Golf Cart Motor Guide: Type,Cost,Material…

Introduction: Navigating the Global Market for golf cart motor

In today’s dynamic global market, sourcing high-performance golf cart motors poses a significant challenge for international B2B buyers. With a diverse range of applications—from leisure activities on golf courses to utility uses in resorts and communities—understanding the nuances of motor types, specifications, and supplier capabilities is crucial. This comprehensive guide will delve into various categories of golf cart motors, including electric and high-speed options, while highlighting their suitability for different terrains and operational needs.

Buyers will also find valuable insights on how to effectively vet suppliers, ensuring that quality and reliability are prioritized in their purchasing decisions. From cost considerations to the latest technological advancements, this guide is designed to empower businesses in Africa, South America, the Middle East, and Europe—such as those in Nigeria and Vietnam—to make informed choices that align with their operational goals.

By equipping buyers with essential knowledge and actionable strategies, this resource aims to streamline the procurement process, enabling businesses to invest in golf cart motors that enhance performance and meet specific demands. Whether you are upgrading an existing fleet or entering the market for the first time, understanding the complexities of golf cart motor sourcing is the key to achieving operational excellence.

Understanding golf cart motor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Series DC Motors | Simple design, high torque at low speeds, no speed control. | Basic golf carts, utility vehicles. | Pros: Cost-effective, reliable. Cons: Limited speed and efficiency. |

| Regen DC Motors | Features regenerative braking, improved efficiency. | Eco-friendly applications, urban areas. | Pros: Energy-efficient, better range. Cons: More complex and expensive. |

| AC Motors | High performance, smooth acceleration, and speed. | Performance-driven applications. | Pros: Superior torque and speed. Cons: Higher initial investment. |

| High-Speed Motors | Designed for maximum speed, often built for racing. | Golf courses, entertainment venues. | Pros: Exceptional speed, thrilling experience. Cons: May require additional modifications. |

| Custom Motors | Tailored specifications for unique applications. | Specialized uses, custom builds. | Pros: Meets specific needs. Cons: Longer lead times, potentially higher costs. |

What Are the Key Characteristics of Series DC Motors?

Series DC motors are characterized by their simplicity and robust design. They provide high torque at low speeds, making them suitable for basic golf carts and utility vehicles that require reliable performance without complex controls. For B2B buyers, the primary considerations include cost-effectiveness and reliability, though these motors may fall short in terms of speed and efficiency compared to other options. This makes them ideal for applications where speed is not a priority.

How Do Regen DC Motors Enhance Efficiency?

Regen DC motors stand out due to their regenerative braking capabilities, allowing them to convert kinetic energy back into stored energy, thus improving overall efficiency. These motors are particularly suitable for eco-friendly applications and urban environments where energy conservation is critical. B2B buyers should weigh the benefits of energy savings against the higher complexity and cost associated with these systems. Their ability to extend the range of golf carts makes them a compelling choice for businesses focused on sustainability.

What Advantages Do AC Motors Offer for Performance?

AC motors are designed for high performance, providing smooth acceleration and superior speed capabilities. They are often employed in applications where performance is paramount, such as racing or high-end golf courses. B2B buyers will appreciate the torque and speed benefits that AC motors offer, though it is essential to consider the higher initial investment. These motors are ideal for businesses looking to enhance the performance of their golf carts and provide a premium experience.

What Features Define High-Speed Motors?

High-speed motors are engineered specifically for maximum speed, often used in racing scenarios or entertainment venues. They provide exceptional speed and a thrilling experience, making them popular among golf courses and recreational facilities. However, B2B buyers should be aware that these motors may require additional modifications to ensure compatibility with existing systems. While the speed advantage is significant, the potential for increased maintenance and operational costs should be factored into purchasing decisions.

Why Consider Custom Motors for Specialized Applications?

Custom motors are tailored to meet unique specifications and requirements, making them suitable for specialized applications. Businesses that require specific performance characteristics or configurations can benefit from custom solutions. However, B2B buyers should consider the longer lead times and potentially higher costs associated with custom motors. For organizations needing specialized equipment, the ability to meet precise needs can outweigh the drawbacks, offering a strategic advantage in competitive markets.

Key Industrial Applications of golf cart motor

| Industry/Sector | Specific Application of golf cart motor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Resort Transportation | Enhances guest experience with eco-friendly transport | Reliability, battery compatibility, service support |

| Golf Courses | Golf Cart Fleet Management | Increases operational efficiency and customer satisfaction | Performance specifications, maintenance ease, durability |

| Industrial Facilities | On-Site Material Handling | Streamlines logistics and reduces manual labor | Load capacity, torque requirements, speed adaptability |

| Event Management | Shuttle Services for Large Venues | Provides efficient guest movement and accessibility | Customization options, range, battery life |

| Agriculture | Utility Vehicles for Farming | Facilitates field operations and reduces labor costs | Terrain compatibility, motor power, battery longevity |

How are Golf Cart Motors Used in Hospitality Settings?

In the hospitality sector, golf cart motors are utilized for resort transportation, providing guests with an eco-friendly and efficient means to navigate sprawling properties. These vehicles enhance the overall guest experience by offering convenient transport options that are quieter and more sustainable than traditional vehicles. For international buyers, especially in regions like Africa and the Middle East, sourcing durable and reliable motors is crucial to ensure consistent service levels in varied climates.

What Role do Golf Cart Motors Play in Golf Course Management?

Golf courses leverage golf cart motors to manage fleets of electric carts, improving operational efficiency and enhancing the customer experience. High-performance motors allow carts to traverse hilly terrains and maintain speed, ensuring that golfers can easily move between holes. Buyers must consider performance specifications, battery compatibility, and ease of maintenance to ensure the longevity and reliability of the carts, especially in regions like South America where terrain can be challenging.

How are Golf Cart Motors Integrated into Industrial Facilities?

In industrial settings, golf cart motors are increasingly used for on-site material handling. These motors power utility vehicles that transport goods and personnel across large facilities, significantly streamlining logistics and reducing manual labor. Businesses in sectors such as manufacturing and warehousing should prioritize torque requirements and load capacity when sourcing motors, particularly in European markets where efficiency and compliance with safety standards are paramount.

Why are Golf Cart Motors Important for Event Management?

Event management companies utilize golf cart motors to provide shuttle services at large venues, ensuring efficient guest movement and accessibility. These carts can be customized to fit the specific needs of events, offering a convenient solution for transporting attendees across expansive areas. Key considerations for sourcing include customization options and battery life, which are vital for ensuring uninterrupted service during high-traffic events in regions like Africa and South America.

How do Golf Cart Motors Benefit Agricultural Operations?

In agriculture, golf cart motors are employed in utility vehicles that facilitate various field operations, from transporting equipment to moving personnel. The use of electric motors reduces fuel costs and greenhouse gas emissions, making them an attractive option for modern farms. Buyers should focus on terrain compatibility and motor power to ensure optimal performance in diverse agricultural environments, especially in developing regions where resource efficiency is critical.

3 Common User Pain Points for ‘golf cart motor’ & Their Solutions

Scenario 1: The Challenge of Performance Upgrades in Diverse Terrain

The Problem: B2B buyers, particularly those operating in regions with varied terrain such as hilly landscapes or off-road conditions, often find standard golf cart motors insufficient for their needs. Many motors may lack the necessary torque and speed to handle steep inclines or rough surfaces. This limitation can hinder operations in sectors like golf course management, tourism, and recreational vehicle rental, where performance directly impacts customer satisfaction and operational efficiency. Buyers might also face challenges when attempting to source motors that can be customized for specific applications or brands, leading to delays and increased costs.

The Solution: To address performance issues, buyers should consider sourcing high-performance motors designed specifically for varied terrain. Engaging with manufacturers like Plum Quick or D&D Motor Systems, which offer motors tailored for high torque and speed, is essential. When selecting a motor, it’s crucial to specify the required voltage and horsepower based on the intended application, such as off-roading or steep climbs. Additionally, investing in controller upgrades can enhance the performance of existing motors. Buyers should also explore conversion kits that allow for the integration of advanced technologies such as regenerative braking, which can improve efficiency and extend battery life. This proactive approach ensures that the golf cart motors not only meet but exceed performance expectations across diverse environments.

Scenario 2: Navigating Compatibility Issues with Existing Golf Cart Models

The Problem: Many B2B buyers face compatibility issues when trying to replace or upgrade golf cart motors for specific brands like Club Car, EZGO, or Yamaha. With the wide variety of models and variations in wiring and motor specifications, selecting the right motor can become a complex task. This often results in incorrect orders, wasted time, and increased costs as buyers may need to return unsuitable products or make additional purchases to complete the installation.

The Solution: To mitigate compatibility issues, buyers should conduct thorough research on the specific model of their golf cart before making a purchase. This includes consulting the manufacturer’s specifications and understanding the differences between series and regenerative motors. Utilizing resources from reputable suppliers, such as Golf Cart Garage, can provide detailed compatibility charts and recommendations based on the buyer’s specific cart model. Additionally, buyers should engage directly with suppliers’ customer service to confirm compatibility before placing an order. Implementing a systematic approach to sourcing motors—by maintaining a catalog of current inventory and specifications—will streamline future purchases and ensure that the correct parts are ordered the first time.

Scenario 3: Addressing Maintenance and Longevity of Golf Cart Motors

The Problem: Another significant pain point for B2B buyers is the maintenance and longevity of golf cart motors. Over time, motors can experience wear and tear, leading to decreased performance and potential failures, which can disrupt operations. Buyers may struggle to find reliable maintenance services or parts that can restore motor functionality without incurring excessive costs. This concern is particularly relevant for businesses that rely on golf carts for daily operations, where downtime can lead to lost revenue.

The Solution: To enhance the longevity of golf cart motors, B2B buyers should prioritize regular maintenance and timely repairs. Establishing a routine maintenance schedule that includes inspecting key components such as bearings, brushes, and wiring can prevent unexpected failures. Suppliers like D&D Motor Systems offer a range of replacement parts that can be sourced easily, allowing for quick repairs when needed. Additionally, consider investing in motors designed for durability and ease of maintenance. Custom-built motors from manufacturers can often offer enhanced features tailored to specific operational needs, which can significantly improve lifespan and reduce the frequency of repairs. Lastly, creating a partnership with a trusted service provider for periodic checks and repairs can further ensure that the golf cart fleet remains operational and efficient.

Strategic Material Selection Guide for golf cart motor

What Are the Key Materials Used in Golf Cart Motors?

When selecting materials for golf cart motors, it is essential to consider properties that directly affect performance, durability, and cost. Here, we analyze four common materials used in golf cart motors: aluminum, copper, steel, and composite materials.

How Does Aluminum Benefit Golf Cart Motor Construction?

Aluminum is widely used in the housing and components of golf cart motors due to its lightweight and excellent corrosion resistance. With a temperature rating up to 150°C, aluminum can withstand the heat generated during motor operation. Its low density also contributes to a reduced overall weight of the golf cart, enhancing performance and efficiency.

Pros: The primary advantages of aluminum include its lightweight nature, which improves fuel efficiency and handling, and its resistance to rust and corrosion, making it suitable for various environments.

Cons: However, aluminum can be more expensive than other materials and may require specialized manufacturing processes, such as welding or anodizing, which can increase production complexity.

Impact on Application: Aluminum’s compatibility with high-performance applications makes it an ideal choice for golf carts used in diverse terrains.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards for aluminum alloys, such as ASTM or JIS, to guarantee quality and performance.

What Role Does Copper Play in Golf Cart Motors?

Copper is predominantly used in the windings of electric motors due to its excellent electrical conductivity, which is crucial for efficient power transfer. Copper can handle high temperatures, with a melting point of 1,984°F (1,085°C), making it suitable for high-performance applications.

Pros: The key advantage of copper is its superior conductivity, which enhances motor efficiency and performance.

Cons: However, copper is relatively expensive and can be prone to corrosion if not properly insulated, which may lead to increased maintenance costs over time.

Impact on Application: Copper’s conductivity ensures that motors can operate effectively under high loads, making it suitable for golf carts designed for steep terrains or heavy loads.

Considerations for International Buyers: Buyers should be aware of the global copper market fluctuations and ensure compliance with international standards regarding electrical components.

How Does Steel Contribute to Motor Durability?

Steel is often used in the structural components of golf cart motors, such as the frame and shafts, due to its strength and durability. With a high tensile strength, steel can withstand significant mechanical stress and has a temperature rating of up to 1,500°F (815°C).

Pros: The main advantage of steel is its robustness, which provides long-lasting durability and resistance to wear and tear.

Cons: On the downside, steel is heavier than aluminum, which can negatively impact the overall weight and efficiency of the golf cart. Additionally, it is susceptible to corrosion if not properly treated.

Impact on Application: Steel’s strength makes it suitable for motors that require high durability, especially in rugged environments.

Considerations for International Buyers: Buyers should ensure that the steel used complies with local standards, such as ASTM or DIN, to guarantee structural integrity.

What Advantages Do Composite Materials Offer?

Composite materials, such as reinforced plastics, are increasingly being used in golf cart motors for non-structural components. They offer a unique combination of lightweight properties and resistance to corrosion and chemicals.

Pros: The primary advantage of composites is their lightweight nature, which can significantly reduce the overall weight of the motor while providing good thermal and electrical insulation.

Cons: However, composites can be more expensive to produce and may not offer the same level of strength as metals, making them less suitable for high-stress applications.

Impact on Application: Composites are ideal for components that require insulation or where weight reduction is critical.

Considerations for International Buyers: Buyers should consider the availability and compliance of composite materials with local regulations, particularly in regions with strict environmental standards.

Summary Table of Material Selection for Golf Cart Motors

| Material | Typical Use Case for golf cart motor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Motor housing and components | Lightweight and corrosion-resistant | Higher cost and manufacturing complexity | Medium |

| Copper | Electrical windings | Superior electrical conductivity | Corrosion-prone and expensive | High |

| Steel | Structural components | High strength and durability | Heavier and susceptible to corrosion | Medium |

| Composite | Non-structural components | Lightweight and good insulation properties | Higher production costs and lower strength | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, ensuring informed decisions that align with performance requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for golf cart motor

What Are the Key Stages in the Manufacturing Process of Golf Cart Motors?

The manufacturing process of golf cart motors involves several critical stages, each designed to ensure efficiency and quality. Understanding these stages is vital for B2B buyers seeking reliable suppliers.

Material Preparation: What Materials Are Used in Golf Cart Motor Manufacturing?

The first step in manufacturing golf cart motors involves selecting high-quality raw materials. Typically, manufacturers utilize metals such as aluminum for lightweight components and high-strength steel for durability. The electrical components, including copper for windings and various plastics for insulation, are also essential. Suppliers often conduct thorough inspections of incoming materials to confirm compliance with industry standards before they proceed to the next stage.

Forming: How Are Components Shaped and Structured?

In the forming stage, raw materials are transformed into specific components through various techniques such as machining, die casting, and stamping. For instance, aluminum casings are often die-cast for precision and uniformity, while steel parts may undergo machining to achieve exact specifications. This stage is crucial for ensuring that each part meets the design criteria necessary for optimal motor performance.

Assembly: What Techniques Are Used to Assemble Golf Cart Motors?

Once the individual components are formed, they move to the assembly stage. This process typically involves both manual labor and automated systems. Key techniques include soldering electrical connections, installing bearings, and securing the motor housing. Advanced manufacturers may employ robotics to enhance precision and reduce assembly time, which can lead to cost savings for B2B buyers.

Finishing: How Is the Final Product Prepared for Sale?

The finishing stage encompasses various treatments to enhance the motor’s durability and appearance. This may include surface treatments such as anodizing for aluminum parts, painting, or applying protective coatings. These processes are designed to improve corrosion resistance and aesthetic appeal, which are important factors for end-users. Quality control checks at this stage ensure that the finished product adheres to specifications.

What Quality Assurance Standards Are Relevant for Golf Cart Motor Manufacturing?

Quality assurance is a fundamental aspect of the manufacturing process, particularly for international B2B transactions. Adhering to recognized standards ensures that products meet safety, reliability, and performance criteria.

Which International Standards Should B2B Buyers Be Aware Of?

Manufacturers of golf cart motors often comply with international standards such as ISO 9001, which focuses on quality management systems. This certification is crucial for ensuring consistent quality and customer satisfaction. Additionally, compliance with CE marking requirements indicates that products meet European safety and health standards, which can be particularly relevant for buyers in Europe.

What Industry-Specific Certifications Are Important?

In addition to general quality standards, industry-specific certifications may be required. For example, the American Petroleum Institute (API) offers standards that can be relevant for motors used in industrial applications. Understanding these certifications can help B2B buyers make informed decisions when selecting suppliers.

What Are the Key Quality Control Checkpoints in Golf Cart Motor Manufacturing?

Quality control is integral to maintaining the integrity and performance of golf cart motors. Various checkpoints are established throughout the manufacturing process to ensure product quality.

How Do Incoming Quality Control (IQC) and In-Process Quality Control (IPQC) Work?

Incoming Quality Control (IQC) focuses on inspecting raw materials and components before they enter the production line. This step is essential for identifying defects early on. In-Process Quality Control (IPQC) occurs at various stages of production to monitor processes and ensure they adhere to predefined standards. Regular audits during this phase can prevent defects from progressing to the final product.

What Is the Role of Final Quality Control (FQC)?

Final Quality Control (FQC) is conducted after assembly and finishing to verify that the final product meets all specifications. This includes functional testing, performance evaluation, and visual inspections. Effective FQC helps ensure that only high-quality products reach the market, reducing the likelihood of returns and enhancing customer satisfaction.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial for ensuring reliability and performance.

What Methods Can Buyers Use to Assess Supplier Quality?

B2B buyers can utilize several methods to assess a supplier’s quality control measures. Conducting audits allows buyers to evaluate a manufacturer’s processes firsthand. Additionally, requesting quality assurance reports and certificates can provide insight into the supplier’s adherence to industry standards.

Why Is Third-Party Inspection Important?

Engaging third-party inspection services adds an extra layer of verification. These independent entities can conduct thorough assessments of manufacturing processes and final products, ensuring compliance with international standards. This is particularly beneficial for buyers from regions such as Africa, South America, and the Middle East, where establishing trust with suppliers can be challenging.

What Nuances Should International Buyers Consider Regarding Quality Control?

International buyers must navigate various challenges when assessing quality control in golf cart motor manufacturing.

How Do Cultural Differences Impact Quality Assurance?

Cultural differences can affect communication and expectations regarding quality. Buyers should be aware of regional practices and standards that may differ from their own. Establishing clear communication channels and expectations can mitigate misunderstandings.

What Are the Implications of Local Regulations?

Local regulations may impose additional requirements that affect quality control practices. For instance, some countries may have specific safety standards that manufacturers must comply with. B2B buyers should familiarize themselves with these regulations to ensure that the products they purchase meet local compliance requirements.

Conclusion: Why Is Understanding Manufacturing and Quality Assurance Essential for B2B Buyers?

For international B2B buyers, understanding the manufacturing processes and quality assurance measures in the golf cart motor industry is critical. By recognizing the key stages of production, relevant standards, quality control checkpoints, and verification methods, buyers can make informed decisions that lead to successful partnerships and high-quality products. Investing time in understanding these factors not only enhances product reliability but also fosters long-term relationships with suppliers, ultimately driving business success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘golf cart motor’

Introduction

In the competitive landscape of golf cart motor procurement, making informed decisions is crucial for B2B buyers. This practical sourcing guide serves as a comprehensive checklist, ensuring that you consider all critical aspects when sourcing golf cart motors. From defining specifications to evaluating suppliers, each step is designed to streamline your purchasing process and optimize your investment.

Step 1: Define Your Technical Specifications

Before initiating your search, it’s essential to establish clear technical specifications for the golf cart motor you need. Consider factors such as voltage (36V or 48V), torque requirements, and intended applications (e.g., off-road, high-speed cruising). A well-defined specification will help you avoid mismatched products and unnecessary returns.

Step 2: Research Market Trends

Understanding current market trends can provide valuable insights into the features and technologies available in golf cart motors. Research recent advancements, such as AC versus DC motors, regenerative braking systems, and efficiency ratings. This knowledge not only informs your specifications but also helps in identifying innovative products that can enhance your fleet’s performance.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure they meet your business needs. Request company profiles, product catalogs, and case studies, particularly from clients in similar markets or regions. Pay attention to their reputation for reliability, customer service, and the quality of their motors, as these factors can significantly impact your operations.

Step 4: Verify Supplier Certifications

Confirm that your potential suppliers hold relevant certifications and adhere to industry standards. Look for certifications such as ISO 9001, which demonstrates a commitment to quality management, and any specific certifications pertinent to electric motors. Verified suppliers are more likely to provide high-quality products that meet safety and performance standards.

Step 5: Request Samples and Conduct Testing

Whenever possible, request samples of the motors you are considering. Testing these samples in real-world conditions allows you to evaluate their performance, durability, and compatibility with your existing golf carts. This hands-on approach can prevent costly mistakes and ensure that the motors will meet your operational requirements.

Step 6: Review Warranty and After-Sales Support

A robust warranty policy and reliable after-sales support are vital when sourcing golf cart motors. Ensure that suppliers offer warranties that cover defects and performance issues for a reasonable duration. Additionally, inquire about their support services, including installation assistance and maintenance recommendations, as these can be crucial for long-term satisfaction.

Step 7: Negotiate Terms and Pricing

Once you’ve identified a suitable supplier, it’s time to negotiate terms and pricing. Be clear about your budget and explore options for volume discounts or long-term partnerships. A well-negotiated agreement can enhance your profitability and ensure a stable supply of high-quality motors for your golf cart fleet.

By following these steps, B2B buyers can streamline their procurement process and secure golf cart motors that meet their specific needs, ultimately contributing to the efficiency and success of their operations.

Comprehensive Cost and Pricing Analysis for golf cart motor Sourcing

What Are the Key Cost Components in Golf Cart Motor Sourcing?

When analyzing the cost structure for sourcing golf cart motors, several critical components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materials represent a significant portion of the cost, as high-quality components such as copper wiring, rare earth magnets, and durable casings are essential for performance and longevity. The choice of materials can influence both the initial cost and the long-term reliability of the motors.

Labor costs encompass the wages of skilled workers involved in assembling and testing the motors. In regions with varying wage standards, this can significantly impact the overall cost structure.

Manufacturing overhead includes expenses related to factory operations, utilities, and equipment maintenance, while tooling costs pertain to the machinery required to produce the motors. Efficient production processes can help minimize these costs.

Quality control is crucial in ensuring that the motors meet industry standards, which can involve additional testing and certification processes. This aspect is particularly important for international buyers who may require specific certifications to comply with local regulations.

Logistics costs, including transportation and customs duties, can vary widely depending on the supplier’s location and the destination market. These costs must be factored into the total sourcing price.

Lastly, the margin is the profit that manufacturers and distributors add to their costs, which can vary based on competition and market demand.

What Influences Pricing for Golf Cart Motors?

Several factors can influence the pricing of golf cart motors, particularly for B2B buyers in diverse markets like Africa, South America, the Middle East, and Europe.

Volume and Minimum Order Quantity (MOQ) play a significant role in determining price. Suppliers often offer tiered pricing, where larger orders result in lower per-unit costs. Understanding the MOQ can help buyers negotiate better deals.

Specifications and customization requirements also impact pricing. Custom-built motors or those with specific performance metrics may incur higher costs due to additional engineering and production processes.

Material quality and certifications can further influence pricing. Motors made from premium materials or those that meet stringent industry standards may command a higher price but offer better performance and longevity.

Supplier factors, including reputation, experience, and geographic location, can also affect pricing. Established suppliers may charge a premium for their products due to their reliability and service history.

Additionally, Incoterms dictate the responsibilities of buyers and sellers in shipping and delivery, which can affect overall costs. Understanding these terms can help buyers avoid unexpected expenses.

What Are the Best Tips for Buyers to Negotiate Cost-Efficient Deals?

International B2B buyers should consider several strategies to ensure cost-efficiency when sourcing golf cart motors.

Negotiation is key. Buyers should approach suppliers with a clear understanding of their needs and be prepared to discuss pricing based on order volume and specifications. Building a relationship with suppliers can lead to better terms and discounts.

Total Cost of Ownership (TCO) should be a guiding principle. This involves considering not just the purchase price but also maintenance, energy consumption, and potential downtime costs over the motor’s lifecycle. Investing in higher-quality motors might result in lower TCO despite higher upfront costs.

Buyers should be aware of pricing nuances in different regions. For example, factors like local tariffs, import duties, and currency fluctuations can significantly affect the final cost of motors sourced from abroad.

Finally, maintaining flexibility in sourcing options can lead to better pricing. Exploring multiple suppliers and keeping an open line of communication can help buyers identify the most cost-effective solutions.

Conclusion: Why Are Indicative Prices Important?

It’s essential for buyers to understand that the prices listed for golf cart motors are often indicative and can fluctuate based on the factors discussed. Engaging with suppliers to obtain precise quotes tailored to specific needs is crucial for effective budgeting and sourcing decisions. By taking these considerations into account, international buyers can navigate the complexities of sourcing golf cart motors more effectively.

Alternatives Analysis: Comparing golf cart motor With Other Solutions

Understanding Alternatives to Golf Cart Motors

When considering the best solutions for powering golf carts, it’s essential to evaluate not only traditional golf cart motors but also alternative technologies that can fulfill similar functions. This analysis will provide B2B buyers with insights into the performance, cost, ease of implementation, maintenance, and best use cases of various solutions, allowing for informed purchasing decisions.

| Comparison Aspect | Golf Cart Motor | Lithium-ion Battery System | Gasoline-Powered Engine |

|---|---|---|---|

| Performance | High torque, customizable speed options | Consistent power delivery, longer range | High power output, rapid refueling |

| Cost | Moderate initial investment; variable based on specifications | Higher initial cost, long-term savings on fuel | Lower upfront cost, ongoing fuel expenses |

| Ease of Implementation | Moderate; requires electrical expertise | Easy installation; requires charging infrastructure | Simple; compatible with most existing carts |

| Maintenance | Low maintenance; occasional checks needed | Minimal; battery health monitoring required | Higher; regular servicing and fuel management |

| Best Use Case | Ideal for recreational use, hilly terrains, and modifications | Best for long-distance travel, eco-friendly solutions | Suitable for heavy-duty applications and commercial use |

What Are the Benefits and Drawbacks of Lithium-ion Battery Systems?

Lithium-ion battery systems offer a compelling alternative to traditional golf cart motors, particularly for their energy density and efficiency. These systems provide consistent power delivery and extended operational range, making them ideal for longer journeys. However, they typically come with a higher upfront cost compared to standard golf cart motors. Additionally, while installation is straightforward, it does require a compatible charging infrastructure, which may not be readily available in all regions. Maintenance is minimal, focusing primarily on battery health monitoring, which can be an advantage for businesses looking to streamline operations.

How Do Gasoline-Powered Engines Compare to Golf Cart Motors?

Gasoline-powered engines represent another alternative for golf cart propulsion, particularly in scenarios where high power output is essential. These engines can rapidly refuel, making them suitable for heavy-duty applications and commercial uses, such as in golf courses or resorts. However, they come with ongoing fuel expenses, which can accumulate significantly over time. Additionally, gasoline engines require more frequent maintenance, including oil changes and engine checks, which can burden operational efficiency. While they may have a lower initial cost, the long-term expenses and environmental impact should be considered.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting the right solution for golf cart propulsion, B2B buyers must weigh their specific needs against the characteristics of each alternative. Golf cart motors offer a balance of performance and low maintenance, making them suitable for recreational use. In contrast, lithium-ion battery systems excel in efficiency and range, ideal for eco-conscious operations. Gasoline-powered engines may appeal to those requiring immediate power and quick refueling but come with higher long-term costs and maintenance requirements. By considering these aspects, businesses can make informed decisions that align with their operational goals and budget constraints, ensuring optimal performance for their golf cart fleet.

Essential Technical Properties and Trade Terminology for golf cart motor

What Are the Key Technical Properties of Golf Cart Motors?

Understanding the technical specifications of golf cart motors is crucial for B2B buyers looking to make informed purchasing decisions. Here are some essential properties:

-

Voltage Rating

The voltage rating, typically either 36V or 48V, indicates the electrical potential difference that the motor operates at. Higher voltage ratings generally translate to increased power and speed, making them suitable for various applications, from golf courses to off-road environments. For businesses, selecting the right voltage ensures compatibility with existing systems and can optimize performance. -

Peak Torque

Peak torque refers to the maximum rotational force the motor can produce. This specification is vital for understanding a motor’s ability to handle inclines and heavier loads. For international buyers, particularly in regions with varied terrain, knowing the peak torque helps in selecting motors that can perform reliably under specific conditions, thereby reducing maintenance costs. -

RPM (Revolutions Per Minute)

RPM measures the motor’s speed. A higher RPM indicates faster operation, which can enhance efficiency and reduce the time taken to complete tasks. For B2B buyers, understanding RPM is essential for matching motors to specific operational needs, such as fast-paced golf course maintenance or leisurely cruising. -

Material Grade

The material grade of components, such as the motor casing and internal parts, affects durability and performance. Motors made from high-grade materials resist wear and tear better, leading to longer operational life. For buyers, investing in quality materials can result in lower replacement and maintenance costs over time, particularly in demanding environments. -

Controller Compatibility

Compatibility with different controllers (e.g., DC vs. AC controllers) is a critical factor when selecting a golf cart motor. Controllers manage power delivery, impacting speed and torque performance. Understanding this compatibility helps B2B buyers ensure that the motor will function optimally within their existing systems, which is especially important for companies looking to upgrade or retrofit equipment.

What Are Common Trade Terms Used in Golf Cart Motor Procurement?

Familiarity with industry jargon can streamline the procurement process. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of golf cart motors, an OEM can provide high-quality components that meet specific performance standards. Understanding OEM relationships can help buyers ensure they are sourcing reliable products. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest number of units that a supplier is willing to sell. This is crucial for B2B transactions, as it affects inventory management and pricing. Buyers should negotiate MOQs to balance their needs with supplier capabilities, ensuring they do not overstock or miss out on bulk discounts. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing information from suppliers. This process allows businesses to compare costs and services, facilitating informed decision-making. Effective use of RFQs can lead to better pricing and terms, optimizing procurement strategies. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for B2B buyers to manage shipping costs and risks effectively. -

Aftermarket Parts

These are components made by manufacturers other than the OEM. Aftermarket parts can provide cost-effective alternatives for repairs or upgrades. For B2B buyers, being aware of aftermarket options can enhance flexibility and reduce total ownership costs while ensuring continued performance of golf carts.

By grasping these technical properties and trade terms, B2B buyers can navigate the golf cart motor market more effectively, leading to better purchasing decisions and optimized operational performance.

Navigating Market Dynamics and Sourcing Trends in the golf cart motor Sector

What Are the Current Market Dynamics and Key Trends in the Golf Cart Motor Sector?

The golf cart motor sector is experiencing significant growth driven by several global factors. The increasing popularity of golf as a leisure activity, coupled with the rising demand for electric vehicles (EVs), is propelling innovation and investment in high-performance golf cart motors. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are witnessing a surge in demand for advanced electric golf cart solutions that cater to both recreational and utility applications. Countries such as Nigeria and Vietnam are emerging markets where golf cart usage is expanding beyond traditional golf courses to urban environments, resorts, and rural areas.

Key trends influencing sourcing strategies include the shift towards high-speed and high-torque electric motors, which are essential for off-road capabilities and steep terrain navigation. Additionally, manufacturers are increasingly offering customization options, enabling buyers to tailor motors for specific applications, whether for hunting, leisure, or commercial use. The integration of smart technologies, such as telematics and performance tracking, is also gaining traction, allowing operators to monitor usage patterns and optimize performance.

Moreover, as the market matures, international buyers are focusing on sourcing from reputable suppliers that demonstrate reliability and quality assurance, ensuring a competitive edge in their respective markets.

How Can Sustainability and Ethical Sourcing Impact B2B Purchasing in the Golf Cart Motor Sector?

Sustainability is becoming a critical consideration for B2B buyers in the golf cart motor sector. The environmental impact of manufacturing processes and the lifecycle of products are under scrutiny, prompting companies to adopt greener practices. Buyers are increasingly favoring suppliers who prioritize sustainable materials and production techniques, such as recycled components and low-emission manufacturing processes.

Ethical sourcing is another pivotal aspect that influences procurement decisions. Buyers are seeking suppliers who adhere to fair labor practices and demonstrate transparency in their supply chains. This not only helps mitigate risks associated with unethical practices but also enhances brand reputation among environmentally and socially conscious consumers.

Furthermore, certifications such as ISO 14001 for environmental management and LEED for sustainable design can serve as indicators of a supplier’s commitment to sustainability. By aligning purchasing strategies with sustainable practices, B2B buyers can not only reduce their environmental footprint but also appeal to a growing segment of eco-conscious consumers.

What Is the Brief Evolution and History of Golf Cart Motors Relevant to B2B Buyers?

The evolution of golf cart motors has been marked by significant technological advancements since their inception in the mid-20th century. Initially, golf carts were simple, low-speed vehicles powered by lead-acid batteries, primarily used on golf courses. Over the years, the introduction of electric motors revolutionized the sector, offering quieter, more efficient, and environmentally friendly alternatives to gasoline-powered carts.

In the late 1990s and early 2000s, advancements in battery technology, particularly lithium-ion batteries, allowed for longer ranges and faster charging times, further increasing the appeal of electric golf carts. Today, manufacturers are focused on developing high-performance motors that cater to diverse applications, from recreational use to commercial and utility purposes. This historical context is crucial for B2B buyers as it highlights the rapid innovation and adaptability of the sector, enabling them to make informed purchasing decisions aligned with current and future market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of golf cart motor

-

How do I select the right golf cart motor for my needs?

Choosing the right golf cart motor involves assessing your specific use case, whether it’s for recreational, off-road, or utility purposes. Consider factors such as voltage (36V or 48V), horsepower, torque, and maximum speed. Additionally, evaluate the terrain where the cart will be used, as motors designed for hilly areas may require higher torque. It’s also essential to verify compatibility with your golf cart brand, like Club Car, EZGO, or Yamaha. Consulting with suppliers about their product specifications and performance metrics can help ensure you make an informed decision. -

What is the best golf cart motor for high-speed performance?

For high-speed performance, look for motors specifically designed for speed, such as those with higher horsepower ratings (14 HP or more) and optimized torque for acceleration. Brands like Plum Quick and D&D Motor Systems offer motors that are track-tested and designed for high-speed applications. Ensure the motor is compatible with your cart’s voltage system and consider pairing it with a high-performance controller to maximize speed and efficiency. Always check user reviews and performance testimonials to gauge real-world effectiveness. -

What should I consider when vetting suppliers for golf cart motors?

When vetting suppliers, focus on their reputation, experience, and range of products. Look for suppliers with a proven track record in the golf cart industry, ideally with at least 5-10 years of experience. Check for certifications and compliance with international quality standards. Request references or case studies from previous clients, particularly those in your region. Additionally, consider their customer service responsiveness and ability to provide technical support, as these factors can significantly impact your purchasing experience. -

Are there customization options available for golf cart motors?

Yes, many suppliers offer customization options for golf cart motors. Customizations can include adjustments in horsepower, voltage configurations, and specific torque settings tailored to your operational needs. You can also request modifications for unique applications, such as off-road or utility use. It’s advisable to discuss your requirements with potential suppliers early in the procurement process to understand the feasibility, lead times, and any additional costs associated with custom orders. -

What is the minimum order quantity (MOQ) for golf cart motors?

The MOQ for golf cart motors can vary significantly between suppliers. Some may offer motors on a per-unit basis, especially for established clients or those ordering popular models. Others may have a higher MOQ for custom or specialized motors. It’s important to inquire directly with suppliers about their MOQ policies, as well as potential price breaks for larger orders. Understanding these details can help you plan your purchasing strategy and budget accordingly. -

What payment terms should I expect when purchasing golf cart motors internationally?

Payment terms can vary widely based on the supplier and the nature of the transaction. Common practices include payment in advance, a deposit followed by balance upon shipment, or net terms such as net 30 or net 60 days. For international transactions, consider secure payment methods like letters of credit or escrow services to mitigate risk. Always clarify payment terms before finalizing orders and ensure they align with your cash flow management practices. -

How do I ensure quality assurance for golf cart motors?

To ensure quality assurance, request detailed product specifications and certifications from suppliers. Many reputable manufacturers will conduct rigorous testing and provide warranties for their products. Additionally, consider asking for samples or visiting the production facilities if feasible. Establishing clear quality expectations in the contract and having a plan for inspections upon delivery can help mitigate risks associated with product quality and performance. -

What logistics considerations should I keep in mind for international shipping of golf cart motors?

When planning international shipping, consider factors such as shipping costs, lead times, and customs regulations in your country. Work with suppliers who have experience in exporting goods to your region, as they can provide guidance on documentation and compliance. Additionally, consider shipping insurance to protect your investment during transit. Discuss delivery options, including freight forwarding services, to ensure timely and safe arrival of your motors.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Golf Cart Motor Manufacturers & Suppliers List

1. Golf Cart Garage – Golf Cart Motors

Domain: golfcartgarage.com

Registered: 2014 (11 years)

Introduction: Golf Cart Motors for Club Car, EZGO, and Yamaha. Free shipping on most orders over $149.99. Financing available. Family-owned business since 2014. Customer support available Monday-Friday, 9-5 PM ET. Brands include Lester Electrical, Crown Battery, Dakota, Eco Battery, DoubleTake, Trojan Battery, RHOX, MadJax, Steeleng, GTW, Jake’s, Reliance, RedDot, and Navitas. Replacement parts include electric…

2. ShopezGo – Electric Motors

Domain: shopezgo.com

Registered: 2008 (17 years)

Introduction: {“products”:[{“name”:”14.9mph Regenerating Electric Motor”,”sku”:”750439PKG”,”price”:”$1,359.99″},{“name”:”19.9mph Electric Motor”,”sku”:”73124G03″,”price”:”$1,731.99″},{“name”:”48V AC Electric Motor Kit”,”sku”:”671143″,”price”:”$1,046.99″},{“name”:”48V AC Motor Kit”,”sku”:”672531″,”price”:”$1,561.99″},{“name”:”48V DC Electric Motor Kit”,”sku”:”750438PKG”,”price”:”$1,532.99″},{“name”:”48V Electric…

3. D&D Motor Systems – Golf Cart Motors and Controllers

Domain: ddmotorsystems.com

Registered: 2001 (24 years)

Introduction: D&D Motor Systems offers a wide range of golf cart motors and controllers, including both DC and AC options. Key product details include:

– **Motor Types**: Series Motors and Regen Motors

– **Amp Ratings**: 300, 400, 440, 500, 600, and 650 amp controllers available.

– **Popular Models**:

– Series Stock Motor (170-001-0002): 16 MPH, 20% Torque, $580

– Series Speed Motor (170-003-0002): 21…

4. White Lightning Motors – High-Speed Golf Cart Motor Upgrades

Domain: whitelightningmotors.com

Registered: 2020 (5 years)

Introduction: High-Speed Golf Cart Motor Upgrades from White Lightning Motors. Achieve speeds of up to 25+ mph with specialized motor upgrades. Special 2024 Pricing: $300. Free return shipping included. 1-year warranty on all upgraded motors. Additional upgrades available: Heavy duty upgraded 36/48 volt solenoid for $75, Bolt Energy Lithium Batteries, Navitas Controllers, Full AC Kits (contact for prices). Comp…

5. Extreme Kartz – Electric Golf Cart Motors

Domain: extremekartz.com

Registered: 2013 (12 years)

Introduction: This company, Extreme Kartz – Electric Golf Cart Motors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Ezgo – 36v TXT PDS Cart Upgrade

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 36v 1999 Ezgo TXT PDS cart, alltrax 400 amp controller, lithium battery, stock motor speed 13mph on flat ground, seeking motor with more torque and speed without additional modifications.

7. Golf Cart Tire Supply – Performance & Replacement Motors

Domain: golfcarttiresupply.com

Registered: 2014 (11 years)

Introduction: This company, Golf Cart Tire Supply – Performance & Replacement Motors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

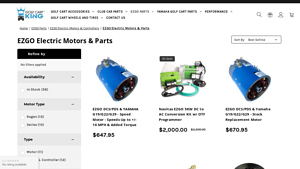

8. Golf Cart King – EZGO Electric Motors & Parts

Domain: golfcartking.com

Registered: 2009 (16 years)

Introduction: EZGO Electric Motors and Parts include Speed Sensors, Couplers, and various components for electric motors. The product range covers EZGO Accelerator Group, Battery Cables, Belts, Body and Trim parts, Brake Group, Carburetors, Clutches, Electric Motors & Controllers, Engines and Parts, Filters, Forward and Reverse Assemblies, Front Suspension parts, Fuel Pumps, Ignition Coils, Mufflers, Rear Axle …

Strategic Sourcing Conclusion and Outlook for golf cart motor

In summary, strategic sourcing of golf cart motors is vital for businesses looking to enhance operational efficiency, improve performance, and achieve cost savings. By leveraging high-quality suppliers, such as those offering specialized motors for various brands like Club Car, EZGO, and Yamaha, buyers can ensure they are investing in reliable and durable products tailored to their specific needs. Furthermore, understanding the nuances of electric versus gas motors, as well as the performance metrics of different models, can significantly influence procurement decisions.

As the demand for golf carts continues to rise in emerging markets across Africa, South America, the Middle East, and Europe, international buyers should focus on building strong relationships with manufacturers and distributors. This approach not only fosters better pricing and service but also ensures access to the latest innovations in motor technology.

Looking ahead, the golf cart motor market is poised for growth, driven by advancements in electric vehicle technology and increasing environmental awareness. B2B buyers are encouraged to stay informed about industry trends and explore partnerships that can lead to sustainable and profitable operations. Embrace the opportunity to enhance your fleet’s performance and reliability—start your sourcing journey today!