Discover Top Benefits of TIG Welders for Aluminium (2025)

Introduction: Navigating the Global Market for tig welders for aluminium

In an increasingly competitive global market, sourcing high-quality TIG welders for aluminium can present a formidable challenge for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe strive to meet rising demands for precision and quality, understanding the nuances of different welding technologies becomes essential. This guide serves as a comprehensive resource, detailing various types of TIG welders, their specific applications, and the critical factors to consider when selecting suppliers.

From evaluating the technical specifications of equipment to understanding the cost implications and sourcing logistics, this guide empowers B2B buyers to make informed purchasing decisions. It addresses key questions such as: What are the best practices for vetting suppliers? How do different models affect efficiency and output? What are the regional considerations for sourcing equipment in markets like Kenya or Turkey?

By offering actionable insights and expert analysis, this guide is tailored to help businesses navigate the complexities of the welding equipment market, ensuring they can successfully procure the right tools for their operations. Whether you are looking to enhance your production capabilities or streamline your supply chain, understanding the landscape of TIG welders will be crucial to your success.

Understanding tig welders for aluminium Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| AC TIG Welders | Operate on alternating current, ideal for aluminum | Aerospace, automotive, and fabrication | Pros: Excellent for thin aluminum; Cons: More complex settings. |

| DC TIG Welders | Use direct current, suitable for thicker materials | Heavy industrial applications | Pros: Stronger penetration; Cons: Not ideal for thin aluminum. |

| Pulsed TIG Welders | Feature adjustable pulse frequency and width | Precision welding in electronics | Pros: Reduces heat input; Cons: Higher cost. |

| Multi-Process Welders | Combine TIG with MIG and stick welding capabilities | Versatile applications across industries | Pros: Flexibility; Cons: Can be bulky. |

| Portable TIG Welders | Lightweight and easy to transport, often battery-operated | Fieldwork and small workshops | Pros: Convenience; Cons: Limited power output. |

What are the Characteristics of AC TIG Welders for Aluminum?

AC TIG welders are specifically designed to handle aluminum welding by alternating the current direction. This feature helps in cleaning the aluminum oxide layer, ensuring a strong bond. They are particularly suited for applications in industries such as aerospace and automotive, where precision and quality are paramount. When purchasing, buyers should consider the machine’s duty cycle and maximum amperage, as these factors will affect their performance on various aluminum thicknesses.

Why Choose DC TIG Welders for Thicker Aluminum Materials?

DC TIG welders are preferred for welding thicker aluminum materials due to their ability to provide a stronger arc and deeper penetration. They are commonly used in heavy industrial applications where strength is crucial. Buyers should focus on the welder’s amperage range and whether it supports the necessary tungsten electrode sizes for their specific projects. While they may not be ideal for thin materials, their effectiveness on thicker sections makes them a valuable investment.

What Makes Pulsed TIG Welders Ideal for Precision Work?

Pulsed TIG welders allow for precise control over the heat input, which is essential in applications like electronics and thin-walled components. The adjustable pulse frequency helps prevent warping and reduces the risk of burn-through, making them perfect for delicate welding tasks. When considering a pulsed TIG welder, buyers should evaluate the control options and ease of use, as these features can significantly impact the quality of the weld.

How Do Multi-Process Welders Enhance Versatility?

Multi-process welders offer the flexibility to switch between TIG, MIG, and stick welding, catering to various project requirements. This versatility is particularly beneficial for businesses that handle different materials and welding techniques. Buyers should assess the ease of transitioning between processes and the machine’s overall weight and portability to ensure it meets their operational needs. While they may come at a higher price, the ability to perform multiple welding types can justify the investment.

What are the Advantages of Portable TIG Welders?

Portable TIG welders are designed for convenience, making them ideal for fieldwork and small workshops. Their lightweight and sometimes battery-operated features allow for easy transportation, enabling welding in remote locations. However, buyers should be aware of the limitations in power output and duty cycle compared to larger models. Evaluating the specific requirements of their projects will help buyers decide if a portable option aligns with their needs.

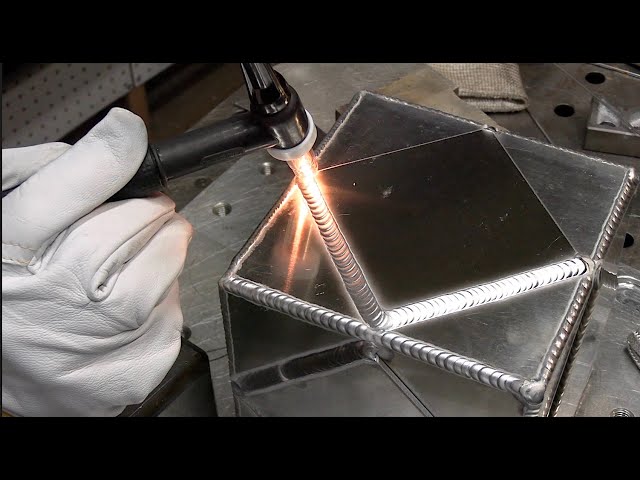

Related Video: Aluminum TIG Welding Basics for Beginners | How to TIG Weld Aluminum

Key Industrial Applications of tig welders for aluminium

| Industry/Sector | Specific Application of TIG Welders for Aluminium | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision welding of aircraft components | Ensures structural integrity and weight reduction | Certification standards, welding speed, and accuracy |

| Automotive | Fabrication of lightweight vehicle parts | Enhances fuel efficiency and performance | Material compatibility, welder versatility, and cost |

| Marine | Construction and repair of aluminum hulls | Increases durability and resistance to corrosion | Environmental conditions, portability, and power source |

| Construction | Welding aluminum frames for buildings | Provides strength and longevity to structures | Compliance with local building codes, weld aesthetics |

| Electronics | Assembly of aluminum housings for electronic devices | Improves thermal management and device reliability | Precision control, heat management, and supplier reliability |

How is TIG Welding Used in the Aerospace Industry?

In the aerospace sector, TIG welders are employed for precision welding of aluminum components, such as fuselage sections and wing structures. The ability to produce clean, strong welds is crucial for meeting stringent safety and performance standards. International B2B buyers must consider the certification requirements for welding equipment, as well as the welder’s capability to maintain high accuracy while working with lightweight materials. Additionally, sourcing suppliers who understand the specific needs of aerospace applications can enhance operational efficiency.

What are the Applications of TIG Welding in the Automotive Industry?

In automotive manufacturing, TIG welders play a vital role in fabricating lightweight aluminum parts that contribute to improved fuel efficiency and overall vehicle performance. Applications include welding components for chassis, engines, and body panels. B2B buyers should focus on the compatibility of TIG welding with various aluminum alloys and the welder’s ability to adapt to different thicknesses. Cost-effectiveness and the potential for reducing weight without compromising strength are key considerations for international buyers, especially in regions like South America and Africa where manufacturing costs are a priority.

How is TIG Welding Applied in the Marine Sector?

TIG welding is extensively used in the marine industry for constructing and repairing aluminum hulls, which require exceptional durability and corrosion resistance. This method allows for the creation of strong, watertight joints essential for the safety and longevity of vessels. Buyers in the Middle East, known for their maritime activities, should prioritize sourcing TIG welders that offer portability and robust performance in varying environmental conditions. Additionally, understanding the local regulations regarding marine construction can guide sourcing decisions.

What Role Does TIG Welding Play in Construction?

In construction, TIG welders are utilized to fabricate aluminum frames and structural components, providing strength and longevity to buildings. The precision of TIG welding ensures that structures can withstand environmental stresses while maintaining aesthetic appeal. For international B2B buyers, especially in Europe, it is crucial to ensure compliance with local building codes and standards. Evaluating the aesthetic quality of welds and the efficiency of the welding process can significantly impact project timelines and costs.

How is TIG Welding Beneficial in Electronics Manufacturing?

TIG welding is critical in the electronics sector for assembling aluminum housings that protect sensitive components. The method’s precision minimizes heat distortion and ensures reliable thermal management, vital for device functionality. International buyers should focus on sourcing TIG welders that provide excellent heat control and adaptability for various housing designs. Supplier reliability and the ability to meet production demands are essential factors for businesses looking to maintain competitive advantage in the fast-paced electronics market.

Related Video: TIG Welding 101: Aluminum TIG Restarts | Everlast Welders

3 Common User Pain Points for ‘tig welders for aluminium’ & Their Solutions

Scenario 1: Inconsistent Weld Quality Due to Equipment Limitations

The Problem: Many B2B buyers in industries such as automotive or aerospace face challenges with inconsistent weld quality when using TIG welders for aluminum. This inconsistency can stem from equipment limitations, including inadequate power settings or subpar torch designs. Buyers often find themselves frustrated when their welds lack the necessary strength or finish, leading to costly rework and project delays.

The Solution: To tackle this issue, buyers should invest in high-quality TIG welders specifically designed for aluminum applications. Look for machines that offer adjustable AC balance control, allowing for precise control over the cleaning action and penetration. Additionally, opt for a welder that features an ergonomic torch design for better maneuverability and comfort during long welding sessions. Regular maintenance and calibration are also critical; ensure that the equipment is checked for wear and tear, and that settings are adjusted according to the material thickness and type. By selecting the right equipment and maintaining it properly, businesses can achieve consistent weld quality and improve overall productivity.

Scenario 2: Difficulty in Finding the Right Filler Material

The Problem: Another common pain point for B2B buyers is the challenge of sourcing the correct filler materials for TIG welding aluminum. Mismatched filler materials can lead to weak welds, porosity, and other defects, which can significantly compromise the integrity of the final product. Buyers may struggle with identifying the appropriate filler alloy that complements the base material, leading to confusion and increased costs.

The Solution: To effectively address this challenge, buyers should conduct thorough research on the various aluminum alloys and their corresponding filler materials. A detailed understanding of the base material’s specifications is essential. Utilize resources such as the Aluminum Association’s guidelines or consult with suppliers who can provide expert advice on filler materials. Establish relationships with reputable suppliers who specialize in aluminum welding products, ensuring that you have access to high-quality filler rods that match your base materials. Additionally, consider investing in training for welding staff to enhance their knowledge about filler materials and application techniques, which can lead to better decision-making and improved welding outcomes.

Scenario 3: High Operational Costs Due to Inefficient Welding Practices

The Problem: B2B buyers often encounter high operational costs associated with inefficient TIG welding practices. This inefficiency can arise from poor technique, inadequate training, or the use of outdated equipment, resulting in increased energy consumption, wasted materials, and extended labor hours. These issues can accumulate, significantly affecting the bottom line for businesses operating in competitive markets.

The Solution: To mitigate these operational costs, companies should prioritize investing in comprehensive training programs for their welding teams. This training should cover proper TIG welding techniques specific to aluminum, including torch angle, travel speed, and filler rod usage. Additionally, consider adopting newer, energy-efficient TIG welding machines that minimize power consumption while maximizing performance. Implementing a practice of continuous improvement—regularly evaluating and refining welding processes—can also lead to significant cost savings. By fostering a culture of learning and efficiency, businesses can optimize their welding operations and enhance profitability in the long run.

Strategic Material Selection Guide for tig welders for aluminium

When selecting materials for TIG welders used in aluminum applications, international B2B buyers need to consider various factors that influence performance, durability, and cost-effectiveness. Below is a detailed analysis of four common materials used in TIG welding, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from regions such as Africa, South America, the Middle East, and Europe.

What are the Key Properties of Aluminum Alloys for TIG Welding?

Aluminum Alloys (e.g., 6061, 4047)

Aluminum alloys are the most common materials used in TIG welding. They offer excellent weldability and are lightweight, making them ideal for various applications, including automotive and aerospace.

- Key Properties: High strength-to-weight ratio, good corrosion resistance, and excellent thermal conductivity.

- Pros: Lightweight, good mechanical properties, and ease of fabrication.

- Cons: Can be more expensive than other metals; some alloys may be less resistant to high temperatures.

- Impact on Application: Suitable for applications requiring lightweight structures, but care must be taken to select the right alloy for the specific environment.

- Considerations for Buyers: Compliance with standards such as ASTM and EN is critical, particularly in industries like aerospace and automotive.

How do Copper Alloys Enhance TIG Welding Performance?

Copper Alloys (e.g., CuSi, CuMg)

Copper alloys are often used for their excellent thermal and electrical conductivity, making them suitable for specific applications in TIG welding.

- Key Properties: High thermal and electrical conductivity, good corrosion resistance, and high ductility.

- Pros: Excellent heat dissipation, which can enhance the welding process; good for high-temperature applications.

- Cons: Generally heavier than aluminum, and can be more expensive; requires careful handling to avoid oxidation.

- Impact on Application: Ideal for applications requiring high thermal conductivity, such as electrical components.

- Considerations for Buyers: Buyers should be aware of the specific copper alloy grades and their compliance with international standards.

What Role Does Stainless Steel Play in TIG Welding?

Stainless Steel (e.g., 304, 316)

While primarily used for welding steel, stainless steel is also relevant in TIG welding, particularly for applications that require corrosion resistance.

- Key Properties: High corrosion resistance, good mechanical properties, and durability.

- Pros: Long-lasting and resistant to rust and corrosion; suitable for harsh environments.

- Cons: Heavier than aluminum and can be more challenging to weld due to higher thermal conductivity.

- Impact on Application: Suitable for applications in marine and chemical environments where corrosion is a concern.

- Considerations for Buyers: Awareness of regional standards and certifications is essential, especially in industries like food processing and pharmaceuticals.

Why is Magnesium Alloy Considered for TIG Welding?

Magnesium Alloys (e.g., AZ31, AZ61)

Magnesium alloys are gaining popularity due to their lightweight and high strength, making them suitable for specialized applications.

- Key Properties: Lightweight, good strength-to-weight ratio, and excellent machinability.

- Pros: Very lightweight, which is beneficial for weight-sensitive applications; good fatigue resistance.

- Cons: More expensive and can be more susceptible to corrosion; requires specific welding techniques.

- Impact on Application: Ideal for aerospace and automotive applications where weight reduction is critical.

- Considerations for Buyers: Buyers should consider the specific magnesium alloy grades and their compliance with international standards, especially in safety-critical applications.

Summary Table of Material Selection for TIG Welders

| Material | Typical Use Case for TIG Welders for Aluminium | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Automotive and aerospace applications | Lightweight and excellent weldability | Higher cost compared to other metals | Medium |

| Copper Alloys | Electrical components and high-temperature applications | Excellent thermal conductivity | Heavier and more expensive | High |

| Stainless Steel | Marine and chemical environments | High corrosion resistance | Heavier and more challenging to weld | Medium |

| Magnesium Alloys | Aerospace and automotive weight-sensitive applications | Very lightweight and good fatigue resistance | More expensive and susceptible to corrosion | High |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions when sourcing materials for TIG welding applications, ensuring compliance with relevant standards and optimizing performance for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for tig welders for aluminium

What are the Main Stages in the Manufacturing Process of TIG Welders for Aluminium?

The manufacturing of TIG (Tungsten Inert Gas) welders specifically designed for aluminium involves several critical stages, each focusing on precision and quality. Understanding these stages is crucial for B2B buyers who need reliable equipment for their operations.

1. Material Preparation

The first stage in manufacturing TIG welders is material preparation. This includes sourcing high-quality materials such as stainless steel, aluminum, and copper. The components must undergo rigorous selection processes to ensure they meet the necessary specifications for conductivity and durability.

Key Techniques:

– Material Inspection: Each batch of materials is subjected to inspection to verify compliance with international standards.

– Cutting and Shaping: Materials are cut to size using CNC machines, which ensures precision and minimizes waste.

2. Forming

After preparation, the next step is forming the components. This involves bending, stamping, or welding the metal parts that will constitute the welder’s casing and internal structures.

A stock image related to tig welders for aluminium.

Key Techniques:

– Laser Cutting: A common method for creating complex shapes with minimal heat distortion.

– Hydraulic Pressing: Used for forming metal sheets into specific shapes required for the welder’s body.

3. Assembly

The assembly stage is where all prepared and formed components come together. This is a highly skilled process that often requires experienced technicians to ensure that each part fits correctly.

Key Techniques:

– Mechanical Assembly: This includes the integration of electronic components, wiring, and safety features.

– Welding: In some cases, parts may be welded together to enhance strength and stability.

4. Finishing

Finishing processes are essential for both aesthetics and functionality. This stage includes painting, coating, and applying any necessary treatments to protect against corrosion and wear.

Key Techniques:

– Powder Coating: A popular method for providing a durable finish that also enhances appearance.

– Quality Control Checks: Final inspections are conducted to ensure that all components meet quality standards before packaging.

What Are the Key Quality Assurance Standards for TIG Welders?

Quality assurance is paramount in the manufacturing of TIG welders, particularly for international markets where standards may vary.

International Standards Relevant to TIG Welders

- ISO 9001: This is the most recognized quality management standard globally. Compliance with ISO 9001 ensures that manufacturers maintain a consistent quality of products and services.

- CE Marking: Essential for products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For specific applications, particularly in the oil and gas industries, adherence to American Petroleum Institute (API) standards may be required.

What Are the Common QC Checkpoints in the Manufacturing Process?

The quality control process in TIG welder manufacturing typically includes several checkpoints:

- Incoming Quality Control (IQC): This is the first line of defense, where raw materials are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): During the manufacturing process, various checks are performed to monitor the quality of the components being produced. This can include visual inspections and measurements.

- Final Quality Control (FQC): Before the product is shipped, a thorough inspection is conducted to ensure that the final product meets all quality standards and specifications.

What Testing Methods Are Commonly Used for TIG Welders?

To ensure the reliability and safety of TIG welders, manufacturers employ various testing methods:

- Functional Testing: Each welder is tested for operational functionality to ensure it performs as expected.

- Electrical Safety Testing: This includes insulation resistance tests and earth continuity tests to prevent electrical hazards.

- Performance Testing: The welders are tested under load conditions to verify their performance in real-world scenarios.

How Can B2B Buyers Verify Supplier Quality Control?

When sourcing TIG welders, especially from international suppliers, B2B buyers should take proactive steps to verify quality control measures:

- Supplier Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing processes and quality control systems.

- Requesting Quality Reports: Buyers should ask for documentation detailing the supplier’s quality assurance processes and test results.

- Third-party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of the manufacturer’s quality practices.

What Are the QC and Certification Nuances for International B2B Buyers?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is crucial:

- Regional Certifications: Different regions may have specific certifications that are necessary for compliance. For example, certifications like GOST in Russia or INMETRO in Brazil can be important for market entry.

- Cultural Considerations: Buyers should be aware of cultural differences that may affect communication and expectations regarding quality assurance.

- Documentation Requirements: Ensuring that all documentation is in compliance with local regulations can prevent delays and complications during importation.

By understanding the manufacturing processes and quality assurance standards associated with TIG welders for aluminium, international B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tig welders for aluminium’

In the world of industrial manufacturing, sourcing TIG welders for aluminum requires a systematic approach to ensure quality and reliability. This checklist will guide international B2B buyers from regions such as Africa, South America, the Middle East, and Europe through the essential steps for effective procurement.

Step 1: Define Your Technical Specifications

Start by outlining your specific needs for TIG welding aluminum. Consider factors like the thickness of materials, the type of aluminum alloys, and the expected production volume. A clear specification helps in identifying suitable machines and prevents costly mispurchases later.

- Welding Capacity: Ensure the welder can handle your required material thickness.

- Power Source: Decide between AC and DC, as different applications may require different setups.

Step 2: Research Market Trends and Technologies

Stay informed about the latest advancements in TIG welding technology. Understanding current trends can help you choose equipment that not only meets your needs but also offers better efficiency and quality.

- Efficiency Ratings: Look for machines with high duty cycles and energy efficiency.

- Advanced Features: Consider options like pulse welding capabilities, which can improve control over heat input and minimize distortion.

Step 3: Evaluate Potential Suppliers

Before making a purchase, thoroughly vet potential suppliers. This includes checking company backgrounds, product offerings, and customer feedback. A reliable supplier will have a proven track record in your industry.

- Company Profile: Request detailed information about the supplier’s history and expertise in TIG welding.

- References: Ask for references or case studies from similar businesses that have used their equipment.

Step 4: Verify Supplier Certifications

Ensure that the suppliers you are considering have the necessary certifications to guarantee the quality and safety of their equipment. This is especially critical when dealing with international suppliers.

- ISO Certifications: Look for ISO 9001 or similar quality management certifications.

- Compliance: Ensure that the equipment meets regional safety and environmental standards.

Step 5: Request Demonstrations or Trials

Where possible, request a demonstration of the TIG welder you are considering. This allows you to assess the equipment’s performance firsthand and ensures it meets your specific requirements.

- Trial Period: Inquire if suppliers offer a trial period during which you can test the machine in your operational environment.

- Technical Support: Assess the availability of technical support during the trial phase.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, discuss pricing, warranties, and after-sales support. Clear terms can help avoid misunderstandings and ensure you receive the necessary support after purchase.

- Payment Terms: Understand the payment schedule and any financing options available.

- Warranty: Confirm warranty duration and what it covers, including parts and service.

Step 7: Plan for Logistics and Installation

Finally, consider the logistics of shipping, installation, and training for your team. Proper planning ensures a smooth transition and minimizes downtime.

- Shipping Costs: Factor in the costs of shipping and customs duties, especially for international purchases.

- Installation Support: Check if the supplier provides installation services and training for your staff to ensure they can operate the equipment effectively.

Following this checklist will help you make informed decisions when sourcing TIG welders for aluminum, ensuring you choose the right equipment for your business needs.

Comprehensive Cost and Pricing Analysis for tig welders for aluminium Sourcing

What Are the Key Cost Components for TIG Welders for Aluminium?

A stock image related to tig welders for aluminium.

When sourcing TIG welders for aluminium, international B2B buyers must understand the various cost components that contribute to the overall price. The primary cost elements include:

-

Materials: The type and quality of materials used in manufacturing TIG welders significantly impact costs. High-grade components, such as copper for electrodes and durable housings, may incur higher upfront costs but can enhance longevity and performance.

-

Labor: Labor costs vary by region. In countries with lower labor costs, such as some parts of Africa and South America, manufacturers may offer competitive pricing. However, the skill level and training of the workforce can affect product quality.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help minimize these costs, affecting the final price.

-

Tooling: Specialized tools and equipment required for the production of TIG welders can be expensive. The complexity of the design can lead to increased tooling costs, particularly for customized units.

-

Quality Control (QC): Investing in stringent QC processes ensures that the welders meet international standards, which is essential for B2B buyers. Enhanced QC can lead to higher costs but reduces the risk of defects and returns.

-

Logistics: Shipping and handling costs, including freight and customs duties, should be factored into the total cost. These costs can vary widely depending on the destination and chosen Incoterms.

-

Margin: Manufacturers typically apply a markup to cover their costs and ensure profitability. This margin can be influenced by market demand, competition, and the perceived value of the product.

How Do Price Influencers Affect TIG Welder Costs?

Several factors can influence the pricing of TIG welders, which B2B buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit prices due to economies of scale. Buyers should negotiate MOQs to optimize their costs.

-

Specifications and Customization: Customized welders designed for specific applications can command higher prices. Buyers should clearly define their requirements to avoid unnecessary expenditures.

-

Materials and Quality Certifications: The choice of materials affects not only the price but also the performance and durability of the welders. Certifications (like ISO or CE) may also influence costs due to the need for compliance checks.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their products due to proven quality and service.

-

Incoterms: The chosen Incoterms dictate the responsibilities of buyers and sellers regarding shipping and handling. Understanding these terms can help buyers manage logistics costs effectively.

What Are the Best Buyer Tips for Cost-Efficiency?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency in sourcing TIG welders:

-

Negotiate Wisely: Leverage your purchasing power by negotiating prices, especially when ordering in bulk. Suppliers may be willing to offer discounts to secure larger contracts.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, operational costs, and potential downtime. A higher initial investment in a quality welder can lead to lower TCO over time.

-

Research Market Trends: Stay informed about market trends and pricing fluctuations. Understanding the market can provide leverage during negotiations.

-

Utilize Local Knowledge: When sourcing from international suppliers, local representatives or agents can provide insights into market conditions, customs regulations, and potential cost-saving opportunities.

-

Beware of Pricing Nuances: Be mindful of hidden costs, such as tariffs or additional fees that may arise during importation. Clarity in contracts and agreements can help mitigate these risks.

Disclaimer on Indicative Prices

Please note that the prices for TIG welders can vary significantly based on the aforementioned factors. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure they receive competitive pricing aligned with their specific needs.

Alternatives Analysis: Comparing tig welders for aluminium With Other Solutions

In the welding industry, selecting the right equipment is crucial for ensuring high-quality results, especially when working with materials like aluminum. While TIG welders are a popular choice for aluminum welding due to their precision and clean finish, it’s essential to explore alternative welding methods that can also achieve satisfactory results. This analysis will compare TIG welders for aluminum with MIG welding and SMAW (Shielded Metal Arc Welding), providing international B2B buyers with valuable insights into their options.

| Comparison Aspect | Tig Welders For Aluminium | MIG Welding | SMAW (Stick Welding) |

|---|---|---|---|

| Performance | High precision, clean welds; ideal for thin materials | Fast welding speed; good for thicker materials | Versatile, suitable for various thicknesses; but less clean |

| Cost | Higher initial investment; cost of consumables can add up | Moderate initial cost; less expensive consumables | Lower initial investment; affordable electrodes |

| Ease of Implementation | Requires skilled operators; setup can be time-consuming | Easier to learn; more user-friendly | Simple setup; requires basic skills |

| Maintenance | Regular maintenance needed for optimal performance | Lower maintenance; requires occasional cleaning | Minimal maintenance; electrodes need storage |

| Best Use Case | Ideal for thin-walled aluminum structures and critical applications | Suitable for both thin and thick aluminum, high-production environments | Good for outdoor work and repair jobs on various metals |

What Are the Advantages and Disadvantages of MIG Welding Compared to TIG Welding?

MIG welding, or Metal Inert Gas welding, is an alternative that offers several advantages over TIG welding. One of the primary benefits of MIG welding is its speed; it allows for faster welding, making it ideal for high-production environments. Additionally, MIG welding is easier for beginners to learn due to its straightforward operation. However, while MIG welding can produce strong welds, it may not achieve the same level of precision or cleanliness as TIG welding, particularly for thin materials. For B2B buyers focused on production efficiency, MIG welding presents a viable alternative, especially when working with thicker aluminum sections.

How Does SMAW Compare to TIG Welders for Aluminum Applications?

SMAW, or Shielded Metal Arc Welding, is another alternative method that offers unique benefits. This technique is known for its versatility, as it can be used on various metals and thicknesses, making it suitable for different applications. Moreover, SMAW is relatively simple and cost-effective, with lower initial investment and consumable costs compared to TIG welding. However, the weld quality may not match that of TIG or MIG welding, particularly in terms of appearance and cleanliness. This method is ideal for outdoor projects or repair jobs where conditions may not be optimal for more delicate processes like TIG welding.

How Should B2B Buyers Choose the Right Welding Solution?

When selecting the right welding solution, B2B buyers should consider their specific needs, including the type of aluminum being welded, the desired weld quality, production speed, and budget constraints. For projects that require high precision and clean welds, TIG welding remains the top choice. However, for those prioritizing speed and ease of use, MIG welding may be more appropriate. Conversely, SMAW is best suited for varied applications where versatility and cost-effectiveness are paramount. By evaluating these factors, buyers can make informed decisions that align with their operational goals and project requirements.

Essential Technical Properties and Trade Terminology for tig welders for aluminium

What Are the Essential Technical Properties of TIG Welders for Aluminium?

When considering TIG welders for aluminium, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some key properties to keep in mind:

1. Material Grade of the Welder

TIG welders designed for aluminium typically use high-grade materials to ensure durability and performance. Look for welders made from aluminum alloys (e.g., 6061 or 5052) which provide excellent corrosion resistance and strength. This is particularly important for industries in Africa and South America, where environmental conditions can be harsh.

2. Welding Current Type

TIG welders can operate using either alternating current (AC) or direct current (DC). For aluminium welding, AC is generally preferred as it helps to clean the oxide layer on the aluminium surface, ensuring better weld quality. Understanding the current type is essential for businesses focused on high-quality outcomes in sectors like automotive or aerospace.

3. Welding Thickness Capacity

Different TIG welders have varying capacities for welding thickness. It’s important to select a welder that can handle the thickness of the materials you typically work with. Common ranges include 1mm to 10mm for aluminium. This specification is vital for manufacturers in the Middle East who often deal with thick aluminium plates in construction.

4. Duty Cycle

The duty cycle of a welder is the percentage of time it can operate within a given time frame (usually 10 minutes) without overheating. A higher duty cycle (e.g., 60% or 100%) allows for extended use, making it essential for high-volume production environments. For European companies, where operational efficiency is paramount, this metric can significantly influence productivity.

5. Cooling System

TIG welders may feature either air-cooled or water-cooled systems. Water-cooled units can handle heavier workloads and longer welding sessions without overheating, making them suitable for industrial applications. In contrast, air-cooled systems are more portable and ideal for smaller tasks. Understanding these options can help businesses select the right equipment for their specific needs.

6. Arc Stability

Stable arc performance is critical for achieving consistent weld quality. Look for welders that offer features like high-frequency start for better arc initiation, especially when working with thin materials. This is particularly relevant for buyers in Africa, where access to skilled labor may be limited, and consistent quality is essential.

What Are Common Trade Terms in the TIG Welder Market?

Familiarity with industry terminology can help B2B buyers navigate the procurement process more effectively. Here are some important terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is vital for ensuring compatibility and quality in welding applications, especially for businesses looking to source reliable machinery.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Knowing the MOQ is crucial for budget-conscious buyers who may want to test a product before committing to larger orders. This term is especially relevant for small to medium enterprises in regions like Turkey, where budget constraints are common.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. Using an RFQ can streamline the procurement process and ensure that all suppliers provide comparable quotes, aiding decision-making.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers in Africa and South America to avoid unexpected costs and ensure smooth logistics.

5. WPS (Welding Procedure Specification)

WPS is a formal document detailing the welding procedures to be followed. It ensures that welds meet the necessary standards for quality and safety. Buyers should seek suppliers who provide clear WPS documentation to ensure compliance with industry standards.

By understanding these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing TIG welders for aluminium, ensuring they select the right equipment for their specific needs and operational contexts.

Navigating Market Dynamics and Sourcing Trends in the tig welders for aluminium Sector

What Are the Key Market Dynamics and Trends in the TIG Welders for Aluminium Sector?

The global market for TIG welders for aluminium is experiencing significant growth driven by several factors. The increasing demand for lightweight materials in industries such as automotive, aerospace, and construction is propelling the adoption of aluminium as a preferred material. Additionally, technological advancements in welding equipment, including the integration of digital controls and automation, are enhancing the efficiency and precision of TIG welding processes. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of the emerging trend of hybrid welding systems that combine TIG with other welding methods, allowing for greater versatility in applications.

In regions like Africa and South America, the growth of infrastructure projects and the automotive sector is stimulating demand for high-quality welding solutions. Meanwhile, in Europe and the Middle East, strict regulations regarding product quality and safety standards are pushing manufacturers towards advanced welding technologies. Buyers are increasingly prioritizing suppliers who offer not only high-performance welders but also comprehensive training and support services to ensure optimal usage.

How Is Sustainability Influencing Sourcing Trends for TIG Welders for Aluminium?

Sustainability is becoming a critical factor in the sourcing of TIG welders for aluminium. The environmental impact of manufacturing processes and the importance of ethical supply chains are gaining traction among international buyers. Companies are now seeking suppliers that prioritize eco-friendly practices, such as reducing energy consumption and waste during production.

Moreover, the use of ‘green’ certifications and materials is essential in this sector. Buyers should look for suppliers who utilize sustainable materials in their products and who adhere to international environmental standards. For instance, the adoption of recyclable materials in the manufacturing of welding equipment can significantly reduce the carbon footprint. Suppliers that demonstrate a commitment to sustainability not only enhance their reputation but also align with the corporate social responsibility goals of their clients, providing a competitive edge in the global market.

A stock image related to tig welders for aluminium.

What Is the Historical Context of TIG Welding Technology?

TIG (Tungsten Inert Gas) welding technology has evolved significantly since its inception in the 1940s. Initially developed for welding magnesium and aluminium, TIG welding has become a preferred method for joining non-ferrous metals due to its precision and versatility. The introduction of advanced materials and technologies, such as inverter technology and pulsed arc welding, has further enhanced the capabilities of TIG welders.

As industries have grown more sophisticated, so too have the requirements for welding processes. The demand for high-quality welds with minimal distortion has made TIG welding an essential technique in sectors like aerospace and automotive manufacturing. Understanding the historical context of this technology allows B2B buyers to appreciate the advancements that have shaped current products and practices in the market, ensuring they make informed sourcing decisions.

In conclusion, navigating the market dynamics and sourcing trends in the TIG welders for aluminium sector requires an understanding of the current drivers, sustainability considerations, and the historical evolution of the technology. By staying informed and aligning sourcing strategies with these insights, international B2B buyers can effectively enhance their procurement processes and product offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of tig welders for aluminium

-

How do I choose the right TIG welder for aluminum?

Choosing the right TIG welder for aluminum involves several factors. First, consider the thickness of the aluminum you will be working with; for thinner materials, a welder with a lower amperage range is ideal. Ensure the welder supports AC output, which is essential for aluminum welding. Additionally, look for features such as high-frequency start and adjustable balance control to manage cleaning action on the weld pool. Finally, consider the welder’s portability and ease of use, especially if you operate in diverse locations across Africa or South America. -

What is the best TIG welder for aluminum welding in industrial applications?

The best TIG welder for industrial aluminum welding is typically one that offers a high duty cycle, allowing for prolonged use without overheating. Look for models from reputable brands that provide features like advanced inverter technology for better efficiency and control. Machines like the Miller Dynasty or Lincoln Electric Square Wave TIG 200 are often recommended due to their reliability and performance. Ensure the welder has a suitable amperage range for your specific aluminum thickness and application requirements. -

What are the common payment terms when sourcing TIG welders internationally?

Common payment terms for international sourcing of TIG welders can include a variety of options such as upfront deposits (typically 30-50%), letters of credit, or payment upon delivery. It’s essential to negotiate terms that align with your cash flow and risk management strategies. Be wary of suppliers requiring full payment in advance, as this can expose you to financial risks. Always request a proforma invoice to clarify terms and conditions before proceeding with payment. -

How can I vet suppliers for TIG welders effectively?

To vet suppliers for TIG welders, start by checking their reputation and reviews online. Look for certifications such as ISO or CE, which indicate adherence to quality standards. Request references from previous clients and inquire about their experiences. Conduct a factory audit if possible, or use third-party inspection services to assess quality and production capabilities. Additionally, ensure the supplier has a clear policy on warranties and after-sales support, which is crucial for long-term relationships. -

What is the minimum order quantity (MOQ) for TIG welders from suppliers?

Minimum order quantities (MOQs) for TIG welders can vary significantly between suppliers, often depending on the model and customization options. Generally, MOQs can range from a single unit for standard models to several units for customized or specialized machines. It’s advisable to discuss your specific needs with the supplier and negotiate MOQs, especially if you are a smaller business or just starting in the welding industry. -

How do I ensure quality assurance (QA) when purchasing TIG welders?

To ensure quality assurance when purchasing TIG welders, request detailed specifications and certifications from the supplier. Establish clear quality control standards and ask about their testing procedures for welders before shipment. Consider using third-party inspection services to verify the quality of the product before it leaves the factory. Additionally, inquire about warranty terms and what support is available should any defects arise after purchase. -

What logistics considerations should I keep in mind when importing TIG welders?

Logistics considerations for importing TIG welders include understanding shipping options, customs duties, and local regulations. Choose a reliable freight forwarder experienced in handling industrial equipment to avoid delays. Ensure that the supplier provides all necessary documentation, including invoices, packing lists, and certificates of origin. Familiarize yourself with your country’s import regulations to avoid unexpected costs or compliance issues upon arrival. -

How can I customize TIG welders to meet my specific needs?

Customizing TIG welders to meet specific needs typically involves discussing requirements directly with the supplier. Many manufacturers offer options such as different amperage ranges, additional features like pulse welding, or tailored accessories to enhance functionality. Be clear about your applications and preferences to ensure the welder is optimized for your projects. Keep in mind that customization may affect lead times and pricing, so factor these into your planning.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for tig welders for aluminium

In today’s competitive landscape, effective strategic sourcing for TIG welders for aluminum is crucial for B2B buyers across Africa, South America, the Middle East, and Europe. Understanding the unique characteristics of TIG welding—such as its suitability for thin and medium-thickness materials—enables businesses to make informed purchasing decisions that enhance operational efficiency and product quality.

By prioritizing reliable suppliers who offer high-quality equipment and support, companies can not only reduce costs but also improve their overall welding capabilities. Additionally, buyers should consider the importance of after-sales support and training, particularly in regions with varying levels of technical expertise.

Looking ahead, the demand for advanced TIG welding technology is expected to grow, driven by industries such as automotive, aerospace, and construction. International B2B buyers are encouraged to stay abreast of technological advancements and market trends to ensure they are well-positioned to capitalize on new opportunities. Engaging with trusted suppliers and participating in industry forums can provide valuable insights and foster strategic partnerships that drive success.

Now is the time to take action—explore your options, evaluate your sourcing strategies, and invest in the right tools to thrive in an evolving market.