Master the Blow-Up Ratio: Your Complete Guide for 2025

Introduction: Navigating the Global Market for blow-up ratio

Navigating the complexities of the global market can be a daunting task for international B2B buyers, particularly when it comes to understanding critical metrics like the blow-up ratio. This key performance indicator not only influences production efficiency but also affects cost structures and profitability across various sectors. Buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Colombia, face unique challenges in sourcing materials and suppliers that align with their operational needs. This guide aims to demystify the blow-up ratio, providing a comprehensive overview of its types, applications, and the factors that influence it.

By exploring the nuances of the blow-up ratio, this guide empowers B2B buyers to make informed purchasing decisions. It covers essential topics such as effective supplier vetting processes, cost implications, and the strategic application of this metric in various industries. Whether you’re seeking to optimize your supply chain or enhance your product offerings, understanding the blow-up ratio is vital for driving efficiency and improving overall business performance. Equip yourself with the insights needed to navigate the global marketplace effectively, ensuring that your investments yield maximum returns while minimizing risks.

Understanding blow-up ratio Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Blow-Up Ratio | Calculated by dividing the volume of the final product by the volume of the raw material. | Manufacturing, Food Processing | Pros: Easy to calculate; widely accepted standard. Cons: May not account for waste or inefficiencies. |

| Effective Blow-Up Ratio | Adjusts the standard ratio by factoring in waste and inefficiencies in production. | Textile, Plastics, and Packaging | Pros: Provides a more accurate representation of efficiency. Cons: More complex to calculate; requires detailed data. |

| Theoretical Blow-Up Ratio | Reflects the ideal scenario where no waste occurs, purely theoretical. | R&D, Conceptual Manufacturing | Pros: Useful for benchmarking; sets performance goals. Cons: Not practical for real-world applications; overly optimistic. |

| Dynamic Blow-Up Ratio | Changes based on varying production conditions or material properties. | Aerospace, Automotive | Pros: Adapts to real-time changes; enhances flexibility. Cons: Requires continuous monitoring and adjustment. |

| Historical Blow-Up Ratio | Based on past production data, providing insights into trends over time. | Quality Control, Process Improvement | Pros: Helps identify long-term trends; aids in forecasting. Cons: May not be relevant in rapidly changing markets. |

What is the Standard Blow-Up Ratio and When Should B2B Buyers Use It?

The Standard Blow-Up Ratio is a fundamental metric used in various industries to assess production efficiency. It is calculated by dividing the final product’s volume by the raw material’s volume. B2B buyers in manufacturing and food processing often rely on this ratio as it provides a straightforward and widely accepted standard for measuring output. However, it does not account for waste or inefficiencies, making it crucial for buyers to consider additional metrics for a comprehensive evaluation.

How Does the Effective Blow-Up Ratio Enhance Production Insights?

The Effective Blow-Up Ratio refines the standard approach by incorporating waste and inefficiencies into its calculations. This type is particularly valuable for B2B buyers in textiles, plastics, and packaging industries, as it offers a more realistic picture of production efficiency. While it provides deeper insights, the Effective Blow-Up Ratio is more complex to calculate, requiring detailed data collection and analysis. Buyers should weigh the benefits of improved accuracy against the need for comprehensive data management.

Why is the Theoretical Blow-Up Ratio Important for B2B Buyers in R&D?

The Theoretical Blow-Up Ratio serves as an idealized benchmark that assumes no waste occurs during production. This metric is especially useful for B2B buyers in research and development or conceptual manufacturing settings, as it helps set performance goals and expectations. However, its overly optimistic nature can lead to unrealistic assessments in practical applications, so buyers should use it alongside more pragmatic ratios for balanced decision-making.

How Can B2B Buyers Leverage the Dynamic Blow-Up Ratio for Flexibility?

The Dynamic Blow-Up Ratio is designed to adjust based on varying production conditions or material properties, making it particularly relevant in industries like aerospace and automotive. This adaptability allows B2B buyers to respond to real-time changes in production, enhancing operational flexibility. However, it requires continuous monitoring and adjustment, which can be resource-intensive. Buyers should consider their capacity for real-time data analysis when adopting this metric.

What Insights Can B2B Buyers Gain from the Historical Blow-Up Ratio?

The Historical Blow-Up Ratio analyzes past production data to identify trends and inform future performance expectations. It is beneficial for B2B buyers focused on quality control and process improvement, as it helps detect long-term patterns and forecast future outcomes. However, its relevance may diminish in rapidly changing markets, where past data may not accurately predict future performance. Buyers should balance historical insights with current market conditions for effective decision-making.

Key Industrial Applications of blow-up ratio

| Industry/Sector | Specific Application of blow-up ratio | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Packaging | Optimizing film thickness in flexible packaging | Reduces material costs while maintaining quality | Material specifications, supplier reliability |

| Construction | Designing lightweight concrete structures | Enhances energy efficiency and reduces costs | Compliance with local regulations, durability |

| Food and Beverage | Manufacturing expanded snack products | Improves product appeal and shelf life | Ingredient sourcing, health and safety standards |

| Automotive | Lightweighting components using blow-molding | Increases fuel efficiency and reduces emissions | Supplier certifications, material compatibility |

| Textiles | Producing high-loft insulation materials | Increases thermal efficiency and comfort | Fiber quality, environmental sustainability |

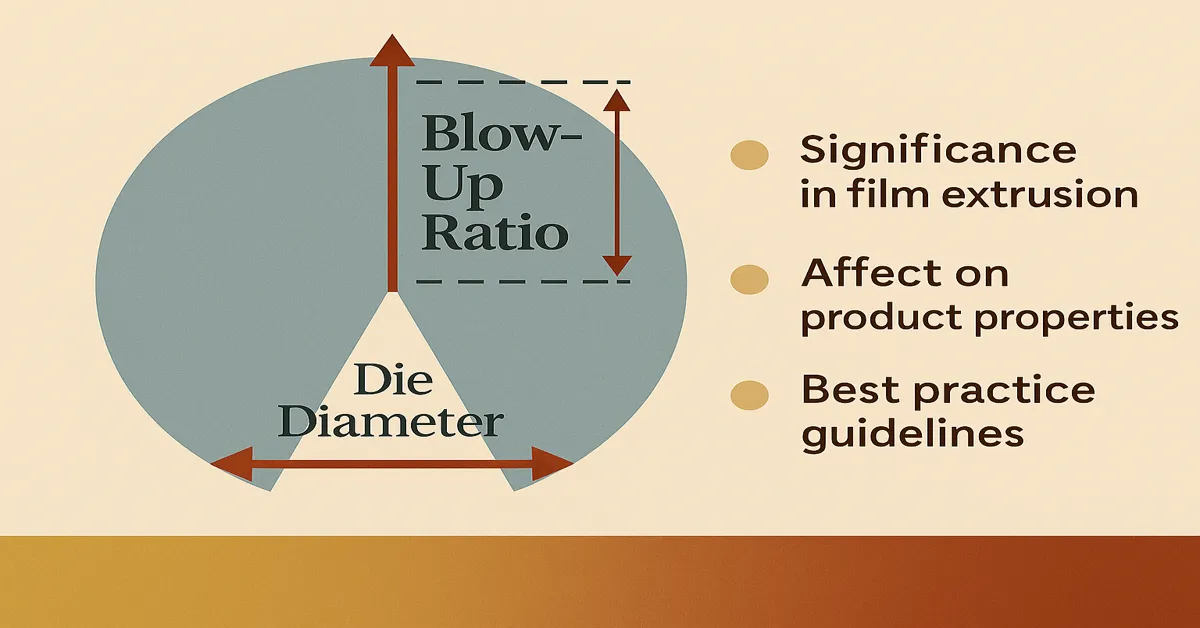

How is Blow-Up Ratio Used in Packaging?

In the packaging industry, the blow-up ratio is critical for determining the optimal thickness of films used in flexible packaging. By adjusting the blow-up ratio, manufacturers can minimize material usage while ensuring that the packaging maintains its structural integrity and barrier properties. This approach not only reduces costs but also supports sustainability efforts by decreasing plastic waste. International buyers should consider suppliers that can provide materials meeting specific performance criteria while also adhering to local regulations on packaging materials.

What Role Does Blow-Up Ratio Play in Construction?

In construction, particularly in the production of lightweight concrete, the blow-up ratio is essential for achieving desired strength and insulation properties. A higher blow-up ratio can lead to lighter concrete mixes, which in turn reduces the overall weight of structures, leading to lower material and transportation costs. Buyers in this sector must evaluate suppliers based on their ability to meet local building codes and the durability of the concrete products offered.

A stock image related to blow-up ratio.

How is Blow-Up Ratio Applied in Food and Beverage?

The blow-up ratio is increasingly utilized in the food and beverage sector for creating expanded snack products, such as puffed snacks and cereals. By manipulating the blow-up ratio during manufacturing, companies can enhance the texture and appeal of their products while extending shelf life. For international buyers, it is vital to source ingredients that comply with health and safety regulations, ensuring that the final products are not only enjoyable but also safe for consumption.

Why is Blow-Up Ratio Important in Automotive Manufacturing?

In the automotive industry, the blow-up ratio is leveraged in the production of lightweight components through blow-molding techniques. This process helps reduce the weight of vehicles, leading to improved fuel efficiency and lower emissions. B2B buyers in this sector should prioritize suppliers with proven certifications and a track record of producing compatible materials that meet stringent automotive standards.

How Does Blow-Up Ratio Benefit the Textile Industry?

The textile industry uses blow-up ratios to create high-loft insulation materials, which are essential for products like jackets and sleeping bags. By optimizing the blow-up ratio, manufacturers can enhance thermal efficiency while maintaining comfort for the end-user. Buyers should consider the quality of fibers used and the supplier’s commitment to environmental sustainability, as these factors can significantly impact product performance and brand reputation.

3 Common User Pain Points for ‘blow-up ratio’ & Their Solutions

Scenario 1: Understanding the Blow-Up Ratio in Diverse Markets

The Problem:

B2B buyers often struggle to grasp the concept of blow-up ratio, particularly when navigating international markets. For instance, a procurement manager in South America might find it challenging to analyze the blow-up ratio of construction materials sourced from Europe. This confusion can lead to poor investment decisions, resulting in budget overruns and project delays. The lack of a standardized approach across different regions exacerbates this issue, leaving buyers uncertain about how to calculate and apply blow-up ratios effectively.

The Solution:

To mitigate this challenge, B2B buyers should invest time in understanding the regional nuances of blow-up ratios. This can be achieved through comprehensive training sessions or workshops focused on specific markets. Engaging with local experts or consultants who specialize in the target region can provide invaluable insights into the factors affecting blow-up ratios. Additionally, creating a standardized template for calculating blow-up ratios tailored to regional specifics can help streamline the process. By adopting this approach, buyers will be better equipped to make informed decisions, ultimately leading to more successful project outcomes.

Scenario 2: Inconsistent Data Sources and Reliability Issues

The Problem:

Another prevalent pain point for B2B buyers is the inconsistency of data sources when evaluating blow-up ratios. For example, an African buyer may rely on various suppliers for pricing data, each providing different blow-up ratios based on their internal calculations. This disparity can lead to confusion and mistrust, complicating the decision-making process and resulting in financial risks if inaccurate data is used.

The Solution:

To overcome this issue, buyers should prioritize sourcing data from reputable, standardized databases or industry benchmarks. Establishing relationships with trusted industry organizations can ensure access to reliable data. Furthermore, implementing a centralized data management system can help streamline data collection and analysis, providing a consistent framework for evaluating blow-up ratios. Regular audits and reviews of these data sources will also enhance credibility, allowing buyers to make decisions based on accurate and trustworthy information.

Scenario 3: Failure to Communicate Blow-Up Ratios Effectively Across Teams

The Problem:

Effective communication of blow-up ratios within organizations is often overlooked, leading to misunderstandings and misalignment among teams. For instance, a buyer in the Middle East may calculate a blow-up ratio based on supplier quotes but fails to communicate this effectively to the finance team, who then prepares budgets without considering these figures. This disconnect can result in severe budget discrepancies and misallocated resources.

The Solution:

To address communication gaps, organizations should establish a clear protocol for sharing blow-up ratio calculations across departments. This could involve creating a shared digital platform where calculations are documented and accessible to all relevant teams. Regular cross-departmental meetings can also facilitate discussions about blow-up ratios and their implications on budgeting and resource allocation. Training sessions that emphasize the importance of blow-up ratios and their impact on overall financial health will foster a culture of transparency and collaboration, ultimately leading to more cohesive operations and better financial management.

Strategic Material Selection Guide for blow-up ratio

What Are the Key Properties of Common Materials Used for Blow-Up Ratio Applications?

A stock image related to blow-up ratio.

When selecting materials for applications involving blow-up ratios, it is crucial to consider specific properties that directly impact product performance. The following materials are commonly used in various industries due to their unique characteristics.

1. Polypropylene (PP)

Key Properties:

Polypropylene is known for its excellent chemical resistance and high melting point (around 160°C). It has a low density, making it lightweight yet durable under moderate pressure.

Pros & Cons:

PP is cost-effective and easy to manufacture, allowing for complex geometries. However, it has limitations in high-temperature applications and can become brittle over time when exposed to UV light.

Impact on Application:

Polypropylene is suitable for applications involving corrosive media, such as acids and alkalis, making it a popular choice in chemical processing.

Considerations for International Buyers:

Buyers from Africa, South America, the Middle East, and Europe should ensure compliance with local standards like ASTM and DIN. The availability of PP in local markets can vary, affecting lead times and costs.

2. Stainless Steel

Key Properties:

Stainless steel offers high strength, excellent corrosion resistance, and can withstand extreme temperatures (up to 870°C). Its durability makes it suitable for high-pressure applications.

Pros & Cons:

While stainless steel is robust and long-lasting, it comes at a higher cost compared to plastic materials. Manufacturing complexity can also be a concern, especially for intricate designs.

Impact on Application:

This material is ideal for applications involving food and pharmaceutical industries due to its hygienic properties and ability to withstand cleaning processes.

Considerations for International Buyers:

Buyers should be aware of the specific grades of stainless steel (e.g., 304, 316) that comply with international standards. Understanding local regulations regarding food safety and material certifications is critical.

3. PVC (Polyvinyl Chloride)

Key Properties:

PVC is a versatile plastic known for its good mechanical properties and chemical resistance. It can operate effectively in temperatures up to 60°C and is often used in lower-pressure applications.

Pros & Cons:

The material is affordable and easy to process, making it widely used in construction and plumbing. However, PVC can become brittle over time and is less suitable for high-temperature applications.

Impact on Application:

PVC is commonly used in piping systems and electrical insulation, but it may not be compatible with certain solvents, which can limit its use in chemical applications.

Considerations for International Buyers:

International buyers should check for compliance with local building codes and standards, as PVC regulations can vary significantly across regions.

4. Glass Reinforced Plastic (GRP)

Key Properties:

GRP combines plastic with glass fibers, resulting in a lightweight yet strong material with excellent corrosion resistance. It can handle temperatures up to 120°C and is ideal for various pressures.

Pros & Cons:

GRP is highly durable and can be molded into complex shapes. However, it is generally more expensive than traditional plastics and requires specialized manufacturing techniques.

Impact on Application:

This material is particularly effective in environments with high chemical exposure, making it suitable for the oil and gas industry.

Considerations for International Buyers:

Buyers should consider the availability of GRP suppliers in their region and ensure that products meet international quality standards.

Summary Table of Material Selection for Blow-Up Ratio

| Material | Typical Use Case for Blow-Up Ratio | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Chemical processing applications | Excellent chemical resistance | Limited high-temperature capability | Low |

| Stainless Steel | Food and pharmaceutical industries | High strength and durability | Higher cost and manufacturing complexity | High |

| PVC | Plumbing and electrical insulation | Cost-effective and easy to process | Brittle over time, lower temp use | Low |

| Glass Reinforced Plastic | Oil and gas industry applications | Lightweight and strong | More expensive, requires special manufacturing | Med |

This guide provides international B2B buyers with insights into the material selection process for applications involving blow-up ratios, ensuring informed decisions that align with regional standards and operational requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for blow-up ratio

What Are the Main Stages of Manufacturing Processes for Blow-Up Ratio?

The manufacturing process for products with a blow-up ratio typically involves several key stages, each critical to ensuring the final product meets quality standards. Understanding these stages will help B2B buyers from regions like Africa, South America, the Middle East, and Europe make informed decisions when selecting suppliers.

1. Material Preparation

The first step in the manufacturing process involves selecting the right materials, which significantly influences the blow-up ratio. Common materials include polymers and composites, chosen for their elasticity and strength. The preparation process often includes the following:

- Material Sourcing: Ensure that materials are sourced from reputable suppliers. Buyers should look for certifications that validate the quality of the materials.

- Quality Inspection: Incoming materials undergo rigorous inspection to confirm they meet specified standards. This includes checking for purity, moisture content, and other relevant properties.

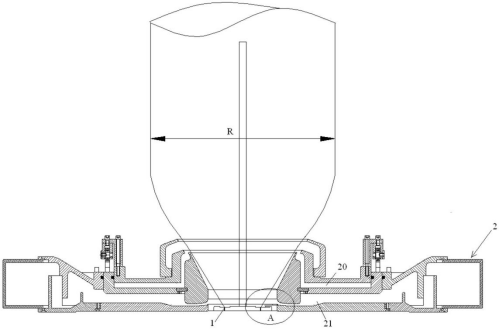

2. Forming Techniques Used in Blow-Up Ratio Production

After material preparation, the next stage is forming, where raw materials are transformed into the desired shape. This stage is crucial for achieving the correct blow-up ratio. Key forming techniques include:

- Blow Molding: A widely used method where heated plastic is inflated into a mold. B2B buyers should inquire about the specific blow molding techniques employed, as different methods can yield varying blow-up ratios.

- Injection Molding: This involves injecting molten material into a mold. It’s essential for complex designs but may not always provide the same blow-up ratio as blow molding.

Understanding these techniques helps buyers gauge the manufacturer’s capabilities and the potential for product variations.

3. Assembly Processes and Their Impact on Blow-Up Ratio

In some cases, multiple components need to be assembled to create the final product. This stage can affect the blow-up ratio if not executed correctly. Key considerations include:

- Precision Assembly: Ensuring that parts fit together precisely can impact the overall functionality and performance of the final product.

- Automated vs. Manual Assembly: Buyers should ask about the assembly methods used. Automated processes often yield higher consistency and lower defects.

4. Finishing Techniques and Their Role in Quality Assurance

Finishing processes enhance the product’s appearance and functionality. Common finishing techniques include:

- Surface Treatment: Techniques such as painting, coating, or polishing can improve aesthetics and durability.

- Quality Control During Finishing: It’s vital to ensure that finishing processes do not compromise the blow-up ratio. Regular checks should be implemented to confirm that finishing does not introduce defects.

How Is Quality Assurance Implemented in Blow-Up Ratio Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process, especially for products where the blow-up ratio is essential for performance. International standards and industry-specific guidelines help ensure that products meet buyer expectations.

1. What Are the Relevant International Standards for Quality Assurance?

B2B buyers should ensure that their suppliers adhere to international quality standards. The following are particularly relevant:

- ISO 9001: This standard outlines requirements for a quality management system (QMS). It’s essential for manufacturers to demonstrate consistent quality in their products.

- CE Marking: For products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For products in the oil and gas sector, adherence to American Petroleum Institute (API) standards is crucial.

Understanding these certifications provides buyers with a framework to evaluate supplier quality.

2. What Are the Key Quality Control Checkpoints?

Quality control (QC) is implemented at various stages of the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This is the first line of defense, where raw materials are inspected before use.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing ensures that any deviations are caught early, minimizing waste and defects.

- Final Quality Control (FQC): This stage involves comprehensive testing of the finished product to ensure it meets all specifications, including the blow-up ratio.

Buyers should request detailed reports on these QC processes to verify compliance.

3. How Can B2B Buyers Verify Supplier Quality Control?

When sourcing products, especially those reliant on specific blow-up ratios, buyers must verify the supplier’s QC practices. Here are actionable steps:

- Conduct Audits: Regular audits help assess the supplier’s adherence to quality standards. Buyers can either conduct these audits themselves or hire third-party inspection services.

- Request Documentation: Suppliers should provide quality control documentation, including inspection reports and certifications.

- Engage Third-Party Inspectors: Utilizing independent inspectors can provide an objective assessment of the supplier’s quality management processes.

What Testing Methods Are Commonly Used in Blow-Up Ratio Manufacturing?

Various testing methods are employed to ensure that products meet the required specifications for blow-up ratios. Buyers should be aware of these methods to understand the reliability of the products they are purchasing.

- Hydrostatic Testing: This method tests the integrity of the product under pressure, ensuring it can withstand operational conditions.

- Dimensional Inspection: Measuring the product against specified dimensions helps verify that it meets design criteria.

- Performance Testing: This involves assessing the product’s performance under conditions that mimic real-world applications, including its blow-up ratio.

A stock image related to blow-up ratio.

Conclusion: Navigating Quality Assurance in International B2B Purchasing

Understanding the manufacturing processes and quality assurance measures related to blow-up ratios is crucial for international B2B buyers. By focusing on material preparation, forming techniques, assembly processes, and rigorous quality checks, buyers can ensure they source high-quality products that meet their specific needs. Engaging in thorough supplier audits, verifying certifications, and understanding testing methods will empower B2B buyers to make informed decisions and establish long-lasting partnerships with reliable manufacturers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘blow-up ratio’

To successfully procure the right blow-up ratio for your business needs, it is essential to follow a systematic approach. This step-by-step checklist will guide international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, in making informed sourcing decisions.

Step 1: Define Your Technical Specifications

Clearly outline what you require in terms of blow-up ratio. This includes understanding the specific metrics that are critical for your operations, such as size, material properties, and performance standards. Having precise specifications will help ensure that you communicate effectively with potential suppliers and evaluate their offerings accurately.

Step 2: Research Market Trends and Standards

Investigate current market trends related to blow-up ratios in your industry. This includes studying regulatory standards and technological advancements that may affect product quality. Understanding these elements will help you identify reputable suppliers who adhere to the latest industry practices.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, conduct a thorough evaluation. Request detailed company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers with a proven track record of delivering high-quality products that meet your specifications.

- Check Reviews and Ratings: Use platforms like LinkedIn or industry-specific forums to gauge supplier reputation.

- Request Samples: If possible, obtain samples to assess the quality firsthand.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers possess relevant certifications that validate their compliance with industry standards. This might include ISO certifications or specific quality assurance certifications pertinent to the blow-up ratio. Verifying these credentials can prevent future complications and ensure reliability.

Step 5: Assess Pricing and Payment Terms

Analyze the pricing structures of shortlisted suppliers. While lower prices may be tempting, ensure that they do not compromise quality. Additionally, clarify payment terms to avoid misunderstandings later.

- Consider Total Cost of Ownership: Factor in shipping, tariffs, and potential downtime costs that could arise from lower-quality products.

- Negotiate Payment Terms: Flexible payment terms can improve cash flow and reduce financial risks.

Step 6: Establish Communication Channels

Set up clear communication channels with your chosen supplier. Effective communication is crucial for addressing any potential issues during the procurement process. Ensure that there are designated points of contact for both parties to facilitate smooth interactions.

- Use Project Management Tools: Consider using tools that allow for shared updates and timelines to keep all stakeholders informed.

- Schedule Regular Check-Ins: Regular updates can help mitigate any risks before they escalate.

Step 7: Plan for Quality Assurance and Inspection

Before finalizing the order, establish a quality assurance plan. This includes setting criteria for inspections and testing to ensure that the blow-up ratio meets your requirements upon delivery.

- Define Acceptance Criteria: Clearly outline what constitutes acceptable quality.

- Consider Third-Party Inspections: Engaging third-party quality assurance firms can provide an unbiased assessment of the products.

By following this comprehensive checklist, B2B buyers can navigate the complexities of sourcing blow-up ratios more effectively, ensuring they make informed and beneficial procurement decisions.

Comprehensive Cost and Pricing Analysis for blow-up ratio Sourcing

What Are the Key Cost Components in Blow-Up Ratio Sourcing?

When evaluating the costs associated with sourcing blow-up ratios, it is essential to consider various components that contribute to the overall pricing structure. The main cost elements include:

-

Materials: The choice of materials directly affects the cost of production. High-quality materials may increase initial costs but can lead to better performance and longevity, reducing the Total Cost of Ownership (TCO) in the long run.

-

Labor: Labor costs can vary significantly by region. In countries with lower labor costs, such as some parts of Africa and South America, sourcing may be more economical. However, skill levels and labor availability must also be assessed.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and other indirect costs associated with production. Efficient manufacturing processes can help reduce these overheads.

-

Tooling: Initial investments in tooling can be substantial, especially for custom blow-up ratios. Buyers should consider whether the tooling costs can be amortized over large production volumes.

-

Quality Control (QC): Implementing rigorous QC measures can add to costs but is essential for ensuring product reliability and compliance with international standards, especially for buyers in Europe and the Middle East.

-

Logistics: Shipping and transportation costs can vary widely based on distance, shipping method, and trade agreements. Understanding Incoterms is crucial for managing these expenses effectively.

-

Margin: Supplier margins will depend on the market dynamics and competition. Buyers should compare multiple suppliers to ensure they are getting a fair deal.

How Do Price Influencers Affect Blow-Up Ratio Sourcing?

Several factors can influence the pricing of blow-up ratios, particularly for international buyers:

-

Volume/MOQ: Minimum Order Quantities (MOQ) can significantly affect pricing. Larger orders often yield lower unit costs, making it essential for buyers to assess their demand forecasts and negotiate favorable terms.

-

Specifications and Customization: Custom specifications may lead to higher costs due to additional tooling and production time. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials may come with a premium price. Certifications that verify material standards can also add to costs but are crucial for compliance in regulated markets.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but offer better quality assurance and delivery reliability.

-

Incoterms: The choice of Incoterms affects the distribution of costs and responsibilities between buyers and suppliers. Understanding these terms can lead to better negotiation outcomes.

What Are Some Effective Buyer Tips for Sourcing Blow-Up Ratios?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, here are actionable insights to optimize sourcing:

-

Negotiate Terms: Always negotiate payment terms, delivery schedules, and other contractual obligations. Leverage competition among suppliers to secure better deals.

-

Focus on Cost-Efficiency: Look beyond the sticker price. Consider the Total Cost of Ownership, which includes long-term maintenance and operational costs. This perspective can lead to smarter purchasing decisions.

-

Understand Pricing Nuances: Be aware of seasonal fluctuations in pricing, especially if sourcing from regions with variable production capacities. This knowledge can help in timing your purchases for better rates.

-

Evaluate Supplier Relationships: Building strong relationships with suppliers can lead to better prices and terms over time. Consider establishing long-term partnerships for consistent quality and service.

-

Research Market Trends: Stay informed about global market trends, including raw material prices and geopolitical factors that could affect supply chains. This insight can aid in strategic planning and risk management.

Disclaimer on Indicative Prices

Prices for blow-up ratios can vary widely based on numerous factors, including location, volume, and customization. It is advisable to obtain multiple quotes and conduct thorough market research to ensure competitive pricing tailored to specific needs.

Alternatives Analysis: Comparing blow-up ratio With Other Solutions

When evaluating solutions for specific business needs, it’s essential to consider alternatives that can achieve similar outcomes. The “blow-up ratio,” often used in various industries to assess performance metrics, can be compared against other viable methods to help international B2B buyers make informed decisions. Below is a comparison of the blow-up ratio with two alternative solutions: Cost-Benefit Analysis and Value Stream Mapping.

| Comparison Aspect | Blow-Up Ratio | Cost-Benefit Analysis | Value Stream Mapping |

|---|---|---|---|

| Performance | Offers a clear metric for measuring operational efficiency; effective in high-volume environments. | Provides a comprehensive view of financial implications; good for ROI calculations. | Visualizes workflow and identifies waste; effective in process improvement. |

| Cost | Generally low-cost to implement, depending on data collection methods. | Can be resource-intensive, requiring detailed data analysis and software tools. | Moderate cost; may require training and software tools for effective mapping. |

| Ease of Implementation | Relatively straightforward; requires data on inputs and outputs. | More complex; necessitates financial expertise and thorough data gathering. | Requires some training; involves collaboration across departments for accurate mapping. |

| Maintenance | Minimal ongoing maintenance; periodic reviews needed for accuracy. | Ongoing updates needed as market conditions change; requires continuous analysis. | Requires regular updates to reflect process changes; involves continuous team engagement. |

| Best Use Case | Best for high-volume production settings where operational efficiency is critical. | Ideal for project evaluations and financial decision-making. | Best for organizations looking to streamline processes and eliminate waste. |

What Are the Pros and Cons of Cost-Benefit Analysis?

Cost-Benefit Analysis (CBA) is a systematic approach to estimating the strengths and weaknesses of alternatives in terms of their costs and benefits.

Pros:

– Provides a comprehensive financial overview, making it easier to justify investments.

– Helps identify the most financially viable options among various alternatives.

Cons:

– Can be time-consuming and requires accurate data collection, which may not always be readily available.

– May overlook qualitative factors that are harder to quantify but essential for long-term success.

How Does Value Stream Mapping Compare?

Value Stream Mapping (VSM) focuses on analyzing the flow of materials and information currently required to bring a product or service to a consumer.

Pros:

– Offers a visual representation of processes, making it easier to identify bottlenecks and inefficiencies.

– Encourages team collaboration and involvement, fostering a culture of continuous improvement.

Cons:

– Requires training and buy-in from team members, which can be a barrier to implementation.

– The effectiveness is heavily reliant on the accuracy of the mapping and the commitment of the team to follow through on improvements.

How Can B2B Buyers Choose the Right Solution?

When selecting the appropriate method or technology for their needs, B2B buyers should consider several factors. First, assess the specific goals of the business—whether it is to improve efficiency, reduce costs, or enhance product quality. Additionally, consider the resources available, including time, budget, and expertise. A thorough evaluation of each alternative’s pros and cons, as outlined in the comparison, will enable buyers to make informed choices that align with their strategic objectives. Ultimately, the right solution will depend on the unique context of the business and its operational requirements.

Essential Technical Properties and Trade Terminology for blow-up ratio

What Are the Key Technical Properties of Blow-Up Ratio?

Understanding the technical properties of blow-up ratio is crucial for B2B buyers, especially when sourcing materials or products that require precise specifications. Here are some essential properties to consider:

-

Material Grade

The material grade determines the quality and performance of the product. For instance, in the context of polymers, different grades can exhibit varying blow-up ratios due to their molecular structure. Selecting the appropriate material grade is vital for ensuring that the final product meets durability and performance standards. -

Tolerance Levels

Tolerance levels define the permissible limits of variation in a physical dimension. In applications where blow-up ratio is critical, precise tolerances can prevent defects and ensure product consistency. For B2B buyers, understanding tolerance levels is essential to avoid costly rework or product failures. -

Blow-Up Ratio Specification

The blow-up ratio itself is a measure of the expansion of a material when subjected to a specific process, often related to packaging or molding. A higher blow-up ratio indicates greater expansion, which can impact the material’s properties and end-use applications. Buyers should assess the blow-up ratio to ensure compatibility with their production processes. -

Processing Conditions

The conditions under which materials are processed can significantly affect the blow-up ratio. Parameters such as temperature, pressure, and cooling rates can alter the material’s properties. B2B buyers need to communicate their processing conditions to suppliers to ensure the correct material properties are achieved. -

Thermal Stability

Thermal stability indicates how well a material can maintain its properties under heat. This is particularly important in applications where the blow-up ratio is influenced by temperature changes. Buyers should consider thermal stability to prevent deformation or degradation during use. -

Mechanical Properties

Mechanical properties, including tensile strength and elongation, affect how a material behaves under stress. These properties can influence the blow-up ratio during manufacturing. Understanding these characteristics helps buyers select materials that will perform reliably in their applications.

What Trade Terminology Should B2B Buyers Know Regarding Blow-Up Ratio?

Familiarity with specific trade terminology can streamline communication and negotiations for international B2B buyers. Here are some common terms related to blow-up ratio:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify quality sources for components that meet specific blow-up ratio requirements. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. B2B buyers must be aware of MOQs when sourcing materials, as this can affect inventory costs and supply chain management. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. When including blow-up ratio specifications, buyers can ensure they receive accurate pricing and terms from potential suppliers. -

Incoterms

Incoterms (International Commercial Terms) are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for managing logistics and costs associated with shipping materials with specific blow-up ratio requirements. -

Lead Time

Lead time refers to the amount of time it takes for a supplier to fulfill an order. For products with specific blow-up ratio specifications, understanding lead times can help buyers plan their production schedules effectively. -

Quality Assurance (QA)

QA refers to the processes and procedures put in place to ensure product quality. Buyers should inquire about QA measures related to blow-up ratio to ensure the consistency and reliability of their sourced materials.

By mastering these technical properties and trade terminologies, international B2B buyers can make informed decisions that align with their operational needs and enhance supply chain efficiency.

Navigating Market Dynamics and Sourcing Trends in the blow-up ratio Sector

What Are the Current Market Dynamics and Key Trends in the Blow-Up Ratio Sector?

The blow-up ratio sector is witnessing transformative changes influenced by global economic factors and technological advancements. Key drivers include increasing demand for high-performance materials in various industries such as automotive, aerospace, and consumer goods. B2B buyers from regions like Africa, South America, the Middle East, and Europe (e.g., Vietnam and Colombia) are increasingly looking for suppliers that can provide innovative solutions that enhance product efficiency and reduce costs.

Emerging trends include the integration of Industry 4.0 technologies, such as IoT and AI, which enhance production processes, improve quality control, and enable real-time monitoring of material performance. Additionally, the rise of digital platforms for sourcing and procurement is simplifying the supply chain, allowing international buyers to connect with manufacturers more efficiently. This digital transformation is crucial for B2B buyers who are seeking agility and responsiveness in their supply chains.

Another notable trend is the shift towards localized sourcing as companies aim to mitigate risks associated with global supply chain disruptions. For buyers in Africa and South America, this presents an opportunity to strengthen regional supply chains while potentially reducing costs associated with logistics and tariffs.

How Can Sustainability and Ethical Sourcing Impact the Blow-Up Ratio Sector?

Sustainability and ethical sourcing are becoming increasingly critical for B2B buyers in the blow-up ratio sector. The environmental impact of production processes is under scrutiny, prompting companies to adopt greener practices. This shift not only addresses regulatory pressures but also responds to consumer demand for environmentally responsible products.

Buyers should prioritize suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials or implementing energy-efficient manufacturing processes. Certifications like ISO 14001 (Environmental Management) and the Global Organic Textile Standard (GOTS) can serve as benchmarks for evaluating a supplier’s sustainability efforts. By opting for suppliers with these certifications, B2B buyers can ensure that their sourcing decisions contribute to a more sustainable supply chain.

Moreover, the integration of ‘green’ materials in products can enhance marketability, as consumers increasingly favor brands that prioritize sustainability. For instance, incorporating biodegradable or recyclable materials in blow-up ratio products not only reduces environmental impact but also appeals to a growing base of eco-conscious customers.

What Is the Historical Context of the Blow-Up Ratio Sector?

The blow-up ratio concept has evolved significantly since its inception, reflecting broader industrial advancements. Originally rooted in the manufacturing and engineering sectors, the blow-up ratio was primarily used to assess material properties in high-stress applications. Over the decades, as industries have diversified and technology has advanced, the applications of the blow-up ratio have expanded to include various sectors, including construction, textiles, and packaging.

Historically, the focus was predominantly on enhancing performance and durability. However, recent shifts towards sustainability have influenced how the blow-up ratio is viewed, with increased emphasis on the environmental and social implications of sourcing materials. This evolution presents an opportunity for B2B buyers to engage with suppliers who are not only focused on performance metrics but are also committed to ethical and sustainable practices.

Understanding this historical context is vital for international buyers as it shapes current sourcing strategies and informs future procurement decisions in the blow-up ratio sector. By aligning sourcing practices with historical insights and contemporary trends, businesses can position themselves competitively in an evolving marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of blow-up ratio

-

How do I calculate the blow-up ratio for my business needs?

To calculate the blow-up ratio, you will need to divide the final volume of the product after expansion by its original volume. This ratio is essential for understanding how much a material or product will increase in size, which is particularly important in industries like packaging and manufacturing. For accurate results, ensure you measure the dimensions of the product before and after expansion carefully. This calculation will help you determine the efficiency of your materials and their suitability for your specific applications. -

What is the best blow-up ratio for packaging materials?

The optimal blow-up ratio for packaging materials often depends on the product’s nature and the intended use. Generally, a blow-up ratio between 2:1 and 3:1 is considered effective for most packaging applications, providing sufficient volume while maintaining structural integrity. However, for specialized products that require enhanced cushioning or insulation, a higher ratio may be beneficial. Always consider the product’s fragility and shipping conditions when selecting the appropriate blow-up ratio. -

What factors should I consider when sourcing suppliers for blow-up ratio products?

When sourcing suppliers for products with specific blow-up ratios, consider their experience in the industry, the quality of their materials, and their ability to meet your customization needs. Evaluate their production capabilities, lead times, and compliance with international quality standards. Additionally, request samples to assess the blow-up ratio performance and ensure it aligns with your requirements. Establish clear communication regarding your expectations to foster a successful partnership. -

How can I ensure the quality of blow-up ratio products I import?

To ensure the quality of imported blow-up ratio products, implement a robust supplier vetting process. This includes checking references, reviewing certifications, and conducting factory audits if possible. It is also advisable to request third-party quality assurance testing for critical materials. Establish clear quality criteria and conduct regular inspections during production and before shipment. Utilizing a reliable logistics partner can help maintain the integrity of your products during transit. -

What are the minimum order quantities (MOQ) for blow-up ratio products?

Minimum order quantities (MOQ) for blow-up ratio products can vary significantly by supplier and product type. Typically, MOQs can range from a few hundred to several thousand units. When negotiating with suppliers, discuss your specific needs and explore options for lower MOQs, especially if you are a new buyer or testing a new product line. Some suppliers may be open to flexibility, particularly if you can demonstrate potential for future orders. -

What payment terms should I negotiate when sourcing blow-up ratio products?

When negotiating payment terms for sourcing blow-up ratio products, aim for terms that provide you with sufficient cash flow while ensuring the supplier’s security. Common arrangements include 30% upfront and 70% upon delivery or a letter of credit for larger transactions. Consider the supplier’s reputation and financial stability when determining the terms. Additionally, explore the possibility of discounts for early payments or bulk orders, which can enhance your overall cost-efficiency. -

How do logistics impact the sourcing of blow-up ratio products internationally?

Logistics play a critical role in the sourcing of blow-up ratio products, particularly in terms of transportation costs, delivery times, and product integrity. Choose a logistics partner experienced in handling the specific requirements of your products to minimize the risk of damage during transit. It’s essential to understand customs regulations and potential tariffs that could affect your overall cost. Efficient logistics management can improve your supply chain’s reliability and responsiveness, ultimately benefiting your business. -

What customization options are available for blow-up ratio products?

Customization options for blow-up ratio products can include variations in size, material, thickness, and specific blow-up ratios tailored to your needs. Many suppliers offer the ability to modify existing designs or create entirely new products based on your specifications. When discussing customization, clearly communicate your requirements and the intended application of the product. This approach helps suppliers provide you with the best solutions to meet your unique operational needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for blow-up ratio

In summary, understanding and effectively utilizing the blow-up ratio is essential for international B2B buyers aiming to optimize their sourcing strategies. This metric not only highlights potential risks associated with supplier relationships but also underscores the importance of robust supplier evaluations and performance monitoring. By integrating a clear assessment of the blow-up ratio into your strategic sourcing framework, you can mitigate risks, enhance supplier accountability, and ultimately achieve better procurement outcomes.

For buyers across Africa, South America, the Middle East, and Europe, leveraging this knowledge can lead to more informed decision-making and improved negotiation leverage. As the global market continues to evolve, staying ahead of industry trends and adopting proactive sourcing practices will be key to maintaining a competitive edge.

Looking forward, international B2B buyers are encouraged to actively engage with suppliers and invest in technology that facilitates real-time data analysis of sourcing metrics, including the blow-up ratio. By prioritizing these actions, businesses can foster stronger partnerships and navigate the complexities of global supply chains more effectively.