Mag Grip Guide: Type,Cost,Material…

Introduction: Navigating the Global Market for mag grip

In the competitive landscape of fitness equipment, sourcing high-quality MAG Grip attachments can pose significant challenges for B2B buyers seeking to enhance their offerings. With the global market expanding rapidly, particularly in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of MAG Grip products is essential for making informed purchasing decisions. This comprehensive guide delves into various types of MAG Grip attachments, their applications in both commercial and home gym settings, and the critical aspects of supplier vetting.

Throughout this guide, we will explore the unique benefits of MAG Grip technology, including ergonomic design and enhanced performance during upper body workouts. We will also address key considerations such as pricing, shipping logistics, and the importance of quality assurance when sourcing from international suppliers. By equipping buyers with actionable insights, this resource aims to empower businesses to confidently navigate the complexities of the MAG Grip market.

Whether you are a gym owner looking to upgrade your equipment or a distributor aiming to expand your product line, understanding the MAG Grip’s value proposition will enable you to meet the diverse needs of your clientele. With a focus on maximizing efficiency and user experience, this guide serves as your essential roadmap to successful sourcing in the evolving fitness equipment landscape.

Understanding mag grip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| MAG Medium Grip Supinate | Ergonomic design with a wider grip for comfort | Commercial gyms, rehabilitation centers | Pros: Excellent for upper body workouts; reduces strain on joints. Cons: May not suit all hand sizes. |

| MAG Close Grip Supinate | Compact design focusing on close grip exercises | Personal training studios, home gyms | Pros: Ideal for triceps and back isolation; versatile. Cons: Limited to specific exercises. |

| MAG Medium Grip Pronate | Contoured handle for a natural pulling motion | Strength training facilities | Pros: Enhances lat isolation; ergonomic for various users. Cons: May require adjustment period for new users. |

| MAG Three Quarter Grip | Balanced size between medium and wide for diverse athletes | Fitness clubs, sports performance centers | Pros: Versatile for different body types; comfortable grip. Cons: Less specialized than other options. |

| MAG Palm Press | Unique design for both back and triceps exercises | Personal trainers, functional training | Pros: Multi-functional; effective for varied workouts. Cons: May not outperform dedicated attachments for specific exercises. |

What Are the Key Characteristics of the MAG Medium Grip Supinate?

The MAG Medium Grip Supinate is designed with an ergonomic focus, allowing for a wider grip that enhances comfort during workouts. This grip is particularly beneficial for upper body exercises, as it reduces strain on the wrists and elbows. B2B buyers should consider its application in commercial gyms and rehabilitation centers, where user comfort and injury prevention are paramount. However, it’s essential to note that this grip may not accommodate all hand sizes, which could limit its versatility in diverse gym environments.

How Does the MAG Close Grip Supinate Cater to Specific Training Needs?

The MAG Close Grip Supinate features a compact design that emphasizes close grip exercises, making it ideal for triceps and back workouts. This attachment is particularly well-suited for personal training studios and home gyms, where space and equipment versatility are crucial. It offers excellent isolation for targeted muscle groups, although its functionality may be limited to specific exercises, potentially requiring additional attachments for a comprehensive workout regimen.

What Makes the MAG Medium Grip Pronate Stand Out in Strength Training?

The MAG Medium Grip Pronate is characterized by its contoured handle, which supports a natural pulling motion, making it a favorite among strength training facilities. This grip enhances lat muscle isolation, providing an ergonomic experience that can be adjusted to fit various user preferences. Buyers should consider its effectiveness for a broad range of exercises, though new users may need time to adjust to its unique feel, which could affect initial performance.

Why Should Fitness Facilities Consider the MAG Three Quarter Grip?

The MAG Three Quarter Grip offers a balanced size that fills the gap between medium and wide grips, catering to a diverse range of athletes. This versatility makes it an excellent addition to fitness clubs and sports performance centers where different body types and training styles are prevalent. While it provides a comfortable grip for various exercises, it may be less specialized than other options, which could impact its effectiveness for specific training goals.

How Does the MAG Palm Press Enhance Functional Training Options?

The MAG Palm Press is a unique attachment that serves dual purposes for both back and triceps exercises. Its innovative design allows for a wide range of movements, making it a valuable tool for personal trainers and functional training environments. While it excels in versatility, it may not outperform dedicated attachments for specific exercises, which is a consideration for B2B buyers looking for specialized equipment.

Key Industrial Applications of mag grip

| Industry/Sector | Specific Application of mag grip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fitness & Rehabilitation | Use in gyms for strength training and rehabilitation | Enhances workout efficiency, reduces injury risk | Quality assurance, ergonomic design, material durability |

| Sports Performance | Training equipment for athletes | Improves upper body strength, aids in injury recovery | Customization options, compatibility with existing gear |

| Commercial Gym Equipment | Retail and distribution of MAG grips | Differentiates product offerings, meets diverse client needs | Supplier reputation, warranty, and customer support |

| Health & Wellness Facilities | Equipment for physical therapy and wellness programs | Supports patient rehabilitation, enhances service offerings | Compliance with health regulations, ergonomic standards |

| Home Gym Market | Direct-to-consumer sales for home gym setups | Expands customer base, caters to growing home fitness trend | Shipping logistics, return policies, customer reviews |

How is ‘mag grip’ Used in the Fitness & Rehabilitation Sector?

In the fitness and rehabilitation sector, MAG grips are utilized in gyms for both strength training and physical therapy. Their ergonomic design allows users to perform a variety of exercises, targeting the upper body without the risk of strain or injury. This is particularly beneficial for rehabilitation programs where patients need to maintain strength while recovering from injuries. Buyers from this sector should prioritize sourcing grips that meet safety standards and offer a comfortable experience for users, ensuring long-term satisfaction and effectiveness.

What Role Do MAG Grips Play in Sports Performance Training?

In sports performance training, MAG grips serve as essential tools for athletes looking to enhance their upper body strength. These grips allow for more natural pulling movements, which can be crucial for sports that rely heavily on upper body strength. By minimizing strain on joints, they facilitate recovery from injuries and improve overall performance. B2B buyers in this sector should consider the customization options available for MAG grips to cater to specific training needs and athlete preferences.

How Do MAG Grips Benefit Commercial Gym Equipment Providers?

For commercial gym equipment providers, incorporating MAG grips into their offerings can significantly differentiate their product lines. These grips cater to a diverse range of clients, from bodybuilders to casual gym-goers, enhancing the overall appeal of gym facilities. Additionally, offering MAG grips can help gyms meet the demand for high-quality, versatile equipment. Buyers should evaluate supplier reputation and warranty options to ensure they are providing reliable and durable products to their customers.

Why Are MAG Grips Important for Health & Wellness Facilities?

Health and wellness facilities use MAG grips to provide effective tools for physical therapy and rehabilitation programs. These grips help patients regain strength and mobility, making them an essential component of treatment plans. By integrating MAG grips into their services, these facilities can enhance their offerings and improve patient outcomes. Buyers in this sector must ensure that the grips comply with health regulations and ergonomic standards to maximize safety and effectiveness.

How Do MAG Grips Cater to the Home Gym Market?

The rise of the home gym market has seen an increasing demand for high-quality equipment like MAG grips. These attachments are perfect for individuals looking to optimize their home workouts without compromising on performance. By sourcing MAG grips directly, businesses can tap into a growing customer base that values convenience and efficiency in their fitness routines. When sourcing for this market, considerations around shipping logistics and return policies are crucial to ensure customer satisfaction and retention.

3 Common User Pain Points for ‘mag grip’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality MAG Grip Products

The Problem:

B2B buyers often face challenges when sourcing high-quality MAG Grip products. In regions like Africa and South America, access to reliable suppliers can be limited, leading to concerns about product authenticity, quality, and after-sales support. Many buyers report receiving subpar or counterfeit products that do not perform as expected, resulting in dissatisfaction among their clients and potential damage to their own reputation.

The Solution:

To mitigate these issues, B2B buyers should conduct thorough research before making purchases. Start by identifying reputable manufacturers and distributors of MAG Grip products, such as Maximum Advantage Grip. Utilize online platforms, trade shows, and industry forums to gather reviews and testimonials from other buyers. Furthermore, consider establishing direct relationships with manufacturers to negotiate bulk purchasing agreements, ensuring product authenticity and consistency in quality. Buyers should also request samples before committing to large orders, allowing them to assess the quality and performance firsthand. By prioritizing reliable sourcing channels, buyers can enhance their offerings and maintain customer satisfaction.

Scenario 2: Inadequate Training and Knowledge on MAG Grip Usage

The Problem:

Another common pain point is the lack of adequate training and knowledge regarding the proper use of MAG Grip attachments among gym staff and clients. This can lead to ineffective workouts, injuries, and a lack of customer satisfaction. Many users may not understand the unique design features of MAG Grips that differentiate them from traditional cable attachments, resulting in missed opportunities for optimal performance.

The Solution:

To address this challenge, B2B buyers should implement comprehensive training programs for their staff and clients. Begin by creating instructional materials, such as videos and guides, that detail the benefits and proper usage of MAG Grip products. Hosting workshops or training sessions can also be beneficial, allowing users to experience the equipment firsthand under the guidance of knowledgeable trainers. Additionally, consider collaborating with fitness professionals or influencers who can provide expert demonstrations and insights. By investing in education, buyers can ensure that users are maximizing the potential of MAG Grips, ultimately leading to improved workout outcomes and higher customer retention rates.

Scenario 3: Managing Inventory and Product Variety

The Problem:

B2B buyers frequently struggle with managing inventory levels and product variety, particularly when dealing with a diverse range of MAG Grip attachments. This complexity can lead to overstocking certain items while understocking others, resulting in lost sales opportunities and increased carrying costs. Additionally, buyers may find it challenging to keep up with new product releases and variations, which can further complicate inventory management.

The Solution:

To optimize inventory management, B2B buyers should adopt a data-driven approach. Implement inventory management software that tracks sales trends and forecasts demand for different MAG Grip attachments. This technology can help identify which products are most popular, enabling buyers to make informed purchasing decisions. Additionally, consider establishing a flexible inventory system that allows for easy adjustments based on seasonal trends or new product launches. Buyers should also maintain open communication with suppliers to stay informed about upcoming product releases and promotions, ensuring that they can adjust their inventory accordingly. By streamlining inventory processes, businesses can enhance their operational efficiency and better meet customer demands.

Strategic Material Selection Guide for mag grip

When selecting materials for MAG Grip products, it is essential to consider various factors that influence performance, durability, and cost. Below is an analysis of four common materials used in the manufacturing of MAG Grips, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What are the Key Properties of Aluminum in MAG Grip Manufacturing?

Aluminum is a lightweight yet strong material commonly used in MAG Grip products. It boasts excellent corrosion resistance, making it suitable for environments with high humidity or exposure to sweat. Aluminum can withstand moderate temperatures and pressures, ensuring that it maintains its integrity during intense workouts.

Pros: The primary advantage of aluminum is its lightweight nature, which enhances user comfort and reduces fatigue during extended use. Additionally, aluminum is relatively cost-effective and easy to manufacture, allowing for a variety of designs.

Cons: However, aluminum may not be as durable as other metals, especially under extreme stress or impact. It can also be prone to scratching, which may affect its aesthetic appeal over time.

Impact on Application: Aluminum is compatible with various media, including water and sweat, making it ideal for gym environments. However, it may not be suitable for applications requiring heavy-duty performance.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure that the aluminum used meets international standards such as ASTM B221. Additionally, they should consider local regulations regarding material sourcing and environmental impact.

How Does Stainless Steel Compare as a Material for MAG Grips?

Stainless steel is renowned for its exceptional strength and resistance to corrosion, making it a preferred choice for high-performance MAG Grip products. Its ability to withstand extreme temperatures and pressures enhances its durability in various environments.

Pros: The key advantage of stainless steel is its longevity; it can endure heavy use without significant wear and tear. Its sleek appearance also adds to the aesthetic value of fitness equipment.

Cons: The main drawback is the higher cost associated with stainless steel compared to aluminum. Additionally, its weight may be a concern for users who prefer lighter equipment.

Impact on Application: Stainless steel is highly compatible with a range of media, including saltwater, making it suitable for diverse environments. Its robust nature allows for versatile applications, from home gyms to commercial fitness centers.

Considerations for International Buyers: Buyers should verify compliance with standards such as ASTM A240 for stainless steel. In regions like the Middle East, where humidity is high, ensuring the right grade of stainless steel is crucial to prevent rust.

What Role Does Plastic Play in MAG Grip Products?

Plastic, particularly high-density polyethylene (HDPE) or polypropylene, is sometimes used in MAG Grips for its lightweight and flexible properties. It is resistant to moisture and can withstand a range of temperatures.

Pros: The primary advantage of plastic is its cost-effectiveness and ease of manufacturing. It can be molded into various shapes, allowing for innovative designs.

Cons: However, plastic may lack the durability of metal options and can wear down more quickly under heavy use. It may also be less aesthetically pleasing compared to metal finishes.

Impact on Application: Plastic is suitable for environments where moisture is prevalent, such as gyms. However, it may not be ideal for applications requiring high strength and durability.

Considerations for International Buyers: Buyers should ensure that the plastic used complies with safety standards such as ASTM D638. In regions like Europe, environmental regulations regarding plastic use may also influence material selection.

How Does Rubber Enhance the Performance of MAG Grip Products?

Rubber is often used in conjunction with other materials to enhance grip and comfort. It provides excellent traction, reducing the risk of slipping during workouts.

Pros: The key advantage of rubber is its ability to absorb shock and reduce strain on the hands, enhancing user experience. It is also resistant to moisture and can withstand varying temperatures.

Cons: On the downside, rubber can degrade over time due to exposure to UV light and extreme temperatures. Additionally, it may require more maintenance to keep it clean and in good condition.

Impact on Application: Rubber is highly compatible with sweaty environments, making it ideal for gym equipment. However, it may not be suitable for outdoor applications where UV exposure is significant.

Considerations for International Buyers: Buyers should ensure that the rubber used meets international standards such as ASTM D2000. Additionally, they should consider local climate conditions that may affect rubber longevity.

Summary Table

| Material | Typical Use Case for mag grip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | General-purpose MAG Grips | Lightweight and cost-effective | Less durable under extreme stress | Medium |

| Stainless Steel | High-performance MAG Grips | Exceptional strength and longevity | Higher cost and heavier weight | High |

| Plastic | Lightweight grips and attachments | Cost-effective and versatile design | Less durable and aesthetically pleasing | Low |

| Rubber | Grip enhancement for various attachments | Excellent shock absorption and grip | Degrades over time with UV exposure | Medium |

This guide provides a comprehensive overview of material selection for MAG Grip products, helping international B2B buyers make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for mag grip

What Are the Key Stages in the Manufacturing Process of MAG Grips?

The manufacturing process of MAG grips involves several critical stages designed to ensure high-quality products tailored for performance and durability. Understanding these stages is essential for B2B buyers seeking reliable suppliers.

Material Preparation: What Materials Are Used in MAG Grip Production?

The first step in the manufacturing process is material preparation. MAG grips are typically made from high-grade steel and durable plastic composites. The selection of materials is pivotal as it directly impacts the product’s strength, performance, and longevity. Steel provides the necessary structural integrity, while the ergonomic plastic components enhance user comfort and grip.

Materials are sourced from certified suppliers to guarantee compliance with international standards. This initial stage also includes testing raw materials for quality assurance, such as tensile strength and flexibility, ensuring that only the best materials proceed to the next phase.

How Are MAG Grips Formed and Shaped?

The forming stage involves several advanced techniques, including precision machining and injection molding.

-

Precision Machining: For metal components, CNC (Computer Numerical Control) machining is employed to shape the steel into the desired profiles. This process allows for high accuracy and repeatability, ensuring that each grip meets the specified dimensions.

-

Injection Molding: The ergonomic handles are produced using injection molding techniques. This method allows for intricate designs that enhance grip comfort and usability while maintaining consistent quality across production runs.

Both techniques are critical in achieving the ergonomic design that MAG grips are known for, which significantly enhances user experience.

What Does the Assembly Process Look Like?

Once the components are formed, they move to the assembly stage. Here, skilled technicians carefully combine the metal and plastic parts to create the final product. This process often involves:

- Quality Checks: During assembly, each component is inspected for defects and alignment. Any discrepancies are corrected immediately to maintain quality standards.

- Testing for Ergonomics: Assemblers may also conduct preliminary usability tests to ensure that the grips meet ergonomic standards before moving on to the finishing stage.

This meticulous assembly process is crucial for ensuring that the final product not only functions well but also feels comfortable during use.

What Finishing Techniques Are Applied to MAG Grips?

The finishing stage is where MAG grips receive their final touches. This includes surface treatment processes such as powder coating or anodizing, which enhance durability and aesthetics.

- Powder Coating: This method provides a robust finish that resists wear and corrosion, making the grips suitable for extensive use in various environments.

- Anodizing: For certain metal components, anodizing can increase corrosion resistance and improve surface hardness.

These finishing techniques not only enhance the lifespan of the grips but also contribute to their visual appeal, making them attractive to buyers in diverse markets.

How Is Quality Assurance Implemented in MAG Grip Manufacturing?

Quality assurance is a cornerstone of the manufacturing process for MAG grips, ensuring that the final products meet or exceed industry standards.

What International Standards Are Relevant for MAG Grip Products?

MAG grip manufacturers typically adhere to several international quality standards, including:

- ISO 9001: This standard focuses on quality management systems and is fundamental for companies aiming to enhance customer satisfaction through effective process management.

- CE Certification: For products marketed in Europe, CE certification indicates compliance with safety and health standards, allowing for smoother entry into EU markets.

- API Standards: For certain applications, adherence to American Petroleum Institute (API) standards may be necessary, especially if the grips are used in specialized environments.

These certifications provide assurance to B2B buyers that the products are safe, reliable, and of high quality.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated throughout the manufacturing process, with specific checkpoints established to maintain standards:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for compliance with specifications before they enter the production process.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to ensure that each stage meets quality standards. This includes checking dimensions, surface finishes, and assembly integrity.

-

Final Quality Control (FQC): After assembly, a final inspection ensures that the finished grips meet all quality criteria. This may involve functional testing to verify performance under load.

These checkpoints are crucial for identifying defects early in the process, reducing waste, and ensuring product consistency.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensuring product reliability.

What Steps Can Buyers Take to Ensure Quality?

-

Conduct Supplier Audits: Regular audits can help assess the manufacturing processes and quality control measures in place. Buyers should request access to QC documentation and audits performed by third parties.

-

Request Quality Control Reports: Suppliers should provide detailed QC reports, including test results from various stages of production. These documents can help buyers understand the supplier’s commitment to quality.

-

Utilize Third-Party Inspection Services: Engaging third-party inspectors can provide an unbiased evaluation of the manufacturing processes and final products, offering additional assurance of quality.

-

Understand Regional Compliance Nuances: Buyers should be aware of any specific regulatory requirements in their region. For instance, certifications like ISO or CE may be more critical in European markets compared to others.

By taking these proactive steps, B2B buyers can mitigate risks associated with supplier quality and ensure they are investing in reliable and high-performance products.

Conclusion: The Importance of Quality in MAG Grip Manufacturing

In summary, the manufacturing processes and quality assurance measures for MAG grips are designed to deliver high-quality, durable products that meet international standards. B2B buyers should prioritize suppliers that demonstrate robust quality control practices and compliance with relevant certifications. By understanding these processes, buyers can make informed decisions that enhance their product offerings and ultimately contribute to their business success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mag grip’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure MAG Grip cable attachments. Understanding the nuances of sourcing these products can significantly enhance your procurement strategy, ensuring you invest in high-quality equipment that meets your business needs. The following steps will help streamline your purchasing process and maximize the value of your investment.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for MAG Grip attachments. This includes determining the types of grips needed (e.g., medium, close, or wide), the intended applications (e.g., strength training, rehabilitation), and any compatibility with existing equipment. A precise definition of specifications not only saves time but also ensures that you select the right products for your gym or training facility.

Step 2: Research the Market Landscape

Conduct thorough market research to identify potential suppliers of MAG Grip products. Look for established brands with a good reputation in the fitness equipment industry. Pay attention to customer reviews, testimonials, and ratings to gauge the reliability and quality of the products offered. This foundational step helps you understand the competitive landscape and prepares you for informed negotiations.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, product catalogs, and references from other buyers in similar industries or regions. Look for suppliers who have demonstrated experience with MAG Grip products and can provide case studies that highlight their success with other clients. This due diligence will help you avoid potential pitfalls and ensure a smooth procurement process.

Step 4: Verify Quality Assurance Standards

Quality assurance is paramount when sourcing fitness equipment. Verify that your chosen suppliers adhere to international quality standards and certifications, such as ISO or CE marking. Inquire about their manufacturing processes and quality control measures to ensure that the MAG Grip products are durable and reliable. Quality equipment not only enhances user experience but also minimizes long-term costs associated with replacements and repairs.

Step 5: Assess Pricing and Payment Terms

Request detailed quotes from multiple suppliers and compare their pricing structures. Be sure to consider the total cost of ownership, which includes shipping, taxes, and any additional fees. Evaluate payment terms and conditions, looking for options that provide flexibility while ensuring security. A transparent pricing structure is crucial for maintaining budgetary control and fostering a trustworthy relationship with your supplier.

Step 6: Request Samples for Testing

Before making a bulk purchase, request samples of the MAG Grip attachments you are considering. Testing the products firsthand allows you to evaluate their comfort, usability, and effectiveness in real-world scenarios. This step is vital to ensure that the equipment meets your expectations and the needs of your users, thereby reducing the risk of dissatisfaction post-purchase.

Step 7: Finalize the Contract and Place Your Order

Once you have selected a supplier and confirmed the products, finalize the contract details. Ensure that all terms, including delivery schedules, warranties, and return policies, are clearly outlined. After both parties agree, place your order and maintain communication with the supplier to monitor the progress of your shipment. A well-structured contract protects your interests and helps prevent misunderstandings during the transaction.

By following this checklist, B2B buyers can confidently navigate the procurement process for MAG Grip cable attachments, ensuring a successful investment for their fitness facilities.

Comprehensive Cost and Pricing Analysis for mag grip Sourcing

What Are the Key Cost Components in MAG Grip Manufacturing?

Understanding the cost structure of MAG Grip products is crucial for international B2B buyers. The primary cost components include:

-

Materials: The quality of materials significantly influences the overall cost. MAG Grips are typically made from high-grade metals and plastics, which provide durability and ergonomic benefits. Sourcing quality materials can raise initial costs but ensures longevity and performance.

-

Labor: Labor costs vary by region. In countries with lower wage standards, like certain areas in South America or Africa, labor costs may be reduced, potentially lowering the final price. However, skilled labor is often necessary for quality control and manufacturing precision, which can increase costs.

-

Manufacturing Overhead: This includes costs related to facilities, equipment maintenance, and utilities. Efficient manufacturing processes can help keep overhead low, but high-quality production often requires advanced machinery and technologies, which adds to costs.

-

Tooling: Custom tooling for specific MAG Grip designs can be a significant upfront investment. Buyers should consider whether they require customized attachments, as this will influence both initial costs and lead times.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and safety, which is vital in the fitness equipment market. However, this adds to the cost structure and should be considered when evaluating suppliers.

-

Logistics: The costs associated with shipping and handling can fluctuate based on the supplier’s location and the buyer’s destination. International logistics can be complex, with varying tariffs and taxes that impact overall pricing.

-

Margin: Suppliers typically add a margin that reflects their business model, market position, and competition. Understanding the market dynamics can help buyers assess whether the pricing is justified.

How Do Price Influencers Affect MAG Grip Sourcing Decisions?

Several factors can influence the pricing of MAG Grips, which buyers must consider:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer better pricing for larger orders. Understanding the MOQ can help buyers negotiate more favorable terms.

-

Specifications and Customization: Custom designs or specific features can increase costs. Buyers should weigh the benefits of customization against the additional expenses.

-

Material Quality and Certifications: High-quality materials and industry certifications may raise costs but can also enhance product value and safety, making them worth the investment.

-

Supplier Factors: Supplier reputation, reliability, and geographic location can affect pricing. Engaging with reputable suppliers often results in better quality assurance and service.

-

Incoterms: Understanding international shipping terms (Incoterms) is essential. They dictate the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk, impacting overall pricing.

What Are Some Buyer Tips for Cost-Efficiency in MAG Grip Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate Effectively: Don’t hesitate to negotiate terms with suppliers. Understanding the cost structure can provide leverage in discussions.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, durability, and replacement. Investing in higher-quality MAG Grips can lead to lower TCO.

-

Be Aware of Pricing Nuances: Different regions may have varying market conditions and pricing strategies. Conduct thorough market research to understand local pricing dynamics and avoid overspending.

-

Plan for Currency Fluctuations: For buyers operating in different currencies, be mindful of exchange rate fluctuations that could affect purchasing power.

Disclaimer on Indicative Prices

Prices for MAG Grips can vary widely based on the factors mentioned above. Buyers should seek quotes from multiple suppliers and consider all cost components before making purchasing decisions. Always request detailed pricing breakdowns to ensure transparency and facilitate effective budget planning.

Alternatives Analysis: Comparing mag grip With Other Solutions

Exploring Alternatives to MAG Grip: A Comprehensive Comparison

In the fitness equipment market, particularly in the realm of cable attachments, the MAG Grip has garnered significant attention due to its innovative design and performance. However, as with any product, it’s essential for B2B buyers to consider viable alternatives that may better suit their specific needs or budget constraints. This analysis will compare the MAG Grip against two notable alternatives: traditional lat pulldown bars and other ergonomic cable attachments.

| Comparison Aspect | Mag Grip | Traditional Lat Pulldown Bar | Ergonomic Cable Attachments |

|---|---|---|---|

| Performance | Superior grip and comfort, enhances muscle isolation, reduces strain on joints. | Basic functionality, less ergonomic, may lead to discomfort during use. | Varies by design; some offer good grip and comfort, but not all enhance isolation. |

| Cost | Premium pricing, often considered an investment for serious athletes and gyms. | Generally more affordable, widely available. | Mid-range pricing, depending on brand and design. |

| Ease of Implementation | Simple to attach to existing cable machines, minimal learning curve. | Standard attachment process, familiar to users. | Easy to install, but effectiveness varies with design. |

| Maintenance | Durable with minimal maintenance required, but should be cleaned regularly. | Low maintenance, but may wear out faster due to simpler construction. | Maintenance varies; high-quality options require less upkeep. |

| Best Use Case | Ideal for serious lifters looking for maximum efficiency and comfort in back workouts. | Suitable for general fitness use, especially in budget-friendly setups. | Best for users seeking specific ergonomic features for comfort during varied workouts. |

What Are the Pros and Cons of Using Traditional Lat Pulldown Bars?

Traditional lat pulldown bars are ubiquitous in gyms and fitness centers. They provide basic functionality for back workouts, allowing users to perform a range of exercises. The primary advantage of these bars is their affordability and availability. However, they often lack ergonomic design features, which can lead to discomfort and ineffective muscle engagement. Users may experience strain on their wrists and elbows, particularly during heavy lifts, which can deter consistent use.

How Do Ergonomic Cable Attachments Compare to MAG Grip?

Ergonomic cable attachments present a middle ground between traditional bars and specialized equipment like MAG Grip. These attachments are designed to enhance grip comfort and reduce strain on the joints. While many ergonomic options provide better hand positioning than standard bars, they may not always match the level of muscle isolation and performance that MAG Grip offers. Additionally, the quality of these attachments can vary significantly between brands, making it essential for buyers to evaluate specific products carefully.

Conclusion: How Can B2B Buyers Choose the Right Solution?

Choosing the right cable attachment depends on several factors, including performance needs, budget, and user experience. For serious athletes or facilities focusing on high-performance training, the MAG Grip stands out as a premium option that delivers enhanced muscle isolation and comfort. Conversely, traditional lat pulldown bars may serve well for budget-conscious gyms that cater to a broader audience. Ergonomic cable attachments can be a suitable compromise, providing comfort without the premium price tag. Ultimately, B2B buyers should assess their specific use cases, user demographics, and long-term investment potential before making a decision.

Essential Technical Properties and Trade Terminology for mag grip

What Are the Key Technical Properties of MAG Grip?

When considering MAG Grip products for your business, understanding their essential technical properties is crucial. Here are some critical specifications that highlight their performance and suitability for various applications:

-

Material Grade

MAG Grips are typically made from high-grade materials such as stainless steel or heavy-duty plastics. The choice of material affects durability, corrosion resistance, and overall performance. For B2B buyers, selecting products made from superior materials ensures longevity and reliability, reducing the frequency of replacements. -

Grip Design and Ergonomics

The MAG Grip features an innovative ergonomic design that promotes natural hand positioning during use. This design minimizes strain on the wrists and forearms, enhancing user comfort and performance. For businesses, investing in ergonomic equipment can lead to higher user satisfaction, improved productivity, and reduced risk of workplace injuries. -

Weight Capacity

Each MAG Grip attachment is engineered to support a specific weight limit, which can range from moderate to heavy loads. Understanding the weight capacity is vital for businesses that cater to different fitness levels. Ensuring that the equipment can handle the anticipated loads is essential for safety and operational efficiency. -

Compatibility with Cable Machines

MAG Grips are designed to fit a variety of cable machines, making them versatile for different gym setups. This compatibility allows businesses to offer a broader range of training options without the need for extensive equipment modifications. It also facilitates easier integration into existing facilities, saving time and costs. -

Tolerance Levels

Precision manufacturing processes ensure that MAG Grips maintain tight tolerances, which is crucial for effective performance. This specification affects how well the grips fit onto machines and interact with weights. For B2B buyers, understanding tolerances can help in selecting the right products that ensure seamless operation and safety.

What Are Common Trade Terms Related to MAG Grip?

Navigating the B2B landscape requires familiarity with specific terminology. Here are some essential terms that are commonly used in the context of MAG Grip and similar products:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. For businesses, partnering with an OEM for MAG Grip products can facilitate custom solutions that meet specific market needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is essential for businesses to manage inventory effectively and ensure that they are ordering sufficient quantities to meet demand without overstocking. -

RFQ (Request for Quotation)

An RFQ is a document used by businesses to solicit price quotes from suppliers for specific products or services. For MAG Grip procurement, issuing an RFQ can help compare pricing, terms, and conditions among different suppliers, ensuring the best deal. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for businesses importing MAG Grip products, as they dictate shipping, insurance, and liability terms, impacting cost and delivery timelines. -

Lead Time

Lead time is the time it takes from placing an order to receiving the goods. For businesses, understanding lead times for MAG Grip products is essential for planning inventory and ensuring timely availability to customers. -

Warranty and Return Policies

Warranty terms define the manufacturer’s guarantee regarding the quality and performance of the product. Knowledge of warranty and return policies is critical for B2B buyers to mitigate risks associated with defective products and ensure customer satisfaction.

By grasping these technical properties and trade terms, businesses can make informed decisions when sourcing MAG Grip products, optimizing their offerings and enhancing customer experience.

Navigating Market Dynamics and Sourcing Trends in the mag grip Sector

What Are the Current Market Dynamics and Key Trends in the Mag Grip Sector?

The global market for mag grips, particularly cable attachments, has experienced robust growth driven by an increasing awareness of fitness and strength training across diverse demographics. As more individuals and organizations invest in home gyms and commercial fitness facilities, the demand for innovative equipment like MAG Grip attachments is surging. This trend is particularly pronounced in regions such as Africa, South America, the Middle East, and Europe, where there is a growing emphasis on enhancing physical fitness and well-being.

Current sourcing trends indicate a shift toward technology-driven solutions. The integration of smart features in fitness equipment, such as connectivity for tracking performance, is becoming increasingly important. International B2B buyers are looking for suppliers who can offer advanced, ergonomic designs that enhance user experience while also providing data-driven insights for better workout optimization. Additionally, the demand for customizability in equipment—such as varying grip sizes and styles—reflects a growing trend toward personalized fitness solutions.

Moreover, the emphasis on quality and durability remains strong. Buyers are increasingly discerning, favoring products that not only perform well but also withstand rigorous use over time. This dynamic is critical for suppliers aiming to penetrate or expand in competitive markets, as they must demonstrate the efficacy and longevity of their offerings.

How Is Sustainability Influencing B2B Sourcing Decisions in the Mag Grip Sector?

Sustainability is a pivotal consideration for B2B buyers in the mag grip sector, reflecting a broader trend towards environmentally responsible practices across industries. The environmental impact of manufacturing processes, including the sourcing of raw materials, has come under scrutiny. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainability through ethical sourcing, reduced carbon footprints, and environmentally friendly production methods.

The importance of ethical supply chains cannot be overstated. Buyers are looking for transparency in sourcing practices, ensuring that materials used in mag grips are obtained responsibly and that labor practices adhere to fair standards. Certifications such as ISO 14001 for environmental management and Fair Trade certifications are becoming significant markers of credibility in supplier selection.

Furthermore, the use of ‘green’ materials, such as recycled plastics and sustainably sourced metals, is gaining traction. Suppliers who can provide eco-friendly options not only meet the demands of environmentally conscious buyers but also differentiate themselves in a crowded marketplace. Ultimately, sustainability not only enhances brand reputation but also aligns with the values of a growing segment of consumers, making it a crucial factor in sourcing decisions.

What Is the Evolution of Mag Grip Technology and Its Impact on B2B Buying?

The mag grip technology has evolved significantly over the past two decades, transitioning from basic attachments to highly specialized equipment designed to optimize back workouts and other pulling movements. Initially, fitness accessories were limited in variety and functionality, often leading to discomfort and inefficient workouts. However, the introduction of the Maximum Advantage Grip (MAG) has transformed the landscape by offering ergonomic designs that enhance grip, reduce strain, and improve workout efficacy.

This evolution has profound implications for B2B buyers. As the technology behind mag grips continues to advance, suppliers are introducing a range of innovative products tailored to meet specific fitness needs. This allows buyers to select equipment that not only meets their functional requirements but also aligns with their brand identity and customer preferences. Additionally, the emphasis on research and development in this sector indicates that suppliers who invest in innovation will likely gain a competitive edge, making it essential for international buyers to stay informed about the latest advancements.

In conclusion, navigating the mag grip sector requires an understanding of market dynamics, a commitment to sustainability, and an appreciation for the evolution of technology. By focusing on these aspects, B2B buyers can make informed decisions that align with their business goals and customer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of mag grip

-

How do I evaluate the quality of MAG Grip products before purchasing?

When sourcing MAG Grip products, assess quality through a combination of supplier reviews, product samples, and certifications. Look for suppliers with a proven track record in the fitness equipment market. Request product samples to evaluate materials, ergonomics, and overall craftsmanship. Additionally, inquire about any quality assurance processes in place, including testing for durability and performance. This ensures that the products meet international standards, particularly important when catering to diverse markets across Africa, South America, the Middle East, and Europe. -

What is the best MAG Grip attachment for enhancing back workouts?

The MAG Medium Grip Supinate is widely regarded as one of the best attachments for back workouts. Its unique design allows for optimal hand positioning, reducing strain on the wrists and forearms while maximizing muscle engagement during pull exercises. This grip is particularly effective for targeting the lats and improving overall upper body strength. For businesses catering to serious fitness enthusiasts or professional gyms, this attachment can be a key offering to differentiate your product range. -

What are the minimum order quantities (MOQ) for MAG Grip products?

Minimum order quantities for MAG Grip products can vary significantly by supplier and specific product lines. Generally, MOQs can range from as low as 10 units for smaller businesses to several hundred units for larger bulk orders. It’s essential to communicate directly with potential suppliers to understand their MOQ policies, as well as any potential for negotiation based on your purchasing needs. This information is crucial for businesses looking to maintain inventory without overcommitting financial resources. -

What payment terms should I expect when sourcing MAG Grip products internationally?

Payment terms can vary based on the supplier’s policies and your negotiation skills. Common terms include 30% upfront payment with the balance due upon shipment or delivery. For larger orders, some suppliers may offer net 30 or net 60 terms, allowing you to pay after receiving the goods. Always clarify the payment options available, including any discounts for early payment or bulk purchases, to ensure favorable cash flow management for your business. -

How can I customize MAG Grip products for my brand?

Customization options for MAG Grip products typically include logo printing, color variations, and packaging design. Many manufacturers offer branding opportunities to enhance your product’s marketability. To pursue customization, communicate your specific requirements early in the sourcing process, and request samples of customized designs to ensure they align with your brand image. This approach can strengthen your market presence and attract customers looking for unique fitness solutions. -

What logistics considerations should I keep in mind when importing MAG Grip products?

When importing MAG Grip products, consider logistics factors such as shipping costs, lead times, and customs regulations. Work with experienced freight forwarders familiar with international shipping to navigate potential challenges, including tariffs and import duties. Additionally, plan for warehousing and distribution within your target market to ensure timely delivery. Understanding these logistics will help streamline your supply chain and maintain customer satisfaction. -

How do I vet suppliers of MAG Grip products for reliability?

To vet suppliers, start by researching their reputation within the fitness equipment industry. Look for customer testimonials, online reviews, and case studies that highlight their experience and reliability. Additionally, request references from previous clients and inquire about their manufacturing processes. Conducting factory visits or audits can further ensure that the supplier adheres to quality standards and ethical practices, crucial for long-term partnerships. -

What quality assurance processes should be in place for MAG Grip products?

Quality assurance processes for MAG Grip products should include stringent testing protocols at multiple stages of production. This may involve material inspections, functional testing, and ergonomic assessments to ensure the products meet specified standards. Inquire if the supplier has certifications such as ISO or relevant industry standards. A robust QA process not only guarantees product quality but also protects your brand reputation in competitive markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Mag Grip Manufacturers & Suppliers List

1. Maxagrip – Essential Grips

Domain: maxagrip.com

Registered: 2010 (15 years)

Introduction: [{‘name’: ‘Palm Press’, ‘code’: ‘PP009’, ‘price’: 64.95}, {‘name’: ‘Three Quarter Grip’, ‘code’: ‘TQ008’, ‘price’: 69.95}, {‘name’: ‘Close Grip Neutral’, ‘code’: ‘CN001’, ‘price’: 59.95}, {‘name’: ‘Close Grip Pronate’, ‘code’: ‘CP002’, ‘price’: 59.95}, {‘name’: ‘Close Grip Supinate’, ‘code’: ‘CS003’, ‘price’: 59.95}, {‘name’: ‘Medium Grip Neutral’, ‘code’: ‘MN004’, ‘price’: 64.95}, {‘name’: ‘Mediu…

2. Reddit – MAG Handle Guide

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: MAG Handle Comprehensive Guide – After 5+ Years of Reps, Sets, and Workouts. Detailed overview of MAG handles, including usage and effectiveness for back development. Discussion on targeting biceps with MAG handles versus traditional methods. User feedback highlights lack of comprehensive information from MAG’s official resources.

3. T-Nation – MAG Grips

Domain: t-nation.com

Registered: 2002 (23 years)

Introduction: MAG Grips come in various attachments, including narrow supinating grips favored for rows and triceps exercises. Users report that these grips allow for increased weight usage and better alignment of elbows, enhancing lat engagement during exercises like pull downs and rows. Some users have compared MAG Grips to copycat versions, noting that while the copycats may feel similar, they can be heavier…

4. Garage Gym Life – MAG Grips

Domain: garagegymlifemedia.com

Registered: 2019 (6 years)

Introduction: MAG Grips are designed to enhance grip and performance during workouts. They feature a unique design that allows for better control and stability. The grips are made from durable materials, ensuring longevity and resistance to wear and tear. They are suitable for various exercises, including weightlifting and bodyweight movements. The grips are lightweight and portable, making them easy to carry t…

5. Walmart – Totoe 3 in 1 Charging Station

Domain: walmart.com

Registered: 1995 (30 years)

Introduction: This company, Walmart – Totoe 3 in 1 Charging Station, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

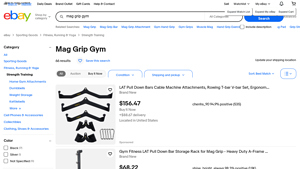

6. Mag Grip – LAT Pull Down Bar

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Mag Grip LAT Pull Down Bar with 6 Ergonomic Handles (Neutral Grip, Wide Grip) – Brand New, Price: $118.89, Free delivery, Located in United States. Other listings include: LAT Pulldown Attachments, LAT Pull Down Bar Storage Rack for Mag Grip, Heavy Duty A-Frame Stand Attachments, with prices ranging from $44.06 to $135.99, all brand new with free delivery options.

7. ScrapingDog – Instagram Data Services

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: Contact us at info@scrapingdog.com for scraping Instagram. Let us know how many pages you want to scrape per month.

8. MAG – Medium Grip Neutral

Domain: garagegymreviews.com

Registered: 2014 (11 years)

Introduction: Product Name: MAG Medium Grip Neutral

Design: Steel and rubber construction, chip and scratch-resistant

Manufacturing: Made in the USA

Target Audience: Suitable for novice and highly trained athletes

Functionality: Easy to isolate and target muscle groups, provides wrist support

Unique Features: Unique hand placement to prevent energy loss and disperse force evenly across hands and wrists

Pros: Hi…

Strategic Sourcing Conclusion and Outlook for mag grip

What Are the Key Benefits of Strategic Sourcing for MAG Grip Products?

In conclusion, strategic sourcing of MAG Grip products presents a unique opportunity for international B2B buyers to enhance their fitness equipment offerings. These innovative cable attachments not only revolutionize upper body workouts but also cater to a diverse range of users, from elite athletes to casual gym-goers. By prioritizing quality and ergonomics, MAG Grips have established themselves as essential tools for maximizing workout efficiency and comfort.

Investing in MAG Grip products ensures that businesses remain competitive in the growing fitness market, particularly in regions like Africa, South America, the Middle East, and Europe. As consumer demand for specialized fitness equipment continues to rise, sourcing these high-quality attachments can lead to increased customer satisfaction and loyalty.

How Can International Buyers Capitalize on This Trend?

As the global fitness landscape evolves, now is the time for international B2B buyers to align their purchasing strategies with innovative solutions like MAG Grips. By doing so, businesses can not only meet market demands but also position themselves as leaders in the fitness equipment sector. Take action today by exploring partnerships with reliable suppliers and integrating MAG Grip products into your inventory, ensuring your offerings are top-notch and ahead of the competition.