Maximize Efficiency: The Ultimate 48V Battery Guide (2025)

Introduction: Navigating the Global Market for 48v battery

In today’s fast-evolving energy landscape, sourcing high-quality 48V batteries is a critical challenge for international B2B buyers, especially those operating in emerging markets like Africa, South America, the Middle East, and Europe. As businesses increasingly pivot towards sustainable energy solutions, understanding the diverse types and applications of 48V batteries becomes essential for ensuring operational efficiency and aligning with global energy trends. This comprehensive guide delves into various aspects of 48V batteries, from their technical specifications and applications in sectors such as renewable energy and electric vehicles to the nuances of supplier vetting and cost considerations.

International buyers often face hurdles related to quality assurance, regulatory compliance, and logistical challenges when sourcing 48V batteries. This guide empowers decision-makers by providing actionable insights that facilitate informed purchasing decisions. We address crucial questions such as: What are the different types of 48V batteries available? How can buyers effectively evaluate suppliers? What cost factors should be considered when budgeting for battery procurement? By equipping B2B buyers with the knowledge needed to navigate the global market, this guide aims to enhance their competitiveness and support their transition towards innovative energy solutions. Whether you are based in Cairo, Nairobi, or São Paulo, understanding the intricacies of the 48V battery market will position you for success in a rapidly changing world.

Understanding 48v battery Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lithium-ion | High energy density, lightweight, long cycle life | Electric vehicles, renewable energy storage | Pros: High efficiency, low maintenance. Cons: Higher initial cost. |

| Lead-acid | Established technology, cost-effective | Backup power systems, telecommunications | Pros: Lower upfront cost, widely available. Cons: Heavier, shorter lifespan. |

| Nickel-Metal Hydride | Good energy density, better temperature tolerance | Hybrid vehicles, portable electronics | Pros: Safe, moderate cost. Cons: Less common, limited cycle life. |

| Lithium Iron Phosphate | Excellent thermal stability, long cycle life | Solar energy systems, electric buses | Pros: Safe, environmentally friendly. Cons: Lower energy density compared to lithium-ion. |

| Gel Battery | Sealed, maintenance-free, good for deep cycling | Off-grid solar systems, RVs | Pros: Safe, resistant to vibration. Cons: Lower energy density, limited discharge rates. |

What Are the Characteristics and Suitability of Lithium-ion Batteries for B2B Buyers?

Lithium-ion batteries are renowned for their high energy density and lightweight design, making them ideal for applications requiring efficiency and portability. With a long cycle life, they are particularly suited for electric vehicles and renewable energy storage systems. For B2B buyers, it is essential to consider the initial investment, as these batteries tend to be more expensive upfront. However, their longevity and low maintenance requirements often result in lower total cost of ownership over time.

How Do Lead-acid Batteries Compare in Cost and Application?

Lead-acid batteries have been a staple in the battery industry for decades due to their cost-effectiveness and reliability. They are commonly used in backup power systems and telecommunications, where budget constraints are significant. While they offer a lower upfront cost, B2B buyers should weigh this against their heavier weight and shorter lifespan compared to newer technologies. Understanding the trade-offs between initial savings and long-term performance is crucial for making informed purchasing decisions.

What Advantages Do Nickel-Metal Hydride Batteries Offer in Hybrid Applications?

Nickel-metal hydride (NiMH) batteries provide a balanced energy density and are particularly effective in hybrid vehicles and portable electronics. They perform well in a range of temperatures, making them suitable for diverse environments. For B2B buyers, the moderate cost and safety features are appealing, although the limited cycle life might necessitate more frequent replacements. Companies looking for reliable hybrid solutions should consider NiMH as a viable option, especially in applications where safety and temperature tolerance are paramount.

Why Choose Lithium Iron Phosphate Batteries for Energy Storage Solutions?

Lithium iron phosphate (LiFePO4) batteries stand out for their excellent thermal stability and long cycle life, making them ideal for solar energy systems and electric buses. Their safety profile and environmental friendliness are significant selling points for B2B buyers focused on sustainability. However, they do have a lower energy density compared to traditional lithium-ion batteries, which could affect the design and space requirements of energy storage installations. Buyers should evaluate these factors against their specific operational needs.

What Are the Key Benefits of Gel Batteries for Off-grid Applications?

Gel batteries are a type of sealed lead-acid battery known for their maintenance-free operation and resistance to vibration, making them suitable for off-grid solar systems and recreational vehicles (RVs). Their ability to handle deep cycling is beneficial in applications where the battery is frequently discharged. While they offer safety and ease of use, B2B buyers should be aware of their lower energy density and limited discharge rates, which may impact performance in high-demand scenarios. Evaluating these characteristics can help businesses select the right battery for their off-grid energy needs.

Related Video: Choosing the Right Fuse Type for Off-Grid Solar: Expert Guide for 12V to 48V Battery Systems

Key Industrial Applications of 48v battery

| Industry/Sector | Specific Application of 48v battery | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Renewable Energy | Energy storage systems for solar and wind farms | Enhances energy efficiency and reliability | Check for compatibility with existing systems and local regulations. |

| Electric Vehicles (EVs) | Powering electric buses and delivery vehicles | Reduces operational costs and carbon footprint | Assess battery lifecycle, charging infrastructure, and local support. |

| Telecommunications | Backup power for cell towers and data centers | Ensures uninterrupted service and reliability | Evaluate energy capacity, maintenance needs, and supplier reliability. |

| Industrial Automation | Powering automated guided vehicles (AGVs) | Increases operational efficiency and productivity | Look for scalability, charging speed, and integration capabilities. |

| Agriculture | Powering irrigation systems and farm equipment | Enhances productivity and reduces fuel costs | Consider battery life, environmental resilience, and local availability. |

How is the 48v Battery Used in Renewable Energy Applications?

In renewable energy sectors, 48v batteries are vital for energy storage systems linked to solar and wind farms. These batteries store excess energy generated during peak production times and release it during low generation periods, thus enhancing energy efficiency and reliability. For B2B buyers, particularly in regions like Africa and South America, it is essential to ensure that the batteries are compatible with existing renewable systems and comply with local regulations regarding energy storage.

What Role Does the 48v Battery Play in Electric Vehicles?

The electric vehicle (EV) industry utilizes 48v batteries to power electric buses and delivery vehicles, significantly reducing operational costs and lowering the carbon footprint. This application is particularly relevant for businesses in Europe and the Middle East, where sustainability is a growing concern. Buyers should assess the battery’s lifecycle, the availability of charging infrastructure, and local technical support when sourcing these batteries to ensure optimal performance and longevity.

How Does the 48v Battery Support Telecommunications?

In the telecommunications sector, 48v batteries provide backup power for cell towers and data centers, ensuring uninterrupted service during power outages. This reliability is crucial for maintaining customer satisfaction and operational continuity. For B2B buyers, evaluating energy capacity, maintenance requirements, and the reliability of suppliers is essential to ensure that the backup systems function effectively and can withstand local environmental conditions.

In What Ways are 48v Batteries Used in Industrial Automation?

Within industrial automation, 48v batteries are used to power automated guided vehicles (AGVs), which are essential for enhancing operational efficiency and productivity in manufacturing and logistics. These batteries enable AGVs to operate autonomously, reducing the need for manual labor. Buyers should focus on scalability, charging speed, and integration capabilities with existing systems when sourcing batteries for industrial applications, particularly in rapidly developing regions like Kenya and Egypt.

How are 48v Batteries Transforming Agriculture?

In agriculture, 48v batteries power irrigation systems and various farm equipment, enhancing productivity and reducing reliance on fossil fuels. This application is especially beneficial in regions where access to consistent energy sources is limited. B2B buyers should consider factors such as battery life, resilience to environmental conditions, and the availability of local suppliers when sourcing batteries for agricultural applications, ensuring that they meet the unique demands of their operations.

Related Video: YX850 Power Failure Automatic Switching Standby Battery Lithium Battery Module 5V-48V Emergency UPS

3 Common User Pain Points for ’48v battery’ & Their Solutions

Scenario 1: Inconsistent Power Supply for Critical Operations

The Problem: For many businesses relying on 48v batteries, an inconsistent power supply can lead to severe operational disruptions. This is particularly challenging in regions like Africa and South America, where infrastructure may not be as reliable. A buyer might face issues such as unexpected downtime in manufacturing processes or insufficient energy storage for renewable energy applications. These interruptions can result in lost productivity and revenue, along with damage to equipment and customer trust.

The Solution: To combat this issue, B2B buyers should prioritize sourcing high-quality 48v batteries with robust performance specifications, including a reliable discharge cycle and thermal management features. Investing in batteries from reputable manufacturers that offer warranties can provide peace of mind. Additionally, implementing a battery management system (BMS) can help monitor performance and predict failures before they occur. This proactive approach not only extends battery life but also ensures consistent power delivery, reducing the likelihood of operational disruptions.

Scenario 2: Challenges in Battery Compatibility Across Different Systems

The Problem: Another common pain point for international B2B buyers is the compatibility of 48v batteries with existing systems. Companies that use various energy sources or battery technologies may find it difficult to integrate new 48v batteries into their operations. This situation often leads to increased costs due to the need for additional adapters, converters, or even complete system overhauls, which can be particularly burdensome for businesses in the Middle East and Europe.

The Solution: To mitigate compatibility challenges, buyers should conduct a thorough compatibility assessment before procurement. This involves evaluating existing systems and understanding the technical specifications of the 48v batteries being considered. Engaging with suppliers who provide comprehensive technical support can also facilitate smoother integration. Buyers might consider modular battery solutions that allow for flexible configurations, enabling easier upgrades and adjustments to existing systems without extensive modifications.

Scenario 3: Difficulty in Sourcing Reliable and Cost-Effective Batteries

The Problem: Sourcing reliable and cost-effective 48v batteries can be a daunting task, especially for businesses in developing markets where supply chains may be less established. Buyers often struggle with finding a balance between cost and quality, leading to potential pitfalls such as purchasing lower-quality batteries that may fail prematurely or are not suited for their specific applications. This can result in higher long-term costs due to replacements and increased maintenance.

The Solution: To find reliable and cost-effective options, B2B buyers should adopt a multi-sourcing strategy. This involves reaching out to multiple suppliers and comparing not only prices but also battery specifications, certifications, and customer reviews. Participating in industry trade shows and networking with peers can also uncover reputable suppliers that are not widely known. Buyers should also consider long-term total cost of ownership (TCO) rather than just upfront costs. This includes evaluating warranties, expected lifespan, and performance metrics, ensuring that the selected 48v batteries will meet their operational needs without compromising quality or reliability.

Strategic Material Selection Guide for 48v battery

When selecting materials for 48V batteries, international B2B buyers must consider various factors that influence performance, cost, and application suitability. Here, we analyze four common materials used in 48V battery construction: Lithium-ion, Lead-acid, Nickel-Metal Hydride (NiMH), and Graphene. Each material has unique properties and implications for buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Lithium-ion Batteries?

Lithium-ion batteries are widely recognized for their high energy density and efficiency. They typically operate effectively in a temperature range of -20°C to 60°C, making them suitable for diverse climates. Their low self-discharge rate and high cycle life (up to 2,000 cycles) contribute to their popularity in various applications.

Pros & Cons: The primary advantages of lithium-ion batteries include their lightweight nature and compact size, which enhance portability. However, they come with a higher cost and require sophisticated manufacturing processes, making them less accessible for some markets. Additionally, they may pose safety concerns if not properly managed, particularly in high-temperature environments.

Impact on Application: Lithium-ion batteries are compatible with various media, including electric vehicles and renewable energy systems. Their performance can be affected by extreme temperatures, necessitating careful consideration in regions with fluctuating climates.

How Do Lead-Acid Batteries Compare in Terms of Durability and Cost?

Lead-acid batteries have been a staple in the battery industry for decades. They are known for their robustness and ability to perform under high-pressure conditions. Operating efficiently in temperatures ranging from -20°C to 50°C, they are suitable for various applications, particularly in automotive and backup power systems.

Pros & Cons: The durability and low cost of lead-acid batteries are significant advantages. However, they have a shorter cycle life (around 500 cycles) and are heavier than alternatives, which can limit their use in portable applications. Environmental concerns regarding lead disposal also pose challenges for compliance with regulations in many regions.

Impact on Application: Lead-acid batteries are often used in stationary applications where weight is less of a concern. Their compatibility with high discharge rates makes them suitable for applications requiring immediate power, but they may not be ideal for long-term energy storage.

What Are the Benefits of Using Nickel-Metal Hydride (NiMH) Batteries?

Nickel-Metal Hydride (NiMH) batteries offer a middle ground between lithium-ion and lead-acid technologies. They feature a moderate energy density and can operate effectively in temperatures from -20°C to 60°C. Their cycle life typically ranges from 500 to 1,000 cycles.

Pros & Cons: NiMH batteries are less expensive than lithium-ion batteries and are more environmentally friendly, as they do not contain toxic materials. However, they have a lower energy density and are heavier than lithium-ion options, which can affect their suitability for certain applications.

Impact on Application: NiMH batteries are often used in hybrid vehicles and consumer electronics. Their performance can be affected by temperature extremes, and they may require specific charging protocols to maximize lifespan.

What Advantages Does Graphene Offer for 48V Battery Applications?

Graphene is an emerging material in battery technology, known for its exceptional conductivity and strength. Although still in the developmental phase for widespread commercial use, graphene batteries can potentially operate at higher temperatures and provide faster charging times.

Pros & Cons: The main advantage of graphene batteries is their potential for high performance and longevity. However, the technology is still costly and complex to manufacture, which may limit its immediate applicability in the market.

Impact on Application: Graphene batteries could revolutionize applications requiring rapid charging and high energy density, such as electric vehicles and portable electronics. Buyers must stay informed about advancements in this area, as it may soon become a viable option.

Summary Table of Material Selection for 48V Batteries

| Material | Typical Use Case for 48V Battery | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Lithium-ion | Electric vehicles, renewable energy systems | High energy density, lightweight | Higher cost, safety concerns | High |

| Lead-acid | Automotive, backup power systems | Low cost, robust performance | Shorter cycle life, environmental concerns | Low |

| Nickel-Metal Hydride (NiMH) | Hybrid vehicles, consumer electronics | Environmentally friendly, moderate cost | Lower energy density, heavier | Medium |

| Graphene | Advanced electric vehicles, portable electronics | Fast charging, high performance | High cost, complex manufacturing | High |

In conclusion, when selecting materials for 48V batteries, international B2B buyers must weigh the benefits and limitations of each option carefully. Understanding the unique properties and market implications of these materials will enable buyers to make informed decisions that align with their specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 48v battery

What Are the Main Stages in the Manufacturing Process of 48V Batteries?

The manufacturing process of 48V batteries involves several critical stages that ensure efficiency, safety, and performance. Understanding these stages is essential for international B2B buyers looking to procure high-quality batteries.

-

Material Preparation: This initial stage involves sourcing and preparing raw materials, such as lithium, cobalt, nickel, and graphite. Suppliers must ensure that these materials meet specific purity and quality standards. Buyers should inquire about the suppliers’ sourcing practices and the traceability of raw materials, particularly in regions where ethical sourcing is a concern, such as Africa and South America.

-

Forming: In this phase, the prepared materials are processed into cells. Techniques like electrode coating, cell assembly, and electrolyte filling are employed. The precision in this stage is paramount as it directly impacts battery performance. B2B buyers should look for manufacturers that utilize automated processes to minimize human error and ensure consistency.

-

Assembly: The battery cells are assembled into modules and then into packs. This step often involves the integration of battery management systems (BMS) that monitor and manage the battery’s performance. Buyers should verify that suppliers employ advanced assembly techniques that enhance safety and efficiency, particularly if the batteries will be used in critical applications.

-

Finishing: The final stage includes testing, packaging, and preparing the batteries for shipment. This step is crucial for ensuring that the batteries meet the required specifications and performance standards. B2B buyers should ask for detailed documentation of the finishing processes, including any tests conducted before shipment.

How Is Quality Assurance Implemented in 48V Battery Manufacturing?

Quality assurance (QA) is vital in the production of 48V batteries, as it ensures that the end products meet international standards and customer expectations. Here are the key components of QA in the manufacturing process:

-

What Are the Relevant International Standards for Battery Quality Control?

Compliance with international standards such as ISO 9001 is essential. This standard outlines criteria for a quality management system and is applicable to any organization. Additionally, industry-specific certifications like CE marking (for European markets) and API standards (for applications in oil and gas) are crucial. Buyers should prioritize suppliers who have these certifications, as they indicate a commitment to quality and safety. -

What Are the Key Quality Control Checkpoints?

Effective quality control incorporates several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial checkpoint ensures that the raw materials meet the required specifications before production begins.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages helps to identify any deviations from the standard immediately.

– Final Quality Control (FQC): At this stage, the finished products undergo rigorous testing to confirm they meet performance and safety criteria. -

What Common Testing Methods Are Used for 48V Batteries?

Testing methods include:

– Electrical Testing: Measures voltage, capacity, and internal resistance.

– Environmental Testing: Assesses the battery’s performance under various temperature and humidity conditions.

– Safety Testing: Ensures that the batteries comply with safety regulations and do not pose risks during operation.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is critical. Here are actionable steps to ensure that suppliers maintain robust QC protocols:

-

Conduct Supplier Audits: Regular audits help assess the compliance of suppliers with quality standards. B2B buyers should establish an audit schedule and consider third-party auditing firms for unbiased assessments.

-

Request Quality Assurance Documentation: Buyers should demand comprehensive QA documentation, including quality control reports, test results, and certifications. This documentation should detail the processes and measures taken at each stage of manufacturing.

-

Engage in Third-Party Inspections: Utilizing third-party inspection services can provide an additional layer of verification. These services can independently assess the quality of the products before they are shipped.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When sourcing 48V batteries globally, B2B buyers must be aware of the nuances in quality control and certification. Here are key considerations:

-

Regional Compliance Differences: Different regions may have varying regulatory requirements. For instance, CE certification is mandatory for products sold in Europe, while UL certification is significant in North America. Buyers should ensure that suppliers are compliant with the specific regulations applicable to their target markets.

-

Cultural and Ethical Considerations: In regions like Africa and South America, ethical sourcing and environmental impact are significant. Buyers should prioritize suppliers who adhere to sustainable practices and demonstrate corporate social responsibility.

-

Understanding Warranty and After-Sales Support: Quality control doesn’t end at the point of sale. Buyers should understand the warranty terms and the manufacturer’s commitment to after-sales support. This aspect is crucial for maintaining long-term business relationships and ensuring the reliability of battery performance.

Conclusion

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance practices for 48V batteries is essential. By focusing on quality control checkpoints, international standards, and effective verification methods, buyers can mitigate risks and ensure the procurement of high-quality, reliable batteries. Engaging with suppliers who prioritize transparency and ethical practices will further enhance the procurement process, fostering long-term partnerships and business success.

Practical Sourcing Guide: A Step-by-Step Checklist for ’48v battery’

Introduction

Sourcing a reliable 48v battery is critical for ensuring optimal performance in various applications, from renewable energy systems to electric vehicles. This practical sourcing guide provides B2B buyers with a comprehensive checklist to streamline the procurement process. By following these actionable steps, you can mitigate risks, enhance supplier relationships, and secure quality products that meet your business needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to clearly define your technical requirements. Consider factors such as capacity (Ah), discharge rates, dimensions, and weight. Understanding these specifications helps in narrowing down potential suppliers who can meet your exact needs, ensuring compatibility with your existing systems.

- Capacity and Performance: Assess how much energy storage and output you require.

- Environment Considerations: Determine if the battery will be used in extreme temperatures or conditions, influencing chemistry choices.

Step 2: Conduct Market Research on Suppliers

Thorough market research is vital for identifying potential suppliers who specialize in 48v batteries. Look for manufacturers with a proven track record and positive customer reviews. This step helps in forming a shortlist of candidates who are credible and reliable.

- Industry Reputation: Utilize platforms like LinkedIn and industry forums to gather insights about suppliers.

- Comparative Analysis: Consider geographical factors, especially for buyers from Africa, South America, and the Middle East, as local suppliers may offer logistical advantages.

Step 3: Evaluate Potential Suppliers

Before committing, vet potential suppliers thoroughly. Request detailed company profiles, case studies, and references from buyers in similar industries. This evaluation process ensures that you partner with suppliers who have a strong reputation for quality and reliability.

- Quality Assurance: Check if suppliers have certifications like ISO 9001 or similar quality management systems.

- Client Testimonials: Speak directly to previous customers to gauge satisfaction and performance.

Step 4: Request Samples and Conduct Testing

Once you have shortlisted suppliers, request samples of the 48v batteries for testing. This step allows you to evaluate the product’s quality and performance in real-world conditions, ensuring it meets your operational requirements.

- Performance Metrics: Test for efficiency, charge cycles, and discharge rates under your specific usage scenarios.

- Compliance Checks: Ensure the samples meet all relevant safety and regulatory standards applicable in your region.

Step 5: Negotiate Terms and Conditions

Once you are satisfied with the product quality, initiate negotiations regarding pricing, payment terms, and delivery schedules. Clear agreements on these aspects can prevent misunderstandings and ensure a smooth procurement process.

- Bulk Discounts: Inquire about pricing structures for larger orders, which can significantly reduce costs.

- Payment Security: Consider payment methods that offer buyer protection, especially when dealing with international suppliers.

Step 6: Confirm Logistics and Delivery Options

Discuss logistics and delivery options to ensure that the batteries can be shipped to your location efficiently and economically. Understanding lead times and shipping costs is essential for effective inventory management.

- Shipping Partners: Verify if the supplier has reliable shipping partners to minimize delays.

- Customs and Import Regulations: Be aware of any duties or regulations that may affect the import of batteries in your country.

Step 7: Establish a Long-term Relationship

After successful procurement, focus on building a long-term relationship with your supplier. This can lead to better pricing, priority service, and access to new products in the future.

- Regular Communication: Maintain open lines of communication to address any issues promptly.

- Feedback Loop: Provide feedback on product performance, which can help the supplier improve and adapt their offerings to your needs.

Comprehensive Cost and Pricing Analysis for 48v battery Sourcing

What Are the Key Cost Components in 48V Battery Manufacturing?

When sourcing 48V batteries, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The cost of raw materials, such as lithium, cobalt, and nickel, can significantly impact the final price. Prices for these materials can fluctuate based on global supply and demand dynamics, geopolitical factors, and mining costs.

-

Labor: Labor costs vary by region and are influenced by local wage rates, skill levels, and the complexity of manufacturing processes. Countries with lower labor costs may offer competitive pricing but could have trade-offs in quality or reliability.

-

Manufacturing Overhead: This includes expenses related to factory operations, maintenance, utilities, and administrative costs. Efficient production processes can help minimize overhead, leading to more competitive pricing.

-

Tooling: The initial setup for production—such as molds and specialized machinery—can be a significant upfront investment. Buyers should consider this when evaluating pricing from different suppliers.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and safety. While this might increase costs, it can lead to long-term savings by reducing failures and warranty claims.

-

Logistics: Shipping costs, customs duties, and insurance can add to the overall expense. Understanding the logistics involved in international shipping, especially from regions like Africa and South America, is vital for accurate cost forecasting.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on the supplier’s positioning, market demand, and competitive landscape.

How Do Price Influencers Affect 48V Battery Sourcing?

Several factors can influence the pricing of 48V batteries, including:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide better pricing for bulk orders. Buyers should negotiate MOQs to align with their needs while maximizing cost efficiency.

-

Specifications and Customization: Unique specifications or custom designs can lead to higher costs. Buyers should clearly communicate their requirements to avoid unexpected price hikes.

-

Material Quality and Certifications: Higher quality materials and certifications (like ISO or CE) often come at a premium. While it may seem cost-effective to choose cheaper options, the long-term performance and reliability could be compromised.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record may charge higher prices but offer better quality assurance and after-sales support.

-

Incoterms: Understanding the terms of delivery (Incoterms) is essential. Costs can vary significantly based on whether the seller or buyer is responsible for shipping, insurance, and customs clearance.

What Buyer Tips Should Be Considered for Cost-Efficient Sourcing?

To navigate the complexities of 48V battery sourcing effectively, consider the following actionable tips:

-

Negotiate Effectively: Leverage your purchasing power, especially if you are ordering in bulk. Engage in discussions around pricing, payment terms, and delivery schedules to find mutually beneficial arrangements.

-

Focus on Total Cost of Ownership (TCO): When evaluating offers, consider the long-term costs associated with the battery, including maintenance, potential failures, and energy efficiency. A lower upfront cost may not always equate to a better overall value.

-

Research Regional Market Trends: Stay informed about pricing trends in different regions, particularly in Africa, South America, the Middle East, and Europe. This knowledge can provide leverage in negotiations and help identify the best sourcing opportunities.

-

Be Aware of Pricing Nuances: Different markets may have varying expectations regarding pricing structures. Understanding these nuances can help you make informed decisions and avoid common pitfalls.

Disclaimer on Indicative Prices

While this analysis provides a comprehensive overview of the cost structure and pricing influencers in 48V battery sourcing, prices can fluctuate based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough market research and supplier assessments to obtain the most accurate and competitive pricing.

Alternatives Analysis: Comparing 48v battery With Other Solutions

Exploring Alternatives to the 48V Battery

As businesses seek reliable energy storage solutions, understanding the alternatives to the 48V battery is crucial for making informed purchasing decisions. This section provides a comparative analysis of the 48V battery against two viable alternatives: the Lead-Acid Battery and the Lithium-Ion Battery. Each option comes with its own set of advantages and challenges, which can significantly impact operational efficiency and cost.

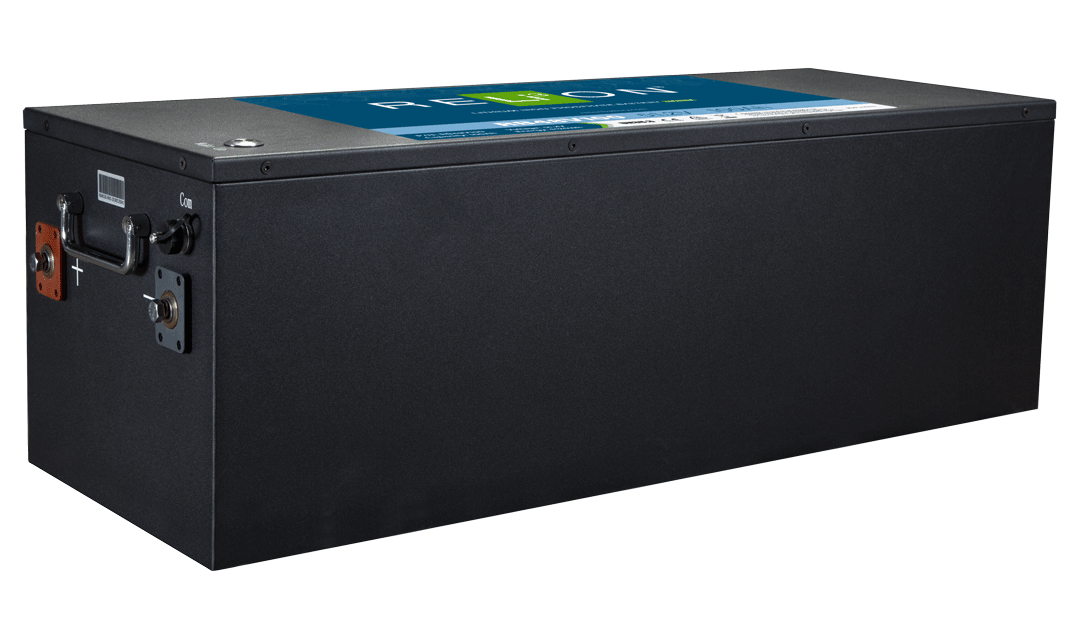

A stock image related to 48v battery.

Comparison Table of 48V Battery vs. Alternatives

| Comparison Aspect | 48V Battery | Lead-Acid Battery | Lithium-Ion Battery |

|---|---|---|---|

| Performance | Moderate energy density; suitable for various applications | Lower energy density; limited cycle life | High energy density; excellent cycle life |

| Cost | Moderate upfront cost; longer lifespan may offset initial expense | Lower initial cost; higher long-term replacement costs | Higher upfront cost; but lower total cost of ownership |

| Ease of Implementation | Generally straightforward; requires proper installation | Widely understood; established practices for installation | Requires specific handling and installation knowledge |

| Maintenance | Low maintenance; occasional checks needed | Regular maintenance required; electrolyte checks | Minimal maintenance; battery management systems enhance longevity |

| Best Use Case | Renewable energy systems, electric vehicles | Backup power, low-cost applications | High-performance applications, portable electronics |

What Are the Pros and Cons of Lead-Acid Batteries?

Lead-acid batteries are one of the oldest and most widely used energy storage solutions. Their primary advantage is their low initial cost, making them accessible for businesses with limited budgets. However, they come with a significant downside: a shorter cycle life and lower energy density compared to the 48V battery and lithium-ion options. This means that while the initial investment is lower, businesses may face higher replacement costs over time, especially in applications requiring frequent cycling.

How Do Lithium-Ion Batteries Compare?

Lithium-ion batteries stand out with their high energy density and longer lifespan, making them ideal for high-performance applications. Despite their higher upfront costs, their total cost of ownership can be lower due to reduced maintenance needs and longer life cycles. However, the complexity of installation and the need for specialized knowledge can be a barrier for some buyers. Additionally, lithium-ion batteries can be sensitive to temperature and require effective battery management systems to ensure safety and longevity.

Making the Right Choice: How Can B2B Buyers Select the Best Battery Solution?

A stock image related to 48v battery.

When selecting an energy storage solution, B2B buyers must assess their specific needs, including budget constraints, application requirements, and long-term operational goals. The 48V battery offers a balanced option for many industries, especially in renewable energy and electric vehicle applications. However, if initial cost is a primary concern, lead-acid batteries may be more attractive despite their limitations. Conversely, for businesses focused on performance and longevity, investing in lithium-ion batteries could yield better returns over time.

Ultimately, understanding the trade-offs between these technologies will empower B2B buyers to make strategic decisions that align with their operational objectives and financial considerations.

Essential Technical Properties and Trade Terminology for 48v battery

What Are the Essential Technical Properties of a 48V Battery?

When considering the procurement of 48V batteries, understanding their technical specifications is crucial for ensuring compatibility and performance in various applications. Here are some key properties to keep in mind:

1. Energy Density

Energy density refers to the amount of energy stored per unit mass or volume of the battery. It is typically measured in watt-hours per kilogram (Wh/kg) or watt-hours per liter (Wh/L). Higher energy density means more energy can be stored in a smaller and lighter package, which is particularly important for applications in electric vehicles and renewable energy systems. For B2B buyers, selecting a battery with optimal energy density can lead to cost savings and improved efficiency.

2. Cycle Life

Cycle life indicates the number of complete charge and discharge cycles a battery can undergo before its capacity significantly diminishes, usually measured in cycles. A longer cycle life is essential for reducing replacement costs and ensuring the longevity of the battery in demanding applications. B2B buyers should prioritize batteries with extended cycle life to maximize their investment over time.

3. Charge/Discharge Rate

The charge/discharge rate, often expressed as a C-rate, signifies how quickly a battery can be charged or discharged relative to its capacity. For example, a 1C rate means that a battery can be fully charged or discharged in one hour. Understanding this specification is vital for applications requiring rapid energy transfer, such as in backup power systems or high-performance electric vehicles. Buyers should evaluate their specific application needs to choose a battery with the appropriate charge/discharge rate.

4. Temperature Range

The operational temperature range indicates the environmental conditions within which the battery can function effectively. Batteries designed for extreme temperatures may be necessary for outdoor applications in regions with harsh climates. B2B buyers should ensure that the chosen battery can operate within the expected temperature range to avoid performance degradation.

5. Safety Ratings

Safety ratings, such as UL certification, assess the battery’s reliability and risk of failure. Batteries with high safety ratings offer assurance against hazards like thermal runaway or leakage, which can be critical for applications in populated areas or sensitive environments. Buyers should prioritize suppliers that provide clear documentation of safety ratings to mitigate risks.

What Are Common Trade Terminology and Jargon Associated with 48V Batteries?

Familiarity with industry jargon and trade terminology can significantly enhance communication between buyers and suppliers. Here are some essential terms to know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products that are then marketed and sold by another company under its brand. In the context of 48V batteries, understanding the OEM’s reputation can help buyers gauge product quality and reliability.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers to manage inventory costs and ensure they are not over-committing to a single supplier. It’s advisable to negotiate MOQs based on demand forecasts.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products or services. For B2B buyers, submitting RFQs can facilitate competitive pricing and enable better budget planning.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers regarding the delivery of goods. Understanding these terms helps buyers clarify shipping, insurance, and risk management responsibilities, ensuring smooth transactions across borders.

5. Warranty Period

The warranty period indicates the duration for which the manufacturer guarantees the product’s performance. A longer warranty often reflects the manufacturer’s confidence in the product’s quality. Buyers should assess warranty terms when comparing suppliers to ensure protection against defects.

By understanding these essential technical properties and trade terminologies, B2B buyers can make informed decisions, optimizing their investments in 48V battery solutions.

Navigating Market Dynamics and Sourcing Trends in the 48v battery Sector

What Are the Current Market Dynamics Driving the 48v Battery Sector?

The 48v battery market is experiencing robust growth, driven by the increasing demand for energy-efficient solutions across various sectors, including renewable energy, electric vehicles (EVs), and industrial applications. The global push for decarbonization and sustainability is a significant factor, as businesses seek to transition to cleaner energy sources. This shift is particularly pronounced in Africa and South America, where renewable energy projects are expanding rapidly to address energy shortages and environmental concerns.

Emerging technologies, such as energy storage systems (ESS) and smart grid solutions, are also reshaping the landscape. These technologies facilitate better energy management and improve efficiency, appealing to B2B buyers looking to optimize their operations. Furthermore, the rise of electric mobility in the Middle East and Europe is propelling the demand for 48v batteries, with manufacturers responding by innovating in battery chemistry and design to enhance performance and safety.

International B2B buyers should be aware of the competitive landscape, characterized by both established players and new entrants. Understanding regional market dynamics is essential, as regulations, incentives, and local manufacturing capabilities can significantly impact sourcing strategies. For example, buyers in Egypt and Kenya may benefit from local partnerships to navigate regulatory frameworks and leverage government support for green initiatives.

How Is Sustainability Shaping Sourcing Strategies in the 48v Battery Market?

Sustainability is no longer a buzzword; it has become a critical factor influencing sourcing decisions in the 48v battery sector. The environmental impact of battery production, particularly concerning resource extraction and waste management, is under scrutiny. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices, such as using recycled materials and minimizing carbon footprints throughout the supply chain.

Ethical sourcing is paramount, with businesses seeking to ensure that their supply chains are free from human rights abuses and environmental degradation. Buyers should look for manufacturers that possess relevant ‘green’ certifications, such as ISO 14001 for environmental management or certifications from recognized sustainability organizations. These certifications not only enhance brand reputation but also align with the growing consumer demand for environmentally responsible products.

Moreover, integrating sustainability into sourcing strategies can yield financial benefits. By investing in eco-friendly materials and processes, companies may qualify for tax incentives and subsidies available in various regions, particularly in Europe and South America. This not only reduces costs in the long run but also positions businesses as leaders in the transition towards a sustainable future.

What Is the Evolution of the 48v Battery Market?

The 48v battery market has evolved significantly over the past decade, driven by technological advancements and changing consumer preferences. Initially dominated by lead-acid batteries, the sector has seen a swift transition to lithium-ion technologies, which offer higher energy density, longer life cycles, and reduced weight. This shift has been particularly beneficial for applications in renewable energy storage and electric vehicles, where performance and efficiency are paramount.

As the demand for reliable and efficient energy solutions continues to grow, the 48v battery market is expected to further innovate, with developments in battery management systems (BMS) and integration with smart technologies. For B2B buyers, understanding this evolution is crucial for making informed decisions about sourcing and partnerships in a rapidly changing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of 48v battery

-

How do I choose the right 48v battery supplier for my business?

Choosing the right supplier for 48v batteries involves several key factors. Start by researching suppliers with a proven track record in your industry and region. Evaluate their certifications, quality assurance processes, and compliance with international standards. It’s also vital to assess their customer service responsiveness and support, as these can impact your operations. Request samples to evaluate battery performance and consider their capacity for customization and scalability, especially if your needs may change over time. -

What are the most important specifications to look for in a 48v battery?

When sourcing a 48v battery, focus on specifications such as capacity (measured in amp-hours), discharge rates, cycle life, and efficiency. Additionally, consider the type of battery chemistry (e.g., lithium-ion, lead-acid) that best suits your application. It’s also essential to evaluate the operational temperature range, weight, and dimensions for compatibility with your systems. Lastly, inquire about warranty terms and after-sales support, as these can significantly affect long-term satisfaction. -

What are the typical minimum order quantities (MOQs) for 48v batteries?

Minimum order quantities for 48v batteries can vary widely depending on the supplier and the specific type of battery. Generally, MOQs can range from 10 to several hundred units. For international buyers, it’s essential to clarify these terms upfront to avoid unexpected costs. If your demand fluctuates, consider negotiating terms with suppliers for smaller initial orders or explore drop shipping options to mitigate risks while establishing a relationship. -

What payment terms should I expect when purchasing 48v batteries internationally?

Payment terms for international purchases of 48v batteries can vary by supplier and country. Common arrangements include advance payments, letters of credit, or payment upon delivery. It’s advisable to establish clear terms that protect your interests, especially in high-value transactions. Consider using escrow services for larger orders to ensure product quality before full payment. Additionally, inquire about currency exchange rates and transaction fees that may affect the final cost. -

How can I ensure the quality and reliability of the 48v batteries I’m sourcing?

To ensure quality and reliability, request certifications and test reports from your supplier, such as ISO or UL certifications. Conduct factory audits if possible, or use third-party inspection services to verify product quality before shipment. Additionally, consider sourcing samples for testing in your own applications to assess performance firsthand. Establishing a long-term relationship with your supplier can also facilitate better quality control over time. -

What logistics considerations should I keep in mind when importing 48v batteries?

Logistics for importing 48v batteries involve several critical factors, including shipping methods, customs regulations, and battery classification for transport. Ensure compliance with international shipping regulations, particularly for lithium-ion batteries, which may require special handling. Work with freight forwarders experienced in handling battery shipments to navigate potential challenges. Additionally, factor in lead times and delivery schedules to align with your operational needs. -

Are there customization options available for 48v batteries?

Many suppliers offer customization options for 48v batteries to meet specific requirements. Customizations can include variations in capacity, size, connectors, and battery management systems. When discussing your needs with suppliers, clearly outline your specifications and intended application. This dialogue can help identify feasible custom solutions. Be aware that custom orders may have longer lead times and higher costs, so plan accordingly. -

What are the common applications for 48v batteries in international markets?

48v batteries are widely used in various applications, including renewable energy systems, electric vehicles, telecommunications, and backup power supplies. In regions like Africa and South America, they are increasingly employed in solar energy storage solutions. In Europe and the Middle East, they are common in industrial and commercial applications. Understanding the specific needs and trends in your target market can help you select the right battery type and supplier for your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 48v battery

As the demand for 48V battery systems continues to rise across various sectors, including renewable energy, electric vehicles, and industrial applications, the importance of strategic sourcing cannot be overstated. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing these batteries is critical for ensuring reliability, cost-effectiveness, and sustainability.

A stock image related to 48v battery.

What are the key takeaways for strategic sourcing of 48V batteries? First, establishing strong relationships with manufacturers and suppliers is essential. This enables buyers to negotiate better terms, ensure quality control, and secure supply chain stability. Second, leveraging local sourcing options can significantly reduce lead times and shipping costs, particularly for buyers in emerging markets. Lastly, keeping abreast of technological advancements and regulatory changes will empower buyers to make informed decisions that align with their long-term strategic goals.

Looking forward, the landscape for 48V batteries is set for transformative growth. By prioritizing strategic sourcing today, international B2B buyers can position themselves to not only meet current demands but also to seize future opportunities in an increasingly electrified world. Engage with trusted suppliers and invest in the right technologies to stay ahead of the curve.