally responsible products.

Furthermore, the push towards circular economy principles is influencing sourcing strategies. This involves considering the end-of-life impact of devil cars and integrating recycling and reuse into the product lifecycle. Buyers should engage with suppliers who are exploring innovative materials, such as bio-based plastics and recycled metals, which can significantly reduce the environmental impact of automotive production.

What Is the Historical Context of the Devil Cars Sector for B2B Buyers?

The devil cars sector has evolved significantly over the past few decades, transitioning from niche products to mainstream offerings. Initially, these vehicles were primarily recognized for their performance and design, attracting a specific consumer segment. However, with advancements in technology and shifts in consumer preferences, the market has expanded to include a broader range of functionalities and features.

This evolution has been influenced by regulatory changes and technological advancements, pushing manufacturers to innovate continually. As a result, B2B buyers today benefit from a wider variety of options, enabling them to select products that align closely with their specific market needs. Understanding this historical context is essential for international buyers to make informed sourcing decisions that consider both current trends and future market trajectories.

Frequently Asked Questions (FAQs) for B2B Buyers of devil cars

-

How do I solve quality assurance issues when sourcing devil cars?

To address quality assurance issues when sourcing devil cars, it is essential to establish a rigorous vetting process for suppliers. Start by requesting certifications and compliance documents to ensure they meet international standards. Conduct on-site visits or audits if feasible, and consider engaging third-party quality control firms to inspect vehicles before shipment. Additionally, implementing a detailed contract that specifies quality expectations and penalties for non-compliance can help mitigate risks associated with product quality. -

What is the best way to vet suppliers for devil cars?

The best way to vet suppliers for devil cars involves a multi-step approach. Begin with online research to gather information about their reputation and track record. Utilize platforms like Alibaba or Global Sources to read reviews and ratings. Follow this with direct communication to assess responsiveness and professionalism. Request references from previous clients and, if possible, visit the supplier’s facilities. Ensure they have the necessary licenses and certifications to operate in your region, particularly for import compliance. -

What are the typical minimum order quantities (MOQ) for devil cars?

Minimum order quantities (MOQ) for devil cars can vary significantly depending on the manufacturer and the specific model. Generally, MOQs may range from 5 to 100 units. It’s advisable to discuss your requirements directly with the supplier, as they may offer flexibility for initial orders or negotiations based on future commitments. Understanding the supplier’s production capabilities can also help you gauge their willingness to accommodate smaller or larger orders. -

What payment terms should I expect when purchasing devil cars?

Payment terms for purchasing devil cars can vary widely among suppliers. Common terms include a deposit of 30% upfront with the balance due upon delivery or prior to shipment. Some suppliers may offer financing options or letters of credit for larger orders. It’s crucial to negotiate payment terms that align with your cash flow and risk management strategies. Always ensure that payment methods are secure and documented to protect against fraud. -

How can I customize devil cars to meet my market needs?

Customizing devil cars to meet market needs typically involves discussing specific features and modifications with the supplier. This can include alterations in design, engine specifications, or additional technology features that cater to local preferences. It’s beneficial to conduct market research to identify the most desirable features in your target market. Collaborating with the supplier during the design phase can also lead to more tailored solutions that enhance your competitive edge. -

What logistics considerations should I take into account when importing devil cars?

When importing devil cars, logistics considerations include shipping methods, import regulations, and customs duties. Choose between sea freight and air freight based on your budget and urgency. Understand the import regulations in your country, as they may require specific documentation or compliance checks. Working with a logistics provider experienced in automotive imports can streamline the process and help you navigate the complexities of customs clearance efficiently.

A stock image related to devil cars.

-

What are the common challenges in international trade for devil cars?

Common challenges in international trade for devil cars include fluctuating tariffs, varying regulations across countries, and the risk of supply chain disruptions. Currency volatility can also impact pricing and profitability. To mitigate these challenges, stay informed about trade policies and economic conditions in both exporting and importing countries. Establishing strong relationships with suppliers and logistics partners can enhance communication and responsiveness to potential issues. -

How do I ensure compliance with local regulations when importing devil cars?

Ensuring compliance with local regulations when importing devil cars requires thorough research and planning. Familiarize yourself with vehicle emission standards, safety regulations, and import duties specific to your country. Consult with local authorities or legal experts to understand the requirements for documentation, inspections, and certifications. Engaging a customs broker can facilitate compliance and help you navigate the complexities of local laws, reducing the risk of delays or penalties.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for devil cars

In navigating the complex landscape of devil cars, strategic sourcing emerges as a critical component for international B2B buyers. By prioritizing a thorough understanding of market dynamics and supplier capabilities, companies can enhance their procurement processes and mitigate risks associated with sourcing from diverse regions, including Africa, South America, the Middle East, and Europe. Key takeaways include the importance of establishing strong supplier relationships, leveraging technology for supply chain transparency, and aligning sourcing strategies with local regulations and cultural nuances.

How can B2B buyers capitalize on emerging trends in devil cars? As the automotive industry continues to evolve, staying ahead of technological advancements and consumer preferences will be paramount. Buyers should consider investing in sustainable sourcing practices and innovative partnerships that can drive competitive advantage.

Looking forward, the demand for devil cars is set to increase, fueled by a growing global market and shifting consumer interests. International B2B buyers are encouraged to proactively seek out opportunities in emerging markets, fostering collaborations that can lead to mutual growth. Embrace strategic sourcing as a pathway to not only navigate the current landscape but also to thrive in the future of the devil car industry.