Improve Comfort: The Ultimate Guide to Patches for Tens Machine (2025)

Introduction: Navigating the Global Market for patches for tens machine

In today’s competitive landscape, sourcing high-quality patches for TENS machines presents a significant challenge for international B2B buyers. The growing demand for effective pain management solutions has led to an influx of suppliers; however, navigating this crowded market can be daunting, especially when considering factors such as product quality, regulatory compliance, and cost-efficiency. This guide offers a comprehensive overview of the various types of patches available, their applications across different therapeutic contexts, and practical insights on supplier vetting processes.

As B2B buyers from regions like Africa, South America, the Middle East, and Europe (including key markets like Germany and Vietnam), understanding the nuances of sourcing these products is crucial. This guide empowers you to make informed purchasing decisions by providing detailed information on product specifications, supplier credentials, and pricing trends.

Moreover, we delve into essential considerations such as shipping logistics, cultural factors that may influence buyer-supplier relationships, and tips for negotiating favorable terms. By equipping yourself with the right knowledge and resources, you can navigate the global market for patches for TENS machines with confidence, ensuring that your organization remains competitive and responsive to client needs. Embrace the insights within this guide to enhance your procurement strategy and ultimately improve patient outcomes.

Understanding patches for tens machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Electrodes | Basic rectangular shape, conductive gel | General pain relief, physiotherapy | Pros: Cost-effective, widely available. Cons: Limited reusability, less effective on sensitive skin. |

| Self-Adhesive Electrodes | Pre-gelled, easy to apply and remove | Home care, portable TENS devices | Pros: Convenient, user-friendly. Cons: Higher cost per use, may lose adhesion over time. |

| Reusable Electrodes | Designed for multiple uses, durable material | Clinical settings, long-term therapy | Pros: Cost-effective over time, eco-friendly. Cons: Requires cleaning, may irritate skin if not maintained. |

| Specialty Electrodes | Shaped for specific body areas, varying sizes | Targeted treatment for specific conditions | Pros: Enhanced effectiveness, tailored solutions. Cons: Limited availability, higher initial investment. |

| Wireless Electrodes | Bluetooth connectivity, no wires | Sports therapy, advanced pain management | Pros: Increased mobility, user-friendly. Cons: Higher cost, battery-dependent. |

What Are Standard Electrodes and When Should They Be Used?

Standard electrodes are the most common type used with TENS machines. They typically come in a rectangular shape and are coated with a conductive gel that enhances electrical conductivity. These electrodes are ideal for general pain relief applications in physiotherapy and rehabilitation settings. When considering a purchase, B2B buyers should evaluate the volume needed for high-demand environments, as these electrodes are cost-effective but may not be suitable for patients with sensitive skin due to potential irritation.

How Do Self-Adhesive Electrodes Enhance User Experience?

Self-adhesive electrodes come pre-gelled, making them incredibly convenient for users. They are particularly well-suited for home care settings and portable TENS devices. Their ease of use can lead to better patient compliance. B2B buyers should consider the balance between initial costs and user satisfaction, as these electrodes can be more expensive per use compared to standard ones but offer a hassle-free application process.

What Are the Benefits of Reusable Electrodes?

Reusable electrodes are designed for multiple applications, making them a sustainable option for clinical settings focused on long-term therapy. They are typically made from durable materials that can withstand repeated use. B2B buyers should take into account the maintenance requirements, as these electrodes must be cleaned regularly to avoid skin irritation. While they may have a higher upfront cost, their longevity can result in significant savings over time.

Why Choose Specialty Electrodes for Targeted Treatments?

Specialty electrodes are specifically shaped and sized for particular body areas, allowing for targeted treatment of specific conditions. These electrodes can enhance the effectiveness of TENS therapy, making them valuable for specialized medical practices. However, B2B buyers should consider the potential for limited availability and the higher initial investment that may come with these tailored solutions. They are best suited for clinics that frequently address specific pain management needs.

What Advantages Do Wireless Electrodes Offer for Mobility?

Wireless electrodes incorporate Bluetooth technology, eliminating the hassle of wires and enhancing patient mobility. This feature is particularly beneficial in sports therapy and advanced pain management scenarios. While these electrodes provide a modern solution for pain relief, B2B buyers should be aware of the higher costs associated with wireless technology and the dependency on batteries. Evaluating the target market and usage frequency will help in justifying the investment.

Related Video: TENS UNIT for PAIN explained | How and why to use a TENS Machine

Key Industrial Applications of patches for tens machine

| Industry/Sector | Specific Application of patches for tens machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Pain management in physical therapy settings | Enhances patient recovery and satisfaction | Regulatory compliance, quality certifications |

| Sports and Fitness | Muscle recovery and rehabilitation for athletes | Reduces downtime and improves performance | Durability under stress, skin compatibility |

| Elderly Care | Non-invasive pain relief for chronic conditions | Improves quality of life and reduces medication reliance | Ease of use, safety features |

| Veterinary Medicine | Pain relief in animals post-surgery or during rehabilitation | Enhances animal recovery and reduces stress in treatments | Biocompatibility, size variations for different animals |

| Beauty and Wellness | Muscle relaxation and stress relief in spa treatments | Increases customer satisfaction and retention | Aesthetic design, hypoallergenic materials |

How Are Patches for TENS Machines Used in Healthcare?

In healthcare settings, patches for TENS (Transcutaneous Electrical Nerve Stimulation) machines are primarily utilized for pain management, especially in physical therapy. They provide non-invasive pain relief for patients recovering from surgery or managing chronic conditions. This application not only enhances patient recovery rates but also leads to higher satisfaction levels. B2B buyers in this sector should prioritize regulatory compliance and ensure that the patches meet necessary quality certifications to maintain safety and efficacy standards.

What Role Do Patches for TENS Machines Play in Sports and Fitness?

In the sports and fitness industry, TENS machine patches are employed for muscle recovery and rehabilitation. Athletes can utilize these patches to alleviate muscle soreness and expedite the healing process after intense workouts or injuries. This application significantly reduces downtime for athletes, allowing them to return to their training regimens more quickly. Buyers in this sector should focus on sourcing patches that demonstrate durability under physical stress and compatibility with various skin types to ensure optimal performance during use.

How Are Patches for TENS Machines Beneficial in Elderly Care?

For elderly care, patches for TENS machines offer a non-invasive solution for chronic pain relief, addressing common issues such as arthritis and neuropathy. This application not only enhances the quality of life for elderly individuals but also reduces their reliance on medications, which can often have adverse side effects. B2B buyers in this field must consider the ease of use and safety features of the patches, ensuring they are user-friendly for caregivers and patients alike.

What Are the Applications of Patches for TENS Machines in Veterinary Medicine?

In veterinary medicine, patches for TENS machines are used to provide pain relief to animals post-surgery or during rehabilitation. This application is crucial for enhancing recovery times and minimizing stress during treatment, ultimately leading to better outcomes for animal patients. B2B buyers in this sector should pay close attention to biocompatibility and the availability of size variations to cater to different animal species, ensuring effective and safe application.

How Can Patches for TENS Machines Enhance Services in Beauty and Wellness?

Within the beauty and wellness industry, patches for TENS machines are increasingly being integrated into spa treatments for muscle relaxation and stress relief. This application not only enhances the overall experience for clients but also contributes to higher customer satisfaction and retention rates. When sourcing these patches, businesses should consider aesthetic design and hypoallergenic materials to cater to a diverse clientele, ensuring that the products align with the wellness philosophy of their services.

3 Common User Pain Points for ‘patches for tens machine’ & Their Solutions

Scenario 1: Sourcing High-Quality Patches for TENS Machines

The Problem:

B2B buyers often struggle with sourcing high-quality patches for TENS machines that meet both safety standards and performance requirements. In regions like Africa and South America, where regulatory standards can vary significantly, ensuring that the patches are compliant with local health regulations is crucial. Additionally, buyers may face challenges in verifying the quality of products from suppliers, leading to concerns about durability and efficacy. This can result in increased costs due to returns, replacements, or potential liability issues if the patches fail to perform.

The Solution:

To navigate the complexities of sourcing, buyers should prioritize establishing relationships with reputable manufacturers who have a proven track record in the industry. Conduct thorough research on suppliers, looking for certifications such as ISO 13485, which indicates compliance with quality management systems for medical devices. Engage in due diligence by requesting samples and conducting performance tests to assess the patches’ durability and effectiveness. Furthermore, leverage technology by utilizing platforms that connect buyers with certified manufacturers, ensuring transparency in the supply chain. This proactive approach not only mitigates risks but also fosters long-term partnerships with reliable suppliers.

Scenario 2: Compatibility Issues with TENS Machines

The Problem:

Compatibility issues between patches and TENS machines can be a significant pain point for buyers. Different brands and models of TENS machines often have varying specifications, which can lead to mismatches with the patches purchased. This not only wastes time and resources but also frustrates end-users who rely on these machines for pain management. In regions where medical supplies are difficult to access, this issue can exacerbate the problem, leading to increased downtime for patients in need.

The Solution:

To avoid compatibility issues, buyers should conduct thorough research on the specifications of both TENS machines and patches before making a purchase. This includes understanding the electrode size, type of adhesive used, and the electrical characteristics of the patches. Establishing a clear communication channel with suppliers to clarify these specifications can prevent potential mismatches. Additionally, consider opting for universal patches that are designed to be compatible with multiple TENS machine models. This not only reduces inventory complexity but also ensures that end-users have a reliable product that meets their needs.

Scenario 3: Managing Cost and Inventory of TENS Machine Patches

The Problem:

Managing the costs and inventory of patches for TENS machines can be a daunting task for B2B buyers, especially in markets where margins are tight. Fluctuating prices and unexpected demand spikes can lead to stock shortages or excess inventory, both of which can negatively impact the bottom line. Buyers in the Middle East and Europe, where competition is fierce, must find ways to optimize their inventory management while keeping costs manageable.

The Solution:

Implementing a just-in-time (JIT) inventory system can significantly improve cost management and inventory efficiency. By closely monitoring usage patterns and demand forecasts, buyers can order patches in smaller, more frequent batches, reducing the risk of overstocking. Collaborating with suppliers who offer flexible order quantities and quick turnaround times can further enhance this approach. Additionally, consider utilizing inventory management software that provides real-time data on stock levels and alerts for reorder points. This proactive strategy not only helps manage costs but also ensures that businesses can respond swiftly to market demands without compromising on quality or availability.

Strategic Material Selection Guide for patches for tens machine

When selecting materials for patches used in TENS (Transcutaneous Electrical Nerve Stimulation) machines, it is crucial to consider various factors that directly impact performance, usability, and compliance with international standards. Below is an analysis of four common materials used in the production of TENS machine patches, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

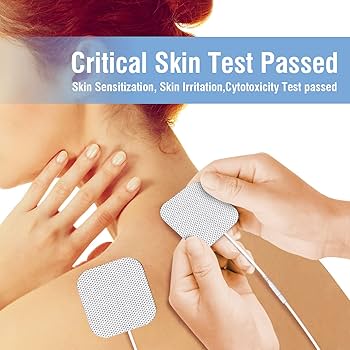

A stock image related to patches for tens machine.

What Are the Key Properties of Silicone for TENS Machine Patches?

Silicone is a popular choice for TENS machine patches due to its excellent biocompatibility and flexibility. It can withstand a wide range of temperatures, making it suitable for various applications. Silicone is also resistant to moisture and has good electrical insulation properties, which is essential for TENS applications.

Pros & Cons:

Silicone patches are durable and can be reused multiple times, which can be cost-effective in the long run. However, they may have a higher initial cost compared to other materials. Manufacturing complexity can also be a concern, as silicone requires specialized processes.

Impact on Application:

Silicone is compatible with various skin types and is less likely to cause irritation, making it ideal for long-term wear.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure that silicone patches comply with relevant standards such as ISO 10993 for biocompatibility. In Africa and South America, understanding local regulations regarding medical devices is crucial.

How Does Conductive Foam Compare as a Material for TENS Machine Patches?

Conductive foam is another common material used for TENS machine patches, primarily due to its excellent conductivity and comfort. It typically has a lower temperature rating than silicone but offers good pressure resistance.

Pros & Cons:

Conductive foam is relatively inexpensive and easy to manufacture, making it a popular choice for high-volume production. However, its durability may be lower than silicone, and it may not be suitable for prolonged use due to potential skin irritation.

Impact on Application:

This material is particularly effective for short-term applications where high conductivity is required, but it may not be ideal for long-term wear.

Considerations for International Buyers:

Buyers should check for compliance with ASTM standards, especially in North America and Europe, to ensure product safety and performance.

Why Is Polyurethane a Viable Option for TENS Machine Patches?

Polyurethane is known for its versatility and durability, making it a viable option for TENS machine patches. It has a good balance of flexibility and strength, with a moderate temperature rating.

Pros & Cons:

Polyurethane patches are durable and can withstand repeated use, but they may be more expensive than conductive foam. The manufacturing process can also be complex, requiring specific techniques to ensure quality.

Impact on Application:

Polyurethane is compatible with a variety of media, making it suitable for diverse applications within TENS therapy.

Considerations for International Buyers:

Compliance with JIS standards is particularly important for buyers in Japan and other Asian markets, while European buyers should consider EN standards related to medical devices.

What Are the Benefits of Using Hydrogel in TENS Machine Patches?

Hydrogel is increasingly used in TENS machine patches due to its excellent moisture retention properties, which enhance comfort during use. It is soft and conforms well to the skin, making it suitable for sensitive users.

Pros & Cons:

Hydrogel patches provide excellent skin adhesion and comfort, but they may have a shorter lifespan than silicone or polyurethane. They can also be more expensive due to their specialized manufacturing processes.

Impact on Application:

Hydrogel is particularly effective for patients requiring prolonged use, as it minimizes skin irritation.

Considerations for International Buyers:

For buyers in Africa and South America, understanding local regulations regarding hydrogel products is essential, as these can vary significantly by region.

Summary Table of Material Selection for TENS Machine Patches

| Material | Typical Use Case for patches for tens machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone | Long-term use patches for sensitive skin | Excellent biocompatibility | Higher initial cost | High |

| Conductive Foam | Short-term use patches for quick relief | Cost-effective and easy to produce | Lower durability | Low |

| Polyurethane | Versatile applications in TENS therapy | Durable and flexible | More complex manufacturing | Medium |

| Hydrogel | Prolonged use patches for sensitive patients | High comfort and skin adhesion | Shorter lifespan | High |

In summary, selecting the right material for TENS machine patches involves balancing performance, cost, and compliance with international standards. Each material offers unique benefits and limitations, making it essential for buyers to consider their specific application needs and regional regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for patches for tens machine

What Are the Main Stages of Manufacturing Patches for TENS Machines?

The manufacturing process for patches used in Transcutaneous Electrical Nerve Stimulation (TENS) machines involves several critical stages: material preparation, forming, assembly, and finishing. Each stage requires meticulous attention to detail to ensure the final product meets quality standards and performs effectively.

-

Material Preparation

The initial step involves selecting appropriate materials, which typically include conductive hydrogels, non-woven fabrics, and adhesive layers. These materials are sourced based on their biocompatibility, conductivity, and durability. Suppliers must conduct thorough inspections to ensure that materials meet both international and industry-specific standards. For international B2B buyers, verifying the quality of raw materials is crucial, as this can significantly affect the efficacy and safety of the patches. -

Forming

In this stage, the prepared materials are cut and shaped into the desired patch form. Advanced techniques such as die cutting or laser cutting are commonly employed to achieve precision and consistency. The forming process must also consider the ergonomics of the patches, ensuring they can comfortably adhere to the skin without causing irritation. Buyers should inquire about the machinery and technology used in this phase, as high-quality equipment often results in superior product quality. -

Assembly

Following the forming stage, the patches undergo assembly, where various components are combined. This may include layering the conductive hydrogel with the adhesive and protective backing. Automated assembly lines are often utilized to enhance efficiency and consistency. B2B buyers should assess whether the manufacturer employs automated systems, as this can reduce human error and increase production capacity. -

Finishing

The final stage includes quality checks, packaging, and labeling. Patches are inspected for defects, and any that do not meet quality standards are discarded. Proper packaging is essential to maintain the sterility and integrity of the patches during storage and transportation. Buyers should look for suppliers who implement a robust finishing process to ensure product reliability.

How Is Quality Assurance Implemented in the Manufacturing of TENS Machine Patches?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for TENS machine patches, ensuring that each product complies with relevant international standards and performs as intended.

-

What Are Relevant International Standards for TENS Machine Patches?

Compliance with international standards such as ISO 9001 is essential for manufacturers. ISO 9001 outlines requirements for a quality management system (QMS) that helps organizations ensure consistent quality in their products and services. Additionally, industry-specific standards like CE marking in Europe and API standards in the pharmaceutical industry may apply, depending on the materials used in the patches. Buyers should verify that their suppliers hold relevant certifications and maintain compliance with these standards. -

What Are the Key Quality Control Checkpoints?

Effective quality control (QC) involves several checkpoints throughout the manufacturing process, including Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

– IQC involves checking raw materials upon receipt to ensure they meet specifications.

– IPQC monitors the production process to identify defects early, allowing for immediate corrective actions.

– FQC occurs after the final assembly, where patches are thoroughly tested for functionality and safety. -

What Common Testing Methods Are Used for TENS Machine Patches?

Testing methods may include electrical conductivity tests, adhesion tests, and biocompatibility assessments. These tests ensure that the patches can effectively deliver electrical impulses and remain securely attached during use. Buyers should inquire about the specific testing protocols employed by manufacturers to ensure their products meet safety and performance standards.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial for ensuring product reliability and compliance.

-

Conducting Supplier Audits

Regular audits of suppliers can help buyers assess the quality management systems in place. During an audit, buyers can review documentation related to quality control processes, production practices, and compliance with international standards. This proactive approach allows buyers to identify potential risks and ensure that suppliers adhere to best practices. -

Requesting Quality Reports

Suppliers should provide comprehensive quality reports, detailing the results of quality tests and inspections conducted throughout the manufacturing process. These reports serve as an official record of compliance and can help buyers make informed decisions about supplier reliability. -

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These services can conduct inspections at various stages of production, ensuring that the patches meet specified standards before they are shipped. This is particularly valuable for buyers who may lack the resources to perform their own inspections.

What Nuances Should International B2B Buyers Be Aware of Regarding Quality Control Certifications?

Navigating quality control certifications can be complex for international B2B buyers. Different regions may have varying requirements and expectations for compliance, which can impact the purchasing process.

-

Regional Differences in Standards

Buyers in Europe may prioritize CE marking, while those in Africa and South America may focus on local regulatory requirements. Understanding these nuances is essential for ensuring that products are compliant in the target market. Buyers should work closely with suppliers to clarify which certifications are necessary for their specific region. -

Evolving Standards and Regulations

Quality standards and regulations are subject to change, and staying informed about these updates is vital for B2B buyers. Regularly reviewing industry publications and engaging with trade organizations can help buyers remain compliant and avoid potential disruptions in their supply chains. -

Documentation and Traceability

Ensuring proper documentation and traceability of materials and processes is critical for quality assurance. Buyers should require suppliers to maintain detailed records that demonstrate compliance with quality standards. This documentation is particularly important in case of product recalls or safety concerns.

By understanding the manufacturing processes and quality assurance protocols for TENS machine patches, international B2B buyers can make informed decisions that enhance their supply chain effectiveness and ensure product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘patches for tens machine’

This guide serves as a practical checklist for B2B buyers looking to source patches for TENS machines. As these devices play a crucial role in pain management, the quality of the patches is paramount. This checklist will help streamline the procurement process, ensuring that you make informed decisions that meet your organization’s needs and standards.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly outline your technical specifications. This includes understanding the size, shape, and material of the patches you require. Additionally, consider the compatibility of the patches with various TENS machines, as some may have unique requirements.

– Key Considerations:

– Adhesive strength

– Skin compatibility and hypoallergenic properties

– Longevity and durability of the patches

Step 2: Research Market Trends for TENS Machine Patches

Understanding current market trends is vital for making informed purchasing decisions. Investigate emerging technologies, new materials, and competitive pricing strategies in the patches market. This knowledge can help you identify innovative suppliers who offer superior products.

– Where to Look:

– Industry reports

– Trade publications

– Online forums and industry groups

Step 3: Identify and Evaluate Potential Suppliers

Once you have a clear understanding of your needs, begin identifying potential suppliers. Evaluate their capabilities by reviewing company profiles, product catalogs, and customer testimonials. This step is crucial to ensure the reliability and quality of your future supply chain.

– What to Assess:

– Years in business and industry experience

– Product certification and compliance with international standards

– Customer service and support capabilities

Step 4: Request Samples for Quality Assessment

Before finalizing any deals, it is prudent to request samples from shortlisted suppliers. Testing these samples allows you to evaluate the quality and performance of the patches firsthand. This step can prevent costly mistakes and ensure that the products meet your organization’s standards.

– Testing Parameters:

– Adhesion properties

– Comfort and user experience

– Performance under various conditions

Step 5: Verify Supplier Certifications and Compliance

Ensure that the suppliers you consider are compliant with relevant industry standards and regulations. Certifications such as ISO, CE, and FDA approval can indicate that the supplier meets high-quality manufacturing practices. Verification of these certifications can safeguard your company against legal and operational risks.

– Checklist for Verification:

– Request copies of certifications

– Confirm validity through official channels

– Investigate any past compliance issues

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, the next step is to negotiate terms and conditions. Discuss pricing, payment terms, delivery schedules, and return policies to ensure that both parties have a clear understanding of the agreement. Strong negotiations can lead to better pricing and improved service levels.

– Key Points to Negotiate:

– Minimum order quantities

– Lead times for production and delivery

– Warranty and after-sales support

Step 7: Establish a Long-term Relationship with Suppliers

Building a long-term relationship with your chosen supplier can lead to better collaboration and more favorable terms in the future. Regular communication and feedback can enhance the partnership and encourage the supplier to prioritize your orders and needs.

– Relationship-Building Strategies:

– Regular check-ins and performance reviews

– Joint product development initiatives

– Participation in supplier training and workshops

By following these steps, international B2B buyers can navigate the procurement process for patches for TENS machines effectively, ensuring they source high-quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for patches for tens machine Sourcing

What Are the Key Cost Components for Patches for TENS Machines?

When sourcing patches for TENS machines, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality adhesive, conductive gel, and fabric are often more expensive but can enhance the efficacy and durability of the patches. Buyers should evaluate the trade-off between cost and performance.

-

Labor: Labor costs can vary widely depending on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but it’s essential to consider the potential impact on quality and compliance with international standards.

-

Manufacturing Overhead: This includes expenses related to production facilities, utilities, and equipment maintenance. A well-optimized manufacturing process can reduce overhead costs, benefiting the final pricing.

-

Tooling: Customization often requires specialized tooling, which can increase upfront costs. However, investing in the right tooling can lead to long-term savings through enhanced production efficiency.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes is vital. While it adds to the cost, it can prevent expensive returns and enhance customer satisfaction.

-

Logistics: Shipping and handling expenses should not be overlooked. Factors like distance, shipping method, and customs duties can substantially affect the total cost.

-

Margin: Suppliers will add their profit margin to the total cost. Understanding the typical margins in the industry can help buyers negotiate better deals.

How Do Price Influencers Affect the Sourcing of TENS Machine Patches?

Several factors can influence the pricing of patches for TENS machines:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for larger orders. Buyers should assess their needs and negotiate terms that align with their purchasing strategy.

-

Specifications and Customization: Custom designs or specifications can lead to higher costs. Buyers should clarify their requirements early in the negotiation process to avoid unexpected charges.

-

Materials: The choice of materials not only affects the performance but also the price. Opting for standard materials can reduce costs, while premium options may offer better features.

-

Quality and Certifications: Certifications for medical devices can add to costs but are essential for compliance in many regions. Buyers should consider whether the additional expense is justified by market requirements.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can influence pricing. Engaging with reputable suppliers who have a track record of quality can mitigate risks.

-

Incoterms: Understanding Incoterms is vital for international shipping. They define the responsibilities of buyers and sellers, impacting overall costs. For example, choosing FOB (Free on Board) can shift some logistics costs to the buyer.

What Tips Can Help International B2B Buyers Optimize Costs?

To achieve cost efficiency when sourcing patches for TENS machines, consider the following tips:

-

Negotiate Effectively: Leverage your purchasing power by negotiating terms, especially for larger orders. Ensure that discussions include all cost components, not just the unit price.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the purchase price. This includes shipping, customs, and potential future costs related to returns or quality issues.

-

Understand Pricing Nuances for Different Regions: Pricing can vary significantly across Africa, South America, the Middle East, and Europe. Familiarize yourself with regional market dynamics to make informed decisions.

-

Stay Updated on Market Trends: Keep abreast of market trends and fluctuations in material costs. This can help you time your purchases to maximize cost savings.

-

Build Long-term Relationships with Suppliers: Establishing strong relationships with suppliers can lead to better pricing, priority service, and access to new products.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and engage in detailed discussions with suppliers to obtain accurate pricing information.

Alternatives Analysis: Comparing patches for tens machine With Other Solutions

Understanding Alternatives to Patches for TENS Machines

When considering the procurement of pain management solutions, B2B buyers must evaluate various options available in the market. Patches for TENS (Transcutaneous Electrical Nerve Stimulation) machines are popular for their ease of use and effectiveness. However, exploring alternative solutions can provide buyers with a broader perspective on functionality, cost, and application. This analysis will compare patches for TENS machines with two viable alternatives: TENS units with lead wires and acupuncture as a pain management method.

Comparison Table of Pain Management Solutions

| Comparison Aspect | Patches For TENS Machine | TENS Units with Lead Wires | Acupuncture |

|---|---|---|---|

| Performance | High | Very High | High |

| Cost | Moderate | Low to Moderate | Moderate to High |

| Ease of Implementation | Very Easy | Moderate | Complex |

| Maintenance | Low | Moderate | High |

| Best Use Case | Home Use | Clinical and Home Use | Chronic Pain Management |

What Are the Pros and Cons of TENS Units with Lead Wires?

TENS units with lead wires offer a robust alternative to patches for TENS machines. Their performance is often rated as very high due to the ability to deliver stronger electrical impulses, which can be more effective for certain types of pain relief. Cost-wise, these units can be less expensive over time as they are reusable and come with multiple applications. However, they require moderate maintenance and setup, which can be a drawback for users seeking convenience. The lead wires can also limit mobility, making them less ideal for on-the-go pain management.

How Does Acupuncture Compare as a Pain Management Method?

Acupuncture is a well-established alternative method for pain management, particularly in chronic cases. Its efficacy is high, with many users reporting significant relief from various pain conditions. The costs can vary widely, depending on the practitioner and location, but they can be moderate to high, especially with multiple sessions required. Acupuncture requires skilled practitioners, making the implementation process complex, and it also involves a higher maintenance level in terms of scheduling and follow-ups. While it may not be suitable for acute pain relief, it excels in managing chronic conditions, making it a preferred choice for long-term pain management strategies.

How to Choose the Right Solution for Your Needs?

Selecting the right pain management solution is crucial for B2B buyers looking to meet the needs of their clients effectively. Factors such as performance, cost, ease of implementation, and maintenance should be carefully weighed against the specific use cases of each solution. For instance, if your target market prioritizes convenience and ease of use, patches for TENS machines may be the best choice. Conversely, if your clients are seeking more robust treatment options and are willing to invest time and resources, TENS units with lead wires or acupuncture could provide superior results. Ultimately, understanding the unique needs of your clientele will guide you in making an informed decision that enhances your product offerings and satisfies your customers.

Essential Technical Properties and Trade Terminology for patches for tens machine

What Are the Key Technical Properties of Patches for TENS Machines?

When sourcing patches for TENS (Transcutaneous Electrical Nerve Stimulation) machines, understanding their technical properties is essential for ensuring compatibility, performance, and user satisfaction. Here are some critical specifications to consider:

1. Material Grade

The material used in TENS machine patches typically includes conductive materials such as carbon or silver, along with a hypoallergenic adhesive. The grade of these materials directly affects conductivity and skin compatibility. For B2B buyers, selecting high-grade materials minimizes the risk of skin irritation and enhances the overall effectiveness of the TENS therapy.

2. Conductivity

Conductivity is a measure of how well a material can conduct electrical currents. For TENS patches, higher conductivity ensures that electrical impulses are transmitted effectively to the skin. This property is crucial for achieving optimal pain relief. Buyers should look for patches with specified conductivity levels to ensure they meet therapeutic standards.

3. Adhesive Strength

Adhesive strength refers to the ability of the patch to stick to the skin during use. Strong yet gentle adhesives are vital to ensure the patch remains in place without causing skin damage upon removal. B2B buyers should inquire about peel strength values to ensure that the patches can withstand various activities while providing comfort to the user.

4. Tolerance

Tolerance in manufacturing refers to the allowable variation in dimensions and performance characteristics. For TENS patches, precise tolerances ensure that the patches fit snugly on the electrodes and that electrical impulses are delivered consistently. Buyers should look for manufacturers that maintain strict quality control to guarantee that the products meet specified tolerances.

5. Shelf Life

Shelf life is the duration that a product can be stored without losing its effectiveness. For TENS patches, this property affects inventory management and overall cost efficiency. B2B buyers should consider the shelf life when negotiating contracts, as longer-lasting products can reduce waste and ensure that inventory remains usable.

What Trade Terminology Should B2B Buyers Understand?

Understanding trade terminology is crucial for successful negotiations and purchasing decisions in the B2B landscape. Here are some common terms related to patches for TENS machines:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of TENS patches, sourcing from an OEM can provide access to high-quality, customized products designed specifically for your brand. This is particularly important for businesses seeking to maintain brand integrity and quality standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers, as it affects cash flow and inventory management. Buyers should negotiate MOQs based on their anticipated demand to optimize purchasing costs and reduce excess inventory.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. For patches for TENS machines, submitting an RFQ helps buyers compare multiple suppliers’ offers and negotiate better pricing and terms. This process is vital for ensuring that you get the best deal available in the market.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers. Understanding these terms is crucial for B2B transactions, especially when dealing with international suppliers. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight), which dictate who bears shipping costs and risks during transit.

By familiarizing yourself with these technical properties and trade terminologies, you can make informed purchasing decisions that align with your business objectives in the competitive market of TENS machine patches.

Navigating Market Dynamics and Sourcing Trends in the patches for tens machine Sector

What Are the Key Market Dynamics in the Patches for TENS Machine Sector?

A stock image related to patches for tens machine.

The patches for TENS (Transcutaneous Electrical Nerve Stimulation) machines sector is experiencing significant growth due to increasing awareness of pain management solutions and a rise in chronic pain conditions globally. Key drivers include an aging population, rising disposable incomes, and advancements in technology that enhance the efficacy and usability of TENS devices. Particularly in regions like Africa and South America, there is a growing demand for affordable and effective pain relief options, propelling market expansion.

A stock image related to patches for tens machine.

Emerging B2B tech trends are centered around digital health solutions, with a notable shift towards telemedicine and remote patient monitoring. This trend is particularly relevant for international buyers, as it presents opportunities to source innovative patches that integrate seamlessly with digital platforms. Additionally, the increasing adoption of e-commerce in Europe and the Middle East is reshaping sourcing strategies, allowing buyers to access a wider array of products and suppliers with greater efficiency.

Furthermore, competition is intensifying as more manufacturers enter the market, prompting buyers to prioritize quality, compliance with international standards, and reliable supply chains. Understanding these dynamics is crucial for international B2B buyers to negotiate better terms and make informed decisions when sourcing patches for TENS machines.

How Is Sustainability Influencing B2B Sourcing in the Patches for TENS Machine Sector?

Sustainability is becoming a pivotal factor in B2B sourcing within the patches for TENS machine sector. As environmental concerns rise globally, companies are increasingly held accountable for their supply chain practices. Buyers from Africa, South America, the Middle East, and Europe must consider the environmental impact of their sourcing choices, including the lifecycle of materials used in patches.

Ethical sourcing practices are gaining traction, with an emphasis on transparency and social responsibility. This means that international buyers should prioritize suppliers who demonstrate commitment to ethical labor practices and sustainable production methods. Certifications such as ISO 14001 for environmental management and OEKO-TEX for textile safety can serve as benchmarks for assessing potential suppliers.

Moreover, the demand for “green” materials—such as biodegradable or recyclable options—is on the rise. By sourcing eco-friendly patches, buyers not only meet regulatory requirements but also align with consumer preferences for sustainable products. This strategic focus on sustainability can enhance brand reputation and customer loyalty, making it a vital aspect of sourcing strategies in the patches for TENS machine sector.

How Have Patches for TENS Machines Evolved Over Time?

The evolution of patches for TENS machines reflects broader advancements in medical technology and consumer healthcare. Initially, TENS machines were bulky and limited in application, but the introduction of more sophisticated patches has transformed the user experience. Over the years, materials have improved, leading to better adhesion, comfort, and effectiveness.

The integration of smart technology into TENS patches is a recent development, allowing users to monitor their pain management more effectively through mobile applications. This evolution not only enhances treatment efficacy but also opens new avenues for international B2B buyers to explore cutting-edge products that meet modern healthcare needs.

As the market continues to evolve, understanding these historical trends will help buyers anticipate future developments and make strategic sourcing decisions that align with both current demands and future innovations in the patches for TENS machine sector.

Frequently Asked Questions (FAQs) for B2B Buyers of patches for tens machine

-

How do I choose the right patches for a TENS machine?

Selecting the appropriate patches for a TENS machine involves considering several factors such as size, material, and compatibility with your specific device. Look for patches that are hypoallergenic to minimize skin irritation, especially for patients with sensitive skin. Additionally, ensure the patches are designed for the intended therapeutic applications, whether pain relief or muscle stimulation. Always request samples from potential suppliers to evaluate quality and performance before making a bulk purchase. -

What are the key features to look for in TENS machine patches?

When sourcing TENS machine patches, prioritize features like conductivity, adhesion, and durability. High-quality conductive materials enhance the effectiveness of electrical stimulation, while strong adhesive properties ensure the patches stay in place during use. Additionally, consider the lifespan of the patches; some are reusable while others are single-use. Understanding these features will help you select patches that provide optimal performance and value for your customers. -

What is the minimum order quantity (MOQ) for TENS machine patches?

Minimum order quantities for TENS machine patches can vary significantly among suppliers, often ranging from 100 to 1,000 units. Factors influencing MOQ include the type of patch, customization options, and supplier policies. For international buyers, negotiating MOQs can be beneficial, especially if you are a small business or new to the market. Always clarify MOQs early in your discussions to avoid unexpected costs and ensure you can meet demand. -

What payment terms should I expect when sourcing TENS machine patches internationally?

Payment terms for international purchases of TENS machine patches typically include options like advance payment, letter of credit, or net terms (e.g., 30/60/90 days). It’s essential to discuss payment terms upfront with suppliers to ensure they align with your cash flow requirements. Consider using secure payment methods, such as PayPal or escrow services, to protect your transaction. Furthermore, establishing a good relationship with your supplier can lead to more favorable payment terms over time. -

How can I verify the quality of TENS machine patches from suppliers?

To ensure the quality of TENS machine patches, request certifications and compliance documents such as ISO 13485 or CE marking, which indicate adherence to international quality standards. Additionally, conduct thorough supplier audits and assess their production processes. You may also consider third-party quality assurance services to inspect samples before bulk orders. Building a relationship with trusted suppliers who prioritize quality control will enhance your confidence in your purchases. -

What logistics considerations should I keep in mind when importing TENS machine patches?

Logistics play a crucial role in importing TENS machine patches. Be aware of shipping methods, costs, and delivery timelines, as these can vary greatly by supplier and origin. Additionally, familiarize yourself with customs regulations in your destination country to avoid delays and unexpected fees. Working with a reliable freight forwarder can streamline the import process, ensuring timely and efficient delivery of your products. -

Can I customize TENS machine patches for my brand?

Yes, many suppliers offer customization options for TENS machine patches, allowing you to create products that align with your brand identity. Customization may include branding, specific sizes, shapes, or unique features tailored to your market’s needs. When discussing customization, provide clear specifications and be open to supplier suggestions to achieve the best outcome. Keep in mind that customized patches may have higher MOQs and longer lead times. -

What should I know about regulatory compliance for TENS machine patches in different regions?

Regulatory compliance for TENS machine patches varies by region, with specific requirements in Africa, South America, the Middle East, and Europe. In Europe, for example, patches must comply with the Medical Device Regulation (MDR) and often require CE marking. In the Middle East and Africa, regulations can be less stringent but still vary by country. It’s crucial to research and understand the regulations that apply to your target markets and ensure that your suppliers are compliant to avoid legal complications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for patches for tens machine

In the rapidly evolving landscape of TENS machine patches, strategic sourcing remains a pivotal approach for international B2B buyers. By prioritizing quality, supplier reliability, and cost-effectiveness, businesses can enhance their competitive edge in markets across Africa, South America, the Middle East, and Europe. Understanding local regulations, consumer preferences, and supply chain dynamics is crucial for making informed procurement decisions that align with regional demands.

What are the benefits of strategic sourcing for patches for TENS machines? This approach not only ensures a consistent supply of high-quality products but also fosters long-term partnerships with manufacturers who understand the intricacies of the healthcare sector. Engaging with suppliers who are committed to innovation and sustainability can further enhance product offerings and customer satisfaction.

Looking forward, the demand for TENS machine patches is expected to grow, driven by an increasing awareness of non-invasive pain management solutions. International B2B buyers are encouraged to leverage this opportunity by exploring diverse supplier markets, investing in technological advancements, and aligning sourcing strategies with global health trends. Embrace the future of sourcing today, and position your business to thrive in this dynamic sector.