Improve Indoor Air Quality: The Treated Fresh Air Guide (2025)

Introduction: Navigating the Global Market for treated fresh air

In an increasingly interconnected world, sourcing treated fresh air solutions presents a unique challenge for international B2B buyers. Whether you are in the bustling markets of Africa, the diverse economies of South America, the rapidly developing sectors in the Middle East, or the industrial hubs of Europe, the demand for clean, conditioned air is paramount. This guide is designed to address your needs by providing a comprehensive overview of treated fresh air options, from various types and applications to effective supplier vetting and cost considerations.

Understanding the nuances of treated fresh air systems can significantly impact operational efficiency, employee health, and regulatory compliance. Throughout this guide, we will delve into the different types of systems available, their applications across various industries, and how to navigate the complexities of the global supply chain. Additionally, we will offer insights into the best practices for evaluating suppliers, ensuring you partner with reputable manufacturers who meet international standards.

By leveraging this guide, B2B buyers will be empowered to make informed purchasing decisions that not only enhance air quality but also align with budgetary constraints and sustainability goals. Whether you are seeking solutions for commercial spaces, industrial facilities, or residential projects, our aim is to equip you with the knowledge necessary to thrive in the global market for treated fresh air.

Understanding treated fresh air Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Heat Recovery Ventilation | Utilizes heat exchangers to recover energy from exhaust air | Commercial buildings, manufacturing | Pros: Energy-efficient, reduces heating costs. Cons: Higher initial investment. |

| Desiccant Dehumidification | Employs desiccant materials to remove moisture | Food processing, pharmaceuticals | Pros: Effective moisture control, improves product quality. Cons: Requires regular maintenance. |

| Active Chilled Beams | Integrates cooling and ventilation in a single system | Office buildings, hospitals | Pros: Space-saving, enhances comfort. Cons: Complex installation, may require specific HVAC conditions. |

| Ultraviolet (UV) Air Treatment | Uses UV light to eliminate pathogens and pollutants | Healthcare facilities, schools | Pros: Improves air quality, reduces health risks. Cons: Limited effectiveness against certain chemicals. |

| Variable Air Volume (VAV) | Adjusts airflow based on occupancy and demand | Retail spaces, auditoriums | Pros: Energy-efficient, customizable. Cons: May lead to inconsistent temperature control. |

What is Heat Recovery Ventilation and When Should B2B Buyers Consider It?

Heat Recovery Ventilation (HRV) systems are designed to capture and reuse energy from exhaust air, making them an excellent choice for commercial buildings and manufacturing facilities. These systems are particularly suitable for environments that require a consistent indoor climate while minimizing energy costs. B2B buyers should consider HRV when evaluating energy efficiency goals, as the initial investment can be offset by significant savings on heating bills over time.

How Does Desiccant Dehumidification Benefit B2B Industries?

Desiccant dehumidification systems use specialized materials to absorb moisture from the air, making them ideal for industries like food processing and pharmaceuticals, where humidity control is critical. These systems enhance product quality by preventing spoilage and maintaining stability in sensitive environments. B2B buyers should keep in mind the importance of regular maintenance, as the desiccant materials require periodic replacement to ensure optimal performance.

Why Choose Active Chilled Beams for Your B2B Facilities?

Active Chilled Beams are an innovative solution that combines cooling and ventilation, making them particularly effective in office buildings and hospitals where space is at a premium. They provide a comfortable indoor environment while being energy efficient. However, B2B buyers should be aware of the complexity involved in the installation of these systems, as they often require specific HVAC configurations to function correctly.

What Advantages Do Ultraviolet Air Treatment Systems Offer?

Ultraviolet (UV) Air Treatment systems are specifically designed to eliminate airborne pathogens and pollutants, making them essential in healthcare facilities and schools. These systems significantly improve indoor air quality and reduce health risks associated with airborne diseases. However, B2B buyers should consider that while UV systems are effective, they may not address all chemical pollutants, necessitating a comprehensive approach to air treatment.

How Can Variable Air Volume Systems Enhance Energy Efficiency?

Variable Air Volume (VAV) systems adjust the airflow based on real-time occupancy and demand, making them suitable for retail spaces and auditoriums. They offer significant energy savings by optimizing the amount of conditioned air supplied, which can lead to lower operational costs. However, B2B buyers should be cautious of potential temperature inconsistencies that may arise if the system is not properly calibrated.

Related Video: Difference between Treated Fresh air unit and Air handling IN HVAC System | unit AHU vs TFA

Key Industrial Applications of treated fresh air

| Industry/Sector | Specific Application of Treated Fresh Air | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Ventilation in production facilities | Improves worker safety and productivity, reduces equipment wear | Compliance with local air quality regulations, energy efficiency |

| Food Processing | Controlled environment for food storage | Extends shelf life, maintains product quality | Temperature control systems, humidity management |

| Pharmaceuticals | Cleanroom air supply for drug manufacturing | Ensures product integrity and compliance with health standards | HEPA filtration systems, monitoring and control systems |

| Data Centers | Climate control for server rooms | Prevents overheating, enhances equipment lifespan | Energy-efficient cooling systems, redundancy in air supply |

| Healthcare | Air purification in hospitals and clinics | Reduces infection rates, enhances patient comfort | Compliance with health regulations, ease of maintenance |

How is Treated Fresh Air Used in Manufacturing?

In the manufacturing sector, treated fresh air is essential for maintaining optimal ventilation in production facilities. By ensuring a steady flow of clean air, businesses can significantly improve worker safety and productivity while reducing equipment wear due to contaminants. International buyers should prioritize sourcing systems that comply with local air quality regulations, focusing on energy-efficient solutions that align with their operational goals.

What Role Does Treated Fresh Air Play in Food Processing?

In food processing, treated fresh air creates a controlled environment for food storage, which is critical for extending shelf life and maintaining product quality. This application is particularly vital in regions with varying climates, such as Africa and South America, where humidity can affect food preservation. Buyers should consider advanced temperature control systems and humidity management solutions to ensure compliance with industry standards and enhance overall operational efficiency.

Why is Treated Fresh Air Critical in Pharmaceuticals?

Treated fresh air is crucial in the pharmaceutical industry, especially in cleanroom environments where drug manufacturing occurs. The integrity of pharmaceutical products relies on the quality of the air supplied, as any contaminants can lead to non-compliance with health standards. B2B buyers should invest in HEPA filtration systems and robust monitoring and control systems to ensure a sterile environment, adhering to stringent regulations prevalent in Europe and the Middle East.

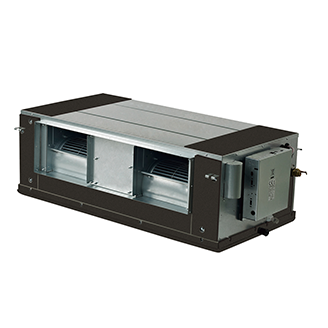

A stock image related to treated fresh air.

How Does Treated Fresh Air Enhance Data Center Operations?

In data centers, treated fresh air is vital for climate control, preventing overheating of servers and enhancing equipment lifespan. As the demand for data processing grows, especially in Europe and the Middle East, maintaining optimal air quality becomes paramount. Buyers should focus on energy-efficient cooling systems and ensure redundancy in air supply to mitigate risks associated with equipment failure.

What Benefits Does Treated Fresh Air Provide in Healthcare Settings?

In healthcare, treated fresh air plays a significant role in air purification within hospitals and clinics. By reducing infection rates and enhancing patient comfort, it directly impacts the quality of care provided. B2B buyers in this sector must ensure compliance with health regulations while also considering ease of maintenance for air purification systems to sustain a healthy environment for both patients and healthcare professionals.

Related Video: How a Chiller, Cooling Tower and Air Handling Unit work together

3 Common User Pain Points for ‘treated fresh air’ & Their Solutions

Scenario 1: Inconsistent Air Quality Control in Industrial Facilities

The Problem:

For many manufacturers and industrial facilities, maintaining consistent air quality is a critical concern. Fluctuations in treated fresh air quality can lead to worker dissatisfaction, health issues, and even regulatory penalties. In regions such as Africa and the Middle East, where environmental conditions can vary greatly, B2B buyers may find that their existing air treatment systems are either overburdened or ineffective. This inconsistency can result in reduced productivity and increased operational costs.

The Solution:

To combat these challenges, it’s essential for B2B buyers to invest in advanced air treatment systems equipped with real-time monitoring capabilities. These systems should be able to adjust airflow and filtration levels automatically based on the current air quality metrics. When sourcing treated fresh air solutions, look for manufacturers that offer customizable systems tailored to your facility’s specific needs. Conduct a thorough evaluation of the technologies available, including air quality sensors and smart controllers, to ensure that the system can adapt to changing environmental conditions and maintain consistent air quality.

Scenario 2: High Energy Costs Associated with Air Treatment Systems

The Problem:

B2B buyers often face the challenge of escalating energy costs due to inefficient treated fresh air systems. In Europe, where energy prices are typically higher, the need for a cost-effective solution is pressing. Many existing systems consume more energy than necessary, leading to increased operational expenses. Companies may struggle to find a balance between providing clean air and keeping energy costs manageable.

The Solution:

A proactive approach is to invest in energy-efficient air treatment technologies, such as those utilizing heat recovery ventilation (HRV) or energy recovery ventilators (ERV). These systems can significantly reduce energy consumption by reusing the thermal energy from exhaust air to precondition incoming fresh air. When selecting a treated fresh air solution, consider conducting an energy audit of your existing systems to identify inefficiencies and potential upgrades. Partner with suppliers who can provide case studies or references demonstrating energy savings achieved through their products, ensuring that you make an informed decision that aligns with your budgetary constraints.

Scenario 3: Regulatory Compliance Challenges in Air Quality Management

The Problem:

International B2B buyers often navigate a complex landscape of air quality regulations that vary by region. For instance, companies operating in South America and Europe may face stringent regulations regarding indoor air quality, which can be challenging to meet without appropriate treated fresh air solutions. Non-compliance can result in significant fines and damage to a company’s reputation.

The Solution:

To ensure compliance, B2B buyers should prioritize sourcing treated fresh air systems that are certified to meet local and international air quality standards. Engage with suppliers who have a deep understanding of the regulatory environment in your operational regions. This includes not only ensuring that the systems meet current standards but also staying updated on potential future regulations. Consider investing in systems with integrated compliance reporting features that can streamline documentation and monitoring processes. Additionally, regular training for facility managers on compliance best practices can further mitigate risks and enhance overall air quality management.

Strategic Material Selection Guide for treated fresh air

When selecting materials for treated fresh air systems, it is essential to consider various factors that influence performance, durability, and compliance with international standards. Below is an analysis of four common materials used in the construction of treated fresh air systems, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Aluminum in Treated Fresh Air Systems?

Aluminum is a lightweight metal known for its excellent corrosion resistance and thermal conductivity. It typically has a temperature rating of up to 150°C and can withstand moderate pressure levels, making it suitable for various HVAC applications.

Pros & Cons:

The primary advantage of aluminum is its durability and low weight, which simplifies installation and maintenance. However, its cost can be higher than other materials, and it may require additional coatings for enhanced corrosion resistance in harsh environments.

Impact on Application:

Aluminum is compatible with a wide range of media, including air and various gases, making it versatile for treated fresh air systems. However, in regions with high humidity or saline environments, special coatings may be necessary to prevent degradation.

Considerations for International Buyers:

Buyers from regions like the Middle East and Africa should ensure compliance with local standards and consider the specific environmental conditions that may affect aluminum’s performance. Familiarity with standards such as ASTM and DIN is crucial for ensuring quality and durability.

How Does Stainless Steel Perform in Treated Fresh Air Applications?

Stainless steel is renowned for its strength and exceptional corrosion resistance, particularly in high-humidity environments. It can handle temperatures up to 300°C and offers high pressure ratings, making it ideal for demanding applications.

Pros & Cons:

The key advantage of stainless steel is its longevity and reliability, which can lead to lower lifecycle costs. However, its initial cost is relatively high, and manufacturing can be complex, requiring specialized equipment.

Impact on Application:

Stainless steel is highly compatible with various media, including corrosive gases, making it suitable for treated fresh air systems in industrial settings. Its robustness ensures that it can withstand the rigors of continuous operation.

Considerations for International Buyers:

In Europe, compliance with EN standards is essential, while buyers in South America should be aware of local regulations concerning material specifications. Understanding the differences in stainless steel grades (e.g., 304 vs. 316) is also critical for selecting the right material for specific applications.

What Are the Benefits of Using Polypropylene in Treated Fresh Air Systems?

Polypropylene is a thermoplastic polymer known for its chemical resistance and lightweight properties. It can operate effectively at temperatures up to 100°C and is relatively pressure-resistant.

Pros & Cons:

The main advantage of polypropylene is its cost-effectiveness and ease of manufacturing, which can lead to lower production costs. However, it may not be suitable for high-temperature applications beyond its limit and can be less durable than metals.

Impact on Application:

Polypropylene is particularly effective in environments where chemical exposure is a concern, such as in laboratories or chemical processing facilities. Its compatibility with various media makes it a popular choice for treated fresh air systems.

Considerations for International Buyers:

Buyers in Africa and South America should consider local temperature ranges and environmental factors that may affect polypropylene’s performance. Familiarity with JIS standards can also help ensure compliance and quality assurance.

Why Choose Galvanized Steel for Treated Fresh Air Systems?

Galvanized steel is carbon steel that has been coated with zinc to enhance its corrosion resistance. It typically has a temperature rating of up to 200°C and can handle moderate pressure levels.

Pros & Cons:

The primary advantage of galvanized steel is its cost-effectiveness and good mechanical properties. However, it may have limitations in highly corrosive environments, and its lifespan can be affected by the quality of the galvanization process.

Impact on Application:

Galvanized steel is suitable for various applications, including ductwork for treated fresh air systems. It performs well in environments where moisture is present but may require additional treatment in coastal areas.

Considerations for International Buyers:

Buyers in Europe should be aware of the EN standards for galvanized products, while those in the Middle East should consider the implications of high temperatures on galvanized coatings. Understanding the local market for galvanized steel can also help in sourcing quality materials.

Summary of Material Selection for Treated Fresh Air Systems

| Material | Typical Use Case for treated fresh air | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | HVAC ductwork | Lightweight and corrosion-resistant | Higher cost, may need coatings | Medium |

| Stainless Steel | Industrial air handling systems | High durability and corrosion resistance | High initial cost, complex mfg | High |

| Polypropylene | Chemical processing facilities | Cost-effective and easy to manufacture | Limited high-temperature use | Low |

| Galvanized Steel | Ductwork in humid environments | Cost-effective and good mechanical properties | Vulnerable in highly corrosive areas | Medium |

A stock image related to treated fresh air.

This guide provides a comprehensive overview of material options for treated fresh air systems, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for treated fresh air

What Are the Key Manufacturing Processes for Treated Fresh Air Systems?

The manufacturing of treated fresh air systems involves several critical stages that ensure the product meets the necessary performance and quality standards. Understanding these processes can help international B2B buyers make informed decisions about their suppliers.

Material Preparation: What Are the Initial Steps?

The first stage of manufacturing treated fresh air systems is material preparation. This involves selecting high-quality raw materials, including filters, fans, heat exchangers, and control systems.

- Quality of Raw Materials: Ensure that suppliers source materials from reputable manufacturers, as the quality directly impacts the system’s efficiency and lifespan.

- Material Testing: Conduct tests for durability, corrosion resistance, and performance metrics before proceeding to the next stage.

Forming: How Are Components Shaped?

Once the materials are prepared, the forming stage shapes the components. This may include cutting, bending, and assembling parts to create the necessary structures.

- Techniques Used: Common techniques include CNC machining for precision components and injection molding for plastic parts.

- Automation and Technology: Look for suppliers who utilize advanced manufacturing technologies, which can enhance precision and reduce lead times.

Assembly: What Does the Assembly Process Look Like?

The assembly stage involves putting together all the components into a complete system.

- Expertise in Assembly: Skilled technicians should perform the assembly to ensure that systems are built to specifications.

- Integration of Systems: Check how the supplier integrates various components, such as air handling units, to ensure optimal performance.

Finishing: What Are the Final Touches?

Finishing processes include painting, coating, and applying protective treatments to enhance durability and aesthetics.

- Quality Control in Finishing: This stage is critical for ensuring that the final product can withstand environmental factors.

- Environmental Compliance: Ensure that suppliers adhere to environmental regulations when selecting finishing materials.

How Is Quality Assurance Implemented in Treated Fresh Air Manufacturing?

Quality assurance (QA) is crucial to the manufacturing of treated fresh air systems, ensuring that products meet international standards and customer expectations.

What Are the Relevant International Standards?

International standards such as ISO 9001 play a significant role in ensuring quality in manufacturing processes.

- ISO 9001: This standard outlines requirements for a quality management system, emphasizing continuous improvement and customer satisfaction.

- Industry-Specific Standards: Depending on the region and application, other certifications like CE (for European markets) or API (for industrial applications) may also be necessary.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are essential throughout the manufacturing process to identify defects early.

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Ongoing checks during manufacturing help identify issues before the final product is completed.

- Final Quality Control (FQC): A thorough inspection of the finished product ensures it meets all specifications and standards before shipping.

What Common Testing Methods Are Used?

Several testing methods are employed to verify the performance and safety of treated fresh air systems.

- Performance Testing: Systems are tested for airflow rates, energy efficiency, and filtration effectiveness.

- Durability Testing: Products may undergo environmental testing to simulate long-term use under various conditions.

- Compliance Testing: Ensure that products meet local and international regulations regarding emissions and safety.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is critical for B2B buyers, particularly those operating in diverse international markets.

What Are the Best Practices for Supplier Audits?

Conducting audits is an effective way to assess a supplier’s quality control system.

- On-Site Audits: Schedule regular on-site evaluations to observe manufacturing practices and QC checkpoints firsthand.

- Audit Checklists: Use standardized checklists to ensure all aspects of the manufacturing process are reviewed.

How Can Buyers Review Quality Reports?

Requesting quality reports can provide insights into a supplier’s performance and adherence to standards.

- Documentation Review: Look for documentation on past quality checks, compliance certifications, and testing results.

- Trend Analysis: Analyze trends in quality metrics over time to assess the reliability of the supplier.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can add an extra layer of assurance.

- Independent Verification: Third-party inspectors can validate the quality of materials and processes, providing unbiased assessments.

- Certification and Compliance: Ensure that third-party inspectors are accredited and recognized within the industry for credibility.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers face unique challenges regarding quality control and certification due to varying regional standards.

- Understanding Local Regulations: Familiarize yourself with local regulations in target markets, as requirements may differ significantly between regions like Africa, South America, the Middle East, and Europe.

- Navigating Certification Processes: Some markets may require additional certifications that are not standard in other regions. For example, buyers in Europe may need CE marking, while those in the Middle East may require specific local certifications.

Conclusion: How to Ensure Quality in Treated Fresh Air Systems?

Investing time in understanding the manufacturing processes and quality assurance systems of treated fresh air suppliers is essential for international B2B buyers. By focusing on comprehensive audits, diligent review of quality reports, and leveraging third-party inspections, buyers can significantly mitigate risks and ensure they receive high-quality products that meet their specific needs.

A stock image related to treated fresh air.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘treated fresh air’

In today’s global market, sourcing treated fresh air is an essential component for businesses looking to improve indoor air quality, enhance energy efficiency, and comply with environmental regulations. This guide offers a practical step-by-step checklist to help B2B buyers from Africa, South America, the Middle East, and Europe navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for treated fresh air systems. This includes understanding the specific airflow rates, filtration efficiency, and energy consumption levels necessary for your facility. Having precise specifications ensures that you communicate effectively with potential suppliers and receive tailored proposals that meet your needs.

Step 2: Conduct Market Research on Suppliers

Invest time in researching suppliers who specialize in treated fresh air solutions. Look for companies with a proven track record in your region and industry. Utilize online platforms, trade shows, and industry publications to compile a list of potential suppliers. Focus on their market presence, product offerings, and customer reviews to gauge their reliability.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; instead, engage with their previous clients to understand their experience. Check for certifications and compliance with international standards to ensure quality.

Step 4: Request Detailed Proposals

Once you have shortlisted potential suppliers, request detailed proposals that include pricing, delivery timelines, and warranty information. This will allow you to make a comparative analysis of each option. Pay attention to the transparency of the proposal—clear breakdowns of costs and terms can indicate the supplier’s professionalism and reliability.

Step 5: Assess After-Sales Support and Maintenance Services

Understanding the level of after-sales support and maintenance services offered by the supplier is vital. Inquire about training programs, technical support, and service agreements. A supplier that provides robust support can help you maximize the performance and longevity of your treated fresh air systems.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, negotiate the terms and conditions of the contract. This includes pricing, payment terms, delivery schedules, and penalties for non-compliance. Ensure that all agreements are documented to avoid misunderstandings in the future. A well-negotiated contract protects your interests and establishes a professional relationship with the supplier.

Step 7: Plan for Installation and Integration

Finally, develop a comprehensive plan for the installation and integration of the treated fresh air system into your existing infrastructure. Collaborate with the supplier to ensure that installation is carried out efficiently, with minimal disruption to your operations. Additionally, consider how the new system will integrate with your current HVAC setup to optimize performance.

By following this checklist, international B2B buyers can streamline the sourcing process for treated fresh air systems, ensuring they make informed decisions that align with their operational needs and regulatory requirements.

Comprehensive Cost and Pricing Analysis for treated fresh air Sourcing

What Are the Key Cost Components in Sourcing Treated Fresh Air?

When sourcing treated fresh air, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials used in the treatment process significantly affect the overall cost. High-quality filtration media, chemical treatments, and energy-efficient systems can drive up prices but ultimately lead to better air quality and lower maintenance costs.

-

Labor: Skilled labor is necessary for the installation and maintenance of treated fresh air systems. Labor costs can vary widely depending on the region, with labor markets in Europe typically having higher wages compared to those in Africa or South America.

-

Manufacturing Overhead: This includes costs associated with the production process, such as utilities, equipment maintenance, and factory operations. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: Specialized tools and machinery may be required for the production of treated fresh air systems. The initial investment in tooling can be substantial, but it is essential for ensuring high-quality output.

-

Quality Control (QC): Implementing rigorous QC measures ensures that the treated fresh air systems meet required standards and certifications. While this adds to upfront costs, it can prevent costly recalls and enhance customer satisfaction.

-

Logistics: Shipping and handling costs can vary depending on the supplier’s location and the destination. International buyers must consider these costs when evaluating total expenses.

-

Margin: Suppliers will typically add a margin to cover their costs and earn a profit. Understanding this margin can help buyers negotiate better pricing.

How Do Price Influencers Impact the Cost of Treated Fresh Air Systems?

Several factors influence the pricing of treated fresh air systems, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders can lead to economies of scale, often resulting in lower per-unit costs. Buyers should assess their needs to negotiate favorable terms.

-

Specifications and Customization: Custom solutions tailored to specific requirements may incur higher costs. Buyers should carefully weigh the benefits of customization against the associated expenses.

-

Materials and Quality Certifications: The choice of materials and the presence of certifications (like ISO or local standards) can significantly impact pricing. Higher quality materials often lead to better performance and longevity.

-

Supplier Factors: Supplier reliability, reputation, and financial stability can influence pricing. Partnering with reputable suppliers may come at a premium but can offer peace of mind and better service.

-

Incoterms: Understanding the Incoterms used in the contract is essential, as they define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs. This can greatly affect the total landed cost.

What Tips Can Help International Buyers Optimize Costs?

International B2B buyers should consider the following strategies to optimize costs when sourcing treated fresh air systems:

-

Negotiation: Engage in open discussions with suppliers about pricing, especially for large orders. Leverage your position as a bulk buyer to request discounts or more favorable payment terms.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider factors like energy consumption, maintenance, and replacement costs over the system’s lifespan.

-

Understand Pricing Nuances: Be aware that pricing can vary significantly by region. For example, suppliers in Europe might charge more due to higher labor costs, while those in South America may offer competitive pricing due to lower operational expenses.

-

Build Long-Term Relationships: Establishing a long-term partnership with reliable suppliers can lead to better pricing and terms over time. Consider suppliers that offer value-added services, such as training or maintenance support.

Disclaimer on Pricing

Prices for treated fresh air systems can fluctuate based on market conditions, currency exchange rates, and supplier pricing strategies. It is essential for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing treated fresh air With Other Solutions

Introduction: What Are the Alternatives to Treated Fresh Air?

In the quest for optimal indoor air quality and energy efficiency, B2B buyers must explore various alternatives to treated fresh air systems. Understanding these alternatives is crucial for making informed purchasing decisions that align with specific operational needs and regional requirements. This analysis will compare treated fresh air with two viable alternatives: Energy Recovery Ventilation (ERV) and Air Purification Systems. Each option presents unique benefits and challenges, making it essential to evaluate them carefully.

Comparison Table

| Comparison Aspect | Treated Fresh Air | Energy Recovery Ventilation (ERV) | Air Purification Systems |

|---|---|---|---|

| Performance | High-quality air with temperature and humidity control | Efficient energy transfer; maintains indoor climate | Removes pollutants but may not control humidity |

| Cost | Higher initial investment, lower long-term operating costs | Moderate initial investment, energy savings over time | Variable costs; high maintenance can increase total cost |

| Ease of Implementation | Requires specialized installation and design | Relatively easy to integrate into existing systems | Simple installation; portable options available |

| Maintenance | Regular filter replacement and system checks | Requires periodic maintenance; filters need replacing | Frequent filter changes and regular cleaning required |

| Best Use Case | Large commercial spaces needing climate control | Moderate-sized buildings seeking energy efficiency | Enclosed spaces needing air quality improvement |

Detailed Breakdown of Alternatives

What Are the Benefits and Drawbacks of Energy Recovery Ventilation (ERV)?

Energy Recovery Ventilation (ERV) systems are designed to improve energy efficiency by recovering heat and humidity from exhaust air and using it to condition incoming fresh air. This system is particularly beneficial for businesses looking to reduce energy costs while maintaining indoor climate comfort. The primary advantage of ERV is its ability to balance energy consumption, especially in moderate climates. However, initial installation costs can be significant, and regular maintenance is required to ensure optimal performance, which may deter some B2B buyers.

How Do Air Purification Systems Compare in Terms of Effectiveness?

Air Purification Systems focus on removing airborne contaminants, including dust, allergens, and pathogens, making them suitable for environments where air quality is a critical concern. These systems can be easily integrated into various settings, including offices and healthcare facilities. While they may have lower upfront costs and can be portable, their effectiveness in controlling humidity is limited. Moreover, ongoing maintenance and filter replacements can lead to higher long-term costs, making them less ideal for large-scale applications compared to treated fresh air or ERV systems.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right solution for enhancing indoor air quality, B2B buyers should consider their specific operational requirements, budget constraints, and environmental conditions. Treated fresh air systems are ideal for large spaces needing controlled climate conditions, while ERV systems offer energy savings for moderate-sized facilities. Air purification systems serve well in confined spaces where air quality is paramount but may not provide the same level of environmental control. By thoroughly evaluating these options, businesses can make strategic decisions that improve air quality and operational efficiency, ultimately benefiting their bottom line.

Essential Technical Properties and Trade Terminology for treated fresh air

When navigating the market for treated fresh air systems, understanding the essential technical properties and trade terminology is crucial for making informed purchasing decisions. This guide breaks down key specifications and common jargon that international B2B buyers should be familiar with, particularly those from Africa, South America, the Middle East, and Europe.

What Are the Key Technical Properties of Treated Fresh Air Systems?

1. Airflow Rate (CFM)

The airflow rate, measured in cubic feet per minute (CFM), indicates the volume of air that can be processed by the system. This specification is critical as it directly impacts the indoor air quality and energy efficiency of a space. Buyers should assess their specific needs based on the size and purpose of the area being ventilated.

2. Energy Efficiency Ratio (EER)

The Energy Efficiency Ratio reflects the cooling output of the system divided by its energy consumption. A higher EER signifies better energy efficiency, which can lead to reduced operational costs and a lower environmental impact. For businesses focused on sustainability, selecting systems with high EER ratings can align with corporate responsibility goals.

3. Filter Efficiency Rating (MERV)

The Minimum Efficiency Reporting Value (MERV) rates the effectiveness of air filters in capturing particles. A higher MERV rating means better filtration, which is essential for maintaining air quality, especially in environments sensitive to pollutants. B2B buyers must consider the MERV rating to ensure compliance with health and safety standards.

4. Noise Level (dBA)

Measured in decibels A-weighted (dBA), the noise level of a treated fresh air system is significant for maintaining a comfortable work environment. Systems that operate quietly can enhance productivity and employee satisfaction. Buyers should evaluate noise specifications to avoid disruptions in workplaces or public spaces.

5. Temperature Control Range

The temperature control range indicates the system’s capability to regulate air temperature. This property is essential for maintaining comfort in varying climates, particularly in regions with extreme weather conditions. Understanding the range helps buyers select systems suitable for their local environment.

Which Trade Terms Should B2B Buyers Understand?

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of treated fresh air systems, understanding OEM relationships can help buyers evaluate product quality and reliability, ensuring they select trusted brands.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for budgeting and inventory management, as it can influence purchasing decisions and overall costs. Buyers should negotiate MOQs to align with their operational needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain pricing and terms for specific products or services. It is an essential tool for B2B buyers to compare offers and negotiate better deals. Crafting a detailed RFQ can lead to more accurate and competitive quotations.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects such as shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and rights, reducing the risk of misunderstandings during cross-border transactions.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is vital for effective project planning and inventory management, particularly in industries where timely delivery can impact operations.

By familiarizing themselves with these technical properties and trade terminologies, international B2B buyers can enhance their procurement strategies for treated fresh air systems, ensuring they make informed decisions that align with their operational and financial goals.

Navigating Market Dynamics and Sourcing Trends in the treated fresh air Sector

What Are the Current Market Dynamics and Key Trends in the Treated Fresh Air Sector?

The treated fresh air sector is experiencing significant growth driven by heightened awareness of indoor air quality and stringent regulations regarding environmental standards. As urbanization accelerates in regions like Africa and South America, the demand for effective air treatment solutions is surging. In Europe, particularly in countries such as Germany, there is a robust push towards energy efficiency, making advanced air treatment systems a priority for businesses aiming to comply with EU regulations.

Emerging technologies are playing a critical role in this sector. Innovations such as IoT-enabled air quality monitors and AI-driven systems that optimize air treatment processes are becoming increasingly prevalent. These technologies not only enhance operational efficiency but also provide actionable data for businesses to make informed decisions. Furthermore, the integration of renewable energy sources into air treatment systems is a key trend, aligning with global sustainability goals.

For B2B buyers, understanding these dynamics is crucial. Companies looking to source treated fresh air solutions should consider suppliers who are not only technologically adept but also compliant with local regulations and international standards. Engaging with vendors who demonstrate a commitment to innovation and sustainability can provide a competitive edge in various markets.

How Can Sustainability and Ethical Sourcing Enhance B2B Operations in the Treated Fresh Air Sector?

Sustainability is no longer a mere buzzword; it has become a fundamental aspect of business strategy, especially in the treated fresh air sector. The environmental impact of air quality management systems is significant, as traditional methods can contribute to pollution and resource depletion. Ethical sourcing practices are essential for minimizing this impact, ensuring that materials used in air treatment systems are sustainable and responsibly sourced.

B2B buyers should prioritize suppliers who offer ‘green’ certifications and utilize environmentally friendly materials. Certifications such as LEED (Leadership in Energy and Environmental Design) and ISO 14001 (Environmental Management Systems) indicate a supplier’s commitment to sustainable practices. Moreover, sourcing from local suppliers can reduce carbon footprints associated with transportation, aligning with broader sustainability goals.

In addition to environmental considerations, ethical sourcing fosters transparency in supply chains, which is increasingly demanded by consumers and regulatory bodies alike. By engaging with suppliers who adhere to ethical practices, companies not only enhance their brand reputation but also mitigate risks associated with supply chain disruptions and compliance issues.

How Has the Treated Fresh Air Sector Evolved Over Time?

The treated fresh air sector has undergone significant transformation over the decades. Initially, air treatment systems focused primarily on filtration, with limited regard for energy efficiency or environmental impact. However, as awareness of air quality issues grew, particularly in densely populated urban areas, the industry began to shift towards more sophisticated solutions that incorporate energy recovery and real-time monitoring.

The advent of advanced materials and technologies has further propelled this evolution. For instance, the introduction of high-efficiency particulate air (HEPA) filters and UV-C light systems has revolutionized how businesses approach air purification. Today, the focus is not only on treating air but also on ensuring that systems are energy-efficient, sustainable, and capable of adapting to varying environmental conditions.

This evolution highlights the importance of staying informed about technological advancements and market shifts. For international B2B buyers, leveraging this historical context can inform better sourcing decisions, ensuring alignment with current trends and future needs in the treated fresh air market.

Frequently Asked Questions (FAQs) for B2B Buyers of treated fresh air

-

How do I solve the problem of poor indoor air quality in my facility?

To address poor indoor air quality, consider investing in treated fresh air systems that ensure adequate ventilation while filtering out pollutants. Conduct an air quality assessment to identify specific contaminants affecting your environment. Collaborate with suppliers who offer customized solutions tailored to your facility’s needs, including the integration of advanced filtration systems and humidity control. Regular maintenance and monitoring will also ensure sustained air quality improvements. -

What is the best type of treated fresh air system for industrial applications?

For industrial applications, the best treated fresh air systems are those that combine energy efficiency with robust filtration capabilities. Look for systems that utilize heat recovery ventilators (HRVs) or energy recovery ventilators (ERVs) to minimize energy costs while maintaining air quality. Ensure the system can handle the specific volume and type of pollutants present in your facility. Consulting with industry experts can help you select the most suitable system based on your operational requirements. -

How do I vet suppliers of treated fresh air systems?

When vetting suppliers, consider their industry experience, customer testimonials, and certifications. Request case studies that demonstrate their successful implementation of treated fresh air systems in similar environments. Evaluate their response time and customer service quality during initial inquiries. It’s also wise to visit their manufacturing facilities, if possible, to assess their production capabilities and quality control processes. -

What are the minimum order quantities (MOQ) for treated fresh air systems?

Minimum order quantities can vary significantly based on the supplier and the complexity of the system. Many manufacturers have flexible MOQs, especially for new clients or small businesses. It’s advisable to communicate your needs directly to suppliers and negotiate MOQs that suit your budget and requirements. Some suppliers may offer pilot programs or trial units, which can be an excellent way to assess their products without committing to large orders. -

What payment terms should I expect when purchasing treated fresh air systems?

Payment terms for treated fresh air systems typically range from upfront payments to net 30 or net 60 days after delivery. International buyers should inquire about the possibility of letters of credit or escrow services to secure transactions. Clear communication with suppliers regarding payment schedules and conditions can help avoid misunderstandings. It’s also advisable to review the terms in the context of your region’s trade regulations. -

How can I ensure the quality assurance (QA) of treated fresh air systems?

To ensure quality assurance, request detailed specifications and compliance certifications from suppliers. Look for systems that adhere to international standards such as ISO 9001 for quality management and other relevant environmental certifications. Additionally, consider establishing a site visit or third-party inspection during manufacturing to verify compliance with your standards. Regularly scheduled maintenance and performance checks post-installation can also help maintain quality over time. -

What logistics considerations should I be aware of when importing treated fresh air systems?

Logistics for importing treated fresh air systems require careful planning. Ensure you understand the shipping methods, customs clearance processes, and potential tariffs that may apply in your region. Collaborate with logistics providers who have experience handling large equipment and can offer insights on the best shipping practices. Additionally, factor in lead times for manufacturing and shipping to align with your project timelines. -

How can I customize treated fresh air systems for my specific industry needs?

Customization of treated fresh air systems can be achieved through collaboration with suppliers who offer tailored solutions. Identify your specific industry requirements, such as the type of contaminants, airflow rates, and space constraints. Engage in discussions with potential suppliers about your needs and explore options for adjustable filtration, variable speed fans, and integration with existing HVAC systems. A well-defined set of specifications will help suppliers provide the most relevant solutions for your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for treated fresh air

As the global demand for treated fresh air continues to rise, B2B buyers must prioritize strategic sourcing to ensure quality, efficiency, and sustainability in their procurement processes. By engaging with reputable suppliers and leveraging technology, businesses can optimize their air treatment systems, enhancing workplace environments and improving overall productivity.

What are the key benefits of strategic sourcing for treated fresh air?

Investing in strategic sourcing allows companies to mitigate risks associated with supply chain disruptions, particularly in the diverse markets of Africa, South America, the Middle East, and Europe. Establishing strong supplier relationships not only fosters trust but also enables buyers to negotiate better terms, access innovative technologies, and achieve cost savings.

How can international buyers prepare for future trends in treated fresh air?

Looking ahead, B2B buyers should stay informed about regulatory changes and environmental standards that impact the treated fresh air market. Adapting to these trends will be crucial for maintaining compliance and enhancing brand reputation.

In conclusion, the journey towards efficient and sustainable air treatment solutions begins with informed strategic sourcing. By actively engaging with suppliers and embracing innovation, international buyers can position themselves for success in a rapidly evolving landscape. Embrace this opportunity to enhance your air quality initiatives and drive your business forward.