Discover Top Benefits of Brand New Cummins ISX Engine for Sale (2025)

Introduction: Navigating the Global Market for brand new cummins isx engine for sale

In the competitive landscape of global commerce, sourcing a brand new Cummins ISX engine for sale can pose significant challenges for international B2B buyers. With varying regulations, diverse market conditions, and a plethora of suppliers, making informed purchasing decisions is crucial. This guide is designed to illuminate the complex process of acquiring these high-performance engines, providing insights into different types, applications, and the critical factors to consider when evaluating suppliers.

Navigating the global market requires a deep understanding of not only the product specifications but also the regional differences in demand and supply dynamics. This comprehensive resource will cover essential topics such as the various Cummins ISX engine models available, their applications across industries, and effective strategies for supplier vetting to ensure reliability and quality. Additionally, we will delve into cost considerations, helping buyers understand pricing structures and negotiate effectively.

By empowering international B2B buyers from regions like Africa, South America, the Middle East, and Europe—including key markets such as Nigeria and Saudi Arabia—this guide aims to streamline the purchasing process. With actionable insights and expert recommendations, you will be equipped to make confident and strategic decisions, ultimately enhancing your operational efficiency and competitive advantage in the market.

Understanding brand new cummins isx engine for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cummins ISX12 | 12-liter engine, high torque, ideal for heavy-duty use | Long-haul trucking, construction | Pros: High durability, excellent power output. Cons: Higher initial cost. |

| Cummins ISX15 | 15-liter engine, advanced fuel efficiency, low emissions | Freight transport, mining vehicles | Pros: Superior fuel economy, lower emissions. Cons: Larger size may limit vehicle compatibility. |

| Cummins ISX CM2250 | Integrated with advanced electronics for diagnostics | Fleet management, heavy machinery | Pros: Enhanced monitoring capabilities. Cons: Complexity may require specialized maintenance. |

| Cummins ISX QSB6.7 | Compact design, versatile applications | Agriculture, light-duty trucks | Pros: Space-saving, flexible installation. Cons: Lower power output compared to larger models. |

| Cummins ISX16 | High displacement, designed for extreme conditions | Oil & gas, extreme environment trucks | Pros: Exceptional reliability under stress. Cons: Heavier, can affect vehicle weight limits. |

What are the Key Characteristics of the Cummins ISX12 Engine?

The Cummins ISX12 is a robust 12-liter engine designed primarily for heavy-duty applications. Its high torque output makes it ideal for long-haul trucking and construction equipment. B2B buyers should consider its durability and performance, particularly in demanding environments. However, the initial investment can be higher than other engines, so companies must evaluate their budget against the expected return on investment from improved operational efficiency.

How Does the Cummins ISX15 Stand Out in the Market?

The Cummins ISX15 engine is a 15-liter powerhouse that emphasizes fuel efficiency and reduced emissions. This makes it a prime choice for freight transport and mining vehicles, where operational costs are critical. Its advanced technology supports better fuel economy, which can significantly lower long-term expenses. Buyers must also consider the engine’s larger size, as it may limit compatibility with certain vehicle models.

What Makes the Cummins ISX CM2250 a Smart Choice for Fleet Management?

The Cummins ISX CM2250 integrates advanced electronics that enhance diagnostic capabilities, making it particularly suitable for fleet management and heavy machinery applications. This engine allows companies to monitor performance closely, leading to proactive maintenance and reduced downtime. While its complexity offers numerous benefits, buyers should be prepared for potentially higher maintenance costs and the need for specialized service.

Why is the Cummins ISX QSB6.7 Engine Popular for Versatile Applications?

The Cummins ISX QSB6.7 is known for its compact design, making it highly versatile across various applications, including agriculture and light-duty trucks. Its space-saving attributes allow for easier installation in diverse vehicle types. However, it has a lower power output compared to larger models, which may not meet the needs of all buyers. Companies should assess their specific requirements to determine if this engine is the right fit.

What are the Advantages of the Cummins ISX16 in Extreme Conditions?

The Cummins ISX16 engine is designed to excel in extreme conditions, making it ideal for oil and gas applications as well as trucks operating in harsh environments. Its high displacement offers exceptional reliability and performance under stress. However, its heavier weight can affect vehicle weight limits, which is a critical consideration for B2B buyers focusing on compliance with regulations. Understanding the balance between performance and regulatory requirements will help in making an informed purchase decision.

Related Video: Cummins ISX Engine ReBuild (Overview and Walk Around)

Key Industrial Applications of brand new cummins isx engine for sale

| Industry/Sector | Specific Application of brand new cummins isx engine for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation & Logistics | Heavy-duty trucks and freight carriers | Enhanced fuel efficiency and reliability for long-haul operations | Compliance with local emissions regulations and standards |

| Construction | Heavy machinery such as excavators and bulldozers | Improved power output and durability for demanding jobs | Availability of service and parts in the region |

| Mining | Mining trucks and equipment | High torque and performance in rugged environments | Proven performance in harsh conditions |

| Agriculture | Agricultural vehicles like tractors and harvesters | Increased productivity and reduced downtime | Adaptability to local farming practices |

| Energy & Power Generation | Backup generators and power units | Reliable power supply and efficiency in energy production | Support for local energy regulations and infrastructure |

How is the Cummins ISX Engine Used in the Transportation & Logistics Sector?

The brand new Cummins ISX engine is widely utilized in heavy-duty trucks and freight carriers, providing the necessary power and efficiency for long-haul transport. This engine is designed to deliver superior fuel efficiency, which is crucial in reducing operational costs for logistics companies. International buyers must consider local emissions regulations to ensure compliance and avoid potential penalties, particularly in regions like Europe and the Middle East.

What Role Does the Cummins ISX Engine Play in the Construction Industry?

In the construction sector, the Cummins ISX engine powers heavy machinery, including excavators and bulldozers. Its robust design offers improved power output and durability, essential for handling demanding construction tasks. Buyers should ensure that they have access to a reliable supply of parts and service in their region to minimize downtime and maintain operational efficiency.

How is the Cummins ISX Engine Beneficial for Mining Operations?

The mining industry benefits significantly from the Cummins ISX engine, which powers mining trucks and equipment. Known for its high torque and performance, this engine is capable of operating efficiently in rugged environments where reliability is paramount. Buyers in this sector should verify the engine’s performance under harsh conditions and consider the availability of technical support and spare parts locally.

How Does the Cummins ISX Engine Enhance Agricultural Productivity?

In agriculture, the brand new Cummins ISX engine is used in tractors and harvesters, enhancing productivity and reducing downtime. Its efficiency allows farmers to operate machinery longer without refueling, which is particularly beneficial in regions with vast farmlands. Buyers should assess the engine’s adaptability to local farming practices and ensure that they have access to service networks for maintenance.

What Advantages Does the Cummins ISX Engine Offer for Energy & Power Generation?

The Cummins ISX engine is also employed in backup generators and power units, providing a reliable power supply for various applications. Its efficiency in energy production is crucial for businesses that require uninterrupted power, especially in areas with unstable energy infrastructure. International buyers should consider local energy regulations and the compatibility of the engine with existing infrastructure to ensure optimal performance.

Related Video: Birth of the X12, new Cummins Heavy Duty engine

3 Common User Pain Points for ‘brand new cummins isx engine for sale’ & Their Solutions

Scenario 1: Navigating Supply Chain Disruptions for Cummins ISX Engines

The Problem: International B2B buyers often face significant challenges in sourcing brand new Cummins ISX engines due to supply chain disruptions. Issues such as geopolitical tensions, transportation delays, and fluctuating trade policies can hinder timely delivery. Buyers from regions like Africa and South America may struggle with additional hurdles, including limited local suppliers and higher shipping costs, which can lead to project delays and increased operational expenses. This situation creates frustration and can jeopardize business relationships and project timelines.

The Solution: To effectively navigate these supply chain challenges, buyers should consider establishing relationships with multiple suppliers, both local and international. This diversification can mitigate risks associated with any single supplier’s delays. Additionally, engaging with suppliers who have a robust logistics network can improve delivery timelines. Buyers should also leverage technology to track shipments in real-time, allowing for proactive management of any potential delays. Furthermore, engaging in long-term contracts with suppliers can lock in prices and availability, providing stability in a volatile market.

Scenario 2: Understanding Technical Specifications and Compatibility

The Problem: When investing in a brand new Cummins ISX engine, buyers may encounter difficulties in understanding the technical specifications and ensuring compatibility with existing machinery. This issue is particularly relevant for companies in the Middle East and Europe, where diverse fleet configurations can complicate integration. Misunderstanding engine specifications can lead to costly mistakes, such as purchasing an engine that does not meet the operational requirements or is incompatible with other components.

The Solution: Buyers should conduct a thorough analysis of their existing equipment and operational needs before making a purchase. Collaborating with technical experts or consulting with Cummins representatives can provide invaluable insights into the right specifications needed for their applications. Creating a detailed checklist of required features and compatibility needs will help streamline the selection process. Additionally, investing in training for the technical staff on engine specifications and maintenance can improve operational efficiency and ensure proper integration of the new engine into their existing systems.

Scenario 3: Ensuring After-Sales Support and Maintenance

The Problem: After purchasing a brand new Cummins ISX engine, many buyers face challenges related to after-sales support and maintenance services. In regions like Nigeria and Saudi Arabia, where access to genuine parts and qualified technicians may be limited, ensuring ongoing engine performance and reliability can be daunting. The lack of proper after-sales support can lead to increased downtime, higher maintenance costs, and concerns over the longevity of the engine.

The Solution: Buyers should prioritize suppliers who offer comprehensive after-sales support, including warranty services and access to genuine parts. Establishing a clear understanding of the warranty terms and maintenance schedules is crucial. It is also advisable to partner with local service centers or authorized dealers who have experience with Cummins engines, ensuring that qualified technicians are available for repairs and maintenance. Additionally, creating a preventive maintenance plan based on the engine’s operational history can help identify potential issues before they escalate, ultimately extending the engine’s lifespan and optimizing performance.

Strategic Material Selection Guide for brand new cummins isx engine for sale

What Are the Key Materials Used in the Cummins ISX Engine?

When selecting a brand new Cummins ISX engine for sale, understanding the materials used in its construction is crucial for international B2B buyers. The choice of materials can significantly impact performance, durability, and overall cost. Below, we analyze common materials found in the Cummins ISX engine, focusing on their properties, advantages, disadvantages, and considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Advantages and Disadvantages of Cast Iron in Engine Manufacturing?

Key Properties: Cast iron is known for its excellent wear resistance and ability to withstand high temperatures and pressures. It typically has a tensile strength of around 200 MPa, making it suitable for engine blocks and cylinder heads.

Pros & Cons: The primary advantage of cast iron is its durability and ability to absorb vibrations, which enhances engine performance. However, it is relatively heavy, which can affect fuel efficiency. Additionally, the manufacturing process can be complex, leading to higher production costs.

Impact on Application: Cast iron is compatible with various engine media, including oil and coolant. However, it may be susceptible to corrosion if not properly maintained.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM or DIN for cast iron components. In regions like Nigeria and Saudi Arabia, understanding the local market’s preferences for engine weight and performance is also essential.

How Does Aluminum Improve Engine Efficiency?

Key Properties: Aluminum is lightweight and has excellent thermal conductivity, making it ideal for components like pistons and cylinder heads. It typically has a melting point of around 660°C and a density of 2.7 g/cm³.

Pros & Cons: The main advantage of aluminum is its weight reduction, which enhances fuel efficiency and performance. However, it has lower tensile strength compared to cast iron, making it less durable under extreme conditions.

Impact on Application: Aluminum is highly compatible with engine oils and coolants, but it may require protective coatings to prevent corrosion.

Considerations for International Buyers: Buyers should be aware of the specific aluminum grades used and ensure they meet international standards. In Europe, for instance, there may be stricter regulations on emissions, making aluminum a preferred choice for efficiency.

What Role Does Steel Play in Engine Components?

Key Properties: Steel is known for its high tensile strength and durability, with a tensile strength ranging from 400 to 600 MPa. It is often used in crankshafts, camshafts, and other critical engine components.

Pros & Cons: Steel’s primary advantage is its strength, which allows for the production of components that can withstand high stress and wear. However, it is heavier than aluminum, which can impact overall engine weight and efficiency.

Impact on Application: Steel components are compatible with various engine fluids but may require additional treatments to enhance corrosion resistance.

Considerations for International Buyers: Compliance with international standards is crucial, especially in regions with specific regulations like South America and the Middle East. Buyers should also consider the availability of steel grades in their local markets.

How Do Composites Enhance Engine Performance?

Key Properties: Composite materials, such as carbon fiber and fiberglass, offer high strength-to-weight ratios and excellent thermal resistance. They can withstand temperatures up to 300°C and are significantly lighter than metals.

Pros & Cons: The key advantage of composites is their lightweight nature, which improves fuel efficiency and performance. However, they can be expensive to manufacture and may not be as widely available in all markets.

Impact on Application: Composites are often used in non-structural components, such as covers and housings, and are compatible with various engine fluids.

Considerations for International Buyers: Buyers should assess the availability of composite materials in their regions and consider the cost implications. In Africa, for instance, the high cost of composites may be a limiting factor for some buyers.

Summary Table of Material Selection for Cummins ISX Engine

| Material | Typical Use Case for brand new cummins isx engine for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Engine blocks, cylinder heads | Excellent durability | Heavy, complex manufacturing | Medium |

| Aluminum | Pistons, cylinder heads | Lightweight, efficient | Lower strength than cast iron | High |

| Steel | Crankshafts, camshafts | High tensile strength | Heavier than aluminum | Medium |

| Composites | Covers, housings | Lightweight, high performance | Expensive, less availability | High |

Understanding these materials and their implications will empower international B2B buyers to make informed decisions when purchasing a brand new Cummins ISX engine, ensuring optimal performance and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for brand new cummins isx engine for sale

What Are the Main Stages of Manufacturing a Brand New Cummins ISX Engine?

The manufacturing of a brand new Cummins ISX engine involves several critical stages that ensure the engine meets the high standards expected in the industry. Understanding these stages can help B2B buyers assess the quality of the engines they are purchasing.

-

Material Preparation: The first stage involves sourcing high-quality raw materials, such as cast iron for the engine block and aluminum for the cylinder head. Suppliers are often selected based on their ability to meet specific material standards and certifications. Material testing is also performed to ensure that they meet the necessary specifications before proceeding to the next stage.

-

Forming: In this phase, the prepared materials undergo various forming processes, including casting, forging, and machining. For instance, the engine block is typically cast in a mold, which is then machined to achieve precise dimensions. This precision is crucial, as even minor deviations can affect engine performance and longevity.

-

Assembly: Once the components are formed, they are assembled in a controlled environment. This process includes the installation of critical parts such as the crankshaft, pistons, and camshaft. Manufacturers often use automated systems to enhance consistency and reduce human error during assembly.

-

Finishing: The final stage involves applying surface treatments and coatings to enhance durability and performance. This may include processes like painting, polishing, and applying protective coatings. Each engine is thoroughly inspected for any visual defects before moving on to quality assurance checks.

How Is Quality Assurance Implemented in the Manufacturing of Cummins ISX Engines?

Quality assurance is a vital part of the manufacturing process, ensuring that each Cummins ISX engine meets international and industry-specific standards. Here are the key components of quality assurance:

-

International Standards: Compliance with international standards such as ISO 9001 is essential for manufacturers. This standard focuses on quality management systems and ensures that processes are efficient and consistently produce quality products. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) provide further assurance of quality and safety.

-

Quality Control Checkpoints: The quality control process is typically divided into several checkpoints throughout the manufacturing cycle:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to verify their compliance with specifications.

– In-Process Quality Control (IPQC): During the manufacturing process, various inspections are conducted to ensure that the production is in line with quality standards.

– Final Quality Control (FQC): After assembly, a comprehensive inspection is performed to check the overall performance and quality of the engine before it is released for sale. -

Common Testing Methods: Various testing methods are employed to ensure the performance and reliability of the engines, including:

– Non-Destructive Testing (NDT): Techniques such as ultrasonic and magnetic particle testing are used to identify internal flaws without damaging the components.

– Performance Testing: Engines undergo rigorous testing in simulated operating conditions to verify their performance metrics, such as power output, fuel efficiency, and emissions levels.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is critical to ensuring that they receive high-quality products. Here are some actionable insights:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and quality control measures in place. During an audit, buyers can assess the production environment, review documentation, and verify compliance with standards.

-

Quality Reports: Requesting quality control reports from the manufacturer can provide insights into their testing methods, results, and compliance with international standards. These reports should detail the results of IQC, IPQC, and FQC stages.

-

Third-Party Inspections: Engaging third-party inspection services can add an additional layer of assurance. These independent organizations can conduct inspections and tests to confirm that the engines meet specified standards and requirements.

What Are the Quality Control Nuances for International Buyers?

International buyers must navigate certain nuances when dealing with quality control in the manufacturing of Cummins ISX engines:

-

Understanding Local Regulations: Different regions have varying regulations regarding emissions, safety, and performance standards. Buyers must ensure that the engines they purchase comply with local laws in their respective countries.

-

Cultural Considerations: Cultural differences may influence business practices, including quality control. Establishing clear communication and understanding the supplier’s commitment to quality is essential.

-

Logistics and Supply Chain: The transportation of engines across borders can introduce risks related to handling and storage. Buyers should ensure that suppliers have robust logistics practices to prevent damage during transit.

Conclusion: The Importance of Quality in the Cummins ISX Engine Manufacturing Process

In summary, understanding the manufacturing processes and quality assurance measures for the brand new Cummins ISX engine is crucial for international B2B buyers. By focusing on the stages of manufacturing, relevant quality standards, and verification methods, buyers can make informed decisions that ensure they are investing in reliable, high-quality engines suited for their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘brand new cummins isx engine for sale’

When sourcing a brand new Cummins ISX engine, having a structured approach can streamline the procurement process and ensure you make informed decisions. This checklist outlines essential steps for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical requirements for the Cummins ISX engine you need. Consider factors such as horsepower, torque, fuel type, and intended application (e.g., trucking, heavy machinery). This step is crucial as it helps narrow down potential suppliers who can meet your specific needs.

Step 2: Research Reliable Suppliers

Conduct thorough research to identify reputable suppliers of brand new Cummins ISX engines. Utilize online platforms, industry forums, and trade associations to compile a list of potential vendors. Look for suppliers with a proven track record in your region, as local expertise can facilitate smoother logistics and support.

- Tip: Check for customer reviews and testimonials to gauge supplier reliability.

Step 3: Verify Supplier Certifications and Compliance

Ensure that your chosen suppliers hold relevant certifications and comply with international standards for engine manufacturing. Certifications such as ISO 9001 indicate a commitment to quality management systems. Compliance with regional regulations is also vital, especially for emissions standards in markets like Europe and North America.

Step 4: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations for the Cummins ISX engines. Ensure that the quotations include pricing, payment terms, delivery timelines, and warranty information. A transparent quotation process allows for easier comparison and can highlight any potential hidden costs.

- Important: Look for bulk purchase discounts or financing options that may be available.

Step 5: Evaluate After-Sales Support and Warranty Terms

Assess the after-sales support and warranty terms offered by each supplier. A reliable supplier should provide comprehensive support, including installation guidance, maintenance, and troubleshooting assistance. Strong warranty terms can protect your investment and provide peace of mind.

- Consider: What is the duration of the warranty? What specific components are covered?

Step 6: Conduct Site Visits or Virtual Inspections

If feasible, conduct site visits to the suppliers’ facilities or arrange for virtual inspections. This step provides insight into the manufacturing processes and quality control measures in place. Engaging directly with the supplier can also help build relationships that may be beneficial for future transactions.

Step 7: Finalize the Purchase Agreement

After thorough evaluation, finalize the purchase agreement. Ensure that all terms, including delivery schedules and payment plans, are clearly defined in the contract. A well-structured agreement minimizes disputes and sets clear expectations for both parties.

Following this checklist will enhance your sourcing experience and increase the likelihood of successfully procuring a brand new Cummins ISX engine that meets your operational needs. By focusing on due diligence and building relationships with trusted suppliers, you can navigate the complexities of international procurement effectively.

Comprehensive Cost and Pricing Analysis for brand new cummins isx engine for sale Sourcing

What Are the Key Cost Components for a Brand New Cummins ISX Engine?

When considering the procurement of a brand new Cummins ISX engine, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials used directly impact the engine’s performance and longevity. High-grade components often lead to higher upfront costs but can result in lower maintenance expenses over time.

-

Labor: Skilled labor is essential in the manufacturing process. Labor costs can vary significantly based on the region and the complexity of the assembly process.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and administrative costs. Efficient manufacturing processes can reduce overhead costs, impacting the final price.

-

Tooling: Custom tooling may be necessary for specific engine configurations. This is a one-time cost that can significantly affect the initial price but can be amortized over larger production runs.

-

Quality Control (QC): Ensuring the engine meets industry standards requires investment in quality assurance processes. This can add to the cost but is critical for maintaining brand reputation and customer satisfaction.

-

Logistics: Shipping costs, tariffs, and handling fees can vary based on the destination and the chosen Incoterms. Understanding these costs can help in budgeting accurately.

-

Margin: Suppliers will include a margin to cover risks and ensure profitability. This can vary based on market conditions and competitive landscape.

How Do Price Influencers Affect the Cost of a Cummins ISX Engine?

Several factors can influence the pricing of a Cummins ISX engine:

-

Volume/MOQ: Larger orders typically come with discounts due to economies of scale. Understanding the minimum order quantity (MOQ) can help buyers negotiate better pricing.

-

Specifications and Customization: Custom specifications can lead to higher costs. Buyers should assess whether the additional features are necessary for their operations.

-

Materials: The choice of materials directly affects both the performance and cost. Premium materials may offer better durability but come at a higher price.

-

Quality and Certifications: Engines that meet specific quality standards or certifications may carry a premium price. Buyers should weigh the benefits of these certifications against their budget.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their brand equity and proven track record.

-

Incoterms: The terms of shipping can affect the final cost. Understanding whether the price includes shipping, insurance, and duties can help buyers avoid unexpected expenses.

What Are the Best Negotiation Tips for International B2B Buyers?

When negotiating the purchase of a Cummins ISX engine, international B2B buyers should consider the following strategies:

-

Research Market Prices: Knowing the average market price for similar engines can provide leverage during negotiations.

-

Focus on Total Cost of Ownership (TCO): Highlighting the long-term savings from a high-quality engine can justify a higher upfront cost. This includes fuel efficiency, maintenance, and potential downtime.

-

Be Transparent About Volume Commitments: If buyers can commit to larger volumes, they should leverage this in negotiations for better pricing.

-

Assess Payment Terms: Flexible payment terms can sometimes lead to better pricing. Buyers should explore options that work for both parties.

-

Consider Long-Term Relationships: Building a rapport with suppliers can lead to better deals in future transactions. Trust and reliability are often rewarded with preferential pricing.

What Should International Buyers Know About Pricing Nuances?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, there are specific pricing nuances to consider:

-

Currency Fluctuations: Exchange rate volatility can impact final costs, making it essential to negotiate prices in a stable currency.

-

Tariffs and Trade Regulations: Understanding the local tariffs and import regulations is vital as these can significantly affect the total landed cost of the engine.

-

Cultural Considerations: Different regions have varying negotiation styles and expectations. Adapting to local customs can facilitate smoother negotiations.

Disclaimer on Indicative Prices

Prices for brand new Cummins ISX engines can vary widely based on the factors discussed above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure they receive competitive pricing.

Alternatives Analysis: Comparing brand new cummins isx engine for sale With Other Solutions

In the competitive landscape of heavy-duty engines, international B2B buyers are faced with various options beyond the brand new Cummins ISX engine for sale. Understanding these alternatives can help buyers make informed decisions that align with their operational needs and budget. This section explores viable alternative solutions, comparing their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Brand New Cummins ISX Engine for Sale | Alternative 1: Detroit Diesel DD16 | Alternative 2: PACCAR MX-13 |

|---|---|---|---|

| Performance | High torque and horsepower for heavy loads | Excellent power-to-weight ratio; smooth operation | Strong fuel efficiency; high torque output |

| Cost | Premium price point; long-term investment | Competitive pricing; good value for performance | Mid-range cost; solid warranty options |

| Ease of Implementation | Requires specialized installation | User-friendly installation; versatile | Straightforward installation with integrated systems |

| Maintenance | Requires regular servicing; high-quality parts | Lower maintenance costs; readily available parts | Moderate maintenance needs; comprehensive support |

| Best Use Case | Ideal for long-haul trucking and heavy-duty applications | Suitable for construction and regional hauling | Best for long-distance freight and fuel-efficient operations |

What are the Benefits and Drawbacks of the Detroit Diesel DD16?

The Detroit Diesel DD16 is a strong contender for buyers seeking a powerful alternative to the Cummins ISX. Known for its impressive power-to-weight ratio, the DD16 delivers smooth performance, making it an excellent choice for construction and regional hauling. One of the key advantages of the DD16 is its competitive pricing, which can lead to significant cost savings for buyers. Additionally, the engine’s parts are readily available, contributing to lower maintenance costs. However, some buyers may find that while the DD16 excels in performance, it may not match the high torque output of the Cummins ISX in extreme heavy-duty applications.

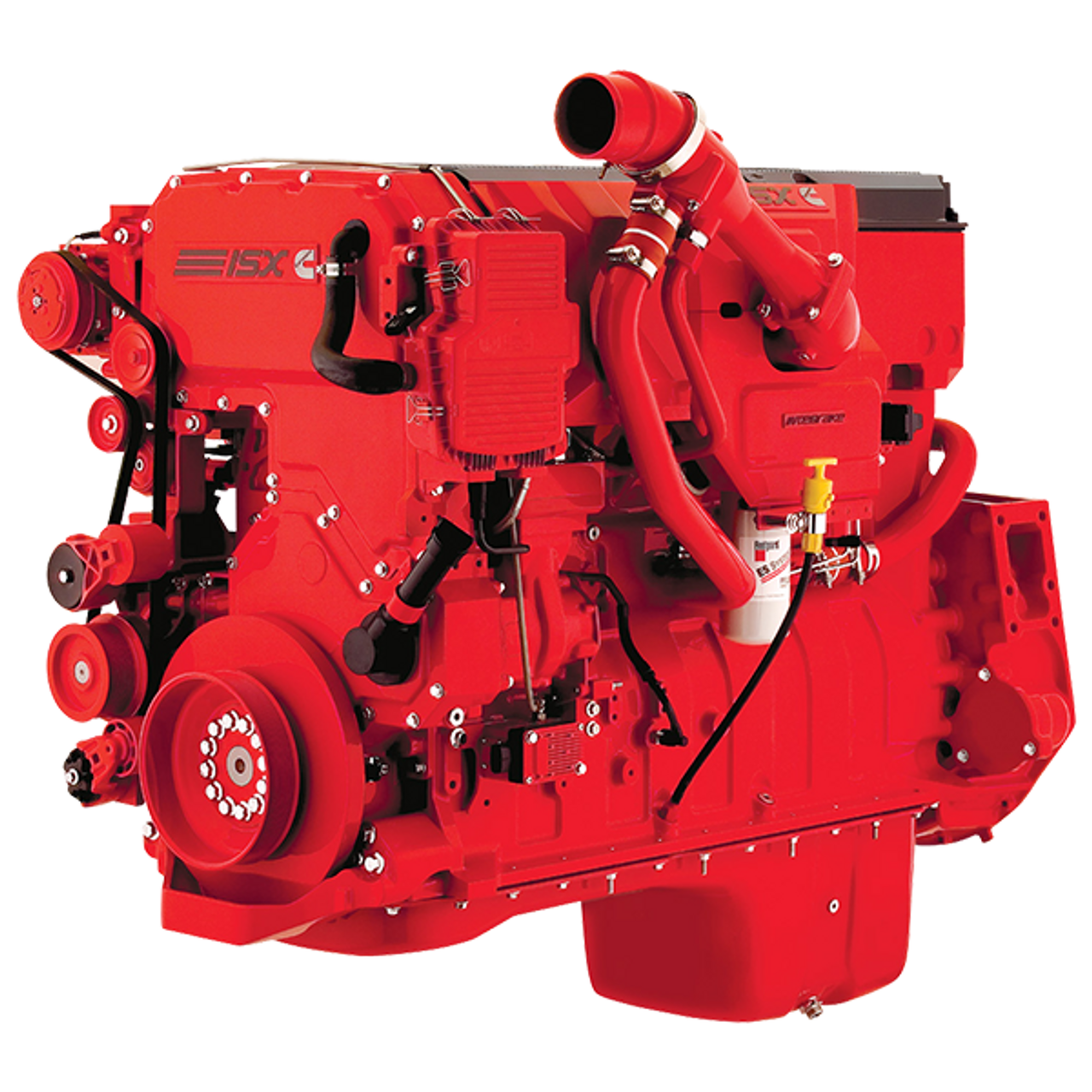

A stock image related to brand new cummins isx engine for sale.

How Does the PACCAR MX-13 Compare in Terms of Fuel Efficiency?

The PACCAR MX-13 engine is another robust alternative, particularly known for its fuel efficiency. This engine is designed to provide high torque output, making it an ideal choice for long-distance freight operations. Buyers appreciate the MX-13’s balance of performance and economy, which can lead to lower operational costs over time. The engine also comes with a solid warranty and comprehensive support, which can ease concerns about reliability. However, its moderate maintenance needs may be a consideration for businesses looking to minimize downtime.

Conclusion: How to Choose the Right Engine Solution for Your Needs?

When selecting the right engine solution, international B2B buyers should consider various factors, including performance requirements, budget constraints, and operational demands. Each alternative to the brand new Cummins ISX engine offers distinct advantages and potential drawbacks. Buyers should evaluate their specific use cases, whether they prioritize high torque for heavy hauling or fuel efficiency for long-distance travel. Conducting thorough research and potentially consulting with industry experts can aid in making the best choice tailored to the unique challenges faced in their operational environments.

Essential Technical Properties and Trade Terminology for brand new cummins isx engine for sale

What Are the Key Technical Properties of a Brand New Cummins ISX Engine?

When considering the purchase of a brand new Cummins ISX engine, understanding its technical specifications is critical for making informed decisions. Here are essential properties to consider:

-

Displacement

The displacement of an engine refers to the total volume of all the cylinders in the engine. For the Cummins ISX, this typically ranges from 8.9 to 15 liters. A larger displacement generally translates to more power and torque, which is crucial for heavy-duty applications, particularly in the trucking and construction sectors. -

Horsepower Rating

The horsepower rating indicates the engine’s power output, which is essential for determining its suitability for specific tasks. The Cummins ISX engines can range from 300 to over 600 horsepower, allowing buyers to select an engine that meets their operational needs while optimizing fuel efficiency and performance. -

Torque Curve

Torque is a measure of rotational force and is critical for vehicle acceleration and load handling. The ISX engine’s torque curve typically peaks at low RPMs, providing excellent low-end power. Understanding the torque characteristics helps buyers identify how well the engine will perform under various load conditions, especially in demanding environments. -

Fuel System Type

The Cummins ISX engine utilizes a high-pressure common rail fuel system. This technology enhances fuel atomization, leading to improved combustion efficiency and reduced emissions. For B2B buyers, this is important not only for compliance with environmental regulations but also for cost savings in fuel consumption. -

Cooling System

The cooling system of the ISX engine plays a vital role in maintaining optimal operating temperatures, preventing overheating during heavy use. Features such as an integrated oil cooler and an efficient radiator design enhance engine longevity and reliability, which are crucial considerations for fleet operators. -

Emissions Standards Compliance

Cummins ISX engines are designed to meet stringent emissions standards, including EPA regulations. Understanding these compliance requirements is essential for international buyers, as it affects the engine’s eligibility for use in various regions, especially in markets such as Europe and North America.

What Are Common Trade Terms Related to the Cummins ISX Engine?

Familiarity with industry jargon is crucial for effective communication and negotiation in the B2B marketplace. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of the Cummins ISX engine, buyers should ensure they are sourcing parts from the OEM to guarantee quality and compatibility. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers, especially those from regions like Africa and South America, where budget constraints may affect purchasing decisions. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for prices and terms for specific products. For B2B buyers, submitting an RFQ for a Cummins ISX engine can streamline the procurement process, ensuring they receive competitive offers tailored to their needs. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of sellers and buyers in shipping contracts. Familiarity with Incoterms is essential for international transactions, as they clarify who bears the risk and costs during transit, ensuring smooth logistics. -

Warranty Period

This term refers to the time frame during which the manufacturer guarantees the engine’s performance and will cover repairs or replacements. Understanding warranty terms is crucial for buyers to assess potential risks and costs over the engine’s lifecycle. -

Lead Time

Lead time is the amount of time it takes from placing an order to receiving the product. For B2B buyers, knowing the lead time for a Cummins ISX engine can help in planning logistics and minimizing downtime in operations.

By mastering these technical properties and trade terms, B2B buyers can make informed purchasing decisions, ensuring they select the right Cummins ISX engine that meets their operational requirements while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the brand new cummins isx engine for sale Sector

What Are the Current Market Dynamics for the Brand New Cummins ISX Engine?

The global demand for high-performance engines, particularly the Cummins ISX, is driven by various factors, including the growth of the logistics and transportation sectors, the push for energy efficiency, and stringent emissions regulations. In regions like Africa and South America, burgeoning economies are investing in infrastructure development, which increases the need for reliable heavy-duty engines. The Middle East is witnessing a similar trend, with ongoing projects in construction and transportation.

Emerging technologies such as telematics and IoT are reshaping sourcing strategies, providing B2B buyers with advanced data analytics to monitor engine performance and maintenance needs. These technologies allow companies to make informed purchasing decisions, optimize fleet management, and enhance overall operational efficiency. As a result, buyers are increasingly seeking suppliers that offer not just products but comprehensive solutions including support services and technological integration.

International B2B buyers should also pay attention to the competitive landscape, as manufacturers innovate with alternative fuel options and hybrid models to meet environmental standards. Understanding regional market dynamics, such as the regulatory environment and economic conditions, is crucial for making informed sourcing decisions.

How Does Sustainability Impact Sourcing Trends for Cummins ISX Engines?

Sustainability has become a pivotal consideration for B2B buyers in the engine sector. The environmental impact of manufacturing processes and the lifecycle of products is under increasing scrutiny. Buyers are now prioritizing suppliers who adhere to sustainable practices and offer environmentally friendly products.

Ethical sourcing is gaining traction, with many companies seeking to ensure that their supply chains are free from exploitation and environmentally harmful practices. Buyers should look for suppliers that possess certifications such as ISO 14001 for environmental management and are transparent about their sourcing processes. Additionally, the use of recycled materials and energy-efficient manufacturing processes is increasingly important in the decision-making process.

In the context of the Cummins ISX engine, buyers should consider the engine’s emissions performance and fuel efficiency. Engines that meet or exceed the latest emissions standards not only reduce environmental impact but also align with corporate sustainability goals, making them more attractive to conscientious buyers.

What Is the Evolution of the Cummins ISX Engine in the B2B Market?

A stock image related to brand new cummins isx engine for sale.

The Cummins ISX engine has a rich history of innovation and reliability, establishing itself as a preferred choice in the heavy-duty engine market. Initially launched in the late 1990s, the ISX series was designed to meet the increasing demands for performance and fuel efficiency while adhering to evolving emissions regulations.

Over the years, Cummins has continually refined the ISX engine, integrating advanced technologies such as turbocharging and electronic fuel injection. These enhancements have improved performance metrics, including torque and fuel efficiency, making the ISX engine a competitive option for B2B buyers focused on operational efficiency.

As the market evolves, the ISX engine continues to adapt, with recent models featuring capabilities for alternative fuels and improved emissions control systems. This evolution not only addresses regulatory challenges but also meets the growing demand for sustainable solutions in the transportation and logistics sectors. For international buyers, understanding the historical context of the Cummins ISX engine can provide insights into its reliability and ongoing innovations, ensuring informed procurement decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of brand new cummins isx engine for sale

-

How do I ensure the quality of a brand new Cummins ISX engine before purchasing?

To ensure quality, conduct thorough research on suppliers and manufacturers. Request detailed specifications, certifications, and quality assurance processes. Ask for references from previous customers and consider visiting the supplier’s facility if possible. Additionally, inquire about warranty terms and after-sales support to confirm the engine’s reliability and the supplier’s commitment to quality. -

What are the key features to look for in a brand new Cummins ISX engine?

When sourcing a Cummins ISX engine, focus on features such as horsepower, torque ratings, fuel efficiency, and emissions compliance. Also, check for advanced technologies like turbocharging, electronic fuel injection, and maintenance-friendly designs. Understanding your specific operational needs will help you select an engine that performs optimally in your application. -

What payment terms should I negotiate when buying a Cummins ISX engine?

Payment terms can vary widely, but it’s important to negotiate favorable conditions. Aim for options like a percentage upfront with the remainder upon delivery or upon successful installation. Explore possibilities for letters of credit or escrow services to ensure security for both parties. Always clarify terms regarding late payments and potential penalties to avoid disputes. -

How can I vet suppliers of brand new Cummins ISX engines effectively?

Start by checking the supplier’s credentials, including their business registration and industry certifications. Look for customer reviews and testimonials, and consider utilizing platforms like Trustpilot or industry-specific forums. Engaging with past clients can provide insights into their reliability and service levels. Additionally, confirm their ability to provide after-sales support and maintenance services. -

What is the minimum order quantity (MOQ) for purchasing Cummins ISX engines?

MOQs can vary by supplier and region. Typically, manufacturers might set a MOQ to ensure production efficiency and cost-effectiveness. For bulk purchases, inquire if the supplier offers flexibility in terms of MOQ or if they can accommodate smaller orders for trial purposes. This is especially relevant for international buyers looking to test market demand before committing to large quantities. -

What logistics considerations should I keep in mind when importing Cummins ISX engines?

Logistics play a crucial role in international trade. Ensure that the supplier has experience with shipping to your region and can handle customs clearance. Discuss shipping methods, insurance, and delivery timelines to avoid unexpected delays. Additionally, assess the total landed cost, including freight, duties, and taxes, to accurately gauge the investment. -

How do I handle customs and import regulations for Cummins ISX engines?

Familiarize yourself with your country’s import regulations and tariffs related to heavy machinery and engines. It’s advisable to work with a customs broker who can navigate the complexities of documentation and compliance. Ensure that the supplier provides all necessary paperwork, including invoices, packing lists, and certificates of origin, to facilitate smooth customs clearance. -

Can I customize my Cummins ISX engine to fit specific requirements?

Yes, many suppliers offer customization options for Cummins ISX engines to meet specific operational needs. Discuss your requirements with the supplier, including modifications related to performance, emissions, and compatibility with existing equipment. Be prepared to provide detailed specifications and understand that customization may affect lead times and pricing.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

A stock image related to brand new cummins isx engine for sale.

Strategic Sourcing Conclusion and Outlook for brand new cummins isx engine for sale

In conclusion, strategic sourcing is a crucial component for international B2B buyers looking to invest in brand new Cummins ISX engines. By understanding the market dynamics across regions such as Africa, South America, the Middle East, and Europe, buyers can make informed decisions that align with their operational needs and budget constraints. Key takeaways include the importance of evaluating suppliers based on reliability, product quality, and after-sales support, as these factors significantly impact overall satisfaction and long-term partnership success.

Moreover, leveraging the right sourcing strategies can enhance negotiation outcomes, ensuring that you not only secure competitive pricing but also favorable terms that contribute to your business’s sustainability. As the demand for high-performance engines continues to grow, now is the time to engage with trusted suppliers and explore innovative financing options that can facilitate your purchasing decisions.

As you navigate this landscape, remember that your sourcing strategy is not just about procurement—it’s about building lasting relationships that will propel your business forward. Embrace the opportunities ahead and position yourself as a leader in your market by investing wisely in the technology that drives your operations.