Pvc Grown Plant Plugs Guide: Type,Cost,Material…

Introduction: Navigating the Global Market for pvc grown plant plugs

In the dynamic landscape of global horticulture, sourcing high-quality PVC grown plant plugs presents a unique challenge for international B2B buyers. These essential growing mediums not only facilitate efficient plant propagation but also impact overall yield and quality. As businesses across Africa, South America, the Middle East, and Europe (including Brazil and Vietnam) seek reliable suppliers, understanding the diverse types and applications of PVC grown plant plugs becomes crucial.

This comprehensive guide delves into the intricacies of PVC plant plugs, offering insights into various types available in the market, their specific applications in different agricultural settings, and vital considerations for supplier vetting. Additionally, we explore cost factors, shipping logistics, and best practices for maximizing return on investment. By equipping buyers with knowledge about product specifications, market trends, and supplier reliability, this guide empowers informed purchasing decisions that can enhance operational efficiency and profitability.

As you navigate the complexities of sourcing PVC grown plant plugs, this resource serves as a roadmap, ensuring you can confidently select products that align with your business needs and contribute to your success in the competitive global market.

Understanding pvc grown plant plugs Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard PVC Plant Plugs | Basic design, typically cylindrical, various sizes | Nurseries, greenhouses, large-scale farming | Pros: Cost-effective, easy to source. Cons: Limited durability under harsh conditions. |

| Threaded PVC Plant Plugs | Features male or female threads for secure fitting | Hydroponics, aquaponics, and irrigation systems | Pros: Secure connection, reusable. Cons: Higher initial cost than standard plugs. |

| Slip PVC Plant Caps | Requires adhesive for sealing, available in various sizes | Custom irrigation setups, DIY projects | Pros: Versatile for custom builds. Cons: Labor-intensive to install. |

| Locking PVC Caps | No glue required, designed for easy reuse | Temporary setups, event gardening | Pros: Quick installation, reusable. Cons: May not provide the same seal as glued options. |

| Custom Molded PVC Plugs | Tailored designs for specific plant types | Specialized nurseries, premium horticulture | Pros: Optimized for specific plants. Cons: Higher cost and longer lead times. |

What are Standard PVC Plant Plugs and Where are They Used?

Standard PVC plant plugs are the most common type used in horticulture. They feature a simple cylindrical design and are available in various sizes to accommodate different plant species. These plugs are particularly popular among nurseries and greenhouses due to their cost-effectiveness and ease of sourcing. However, they may not withstand harsh environmental conditions as well as other options, making them less suitable for long-term outdoor use.

How Do Threaded PVC Plant Plugs Enhance System Integrity?

Threaded PVC plant plugs incorporate male or female threads, allowing for secure connections in hydroponic and aquaponic systems. This feature ensures that water and nutrients are efficiently delivered to the plants without leaks. They are ideal for businesses focusing on precision agriculture or those requiring reliable irrigation setups. While they offer enhanced security and reusability, the initial investment is typically higher than standard plugs.

What are the Benefits of Using Slip PVC Plant Caps?

Slip PVC plant caps are designed to create a seal using adhesive, making them ideal for custom irrigation setups or DIY projects. These caps come in various sizes and are versatile enough to fit different applications. While they allow for creative and tailored solutions, the installation process can be labor-intensive, which may deter some buyers looking for quick deployment options.

Why Choose Locking PVC Caps for Temporary Setups?

Locking PVC caps are designed for easy reuse and do not require glue, making them suitable for temporary gardening setups or events. Their quick installation process is a significant advantage for businesses needing to set up and dismantle systems frequently. However, buyers should consider that while they offer convenience, they may not provide the same level of sealing as glued options, which could lead to potential leaks.

How Do Custom Molded PVC Plugs Cater to Specialized Needs?

Custom molded PVC plugs are tailored specifically for certain plant types, offering advantages in root development and growth. These plugs are particularly beneficial for specialized nurseries and premium horticulture businesses that require optimized solutions. While they provide significant benefits in terms of plant health and growth rates, the higher costs and longer lead times associated with custom orders can be a drawback for some buyers.

Key Industrial Applications of pvc grown plant plugs

| Industry/Sector | Specific Application of PVC Grown Plant Plugs | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Seedling Production | Enhances germination rates and root development | Quality control, size consistency, and material durability |

| Horticulture | Nursery Operations | Facilitates efficient plant propagation and transplanting | Availability of various plug sizes and compatibility with existing systems |

| Hydroponics | Nutrient Film Technique (NFT) Systems | Supports rapid growth in controlled environments | Material compatibility with hydroponic solutions and ease of maintenance |

| Landscaping | Bulk Planting Solutions | Reduces labor costs and improves planting efficiency | Sourcing from reliable suppliers with bulk pricing options |

| Research and Development | Plant Trials and Experiments | Standardizes growth conditions for accurate data collection | Customization options for specific plant varieties and research needs |

How Are PVC Grown Plant Plugs Utilized in Agriculture?

In agriculture, PVC grown plant plugs are primarily used for seedling production, allowing for improved germination rates and enhanced root development. These plugs create a conducive environment for seedlings, ensuring that they receive the necessary moisture and nutrients without the risk of root rot. For international buyers, especially from regions like Africa and South America, sourcing plugs that maintain size consistency and material durability is crucial to ensure uniform growth and minimize crop failure.

What Role Do PVC Grown Plant Plugs Play in Horticulture?

In horticulture, these plugs are integral to nursery operations, where they facilitate efficient plant propagation and transplanting. The use of PVC plugs allows for easy handling and reduces transplant shock, promoting healthier plants. Buyers in Europe and the Middle East should consider suppliers who can provide a variety of plug sizes to accommodate different plant species, ensuring compatibility with their existing growing systems.

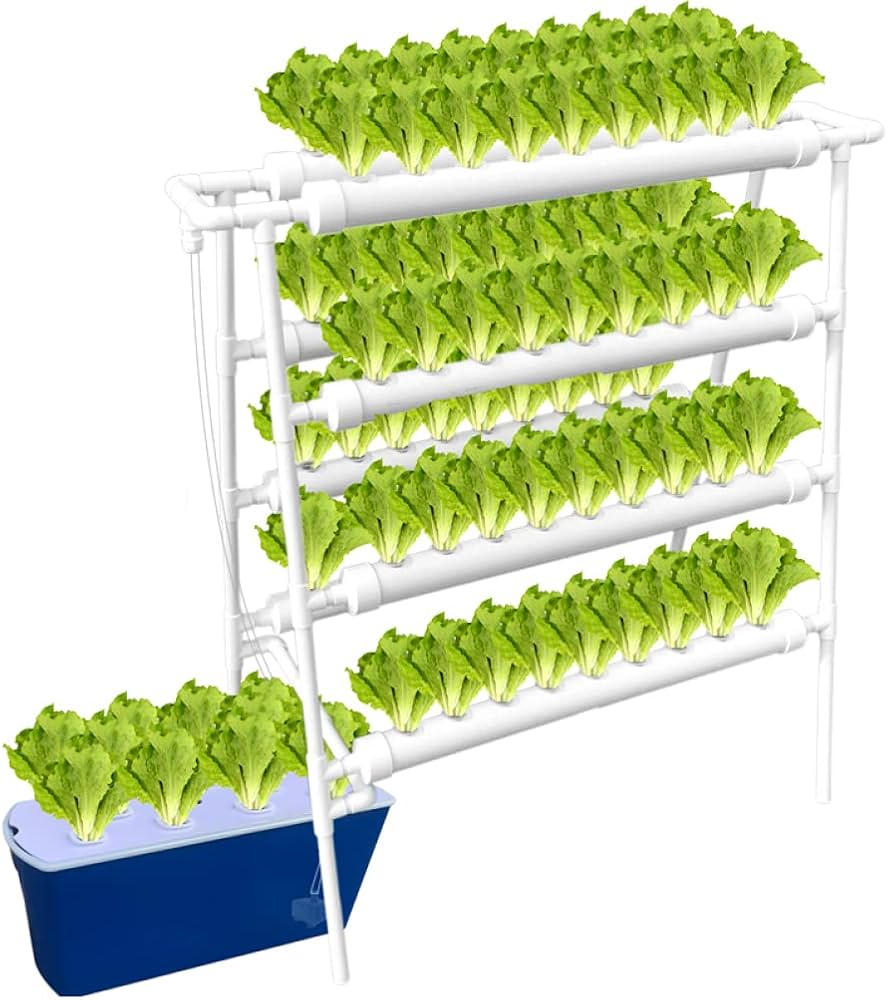

How Do PVC Grown Plant Plugs Benefit Hydroponics Systems?

For hydroponics, PVC grown plant plugs are utilized in Nutrient Film Technique (NFT) systems, where they support rapid growth in controlled environments. The plugs’ design allows for optimal nutrient absorption while minimizing the risk of algae growth. B2B buyers in regions like Vietnam should focus on sourcing plugs that are compatible with their hydroponic setups and easy to maintain, as this can significantly impact crop yields.

What Advantages Do PVC Grown Plant Plugs Offer in Landscaping?

In landscaping, PVC grown plant plugs provide bulk planting solutions that streamline the planting process, reducing labor costs and improving efficiency. The uniformity of plugs ensures that plants are spaced correctly, leading to better aesthetics and healthier growth. Buyers from various regions should seek reliable suppliers that offer bulk pricing options to maximize their cost-effectiveness in large-scale projects.

How Are PVC Grown Plant Plugs Used in Research and Development?

In research and development, PVC grown plant plugs are essential for conducting plant trials and experiments. They standardize growth conditions, allowing researchers to collect accurate data on plant performance under various scenarios. For international buyers involved in agricultural research, sourcing customizable plugs that cater to specific plant varieties and experimental needs is critical for achieving reliable results.

3 Common User Pain Points for ‘pvc grown plant plugs’ & Their Solutions

Scenario 1: Ensuring Consistent Growth Across Diverse Conditions

The Problem: B2B buyers often face challenges with ensuring consistent plant growth when using PVC grown plant plugs, especially in varied climates. For instance, a nursery in Brazil may experience high humidity, while a distributor in Europe deals with cooler temperatures. This disparity can lead to uneven growth rates and inconsistent product quality, which ultimately affects sales and customer satisfaction.

The Solution: To overcome this issue, buyers should invest in high-quality, temperature and humidity-resistant PVC plugs designed for specific regional climates. When sourcing these plugs, it is crucial to work with suppliers who provide detailed specifications about their products, including the material’s resilience to environmental factors. Additionally, implementing a controlled environment for the plugs, such as using greenhouses or climate-controlled storage, can help maintain optimal growing conditions. Regular monitoring of moisture levels and adjusting irrigation systems accordingly will also ensure that plants receive the right amount of water, fostering uniform growth.

Scenario 2: Managing Plug Integrity During Transport

The Problem: Another common pain point is the structural integrity of PVC grown plant plugs during transportation. B2B buyers often face issues where plugs arrive damaged or deformed, which can lead to significant losses. This is particularly problematic for businesses that rely on international shipping, where varying shipping conditions can exacerbate the issue.

The Solution: Buyers should prioritize suppliers who offer robust packaging solutions that protect plant plugs during transit. This includes using shock-absorbent materials and ensuring that the plugs are securely packed to prevent movement. Additionally, establishing partnerships with logistics companies that specialize in agricultural products can ensure better handling practices. It’s also beneficial to conduct trials with different packaging methods and shipping routes to identify the most effective solutions for maintaining plug integrity. Implementing a feedback loop with logistics partners will help continuously improve the transport process.

Scenario 3: Difficulty in Standardizing Plug Sizes for Production

The Problem: Standardization of plug sizes can be a major hurdle for B2B buyers looking to streamline their production processes. Buyers often find that different suppliers offer plugs in varying sizes, which complicates planting schedules and can lead to inefficiencies in production lines. This inconsistency can also impact the compatibility of plugs with existing growing systems.

The Solution: To tackle this challenge, buyers should work closely with a select group of reliable suppliers who can provide standardized sizes and specifications for PVC grown plant plugs. Establishing long-term relationships with these suppliers can lead to custom solutions that meet specific production needs. Furthermore, buyers should consider investing in automated planting systems that can accommodate a range of plug sizes while maintaining efficiency. Conducting thorough research to understand industry standards will also help buyers communicate their needs effectively, ensuring that they receive plugs that fit seamlessly into their production workflows. Regular audits of plug sizes and performance can help identify any discrepancies and inform future purchasing decisions.

Strategic Material Selection Guide for pvc grown plant plugs

What Are the Key Materials for PVC Grown Plant Plugs?

When selecting materials for PVC grown plant plugs, it is crucial to consider the properties, advantages, and limitations of each option. This analysis will focus on four common materials: Polyvinyl Chloride (PVC), Polypropylene (PP), High-Density Polyethylene (HDPE), and Expanded Polystyrene (EPS). Each material has unique characteristics that can significantly impact the performance and suitability of plant plugs in various applications.

How Does PVC Perform as a Material for Plant Plugs?

Key Properties: PVC is known for its excellent chemical resistance and durability. It can withstand a temperature range of -15°C to 60°C, making it suitable for diverse climates. Its rigidity provides structural integrity, which is essential for supporting plant growth.

Pros & Cons: The primary advantage of PVC is its affordability and availability. It is easy to manufacture and mold into various shapes and sizes. However, PVC can become brittle over time when exposed to UV light and may require additives for improved longevity.

Impact on Application: PVC plugs are compatible with a variety of growing media, including soil and hydroponic systems. However, they may not be biodegradable, which could pose environmental concerns in certain markets.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is vital. Buyers from regions like Africa and South America should ensure that the PVC used is free from harmful additives, as regulations may vary.

What Are the Advantages of Polypropylene for Plant Plugs?

Key Properties: Polypropylene is lightweight and possesses a higher melting point than PVC, making it suitable for applications requiring thermal stability. It also exhibits good chemical resistance and is less prone to UV degradation.

Pros & Cons: The key advantage of polypropylene is its strength-to-weight ratio, which allows for thinner designs without compromising durability. However, it is generally more expensive than PVC and may not be as readily available in all markets.

Impact on Application: Polypropylene plugs can be used in various growing environments, including high-temperature settings. They also offer better drainage properties, which can enhance root development.

Considerations for International Buyers: Polypropylene should meet local regulatory standards, especially in Europe, where environmental regulations are stringent. Buyers should also consider sourcing from manufacturers that adhere to sustainable practices.

What Benefits Does High-Density Polyethylene Offer for Plant Plugs?

Key Properties: HDPE is known for its high strength and resistance to impact, chemicals, and moisture. It can handle a temperature range of -40°C to 60°C, making it suitable for various climates.

Pros & Cons: The durability and flexibility of HDPE make it an excellent choice for plant plugs, as it can withstand physical stress without breaking. However, it is typically more expensive than PVC and can be challenging to recycle.

Impact on Application: HDPE plugs are compatible with both soil and hydroponic systems, providing good aeration and drainage. Their resilience makes them ideal for transporting young plants.

Considerations for International Buyers: Buyers should ensure that HDPE materials are compliant with local regulations, particularly in the Middle East and Europe, where environmental standards are increasingly important.

How Does Expanded Polystyrene Compare for Plant Plugs?

Key Properties: EPS is lightweight and offers excellent insulation properties. It is also resistant to moisture, making it suitable for various growing conditions.

Pros & Cons: The primary advantage of EPS is its cost-effectiveness and ease of use. However, it is less durable than other materials and can degrade over time, particularly when exposed to sunlight.

Impact on Application: EPS plugs are ideal for seed starting and can be used in both soil and hydroponic systems. However, their limited lifespan may not be suitable for long-term growing applications.

Considerations for International Buyers: Buyers should be aware of the environmental impact of EPS, as it is not biodegradable. Compliance with local regulations regarding plastic use is essential, especially in regions with stringent environmental laws.

Summary Table of Material Selection for PVC Grown Plant Plugs

| Material | Typical Use Case for PVC Grown Plant Plugs | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General-purpose plant plugs | Cost-effective and readily available | Brittle over time | Low |

| Polypropylene | High-temperature applications | Lightweight and UV resistant | Higher cost | Medium |

| High-Density Polyethylene | Transporting young plants | Durable and flexible | More expensive | High |

| Expanded Polystyrene | Seed starting | Cost-effective and easy to use | Limited lifespan | Low |

This comprehensive analysis provides valuable insights for international B2B buyers considering the best materials for PVC grown plant plugs, ensuring informed decision-making based on performance, cost, and regulatory compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for pvc grown plant plugs

What Are the Key Stages in the Manufacturing Process of PVC Grown Plant Plugs?

The manufacturing of PVC grown plant plugs involves several critical stages, ensuring that the final product meets the high standards required by the agricultural and horticultural industries. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation

The first stage in the manufacturing process is material preparation. High-quality PVC resin is sourced, which is vital for producing durable and reliable plugs. The resin is often blended with additives to enhance properties like flexibility, UV resistance, and color. Suppliers may also conduct preliminary tests on the raw materials to confirm their compliance with international standards.

Forming and Molding Techniques

Once the materials are prepared, the next step involves the forming and molding of the plugs. Common techniques include injection molding and blow molding. In injection molding, the heated PVC is injected into a mold to create the desired shape of the plugs. This method is efficient for mass production and ensures uniformity in size and quality. Blow molding, although less common for plugs, can be used for specific designs requiring hollow structures.

Assembly and Finishing Processes

After forming, the plugs may undergo assembly, where components such as drainage holes or labels are added. This stage is crucial for the functionality of the plugs in various planting systems. Following assembly, finishing processes such as trimming excess material, surface treatment, and quality checks are conducted. This ensures that the plugs are ready for distribution and meet aesthetic and functional requirements.

How is Quality Assurance Implemented in PVC Plant Plug Production?

Quality assurance is integral to the manufacturing process, ensuring that the final products meet both customer expectations and regulatory standards.

What International Standards Should B2B Buyers Consider?

For B2B buyers, understanding the relevant international standards is essential. ISO 9001 is a widely recognized quality management standard that ensures consistent quality in manufacturing processes. Additionally, industry-specific certifications such as CE marking (indicating compliance with European safety standards) and API (American Petroleum Institute) standards may be relevant, depending on the application of the plugs.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter production. Suppliers should conduct rigorous testing to verify that materials meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections and tests are conducted to monitor the quality of the products being produced. This includes checking for dimensional accuracy and material consistency.

-

Final Quality Control (FQC): After the manufacturing process, the finished products undergo comprehensive testing to ensure they meet all quality and safety standards. This includes functional tests, durability assessments, and visual inspections.

What Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to guarantee the quality of PVC grown plant plugs:

-

Physical Testing: This includes measuring dimensions, weight, and tensile strength to ensure the plugs can withstand the rigors of use.

-

Chemical Testing: Ensures that the materials used are free from harmful substances and meet environmental regulations.

-

Performance Testing: Evaluates the plugs’ functionality in real-world conditions, such as water retention and aeration capabilities.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is crucial for B2B buyers looking to ensure product reliability. Here are several strategies:

-

Audits: Conducting regular audits of the supplier’s facilities can provide insight into their manufacturing processes and quality control measures. Buyers should request access to QC documentation, including testing reports and compliance certificates.

-

Reports and Certifications: Suppliers should provide detailed reports on their quality assurance processes and any relevant certifications. This documentation should clearly outline their adherence to international standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing processes and product quality. This is particularly beneficial for international buyers who may not be able to conduct on-site inspections.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate additional complexities in quality control, especially when sourcing from regions like Africa, South America, the Middle East, and Europe.

-

Cultural and Regulatory Differences: Understanding the local regulations and quality standards is essential. Buyers should familiarize themselves with the certification processes in the supplier’s country to ensure compliance with international expectations.

-

Logistics and Supply Chain Considerations: Shipping delays, customs inspections, and local infrastructure can impact the quality of the products upon arrival. Establishing clear communication with suppliers regarding packaging and handling procedures can mitigate these risks.

-

Risk Management: Implementing risk management strategies, such as dual sourcing or maintaining safety stock, can help buyers manage potential quality issues that may arise from international procurement.

By comprehensively understanding the manufacturing processes and quality assurance practices associated with PVC grown plant plugs, B2B buyers can make informed decisions that align with their business needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pvc grown plant plugs’

To effectively procure PVC grown plant plugs, international B2B buyers must follow a structured approach. This guide outlines essential steps to ensure a successful sourcing process, tailored for buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establish clear specifications for the PVC grown plant plugs you need. This includes dimensions, material quality, and any specific features like drainage capabilities or compatibility with existing systems. Having well-defined requirements helps streamline supplier discussions and ensures that the products meet your operational needs.

- Considerations:

- Size: Identify the exact dimensions required for your planting systems.

- Material: Ensure the PVC is of high quality to withstand environmental conditions.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in PVC grown plant plugs. Look for companies that have a strong reputation in the industry and positive reviews from previous clients. This step is critical to finding reliable partners who can meet your quality and delivery expectations.

- Where to Look:

- Industry trade shows and expos for direct connections.

- Online B2B marketplaces and supplier directories.

Step 3: Evaluate Supplier Certifications

Before making any commitments, verify the certifications and compliance of your potential suppliers. Certifications such as ISO 9001 for quality management systems or environmental certifications can be indicators of a supplier’s commitment to quality and sustainability.

- Key Documents to Request:

- Quality assurance certificates.

- Environmental compliance documents.

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of their PVC grown plant plugs. This allows you to assess the quality, durability, and suitability of the products for your needs. Testing samples can prevent costly mistakes and ensure you are making an informed decision.

- Testing Focus:

- Assess the physical properties of the plugs, such as strength and flexibility.

- Check for any manufacturing defects.

Step 5: Negotiate Pricing and Terms

After selecting a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. It’s essential to ensure that the terms align with your budget and operational timelines. Clear agreements can help avoid misunderstandings later.

- Negotiation Tips:

- Inquire about bulk purchase discounts.

- Discuss warranty and return policies.

Step 6: Establish a Communication Plan

Effective communication with your supplier is vital for a successful partnership. Create a communication plan that outlines how you will stay in touch, address concerns, and provide feedback. This proactive approach fosters transparency and strengthens relationships.

- Communication Channels:

- Utilize email for formal communication.

- Schedule regular check-ins via video calls or phone.

Step 7: Plan for Logistics and Distribution

Finally, consider the logistics involved in receiving and distributing the PVC grown plant plugs. Ensure that the supplier can accommodate your shipping needs and that you have a reliable distribution plan in place for the product once it arrives.

- Logistics Considerations:

- Assess shipping options and costs.

- Plan for storage and handling upon arrival.

By following this checklist, B2B buyers can streamline their sourcing process for PVC grown plant plugs, ensuring they find quality products that meet their needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for pvc grown plant plugs Sourcing

What Are the Key Cost Components in Sourcing PVC Grown Plant Plugs?

When analyzing the cost structure for PVC grown plant plugs, several essential components come into play. These include:

-

Materials: The primary material is PVC, which can vary in price based on quality and supplier. Additionally, other materials such as adhesives for caps and any internal components used in the plugs can influence the overall cost.

-

Labor: Labor costs depend on the region of manufacturing. In regions with higher labor costs, such as Europe, the overall expense can be greater compared to areas like Southeast Asia or South America, where labor might be cheaper.

-

Manufacturing Overhead: This encompasses utilities, facility costs, and other indirect expenses associated with the production of PVC plugs. Efficient manufacturing processes can help reduce these costs.

-

Tooling: The initial investment in molds and tooling can be significant, particularly for custom or specialized plug designs. This cost is often amortized over larger production runs.

-

Quality Control (QC): Ensuring that the plugs meet industry standards and specifications is crucial. This may involve additional testing and inspection costs, which should be factored into the price.

-

Logistics: Transportation costs can vary widely based on the shipping method, distance, and volume. International buyers should be particularly mindful of these costs, as they can significantly affect the total landed cost.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on market conditions and the supplier’s pricing strategy.

What Influences the Pricing of PVC Grown Plant Plugs?

Several factors can affect the pricing of PVC grown plant plugs, including:

-

Volume and Minimum Order Quantities (MOQ): Bulk orders generally lead to lower per-unit costs. Buyers should negotiate MOQs to maximize cost-effectiveness.

-

Specifications and Customization: Custom designs or specifications can increase production complexity and costs. Buyers should clearly define their requirements to avoid unexpected price increases.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., ISO, environmental standards) can lead to increased costs. However, they may also result in better durability and performance.

-

Supplier Factors: The supplier’s reputation, reliability, and location can influence pricing. Established suppliers with a history of quality may charge more but offer assurance in terms of service and product quality.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) impacts logistics and responsibility for shipping costs. Understanding these terms is crucial for accurately calculating total costs.

How Can Buyers Negotiate Better Prices for PVC Grown Plant Plugs?

International B2B buyers should consider several strategies to negotiate better pricing:

-

Leverage Volume Discounts: If possible, consolidate orders to meet higher MOQs, which can lead to significant savings.

-

Build Relationships with Suppliers: Establishing long-term relationships can foster better pricing and terms. Frequent communication and transparency can enhance trust.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider ongoing costs such as maintenance, replacement, and logistics. A slightly higher initial cost may yield long-term savings.

-

Stay Informed About Market Trends: Keeping abreast of material price fluctuations and market demand can provide leverage during negotiations. Understanding regional pricing dynamics, especially in diverse markets like Africa and South America, is essential.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers allows for comparison and can uncover competitive pricing.

What Should International Buyers Be Aware of Regarding Pricing Nuances?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be cautious of pricing nuances:

-

Currency Fluctuations: Changes in currency exchange rates can affect total costs. Buyers should account for this in their budgeting.

-

Import Duties and Taxes: Understanding the import regulations and associated costs in the destination country is critical to avoid unexpected expenses.

-

Shipping Times and Costs: Longer shipping times can affect inventory management and operational costs. Buyers should plan accordingly to mitigate disruptions.

-

Cultural Differences in Negotiation: Different regions may have unique negotiation styles and expectations. Being aware of these cultural nuances can enhance negotiation outcomes.

In conclusion, a thorough understanding of the cost components, pricing influencers, negotiation strategies, and international nuances will empower B2B buyers to make informed purchasing decisions regarding PVC grown plant plugs.

Alternatives Analysis: Comparing pvc grown plant plugs With Other Solutions

Introduction to Alternative Solutions for Plant Propagation

In the realm of plant propagation, various methods and products exist that can fulfill similar objectives as PVC grown plant plugs. Understanding these alternatives is crucial for B2B buyers looking to optimize their operations, reduce costs, and improve overall plant health. This section explores two viable alternatives: biodegradable plant plugs and traditional soil-based seedlings. Each alternative presents distinct advantages and challenges that can influence a buyer’s decision-making process.

Comparison Table

| Comparison Aspect | PVC Grown Plant Plugs | Biodegradable Plant Plugs | Soil-Based Seedlings |

|---|---|---|---|

| Performance | High root establishment and growth rate | Good root establishment; performance varies with material quality | Variable, depends on soil type and care |

| Cost | Moderate initial investment | Higher cost due to material | Low initial cost; ongoing soil expenses |

| Ease of Implementation | Simple setup; requires minimal labor | Easy to use; may require specific conditions | Requires more labor and expertise |

| Maintenance | Low; minimal upkeep needed | Low; compostable and reduces waste | Moderate; regular watering and care needed |

| Best Use Case | Commercial nurseries and large-scale growers | Organic farms and eco-conscious growers | Small gardens and home use |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Biodegradable Plant Plugs?

Biodegradable plant plugs are gaining traction among eco-conscious growers. Made from organic materials, these plugs decompose over time, enriching the soil and reducing plastic waste. They perform well in terms of root establishment, but the quality can vary significantly depending on the manufacturer. One of the main challenges is their higher cost compared to PVC plugs, which may deter budget-sensitive buyers. However, they offer a sustainable solution that aligns with modern environmental standards, making them ideal for organic farms.

How Do Soil-Based Seedlings Compare in Terms of Performance?

Soil-based seedlings represent the traditional method of plant propagation. This approach leverages the natural environment of soil, which can provide essential nutrients and support healthy plant growth. While the initial cost is generally lower, the performance can be inconsistent, heavily influenced by soil quality, watering practices, and the skill of the grower. Soil-based seedlings require more labor and expertise, making them less suitable for large-scale operations but appealing for small gardens or home use where personal care is feasible.

Conclusion: How to Choose the Right Propagation Method

When selecting the appropriate propagation method or product, B2B buyers must consider their specific operational needs, budget constraints, and sustainability goals. PVC grown plant plugs offer a reliable and efficient solution for commercial growers focused on maximizing yield with minimal maintenance. In contrast, biodegradable plugs are ideal for those prioritizing environmental impact, while soil-based seedlings suit smaller-scale or more hands-on gardening efforts. By assessing these factors, buyers can make informed decisions that align with their business objectives and operational capabilities.

Essential Technical Properties and Trade Terminology for pvc grown plant plugs

What Are the Key Technical Properties of PVC Grown Plant Plugs?

1. Material Grade

PVC plant plugs are typically made from high-quality polyvinyl chloride (PVC) that meets specific industry standards. The material grade is crucial as it impacts durability, resistance to environmental factors, and overall performance in growing conditions. High-grade PVC ensures that plugs can withstand moisture and temperature fluctuations, which is essential for plant health and growth.

2. Wall Thickness

The wall thickness of the PVC plug is a critical specification that influences its strength and insulation properties. Thicker walls can provide better support for seedlings, reducing the risk of deformation during transport and handling. For B2B buyers, understanding wall thickness can guide decisions on the longevity and usability of the plugs in various climates, especially in regions like Africa and South America where environmental conditions can be extreme.

3. Tolerance Levels

Tolerance refers to the acceptable range of variation in the dimensions of the plugs. Precise tolerances are important to ensure that plugs fit securely in trays and irrigation systems. This is particularly relevant for businesses involved in large-scale planting operations, where consistent sizes can enhance planting efficiency and reduce labor costs.

4. Drainage and Aeration Features

Effective drainage and aeration are vital for promoting healthy root development in seedlings. PVC plugs often come with strategically placed holes or slits to allow excess water to escape and air to circulate. B2B buyers should prioritize plugs with these features as they can lead to better plant growth rates and lower mortality rates, especially in high-humidity environments.

5. Reusability and Environmental Impact

Many PVC plant plugs are designed to be reusable, allowing for cost savings and sustainability. B2B buyers should consider the lifecycle of the plugs, including their recyclability and potential environmental impact. Opting for reusable products aligns with growing sustainability trends in agriculture and can enhance a company’s reputation.

6. Customization Options

Customization refers to the ability to modify the size, shape, and features of the plugs according to specific agricultural needs. This can be particularly beneficial for businesses that cultivate a diverse range of plant species. Understanding available customization options allows B2B buyers to tailor their purchases to maximize efficiency and effectiveness in their operations.

What Are Common Trade Terms in the PVC Plant Plug Industry?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in another company’s products. In the context of PVC plant plugs, an OEM might manufacture plugs for a larger agricultural supply company. Understanding OEM relationships can help buyers identify quality manufacturers and negotiate better pricing.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is critical for budgeting and inventory management. A higher MOQ might lead to cost savings per unit but can strain cash flow if the buyer cannot sell the inventory quickly.

3. RFQ (Request for Quotation)

An RFQ is a document used by businesses to solicit price quotes from suppliers. When dealing with PVC plant plugs, submitting an RFQ can help buyers compare pricing, specifications, and terms from multiple suppliers, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping agreements. Familiarity with these terms is essential for B2B buyers to understand their obligations regarding shipping costs, insurance, and risk during transportation of PVC plant plugs, especially when sourcing from overseas suppliers.

5. Lead Time

Lead time is the period between placing an order and receiving it. For businesses relying on timely delivery of PVC plant plugs, understanding lead times is crucial for planning planting schedules and inventory management. Shorter lead times can lead to more efficient operations and reduced downtime.

6. Certification Standards

Certification standards refer to the compliance of products with specific agricultural and environmental regulations. Buyers should be aware of relevant certifications for PVC plant plugs, as these can impact product quality, safety, and marketability, especially in regions with stringent agricultural standards.

Understanding these technical properties and trade terminology will empower B2B buyers to make informed decisions, fostering successful partnerships in the PVC plant plug supply chain.

Navigating Market Dynamics and Sourcing Trends in the pvc grown plant plugs Sector

What Are the Key Drivers and Trends in the PVC Grown Plant Plugs Market?

The PVC grown plant plugs market is experiencing significant growth fueled by various global drivers. One of the primary factors is the increasing demand for sustainable and efficient horticultural practices, particularly in regions like Africa, South America, the Middle East, and Europe. With a growing focus on agriculture and urban gardening, international B2B buyers are seeking reliable and cost-effective solutions for plant propagation. The trend towards automation in agriculture is also shaping the sourcing dynamics, as advanced technologies such as automated irrigation systems and precision farming tools are becoming more prevalent.

Emerging technologies are enhancing the production and distribution of PVC grown plant plugs. Innovations in manufacturing processes, such as 3D printing and advanced molding techniques, are enabling suppliers to create customized plugs that meet specific client needs. Additionally, digital platforms are revolutionizing sourcing practices, allowing buyers to connect directly with manufacturers and streamline procurement processes. The rise of e-commerce in agriculture is facilitating quicker transactions and wider market reach, making it essential for B2B buyers to adapt to these changes.

How Is Sustainability Influencing Sourcing Trends for PVC Grown Plant Plugs?

Sustainability has become a cornerstone of modern B2B sourcing strategies, particularly in the PVC grown plant plugs sector. The environmental impact of PVC products is under scrutiny, leading to increased demand for sustainable alternatives. Buyers are encouraged to prioritize suppliers who adhere to ethical sourcing practices and utilize eco-friendly materials in their production processes. Certifications such as the Forest Stewardship Council (FSC) and the Global Organic Textile Standard (GOTS) are becoming essential indicators of a supplier’s commitment to sustainability.

Moreover, the integration of recycled PVC in the manufacturing of plant plugs is gaining traction. By opting for products made from recycled materials, businesses can significantly reduce their carbon footprint while promoting a circular economy. As consumers worldwide become more environmentally conscious, B2B buyers must align their sourcing decisions with sustainable practices to enhance brand reputation and meet regulatory requirements.

What Is the Historical Context of PVC Grown Plant Plugs in the B2B Landscape?

The evolution of PVC grown plant plugs can be traced back several decades when the need for efficient plant propagation became increasingly apparent in commercial horticulture. Initially, these plugs were primarily used in large-scale nurseries, but as the agricultural landscape evolved, their application expanded to include urban gardening and home horticulture. The introduction of PVC as a material offered numerous advantages, including durability, versatility, and cost-effectiveness.

Over the years, advancements in manufacturing techniques and a greater understanding of plant biology have led to the development of specialized plugs tailored to various plant species. This has allowed growers to optimize their planting processes and improve overall crop yields. As international markets continue to expand, the PVC grown plant plugs sector is poised for further innovation, driven by the dual demands for efficiency and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of pvc grown plant plugs

-

How do I choose the right PVC grown plant plugs for my needs?

Choosing the right PVC grown plant plugs involves evaluating several factors, including the type of plants you intend to grow, the size of the plugs, and the growing medium used. Consider the growth stage of your plants; for example, smaller plugs are ideal for seedlings, while larger plugs suit more established plants. Additionally, ensure the plugs are compatible with your existing irrigation systems and can support the required moisture levels for your specific plants. Engage with suppliers to discuss your needs and request samples to test before making larger commitments. -

What are the benefits of using PVC grown plant plugs over traditional growing methods?

PVC grown plant plugs offer numerous advantages, such as improved aeration and drainage, which can enhance root development and plant health. They are typically lighter than traditional pots, making them easier to transport and handle. The uniformity of plugs can lead to more consistent plant growth, and their design often allows for efficient nutrient delivery. Furthermore, PVC is durable and resistant to many environmental factors, reducing the risk of damage during transportation and storage. -

What is the minimum order quantity (MOQ) for PVC grown plant plugs?

Minimum order quantities for PVC grown plant plugs can vary significantly among suppliers. Generally, MOQs can range from a few hundred to several thousand units, depending on the manufacturer and your specific requirements. It’s advisable to discuss your needs directly with potential suppliers. If your order does not meet the MOQ, consider consolidating orders with other buyers or exploring alternative suppliers who may offer more flexible terms. -

How can I ensure the quality of PVC grown plant plugs from international suppliers?

To ensure quality, conduct thorough due diligence on potential suppliers. Request certifications related to manufacturing processes, such as ISO or other relevant quality standards. Additionally, ask for samples to assess the quality before placing larger orders. Establish clear quality assurance protocols, including inspections during production and prior to shipment. Building a long-term relationship with trusted suppliers can also help ensure consistent quality over time. -

What payment terms should I expect when sourcing PVC grown plant plugs internationally?

Payment terms can vary widely depending on the supplier and the nature of the transaction. Common terms include payment in advance, letters of credit, or payment upon delivery. It’s crucial to negotiate terms that align with your cash flow and risk tolerance. Many suppliers may offer discounts for early payments or larger orders, so inquire about these options. Always ensure that payment terms are documented in the purchase agreement to avoid misunderstandings. -

What are the logistics considerations when importing PVC grown plant plugs?

Logistics for importing PVC grown plant plugs involve several factors, including shipping method, customs clearance, and delivery timelines. Consider the size and weight of the plugs, as this will affect shipping costs and methods. Work with a reliable freight forwarder familiar with your destination’s import regulations. Understanding local customs duties and taxes is essential to avoid unexpected costs. Establishing a clear timeline for delivery can help ensure that your plugs arrive when needed for planting. -

Can PVC grown plant plugs be customized to meet specific requirements?

Many suppliers offer customization options for PVC grown plant plugs, allowing you to tailor aspects such as size, shape, and even the growing medium used. Customization can help you optimize the plugs for your specific plants or growing conditions. When discussing customization, clearly communicate your requirements and any design specifications. Keep in mind that customized orders may require higher MOQs and longer lead times, so plan accordingly. -

What certifications should I look for when sourcing PVC grown plant plugs?

When sourcing PVC grown plant plugs, look for certifications that demonstrate compliance with industry standards for quality and safety. Key certifications may include ISO 9001 for quality management systems, ISO 14001 for environmental management, and any specific agricultural certifications relevant to your region. These certifications can indicate the supplier’s commitment to producing high-quality products and adhering to environmentally friendly practices. Always request documentation for any claimed certifications to verify their validity.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Pvc Grown Plant Plugs Manufacturers & Suppliers List

1. DripWorks – PVC Caps and Plugs

Domain: dripworks.com

Registered: 1998 (27 years)

Introduction: PVC caps and plugs are used to seal off the end of a PVC line, providing an inexpensive and reliable solution for stopping water flow. DripWorks offers a variety of PVC plugs, caps, and accessories suitable for various projects. Available sizes for PVC threaded plugs include 1/2″, 3/4″, and 1″, with options for male or female threads. PVC slip caps, which require gluing, are available in sizes ran…

2. Reddit – Plant Plugs

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Plant plugs are primarily made of a blend of peat moss and vermiculite, with additional additives such as lime for pH adjustment, mycorrhiza for improved root growth, and guava extract to reduce surface tension for better water absorption. Some plugs may also include perlite as a top dressing, and alternative materials like coco coir, wood fiber, hydrofiber, and sand can be used. The spongy consis…

3. Harris Seeds – Price Lists & Grower Calendar

Domain: harrisseeds.com

Registered: 1997 (28 years)

Introduction: Plug & Liner Price Lists, 2024-2025 Brochure, 2024-2025 Price Lists, 2024-2025 Grower Calendar, Products Available By Supplier, Raker-Roberta’s Main Price List, Raker-Roberta’s Poinsettias, Raker-Roberta’s Mums & Asters, Raker-Roberta’s Specialty Cut Flowers, Four Star Greenhouses, Pleasant View Gardens, Gro ‘n Sell, Mast Young Plants.

4. Houzz – Seedling Plugs and Liners

Domain: houzz.com

Registered: 2006 (19 years)

Introduction: Plugs are tiny seedlings started by seed, often sold in trays with multiple cells (ranging from 144 to 500). They are typically small and may require repotting into larger pots (3 or 4 inch nursery pots) before being planted outside. Liners, or lining out stock, are larger than plugs and consist of rooting cuttings planted in a cube of soil. Plugs can be grown in a home greenhouse with natural lig…

5. Grodan – A-OK Starter Plugs

Domain: morr.com

Registered: 2000 (25 years)

Introduction: Grodan Grow Plugs are designed for seedling and cutting propagation prior to transplanting into larger grow systems. Key products include: 1. Grodan A-OK Starter Plugs – 1.5-Inch – Unwrapped – Sheet of 98 (Case of 30) (8/Plt): Unwrapped plugs for immediate use, 98 plugs per sheet, ideal for commercial-scale operations. 2. Grodan Macro Plugs – 1.5-Inch (Case of 2000) (8/Plt): Bulk quantity of 2000 …

6. EarthBox – PVC Seed Starter

Domain: forum.earthbox.com

Registered: 1996 (29 years)

Introduction: PVC Seed Starter made from 1 inch and 3/4 inch thin walled PVC pipe, cut into 4 inch sections. Designed for starting seeds, particularly okra, using semi wet peat moss packed into the pipe. Each section can hold seeds, with a packed plug at the bottom to keep the peat moss in place. Allows for better seed management by reducing waste, as users can control the number of seeds planted in each sectio…

7. Mumsnet – Plug Plants

Domain: mumsnet.com

Registered: 2000 (25 years)

Introduction: Plug plants including geraniums, cosmos, and various hanging basket plants.

8. Amleo – Grow Plugs

Domain: amleo.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “Grow Plugs”, “sku”: “VP-GROWPLUG”, “price”: “$15.95”, “grouped_product_items”: [{“name”: “FP55 – Grow-Plugs Soilless Seed-Starting Medium, Box of 55 Plugs”, “price”: “$15.95”}, {“name”: “FP1400 – Grow-Plugs Soilless Seed-Starting Medium, Case of 1,400 Plugs”, “price”: “$229.95”}], “features”: [“Stabilized soilless propagation medium”, “Blend of quality peat and organics”, “Foam b…

9. North Creek Nurseries – Landscape Plugs™

Domain: northcreeknurseries.com

Registered: 1999 (26 years)

Introduction: Landscape Plugs™ are low-maintenance native perennials and grasses available in two sizes: LP50 and LP32. LP50 plugs are 5.00″ deep by 2.00″ square, with 50 plugs per standard nursery liner, suitable for forb and grass species with taproots or deep fibrous root systems. LP32 plugs are 4.00″ deep by 2.22″ square, with 32 plugs per standard nursery liner, designed for species with lateral root syste…

Strategic Sourcing Conclusion and Outlook for pvc grown plant plugs

Strategic sourcing in the realm of PVC grown plant plugs is pivotal for international B2B buyers looking to optimize their supply chains. By leveraging reliable suppliers and assessing the quality of materials, businesses can ensure the longevity and effectiveness of their products. Key considerations include evaluating the variety of plugs available—such as threaded and slip options—and understanding their applications in various growing systems. Additionally, cost-effectiveness should be balanced with quality to enhance operational efficiency.

As the demand for sustainable agricultural solutions continues to rise, PVC grown plant plugs present an innovative way to support plant growth while minimizing resource usage. This strategic approach not only leads to improved yield but also fosters environmental responsibility.

Looking ahead, international buyers from regions like Africa, South America, the Middle East, and Europe should actively seek partnerships with manufacturers who prioritize sustainability and innovation. Engaging in strategic sourcing will not only enhance your product offerings but also position your business as a leader in the growing market for environmentally friendly horticultural solutions. Embrace the opportunity to transform your sourcing strategy today and reap the benefits of a greener tomorrow.