Fire Extinguisher Bracket Guide: Type,Cost,Material…

Introduction: Navigating the Global Market for fire extinguisher bracket

In an increasingly globalized marketplace, sourcing effective fire extinguisher brackets can pose significant challenges for international B2B buyers. Whether you are operating in Nigeria, Germany, or Brazil, ensuring that your fire safety equipment is securely mounted and easily accessible is crucial for compliance and safety. This comprehensive guide delves into the various types of fire extinguisher brackets, their applications across different industries, and essential considerations for supplier vetting.

From wall-mounted brackets suitable for commercial spaces to specialized vehicle brackets designed for off-road equipment, understanding the nuances of these products will empower you to make informed purchasing decisions. We will also explore cost factors, quality standards, and regulatory compliance, which are particularly important for buyers in diverse regions such as Africa, South America, the Middle East, and Europe.

By arming yourself with this knowledge, you can navigate the complexities of the fire extinguisher bracket market with confidence. Whether you are looking to enhance workplace safety or comply with local regulations, this guide serves as your go-to resource for ensuring that your fire safety measures are not only effective but also tailored to your specific needs.

Understanding fire extinguisher bracket Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wall Mount Brackets | Fixed installation, typically made of steel | Commercial buildings, warehouses | Pros: Secure mounting, space-saving. Cons: Limited mobility. |

| Vehicle Mount Brackets | Designed for vehicles, often adjustable or custom-fit | Emergency vehicles, fleet vehicles | Pros: Enhances safety in transit. Cons: May require specific vehicle compatibility. |

| Universal Brackets | Versatile design, compatible with various extinguisher types | General use across industries | Pros: Flexible installation options. Cons: May not fit all extinguisher sizes perfectly. |

| Heavy-Duty Brackets | Built to withstand high impacts, often with additional supports | Industrial settings, construction sites | Pros: High durability, suitable for harsh environments. Cons: Higher cost. |

| Marine Brackets | Corrosion-resistant materials, designed for marine use | Boats, ships, offshore platforms | Pros: Weatherproof, ensures safety on water. Cons: Specialized use limits applicability. |

What Are the Characteristics of Wall Mount Brackets for Fire Extinguishers?

Wall mount brackets are typically constructed from sturdy materials like steel, ensuring that fire extinguishers are securely fastened to walls in commercial and industrial settings. They are designed for easy installation at the recommended height of 3.5 to 5 feet above the floor, providing quick access during emergencies. When purchasing, buyers should consider the bracket’s load capacity and compatibility with various extinguisher sizes to ensure optimal safety and compliance with local regulations.

How Do Vehicle Mount Brackets Enhance Safety in Transit?

Vehicle mount brackets are specifically engineered to secure fire extinguishers within emergency and fleet vehicles. Their adjustable designs allow for a custom fit, making them ideal for various vehicle models. For businesses operating in sectors such as emergency services or transportation, investing in these brackets not only complies with safety regulations but also ensures that extinguishers are readily accessible during emergencies. Buyers should evaluate compatibility with vehicle types and ease of installation when selecting these brackets.

What Makes Universal Brackets a Versatile Choice?

Universal brackets offer flexibility in installation, accommodating a wide range of fire extinguisher models. This versatility makes them suitable for diverse industries, from retail to manufacturing. Buyers benefit from the ability to use the same bracket for different extinguisher types, simplifying inventory management. However, it’s essential to check the compatibility of the bracket with specific extinguisher sizes to avoid improper fitting, which could compromise safety.

Why Should Businesses Consider Heavy-Duty Brackets?

Heavy-duty brackets are designed for environments where fire extinguishers may be subject to high impacts or harsh conditions, such as construction sites or industrial facilities. Made from robust materials, these brackets provide a reliable solution for securing extinguishers in challenging settings. While they may come at a higher price point, the investment is justified by their durability and the enhanced safety they offer. Buyers should assess the specific environmental challenges they face to determine if these brackets are necessary.

What Are the Benefits of Marine Brackets for Fire Extinguishers?

Marine brackets are crafted from corrosion-resistant materials to withstand the unique challenges of maritime environments. They are essential for boats, ships, and offshore platforms, ensuring that fire extinguishers remain secure and functional in wet conditions. Businesses operating in the marine sector must prioritize these specialized brackets to comply with safety regulations and maintain operational integrity. When purchasing, buyers should ensure that the brackets meet marine safety standards and are compatible with their specific extinguisher models.

Key Industrial Applications of fire extinguisher bracket

| Industry/Sector | Specific Application of fire extinguisher bracket | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Mounting extinguishers in production facilities | Ensures compliance with safety regulations and quick access during emergencies | Durability, corrosion resistance, and ease of installation are crucial. |

| Transportation | Securing extinguishers in vehicles and fleets | Enhances safety for drivers and passengers, protecting assets from fire risks | Must meet specific vehicle standards and be lightweight yet robust. |

| Hospitality | Installing extinguishers in hotels and restaurants | Protects guests and staff, reducing liability and ensuring safety standards are met | Aesthetic design and compliance with local fire codes are essential. |

| Construction | Brackets for extinguishers on job sites | Minimizes fire hazards and promotes a safe working environment for workers | Should be weather-resistant and capable of securing heavier extinguishers. |

| Marine | Mounting extinguishers on boats and ships | Vital for safety at sea, ensuring quick access in emergencies | Must be rust-proof and suitable for marine environments, complying with maritime regulations. |

How Are Fire Extinguisher Brackets Used in Manufacturing Facilities?

In manufacturing environments, fire extinguisher brackets are essential for securely mounting extinguishers at strategic locations throughout the facility. This positioning ensures compliance with safety regulations and facilitates quick access during emergencies. Buyers in this sector must consider the durability of the brackets, as they need to withstand industrial conditions. Corrosion resistance and easy installation are also critical factors to ensure that the extinguishers remain accessible and functional in high-risk areas.

Why Are Fire Extinguisher Brackets Important for Transportation?

For the transportation industry, fire extinguisher brackets are crucial for securing extinguishers within vehicles, including buses, trucks, and emergency response units. These brackets ensure that extinguishers are readily accessible in case of fire, enhancing the safety of both drivers and passengers. When sourcing, businesses must ensure that the brackets meet specific vehicle standards and are lightweight yet robust to avoid adding unnecessary weight to the vehicle.

What Role Do Fire Extinguisher Brackets Play in Hospitality?

In the hospitality sector, fire extinguisher brackets are used to mount extinguishers in hotels, restaurants, and other venues. This not only protects guests and staff but also helps establishments comply with safety regulations, reducing liability risks. Buyers should prioritize brackets that are aesthetically pleasing and compliant with local fire codes, ensuring that safety measures do not detract from the venue’s overall ambiance.

How Are Fire Extinguisher Brackets Utilized on Construction Sites?

Construction sites present unique fire hazards, making the use of fire extinguisher brackets essential for securing extinguishers in various locations. These brackets minimize fire risks and promote a safe working environment for all personnel on site. Buyers need to look for weather-resistant options that can secure heavier extinguishers, as job sites often expose equipment to harsh conditions.

Why Are Fire Extinguisher Brackets Critical in Marine Applications?

In marine settings, fire extinguisher brackets are vital for securely mounting extinguishers on boats and ships. Quick access to extinguishers can be a matter of life and death in case of fire at sea. Buyers in the marine industry must ensure that the brackets are rust-proof and comply with maritime regulations, as the marine environment poses unique challenges that can compromise safety equipment.

3 Common User Pain Points for ‘fire extinguisher bracket’ & Their Solutions

Scenario 1: Difficulty in Ensuring Compliance with Safety Regulations

The Problem: Many B2B buyers, especially in industries like manufacturing or construction, face challenges in meeting stringent safety regulations regarding fire extinguisher placement. Compliance with standards set by organizations such as OSHA can be daunting. For instance, extinguishers must be mounted at specific heights and locations, which can vary based on the size and type of extinguisher. Failure to comply not only risks fines but can also endanger employees and assets in case of a fire.

The Solution: To ensure compliance, B2B buyers should first familiarize themselves with local and international fire safety regulations relevant to their industry. Investing in adjustable fire extinguisher brackets can be a practical solution, as they allow for flexible installation heights that can accommodate different extinguisher sizes. Suppliers should provide clear guidelines on proper mounting techniques, such as ensuring the carrying handle is positioned between 3 to 5 feet above the ground. Additionally, regular audits and training sessions for staff on the correct usage and maintenance of extinguishers will further enhance compliance and safety culture within the organization.

Scenario 2: Inadequate Mounting Solutions for Diverse Environments

The Problem: Buyers often struggle to find suitable fire extinguisher brackets that can be used across various environments, such as warehouses, vehicles, and outdoor settings. The need for specialized mounting solutions becomes critical when considering factors like temperature variations, vibration from machinery, or exposure to moisture in marine applications. Traditional brackets may not withstand the unique challenges posed by these environments, leading to potential safety hazards.

The Solution: B2B buyers should seek out vendors who offer a diverse range of fire extinguisher brackets tailored for specific applications, such as heavy-duty vehicle brackets or marine-grade mounting solutions. For example, brackets made from rust-resistant materials or those designed to absorb shock can provide the durability needed for rigorous settings. It’s advisable to conduct a thorough assessment of the environment where the extinguisher will be mounted, and consult with manufacturers about the best options for that particular scenario. Consideration of local climate conditions and potential exposure to hazardous materials should also inform the selection process.

Scenario 3: Difficulty in Securing Fire Extinguishers During Transport

The Problem: Companies in sectors like logistics or emergency services often face challenges in ensuring that fire extinguishers are securely mounted during transport, especially when vehicles traverse rough terrain or experience rapid acceleration and deceleration. An inadequately secured extinguisher can become a projectile in an accident, posing risks to safety and compliance.

The Solution: To address this issue, B2B buyers should invest in specialized vehicle fire extinguisher brackets designed to secure extinguishers during transit. Look for brackets that feature locking mechanisms or adjustable straps to prevent movement, as well as those constructed from high-strength materials to withstand extreme conditions. Additionally, training drivers on the importance of checking extinguisher security as part of their pre-trip inspections can significantly mitigate risks. Collaboration with suppliers who provide installation guidance and support can also enhance the effectiveness of these solutions, ensuring that extinguishers are always ready for use while remaining safely secured.

Strategic Material Selection Guide for fire extinguisher bracket

What Are the Common Materials Used for Fire Extinguisher Brackets?

When selecting materials for fire extinguisher brackets, it’s essential to consider the specific properties and performance characteristics of each material. The choice can significantly influence durability, cost, and compliance with international standards, particularly for B2B buyers operating in diverse environments such as Africa, South America, the Middle East, and Europe.

How Does Steel Perform as a Material for Fire Extinguisher Brackets?

Steel is one of the most commonly used materials for fire extinguisher brackets due to its strength and durability. It typically has a high temperature rating, making it suitable for various applications, including those exposed to heat. Steel brackets can be treated with coatings to enhance their corrosion resistance, which is crucial in humid or coastal environments.

Pros: Steel brackets are robust and can withstand significant weight and stress, making them ideal for heavy-duty applications. They are also relatively cost-effective compared to other materials.

Cons: The main drawback of steel is its susceptibility to rust if not properly coated, which can lead to structural failure over time. Additionally, the manufacturing process can be complex, especially when forming intricate designs.

Impact on Application: Steel brackets are compatible with various fire extinguisher types and can be used in both commercial and residential settings. However, they may require regular maintenance in corrosive environments.

Considerations for International Buyers: Buyers should ensure that steel brackets meet local compliance standards such as ASTM in the United States or DIN in Germany. In regions with high humidity, opting for galvanized or powder-coated steel can enhance longevity.

What Are the Advantages of Aluminum in Fire Extinguisher Bracket Manufacturing?

Aluminum is another popular choice for fire extinguisher brackets, particularly in mobile applications like vehicles. It offers excellent corrosion resistance and is lightweight, which is beneficial for applications where weight is a concern.

Pros: Aluminum brackets are easy to install and transport due to their lightweight nature. They also resist corrosion effectively, making them ideal for outdoor or marine environments.

Cons: While aluminum is strong, it may not support as much weight as steel, which can limit its use for larger fire extinguishers. Additionally, aluminum can be more expensive than steel.

Impact on Application: Aluminum brackets are particularly suited for use in vehicles or portable fire extinguishers, where weight savings are critical. Their corrosion resistance makes them suitable for areas with high moisture.

Considerations for International Buyers: Buyers should verify that aluminum brackets comply with relevant standards such as JIS in Japan or local regulations in their respective countries. The cost of aluminum can also vary significantly based on market conditions.

Why Is Plastic Considered for Fire Extinguisher Brackets?

Plastic brackets, often made from high-density polyethylene (HDPE) or polycarbonate, are gaining traction for specific applications. They are lightweight and resistant to corrosion, making them suitable for various environments.

Pros: Plastic brackets are generally less expensive than metal options and offer good resistance to chemicals and moisture. They are also lightweight, making installation easier.

Cons: The primary limitation of plastic is its lower strength compared to metal, which may not be suitable for larger or heavier fire extinguishers. They can also be affected by extreme temperatures, leading to potential deformation.

Impact on Application: Plastic brackets are ideal for lightweight portable extinguishers and in environments where corrosion is a concern. However, their use is limited to smaller extinguishers.

Considerations for International Buyers: Buyers should ensure that plastic brackets meet fire safety standards and are tested for durability in their specific application environments.

Summary Table of Material Selection for Fire Extinguisher Brackets

| Material | Typical Use Case for Fire Extinguisher Bracket | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty wall mounts for commercial use | High strength and durability | Susceptible to rust without coating | Medium |

| Aluminum | Vehicle-mounted extinguishers | Lightweight and corrosion-resistant | Lower weight capacity than steel | High |

| Plastic | Portable extinguishers in humid environments | Cost-effective and lightweight | Lower strength and temperature sensitivity | Low |

By understanding the properties and implications of various materials, international B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for fire extinguisher bracket

What Are the Main Stages in the Manufacturing Process of Fire Extinguisher Brackets?

Manufacturing fire extinguisher brackets involves several key stages that ensure the product is durable, reliable, and compliant with safety standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-quality materials, typically steel or aluminum, known for their strength and corrosion resistance. Suppliers should provide certificates of compliance to ensure materials meet international standards. The raw materials are then cut to size using precision machinery, which minimizes waste and ensures uniformity.

-

Forming: The next stage involves shaping the cut materials into the desired bracket forms. Techniques such as stamping, bending, or laser cutting are employed to achieve precise dimensions. Advanced CNC (Computer Numerical Control) machines are often used for this purpose, ensuring high accuracy and repeatability.

-

Assembly: After forming, the components are assembled. This may include welding or riveting parts together to create a sturdy structure. Assembly is critical, as the integrity of the bracket directly affects its performance in securing fire extinguishers.

-

Finishing: The final stage involves surface treatment to enhance durability and aesthetics. Common finishing techniques include powder coating and galvanization, which protect against rust and wear. The finishing process not only extends the lifespan of the brackets but also ensures they meet industry standards for safety and performance.

How Is Quality Assurance Implemented During the Manufacturing of Fire Extinguisher Brackets?

Quality assurance (QA) is integral to the manufacturing process, ensuring that fire extinguisher brackets are safe and effective. Several international and industry-specific standards guide QA practices, including ISO 9001 for general quality management systems, CE marking for compliance within the European Economic Area, and API standards for equipment used in oil and gas industries.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint verifies the quality of materials upon receipt. Inspectors check for certification documents and conduct physical inspections to confirm that materials meet specified standards.

– In-Process Quality Control (IPQC): During the manufacturing process, IPQC ensures adherence to defined processes and standards. This includes monitoring machinery settings and dimensions at various stages of production.

– Final Quality Control (FQC): Once the brackets are completed, FQC includes comprehensive inspections and testing. This may involve dimensional checks, load testing, and inspection for surface defects. -

Common Testing Methods: Various testing methods are utilized to ensure product reliability. Load tests assess the strength and stability of the brackets under expected conditions. Corrosion resistance tests evaluate how well the finishing withstands environmental factors. Certification from recognized bodies is often required to validate these tests.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial to ensure compliance with safety standards and product reliability.

-

Supplier Audits: Conducting regular audits of suppliers is an effective way to assess their manufacturing practices and quality control processes. Audits should focus on the entire manufacturing workflow, including material sourcing, production methods, and quality assurance practices.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can provide insights into their quality control processes. These reports should outline testing methods, results, and any corrective actions taken in case of non-compliance.

-

Third-Party Inspections: Engaging third-party inspection agencies can further validate a supplier’s claims about their quality control measures. These agencies offer unbiased assessments of the manufacturing processes and products, ensuring compliance with international standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control and certification nuances to ensure that fire extinguisher brackets meet local regulations and standards.

-

Understanding Local Standards: Different regions have specific requirements for fire safety equipment. For instance, European buyers need to ensure compliance with CE marking, while buyers in the United States may require UL certification. Understanding these standards is essential for avoiding legal issues and ensuring product safety.

-

Import Regulations: Importing products may involve compliance with local regulations, including safety standards and testing requirements. Buyers should familiarize themselves with these regulations to ensure that imported brackets are compliant and do not face delays or penalties at customs.

-

Cultural and Market Differences: Different markets may prioritize certain features based on local needs. For example, buyers in regions prone to high humidity may prioritize corrosion-resistant finishes. Understanding these market nuances can help buyers select the right products and suppliers.

In conclusion, B2B buyers in the fire safety industry must consider the intricacies of manufacturing processes and quality assurance when sourcing fire extinguisher brackets. By focusing on material preparation, forming, assembly, and finishing, along with robust quality control practices, buyers can ensure they partner with reliable suppliers who meet international standards and provide safe, effective products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fire extinguisher bracket’

In the competitive landscape of fire safety equipment, sourcing the right fire extinguisher bracket is essential for ensuring compliance, safety, and functionality. This guide outlines a step-by-step checklist to help B2B buyers make informed purchasing decisions for fire extinguisher brackets.

Step 1: Define Your Technical Specifications

Begin by clearly defining the technical specifications required for your fire extinguisher brackets. Consider the size and weight of the extinguishers they will hold, the mounting location (e.g., vehicle, wall), and the environmental conditions (such as outdoor exposure or industrial settings) they need to withstand. This step ensures that you select brackets that meet both safety standards and operational requirements.

Step 2: Research Compliance Standards

Ensure that the fire extinguisher brackets comply with relevant local and international safety standards, such as OSHA regulations or NFPA guidelines. Compliance not only guarantees safety but also protects your organization from potential legal liabilities. Look for certifications and documentation from suppliers that verify adherence to these standards.

Step 3: Evaluate Material Quality

Assess the material quality of the brackets, as this directly impacts durability and performance. High-quality materials, such as powder-coated steel or aluminum, are recommended for their resistance to corrosion and wear. Additionally, consider whether the brackets are designed for easy installation and maintenance, which can save time and costs in the long run.

Step 4: Identify Supplier Credentials

Before committing to a supplier, evaluate their credentials and industry reputation. Seek out suppliers with a proven track record in manufacturing fire safety equipment. Request company profiles, certifications, and references from other buyers in similar industries or regions to ensure reliability and product quality.

Step 5: Request Samples and Test Fit

Whenever possible, request samples of the fire extinguisher brackets to test fit and functionality. This hands-on assessment allows you to verify that the brackets securely hold the extinguishers in various settings, whether in vehicles or on walls. Testing samples can also provide insights into the ease of installation and overall design.

Step 6: Compare Pricing and Terms

Conduct a thorough comparison of pricing and terms among multiple suppliers. While the lowest price may be attractive, consider the overall value, including warranty options, shipping costs, and lead times. A comprehensive evaluation of total cost can prevent unexpected expenses and ensure you select a supplier that offers both quality and affordability.

Step 7: Establish a Long-term Relationship

After selecting a supplier, focus on establishing a long-term relationship. Regular communication and collaboration can lead to better service, discounts on future orders, and updates on new products. Building a solid partnership with your supplier can enhance your procurement process and ensure you always have access to the latest fire safety solutions.

By following this checklist, B2B buyers can confidently procure fire extinguisher brackets that meet their specific needs while ensuring safety and compliance.

Comprehensive Cost and Pricing Analysis for fire extinguisher bracket Sourcing

What Are the Key Cost Components in Fire Extinguisher Bracket Manufacturing?

Understanding the cost structure of fire extinguisher brackets is essential for international B2B buyers. Key components include:

-

Materials: The choice of materials significantly impacts costs. Common materials such as steel and aluminum are favored for their durability and strength. Prices fluctuate based on market demand and availability, so sourcing from local suppliers in regions like Africa or South America can sometimes reduce costs.

-

Labor: Labor costs vary widely depending on the region. For example, manufacturing in Europe may incur higher labor costs compared to countries in Africa or South America. Understanding the local labor market can help buyers estimate overall production costs.

-

Manufacturing Overhead: This includes indirect costs related to production such as utilities, rent, and administrative expenses. Overhead rates can differ based on the supplier’s operational efficiency and location.

-

Tooling: If custom brackets are required, tooling costs can rise significantly. Investing in specialized molds or dies may be necessary for unique designs, impacting the overall pricing structure.

-

Quality Control (QC): Ensuring that brackets meet safety and regulatory standards involves QC processes that can add to the cost. Certifications like ISO or compliance with local safety standards may also influence pricing.

-

Logistics: Transportation costs can vary based on the shipping method, distance, and Incoterms negotiated. Buyers should account for potential tariffs and customs duties when importing brackets from international suppliers.

-

Margin: Suppliers typically apply a profit margin that reflects their operational costs and market conditions. Understanding the average margin in the industry can help buyers gauge whether they are receiving competitive pricing.

How Do Price Influencers Affect Fire Extinguisher Bracket Costs?

Several factors influence pricing in the fire extinguisher bracket market:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing often leads to lower per-unit costs. Suppliers may offer tiered pricing based on order volumes, making it beneficial for larger organizations or those planning extensive installations.

-

Specifications and Customization: Custom designs tailored to specific needs or regulatory requirements may incur additional costs. Buyers should weigh the benefits of customization against the potential price increase.

-

Material Quality and Certifications: Higher-quality materials and certified products generally come at a premium. Buyers in regions with stringent safety regulations may find it necessary to invest in certified brackets to ensure compliance.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven track record and quality assurance processes, while emerging suppliers might offer lower prices to gain market entry.

-

Incoterms: The terms of shipping can greatly affect costs. Understanding the responsibilities and risks associated with different Incoterms (e.g., FOB, CIF) can help buyers negotiate better deals and avoid unexpected expenses.

What Buyer Tips Can Enhance Cost-Efficiency in Fire Extinguisher Bracket Sourcing?

To optimize sourcing costs, international buyers can employ several strategies:

-

Negotiate Wisely: Leverage your purchasing power to negotiate better terms, especially for larger orders. Suppliers may be willing to offer discounts or better payment terms to secure bulk orders.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the long-term costs associated with maintenance, replacement, and compliance. Investing in higher-quality brackets may lead to lower TCO over time.

-

Understand Regional Pricing Nuances: Different regions have varying market dynamics. For instance, buyers from Nigeria may encounter different pricing strategies compared to those in Germany due to local manufacturing capabilities and material availability.

-

Stay Informed on Market Trends: Keep abreast of fluctuations in material costs and labor markets. Understanding these trends can aid in timing purchases to maximize savings.

-

Request Samples and Conduct Quality Checks: Before committing to large orders, request samples to assess quality. Conducting thorough quality checks can prevent costly mistakes and ensure compliance with local regulations.

By considering these insights and strategies, B2B buyers can make informed decisions when sourcing fire extinguisher brackets, ultimately enhancing their procurement processes and ensuring safety compliance.

Alternatives Analysis: Comparing fire extinguisher bracket With Other Solutions

Exploring Alternatives to Fire Extinguisher Brackets: A Comparative Analysis

In the realm of fire safety equipment, fire extinguisher brackets are widely recognized for their role in securely mounting extinguishers, ensuring they are readily accessible in emergencies. However, there are alternative solutions that can also meet safety and accessibility requirements. This analysis compares fire extinguisher brackets with two viable alternatives: fire extinguisher cabinets and wall-mounted fire extinguishers, examining their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Fire Extinguisher Bracket | Fire Extinguisher Cabinet | Wall-Mounted Fire Extinguisher |

|---|---|---|---|

| Performance | High – ensures secure placement and quick access | High – protects extinguishers and maintains visibility | Moderate – depends on visibility and ease of access |

| Cost | Low to moderate | Moderate to high | Low to moderate |

| Ease of Implementation | Easy – requires minimal installation | Moderate – requires more space and installation effort | Easy – simple wall mounting |

| Maintenance | Low – minimal upkeep needed | Moderate – requires periodic checks | Low – minimal upkeep needed |

| Best Use Case | Industrial, commercial, and vehicle use | Public spaces, commercial buildings | Residential and smaller commercial settings |

Detailed Breakdown of Alternatives

Fire Extinguisher Cabinet

Fire extinguisher cabinets provide a protective enclosure for extinguishers, ensuring they are shielded from environmental factors and tampering. They are often made of glass or clear plastic, allowing for visibility while securing the extinguisher inside. The pros include enhanced protection, which is particularly beneficial in high-traffic areas or environments with extreme conditions. However, cabinets can be more costly and require more space, making them less suitable for smaller locations. Additionally, installation may involve more effort compared to brackets.

Wall-Mounted Fire Extinguisher

Wall-mounted fire extinguishers are another alternative that offers a streamlined approach to fire safety. This solution involves directly affixing the extinguisher to the wall without a bracket, often using simple mounting hardware. The primary advantage is ease of installation and low cost, making them accessible for various settings, including homes and small businesses. However, the visibility and accessibility can be compromised if the extinguisher is not placed at the correct height or location, potentially delaying response times during emergencies.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between fire extinguisher brackets and their alternatives, B2B buyers should consider their specific environments and safety requirements. Fire extinguisher brackets offer a practical solution for securing extinguishers in vehicles and industrial settings, where quick access is paramount. In contrast, cabinets are ideal for public spaces needing enhanced protection, while wall-mounted extinguishers suit smaller environments where cost and space are significant factors. Ultimately, the right choice will depend on balancing cost, ease of use, and the level of protection required to ensure fire safety in your operations.

Essential Technical Properties and Trade Terminology for fire extinguisher bracket

What Are the Key Technical Properties of Fire Extinguisher Brackets?

When selecting fire extinguisher brackets, understanding their technical properties is crucial for ensuring safety, compliance, and durability. Here are some essential specifications:

-

Material Grade

Fire extinguisher brackets are typically made from materials like steel or aluminum. High-grade steel is often preferred due to its strength and resistance to corrosion, ensuring longevity even in harsh environments. Aluminum brackets offer a lighter alternative while still providing adequate strength. For B2B buyers, selecting the right material impacts both the lifespan of the product and the safety of the mounted fire extinguishers. -

Weight Capacity

Each bracket is designed to support a specific weight range. Understanding the weight capacity is vital, as it ensures that the bracket can securely hold the fire extinguisher without risk of failure. Buyers should assess the weight of the extinguishers they intend to mount and choose brackets that exceed this weight for added safety. -

Mounting Height

Compliance with safety regulations often dictates the optimal mounting height for fire extinguishers. The Occupational Safety and Health Administration (OSHA) recommends that extinguishers be mounted with the carrying handle between 3.5 to 5 feet above the floor. This specification is critical for ensuring accessibility during emergencies, making it a key consideration for B2B buyers involved in facility management. -

Finish and Coating

The finish of a bracket, such as powder coating or galvanization, plays a significant role in its resistance to rust and wear. A durable finish not only enhances the aesthetic appeal but also protects against environmental factors that could compromise the bracket’s integrity. For businesses operating in humid or corrosive environments, selecting brackets with high-quality finishes is essential. -

Installation Type

Brackets come in various installation types, including wall-mounted and vehicle-specific options. Understanding the installation requirements can help buyers choose the most appropriate bracket for their specific needs, whether for a commercial building or a fleet of vehicles.

What Common Trade Terminology Should B2B Buyers Know?

Navigating the purchasing process for fire extinguisher brackets involves understanding several key industry terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. When sourcing brackets, knowing whether a supplier is an OEM can indicate the quality and compatibility of the product with existing fire safety equipment. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest amount of a product that a supplier is willing to sell. Understanding MOQ is essential for businesses to manage inventory effectively and avoid over-purchasing, which can tie up capital unnecessarily. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to solicit price quotes for specific products. Crafting an effective RFQ can help buyers compare prices and terms from different suppliers, ensuring they receive the best value for their procurement. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risks, facilitating smoother cross-border transactions. -

Lead Time

This term refers to the amount of time it takes for an order to be fulfilled after it is placed. Understanding lead times is crucial for effective project planning and ensuring that fire safety equipment is available when needed.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when sourcing fire extinguisher brackets, ultimately enhancing safety and compliance within their operations.

Navigating Market Dynamics and Sourcing Trends in the fire extinguisher bracket Sector

What Are the Current Market Dynamics and Key Trends Affecting the Fire Extinguisher Bracket Sector?

The fire extinguisher bracket market is undergoing significant transformation driven by several global factors. Increased regulatory scrutiny around fire safety standards, especially in commercial and industrial sectors, has led to a heightened demand for reliable and durable mounting solutions. This trend is particularly pronounced in regions like Europe and the Middle East, where strict compliance with safety regulations is paramount. B2B buyers from Africa and South America are also increasingly prioritizing quality and compliance, moving away from lower-cost options that may compromise safety.

Emerging technologies are reshaping sourcing practices, with manufacturers leveraging advanced materials and manufacturing processes. For instance, brackets made from lightweight yet robust materials such as aluminum and specialized steel alloys are gaining traction. These materials not only enhance durability but also contribute to better aesthetics, making them suitable for various environments—from industrial settings to modern offices. Additionally, the rise of e-commerce platforms is facilitating easier access to a diverse range of products for international buyers, streamlining the sourcing process.

In terms of market dynamics, the competitive landscape is becoming more pronounced, with established players innovating while new entrants focus on niche markets. Buyers are now looking for suppliers that can offer custom solutions tailored to specific applications, such as vehicle or marine environments. This shift towards customization is indicative of a broader trend where businesses seek to differentiate themselves through specialized offerings.

How Is Sustainability and Ethical Sourcing Impacting the Fire Extinguisher Bracket Market?

Sustainability is increasingly becoming a critical consideration in the fire extinguisher bracket sector. The environmental impact of manufacturing processes and materials is under scrutiny, prompting buyers to favor suppliers who prioritize eco-friendly practices. This shift is evident in the use of recycled materials in the production of brackets, as well as the adoption of sustainable manufacturing methods that reduce waste and energy consumption.

Ethical sourcing is also gaining importance, particularly among international buyers who are becoming more conscious of the supply chain’s social and environmental implications. The demand for transparency in sourcing practices is prompting manufacturers to obtain certifications that validate their commitment to sustainability. Certifications such as ISO 14001 (Environmental Management) and other green credentials are becoming essential for suppliers looking to establish credibility in the market.

Moreover, the push for sustainable solutions extends to product design. Buyers are increasingly interested in brackets that not only meet safety standards but also utilize environmentally friendly materials. The integration of biodegradable or recyclable components is becoming a selling point, allowing companies to align their product offerings with the growing consumer demand for sustainability. This focus on ethical sourcing and sustainability will likely continue to shape procurement strategies across the globe.

What Is the Brief History and Evolution of Fire Extinguisher Brackets in the B2B Context?

The evolution of fire extinguisher brackets can be traced back to the increasing recognition of fire safety in both commercial and residential settings. Initially, brackets were simple metal fixtures designed primarily for functionality. Over the years, advancements in materials science and manufacturing technology have led to the development of more sophisticated and durable options.

In the late 20th century, the introduction of regulations governing fire safety prompted manufacturers to innovate, resulting in brackets that not only secured extinguishers but also complied with safety standards. The focus shifted towards creating brackets that could withstand various environmental conditions, catering to industries such as transportation and marine applications.

Today, the market is characterized by a diverse range of products that address specific needs, from lightweight, portable brackets for vehicles to robust solutions designed for industrial use. As the emphasis on safety, sustainability, and customization continues to grow, the fire extinguisher bracket sector is poised for further evolution, adapting to the changing demands of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of fire extinguisher bracket

-

How do I choose the right fire extinguisher bracket for my needs?

Choosing the right fire extinguisher bracket involves considering several factors such as the type of extinguisher, the mounting location, and the environment. Evaluate whether you need a wall-mounted or vehicle bracket based on where the extinguisher will be used. Ensure the bracket can accommodate the size and weight of your extinguisher and is made of durable materials like steel or aluminum to withstand environmental conditions. Additionally, check for compliance with local safety regulations and standards to ensure proper installation and accessibility. -

What are the common materials used in fire extinguisher brackets?

Fire extinguisher brackets are typically made from robust materials like steel and aluminum. Steel brackets often feature a powder-coated finish for corrosion resistance and durability, making them suitable for various environments, including industrial settings. Aluminum brackets are lightweight and rust-resistant, ideal for vehicles and marine applications. When selecting a material, consider factors like the bracket’s intended use, exposure to elements, and overall weight capacity to ensure safety and reliability. -

What are the minimum order quantities (MOQs) for fire extinguisher brackets?

Minimum order quantities for fire extinguisher brackets can vary significantly among suppliers. Generally, MOQs range from 50 to 500 units depending on the manufacturer, customization options, and the type of brackets ordered. It’s advisable to discuss your requirements directly with suppliers, as some may offer flexibility for smaller orders, especially for new customers or bulk purchases. Understanding the MOQ can help you plan your inventory and budget accordingly. -

Can I customize fire extinguisher brackets for my business needs?

Yes, many manufacturers offer customization options for fire extinguisher brackets to meet specific business requirements. Customization can include alterations in size, color, material, and branding elements such as logos. When considering customization, communicate your needs clearly to the supplier and request samples or prototypes if possible. This ensures that the final product aligns with your operational standards and enhances brand visibility. -

What payment terms should I expect when sourcing fire extinguisher brackets?

Payment terms for sourcing fire extinguisher brackets can differ based on the supplier and your negotiation. Common terms include upfront payments, partial payments with the balance due upon delivery, or net 30/60 days payment after receipt of goods. For international transactions, consider discussing payment methods like letters of credit or escrow services to mitigate risks. Always ensure that the terms are documented in the purchase agreement to avoid misunderstandings. -

How can I ensure the quality of fire extinguisher brackets from suppliers?

To ensure the quality of fire extinguisher brackets, conduct thorough supplier vetting before making a purchase. Request certifications that demonstrate compliance with international safety standards, such as ISO or OSHA. Additionally, consider asking for product samples or visiting the manufacturing facility to assess quality control processes. Reading customer reviews and seeking testimonials can also provide insight into the supplier’s reliability and product durability. -

What are the logistics considerations when importing fire extinguisher brackets?

When importing fire extinguisher brackets, logistics considerations include shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder familiar with your destination’s import regulations to navigate customs efficiently. Also, factor in lead times for production and shipping to avoid delays. Understanding the total landed cost, including shipping, duties, and taxes, is crucial for accurate budgeting and cost management. -

What are the best practices for installing fire extinguisher brackets?

Best practices for installing fire extinguisher brackets include selecting a location that is easily accessible and visible in case of an emergency. Ensure the bracket is mounted securely at a height compliant with local regulations—typically between 3.5 to 5 feet for standard extinguishers. Use appropriate mounting hardware and follow the manufacturer’s installation guidelines for safety. Regularly inspect the brackets and extinguishers to ensure they remain secure and functional.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Fire Extinguisher Bracket Manufacturers & Suppliers List

1. Fire Extinguisher Depot – Brackets for All Sizes

Domain: fireextinguisherdepot.com

Registered: 2012 (13 years)

Introduction: Fire Extinguisher Brackets available in various sizes including 2.5 LB, 5 LB, 10 LB, 20 LB, and 30 LB. Brackets are categorized by brand such as Amerex, Ansul/Sentry, and Kidde. Types of brackets include universal brackets, wall brackets, wall strap brackets, vehicle brackets, aviation brackets, rubber strap brackets, heavy-duty vehicle brackets, marine/USCG brackets, and spring clip brackets.

2. Fire Supply Depot – Fire Extinguisher Brackets

Domain: firesupplydepot.com

Registered: 2007 (18 years)

Introduction: Fire Extinguisher Brackets for Wall and Vehicle Mounting. OSHA guidelines recommend mounting fire extinguishers on brackets or in wall cabinets with the carrying handle 3-1/2 to 5 feet above the floor. Larger extinguishers should be mounted with the handle about 3 feet from the floor. Universal wall hangers and vehicle brackets are made of steel with a primed and powder-coated finish. Key products…

3. H3R Performance – ProLock Fire Extinguisher Brackets

Domain: h3rperformance.com

Registered: 2005 (20 years)

Introduction: H3R Performance offers a range of car fire extinguisher brackets suitable for various vehicle types and uses. Key products include: 1. ProLock Fire Extinguisher Brackets – precision-machined from billet aluminum, secure and rattle-free with a lever-action locking/release mechanism. 2. Fire Extinguisher Seat Mount – fully adjustable, easy installation in most vehicles. 3. Extreme Duty Fire Extingui…

4. Buckeye – Mounting Hardware

Domain: buckeyef.com

Registered: 1996 (29 years)

Introduction: Buckeye Fire Equipment manufactures strong and durable mounting hardware (hooks and brackets) for all its hand held fire extinguishers. The mounting hardware includes wall hooks and marine/vehicle brackets designed to keep Buckeye fire extinguishers secure and readily accessible. Suitable for complex vehicle or marine vessel mounting, as well as simple wall mounting.

5. Bracketeer – UFEB1317/D Car Fire Extinguisher Bracket

Domain: thebracketeer.com

Registered: 2015 (10 years)

Introduction: {“Product Name”: “UFEB1317/D Car Fire Extinguisher Bracket”, “Sale Price”: “$59.90”, “Original Price”: “$85.00”, “Features”: {“Mounting Options”: “Front or rear of passenger seat”, “Accessibility”: “Extinguisher out of the way but within easy reach”, “Design”: “Simple clamp-on or bolt-on design”, “Installation”: “Under 10 minutes without drilling”, “Adjustability”: “Adjustable width for various ve…

6. Amerex – Heavy Duty Bracket Model 811

Domain: amerexfireextinguishers.com

Registered: 2007 (18 years)

Introduction: {“products”:[{“model”:”Heavy Duty Bracket – Model 811″,”price”:”$76.00″},{“model”:”Heavy Duty Bracket – Model 861H”,”price”:”$36.00″},{“model”:”Rubber Straps Bracket – Model 860″,”price”:”$43.50″},{“model”:”Aviation Bracket – Model 817S”,”price”:”$29.00″},{“model”:”Vehicle Bracket – Model 846″,”price”:”$42.30″},{“model”:”Vehicle Bracket – Model 896″,”price”:”$36.90″},{“model”:”Pin Hook Wall Bracke…

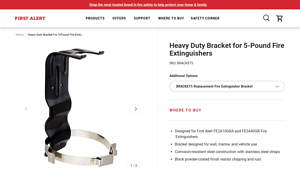

7. First Alert – Heavy Duty Fire Extinguisher Bracket

Domain: firstalert.com

Registered: 1996 (29 years)

Introduction: {‘model’: ‘BRACKET5’, ‘type’: ‘Fire Extinguisher Bracket’, ‘color’: ‘Black’, ‘product_height’: ‘8.3 in; 211 mm’, ‘product_width’: ‘2.5 in; 64 mm’, ‘product_weight’: ‘0.94 lb; 0.43 kg’, ‘sku’: ‘BRACKET5’, ‘features’: [‘Heavy Duty Bracket for 5-Pound Fire Extinguishers’, ‘Compatible with First Alert FE2A10GRA and FE3A40GR Fire Extinguishers’, ‘Designed for wall, marine, and vehicle use’, ‘Corrosion-…

Strategic Sourcing Conclusion and Outlook for fire extinguisher bracket

As the demand for fire safety solutions continues to rise globally, particularly in regions such as Africa, South America, the Middle East, and Europe, the strategic sourcing of fire extinguisher brackets emerges as a crucial aspect for businesses. It is vital to prioritize quality, compliance with local regulations, and the specific needs of different environments—whether commercial or residential.

Investing in robust and versatile mounting solutions not only ensures optimal safety but also enhances operational efficiency. By sourcing high-quality brackets that comply with standards such as OSHA, companies can mitigate risks associated with fire hazards and ensure readiness in emergencies. Additionally, leveraging relationships with reliable suppliers can facilitate better pricing, timely delivery, and superior customer support, which are essential for maintaining safety equipment.

Looking ahead, B2B buyers are encouraged to explore innovative sourcing strategies and partnerships that align with their operational goals. Engage with suppliers that offer customizable solutions tailored to your specific industry requirements. By doing so, businesses can enhance their fire safety preparedness and contribute to a safer working environment. Embrace the opportunity to lead in fire safety standards within your region, setting a benchmark for others in your industry.