Refrigerant Gas R12 Guide: Type,Cost,Material…

Introduction: Navigating the Global Market for refrigerant gas r12

In the ever-evolving landscape of global commerce, sourcing refrigerant gas R12 presents a unique set of challenges for B2B buyers. As a critical component for refrigeration and air conditioning systems, R12—commonly known as Freon—is essential for companies operating in various sectors, including automotive, commercial refrigeration, and industrial applications. However, navigating the complexities of compliance, supplier reliability, and fluctuating costs can be daunting, especially for international buyers from Africa, South America, the Middle East, and Europe.

This comprehensive guide delves into the multifaceted world of refrigerant gas R12, offering insights into its types, applications, and the stringent regulations governing its use. We will explore the intricacies of supplier vetting, providing actionable strategies to ensure you partner with reputable providers. Additionally, we will address cost considerations and market trends that impact procurement decisions.

By equipping B2B buyers with the knowledge and tools necessary to make informed purchasing decisions, this guide aims to simplify the sourcing process. Whether you are in Vietnam, Saudi Arabia, or beyond, understanding the dynamics of the R12 market will empower you to secure the best products while ensuring compliance with environmental standards. Dive in to discover how to optimize your refrigerant sourcing strategy and position your business for success in a competitive global market.

Understanding refrigerant gas r12 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| R-12 (Freon) | CFC-based, high ozone depletion potential | Automotive air conditioning, refrigeration units | Pros: Widely available, effective cooling. Cons: Production banned, environmental concerns. |

| Genetron 12 | Brand name for R-12 with similar properties | Commercial refrigeration, automotive applications | Pros: Trusted brand, reliable performance. Cons: Limited availability due to regulations. |

| Forane 12 | Another brand variant of R-12, used in various systems | Industrial chillers, medical refrigeration | Pros: High efficiency, versatile. Cons: Environmental regulations limit use. |

| CFC-12 | Generic term for R-12, often used interchangeably | Legacy systems, older HVAC equipment | Pros: Compatibility with older systems. Cons: Ozone depletion concerns, phased out. |

| R-12 Replacement | Alternative refrigerants like R-134a or R-1234yf | Modern automotive AC, commercial refrigeration | Pros: Environmentally friendly, compliant. Cons: May require system retrofitting. |

What Are the Key Characteristics of R-12 Refrigerant (Freon)?

R-12, commonly known as Freon, is a chlorofluorocarbon (CFC) refrigerant that has been widely used in various applications, including automotive air conditioning and refrigeration units. Its notable features include a high efficiency in cooling and a relatively low boiling point, making it effective for medium to low-temperature applications. However, the production of R-12 has been banned due to its significant ozone depletion potential, which poses a challenge for businesses relying on this refrigerant in legacy systems. Buyers must consider the availability of R-12 and the implications of using a substance that is no longer produced.

How Does Genetron 12 Compare in the Market?

Genetron 12 is a branded variant of R-12 that shares similar characteristics and applications. It is primarily used in commercial refrigeration and automotive systems. As a trusted name in the refrigerant market, Genetron 12 is recognized for its reliability and performance. However, like R-12, its availability is limited due to environmental regulations, making it essential for B2B buyers to assess their supply options and ensure compliance with local laws when purchasing.

What Makes Forane 12 a Viable Option for Industrial Applications?

Forane 12 is another brand of R-12, recognized for its efficiency in various industrial applications, including medical refrigeration and industrial chillers. It maintains the same chemical properties as R-12, ensuring effective cooling. However, similar to other CFCs, its use is restricted due to environmental concerns. Buyers should weigh the benefits of high efficiency against the potential regulatory challenges and consider transitioning to more sustainable alternatives when planning long-term purchases.

Why Are CFC-12 Variants Still Relevant for Legacy Systems?

CFC-12 is a generic term often used interchangeably with R-12, particularly in discussions about older HVAC equipment and legacy systems. While it is compatible with older technologies, the environmental implications of using CFC-12 cannot be overlooked. Businesses must navigate the balance between maintaining existing systems and adhering to modern environmental standards. Buyers should consider the costs associated with maintaining older systems against potential upgrades to compliant refrigerants.

What Are the Benefits of Considering R-12 Alternatives?

With the phase-out of R-12 and its derivatives, many businesses are exploring alternative refrigerants like R-134a and R-1234yf. These alternatives offer environmentally friendly options that comply with current regulations. While they may require retrofitting of existing systems, the long-term benefits include reduced environmental impact and compliance with sustainability goals. B2B buyers should evaluate the cost of transitioning against the benefits of improved efficiency and compliance to make informed purchasing decisions.

Key Industrial Applications of refrigerant gas r12

| Industry/Sector | Specific Application of refrigerant gas r12 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Automotive Air Conditioning Systems | Enhances passenger comfort and vehicle reliability | Compliance with certification requirements for purchase |

| Commercial Refrigeration | Commercial Freezers and Refrigerators | Preserves food quality and extends shelf life | Availability of R12 in appropriate cylinder sizes |

| Medical | Medical Refrigeration (e.g., vaccine storage) | Ensures proper storage conditions for sensitive items | Need for reliable sourcing to maintain consistent supply |

| Industrial | Industrial Chillers and Cooling Systems | Increases efficiency in manufacturing processes | Consideration of environmental regulations and disposal |

| Aerospace | Cooling Systems in Aircraft | Critical for operational safety and equipment longevity | Strict adherence to safety and certification standards |

Refrigerant gas R12 has been a staple in the automotive sector, particularly in air conditioning systems for vehicles manufactured before 1994. Its ability to provide effective cooling enhances passenger comfort, thereby improving overall vehicle reliability. Buyers in this sector must ensure compliance with certification requirements, such as obtaining a 608 or 609 certification, to purchase R12 legally.

In the commercial refrigeration industry, R12 is widely used in freezers and refrigerators to preserve food quality and extend shelf life. This application is crucial for businesses in the food service and retail sectors, where maintaining optimal temperatures can prevent spoilage and financial loss. Buyers should consider the availability of R12 in various cylinder sizes to suit their operational needs.

The medical industry relies on R12 for refrigeration systems that store vaccines and other temperature-sensitive medical supplies. Proper storage conditions are essential to ensure the efficacy of these products. For international B2B buyers, it is vital to establish reliable sourcing channels to maintain a consistent supply of R12, as any interruption could jeopardize healthcare delivery.

In industrial applications, R12 is utilized in chillers and cooling systems, enhancing efficiency in various manufacturing processes. By maintaining optimal temperatures, businesses can improve productivity and reduce equipment wear. Buyers should be aware of environmental regulations regarding the use and disposal of R12, as compliance is critical for sustainable operations.

Lastly, in the aerospace sector, R12 is employed in cooling systems for aircraft. This application is vital for ensuring operational safety and prolonging the life of sensitive equipment. Companies must adhere to strict safety and certification standards when sourcing R12, given the critical nature of its application in aviation.

3 Common User Pain Points for ‘refrigerant gas r12’ & Their Solutions

Scenario 1: Difficulty in Sourcing Compliant Refrigerant Gas R-12

The Problem: Many B2B buyers face challenges when sourcing R-12 refrigerant gas due to its regulatory restrictions. Since the production of new R-12 has been banned in several regions, including Europe and parts of the Americas, buyers often struggle to find compliant suppliers. This scarcity can lead to inflated prices and unreliable supply chains, particularly for businesses in industries that still rely on older refrigeration systems, such as automotive and commercial refrigeration. Furthermore, buyers must ensure they are purchasing from certified suppliers to avoid legal repercussions and environmental concerns.

The Solution: To navigate these challenges, B2B buyers should focus on establishing relationships with reputable suppliers who specialize in reclaimed or recycled R-12 refrigerant. These suppliers can often provide documentation verifying compliance with environmental regulations. Buyers should also consider joining industry associations or networks that can provide leads on reliable sources. Additionally, implementing a systematic inventory management approach can help businesses anticipate their refrigerant needs, reducing the urgency to source R-12 at inflated prices. Regularly reviewing supplier contracts and maintaining open communication can also mitigate supply chain disruptions.

Scenario 2: Ensuring Proper Handling and Certification Compliance

The Problem: A significant pain point for many businesses is ensuring that their employees are properly certified to handle R-12 refrigerant. In many regions, including the U.S., technicians must hold specific certifications (like EPA 608 or 609) to legally purchase and work with refrigerants. This requirement can create bottlenecks for companies, especially smaller businesses that may not have the resources to train all employees or manage certification processes efficiently. Non-compliance not only leads to legal issues but can also affect operational efficiency.

The Solution: Companies should invest in training programs that cover the necessary certifications for their technicians. Partnering with accredited training organizations can streamline this process and ensure that employees are well-versed in handling R-12 safely and legally. Additionally, businesses can create a compliance checklist that tracks employee certifications and renewal dates, ensuring that all personnel are up to date. Leveraging technology, such as training management software, can also facilitate ongoing education and help track certification progress. By prioritizing employee training, companies can enhance their operational efficiency while remaining compliant with regulatory requirements.

Scenario 3: Managing Environmental and Disposal Concerns

The Problem: As awareness of environmental issues grows, many businesses are increasingly concerned about the environmental impact of using refrigerants like R-12. The ozone-depleting potential of R-12 can lead to significant reputational risks for companies, particularly those in regions where environmental regulations are stringent. Additionally, improper disposal of R-12 can result in hefty fines and negative publicity, posing a challenge for organizations that want to maintain a positive environmental footprint.

The Solution: To address these concerns, businesses should implement robust refrigerant management programs that focus on recovery, recycling, and proper disposal. Partnering with certified refrigerant reclaimers ensures that R-12 is handled in an environmentally responsible manner. Companies can also invest in leak detection technology to minimize emissions and ensure compliance with environmental standards. Furthermore, communicating a commitment to environmental stewardship can enhance a company’s brand image and attract customers who prioritize sustainability. Regular audits of refrigerant usage and disposal practices will help identify areas for improvement, ultimately leading to better compliance and reduced environmental impact.

Strategic Material Selection Guide for refrigerant gas r12

What Materials Are Commonly Used for Refrigerant Gas R12?

When selecting materials for refrigerant gas R12, it is essential to consider their properties, advantages, and limitations. The following materials are commonly used in the storage and handling of R12 refrigerant gas, each with unique characteristics that influence their suitability for various applications.

1. Carbon Steel

Key Properties:

Carbon steel is known for its high tensile strength and excellent pressure rating, making it suitable for high-pressure applications. It has a good temperature resistance, typically handling temperatures from -20°C to 200°C.

Pros & Cons:

Carbon steel is relatively inexpensive compared to other materials, making it a cost-effective choice for large-scale applications. However, it is prone to corrosion, especially in humid environments, which can lead to leaks and reduced lifespan.

Impact on Application:

Carbon steel is widely used for cylinders and pipes in refrigerant systems. Its compatibility with R12 is generally good, but proper coatings or treatments are necessary to mitigate corrosion.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A106 for carbon steel pipes. In regions like Africa and the Middle East, where humidity can be high, additional protective measures may be necessary.

2. Aluminum

Key Properties:

Aluminum offers excellent corrosion resistance and is lightweight, making it easier to handle and transport. Its temperature rating is suitable for refrigerants, generally up to 150°C.

Pros & Cons:

The primary advantage of aluminum is its resistance to corrosion, which extends the lifespan of storage and handling equipment. However, it is more expensive than carbon steel and may have lower tensile strength under high pressure.

Impact on Application:

Aluminum is often used in manufacturing smaller cylinders and components for R12 systems. Its compatibility with R12 is excellent, ensuring minimal risk of chemical reactions.

Considerations for International Buyers:

Buyers should verify that aluminum components meet relevant standards such as ASTM B221. In regions like South America, where cost sensitivity is high, the initial investment in aluminum may be a consideration.

3. Stainless Steel

Key Properties:

Stainless steel boasts superior corrosion resistance and can handle high pressures and temperatures, typically up to 300°C. Its durability makes it ideal for long-term applications.

Pros & Cons:

While stainless steel is highly durable and resistant to corrosion, it comes at a higher cost compared to carbon steel and aluminum. Manufacturing processes can also be more complex, leading to increased production costs.

Impact on Application:

Stainless steel is often used in high-end applications requiring stringent safety measures, such as in medical refrigeration. Its compatibility with R12 is excellent, providing a safe environment for the refrigerant.

Considerations for International Buyers:

Buyers should ensure compliance with standards such as ASTM A312 for stainless steel pipes. In Europe, where regulations are strict, using stainless steel may also provide an advantage in meeting environmental standards.

4. Copper

Key Properties:

Copper is known for its excellent thermal conductivity and resistance to corrosion. It can handle temperatures up to 200°C and is often used in refrigeration systems.

Pros & Cons:

Copper is highly effective for heat exchange applications due to its thermal properties. However, it is more expensive than carbon steel and can be prone to corrosion in certain environments, especially when exposed to moisture.

Impact on Application:

Copper is commonly used in tubing and fittings for R12 systems, ensuring efficient heat transfer. Its compatibility with R12 is good, but care must be taken to avoid corrosion.

Considerations for International Buyers:

Buyers should check compliance with standards such as ASTM B280 for copper tubing. In regions like the Middle East, where high temperatures are prevalent, the thermal properties of copper can be particularly beneficial.

Summary Table

| Material | Typical Use Case for refrigerant gas r12 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Cylinders and pipes | Cost-effective | Prone to corrosion | Low |

| Aluminum | Small cylinders and components | Excellent corrosion resistance | Higher cost than carbon steel | Medium |

| Stainless Steel | High-end applications | Superior durability and safety | High cost and complex manufacturing | High |

| Copper | Tubing and fittings | Excellent thermal conductivity | Higher cost and potential corrosion | Medium |

This guide provides a comprehensive overview of materials commonly used in the context of refrigerant gas R12, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for refrigerant gas r12

What Are the Main Stages in the Manufacturing Process of Refrigerant Gas R12?

The manufacturing process of refrigerant gas R12, also known as dichlorodifluoromethane, involves several critical stages, each designed to ensure the final product meets stringent quality and safety standards.

-

Material Preparation: The first stage involves sourcing high-purity raw materials, primarily chloromethane and hydrofluoric acid. These chemicals undergo rigorous purity checks to ensure they meet the specifications required for refrigerant production. Suppliers must provide material safety data sheets (MSDS) and certificates of analysis (CoA) to verify the quality of the inputs.

-

Chemical Reaction: The second stage is the chemical synthesis, where the prepared materials are subjected to a controlled reaction process. This typically occurs in large reactors under specific temperature and pressure conditions to facilitate the formation of R12. The reaction conditions are crucial, as they influence the yield and purity of the refrigerant gas.

-

Separation and Purification: Once the reaction is complete, the mixture contains various by-products and unreacted materials. Separation techniques, such as distillation, are employed to isolate R12 from these impurities. This step is vital for achieving the required purity levels, often exceeding 99.9%.

-

Formulation and Compression: After purification, the refrigerant gas is formulated into the desired concentrations and pressurized into cylinders. This stage requires precise control to ensure that the gas is safe for storage and transport. The filling process is conducted in specialized environments to prevent contamination.

-

Finishing: Finally, the packaged refrigerant undergoes labeling and documentation processes. Each cylinder is marked with relevant safety information, handling instructions, and batch numbers. This information is crucial for traceability and compliance with international shipping regulations.

Which Quality Control Standards Are Relevant for R12 Refrigerant Manufacturing?

Quality control (QC) is a critical aspect of the manufacturing process for refrigerant gas R12. Compliance with international and industry-specific standards is essential for ensuring product safety and efficacy.

-

International Standards: Many manufacturers adhere to ISO 9001, which sets out criteria for a quality management system. This standard emphasizes continuous improvement and customer satisfaction, which are paramount for B2B suppliers in the refrigerant market.

-

Industry-Specific Certifications: Additional certifications such as CE marking (Conformité Européenne) and API (American Petroleum Institute) standards are relevant. These certifications demonstrate compliance with safety and environmental regulations, particularly for businesses operating in regions with stringent environmental laws.

What Are the Key QC Checkpoints in Refrigerant Gas R12 Production?

To maintain the highest quality standards, manufacturers implement several key QC checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial checkpoint occurs when raw materials arrive at the facility. Incoming materials are tested for purity and composition against supplier documentation to ensure they meet predefined specifications.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections and tests are conducted. This includes monitoring reaction parameters, conducting mid-process analyses, and ensuring that separation and purification processes are functioning correctly.

-

Final Quality Control (FQC): The final checkpoint involves comprehensive testing of the finished product. This includes gas composition analysis, pressure tests, and environmental impact assessments to ensure compliance with relevant regulations.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s QC processes is essential. Here are actionable steps buyers can take:

-

Request Documentation: Buyers should ask for QC documentation, including ISO certificates, audit reports, and test results. This paperwork provides insights into the manufacturer’s compliance with international standards.

-

Conduct Audits: Engaging in supplier audits is a proactive way to assess a manufacturer’s QC systems. Audits should evaluate the entire production process, from raw material sourcing to final packaging.

-

Third-Party Inspections: Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s QC practices. These inspections can validate claims made by the supplier regarding their manufacturing processes and product quality.

-

Check for Complaints and Recalls: Researching the supplier’s history for any complaints or recalls related to their refrigerant products can provide insight into their reliability and commitment to quality.

What Are the Quality Control Nuances for International B2B Buyers of R12 Refrigerant?

B2B buyers operating internationally must navigate various quality control nuances when sourcing refrigerant gas R12:

-

Regulatory Compliance: Different regions may have specific regulations governing the production and sale of refrigerants. Buyers should familiarize themselves with local laws and ensure their suppliers comply to avoid legal complications.

-

Environmental Considerations: Given the ozone-depleting nature of R12, buyers should prioritize suppliers who demonstrate a commitment to sustainable practices, including reclamation and recycling of refrigerants.

-

Cultural and Economic Factors: Understanding cultural differences in business practices and economic conditions can facilitate better communication and negotiation with suppliers. This knowledge can help in establishing long-term partnerships based on trust and reliability.

Conclusion

Manufacturing refrigerant gas R12 involves complex processes that require stringent quality control measures. For B2B buyers, understanding these processes and standards is crucial for making informed purchasing decisions. By implementing thorough verification strategies, buyers can ensure they source high-quality refrigerants that comply with international regulations, ultimately supporting their operational needs and environmental responsibilities.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘refrigerant gas r12’

In the competitive landscape of refrigerant procurement, specifically for R-12, it’s vital for B2B buyers to follow a structured approach. This guide provides a step-by-step checklist to help international buyers make informed purchasing decisions while ensuring compliance with relevant regulations.

Step 1: Understand Regulatory Requirements

Before initiating any procurement, familiarize yourself with the local and international regulations surrounding R-12 refrigerant. Since R-12 is a chlorofluorocarbon (CFC) with restrictions due to its ozone-depleting potential, ensure that your purchase aligns with environmental regulations in your region. This may include obtaining necessary permits or certifications to handle and use R-12.

Step 2: Define Your Technical Specifications

Establish clear technical requirements for the R-12 refrigerant you intend to procure. Consider factors such as purity level, packaging sizes (e.g., 12 oz. cans, 30 lb. cylinders), and intended applications (automotive, commercial refrigeration, etc.). Providing precise specifications helps in sourcing the right product and avoids future complications.

Step 3: Verify Supplier Certifications

It’s crucial to ensure that your suppliers are certified to sell refrigerants. Request proof of certifications such as EPA Section 608 or 609, which verify that they meet the necessary standards for handling refrigerants. This step not only protects your business from potential legal issues but also ensures that you are purchasing from reputable sources.

Step 4: Evaluate Potential Suppliers

Conduct a thorough evaluation of potential suppliers before making a commitment. Look for company profiles, customer testimonials, and case studies related to their experience with R-12. Assess their ability to meet your specific volume requirements and delivery timelines. A well-vetted supplier can significantly impact your operational efficiency.

Step 5: Request Samples for Quality Assurance

Before finalizing a large order, request samples to assess the quality of the R-12 refrigerant. This is especially important for ensuring that the product meets your technical specifications and industry standards. Evaluate factors such as purity and performance, which can influence the efficiency of your cooling systems.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations to establish favorable terms and conditions. Discuss pricing, payment terms, delivery schedules, and any after-sales support offered. Clear communication at this stage can prevent misunderstandings and foster a long-term business relationship.

Step 7: Implement a Compliance and Storage Plan

Lastly, create a compliance and storage plan for your R-12 refrigerant. Proper storage is essential to maintain the integrity of the product and to comply with safety regulations. Ensure that your facility is equipped to store refrigerants safely and that staff are trained to handle them in accordance with relevant guidelines.

By following this checklist, B2B buyers can streamline their procurement process for R-12 refrigerant, ensuring compliance, quality, and efficiency in their operations.

Comprehensive Cost and Pricing Analysis for refrigerant gas r12 Sourcing

When sourcing refrigerant gas R-12, understanding the cost structure and pricing dynamics is critical for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis delves into the various cost components and price influencers that can affect purchasing decisions.

What Are the Key Cost Components in R-12 Refrigerant Sourcing?

The cost structure of R-12 refrigerant encompasses several components:

-

Materials: The primary cost driver is the raw material itself, which is subject to fluctuations based on global demand and environmental regulations. Although R-12 is no longer produced, existing supplies can be sourced from reclamation and recycling efforts, impacting pricing.

-

Labor: Labor costs are associated with the handling, storage, and distribution of refrigerants. Skilled personnel are often required to ensure compliance with safety and environmental standards, especially in regions with stringent regulations.

-

Manufacturing Overhead: This includes costs related to facilities, equipment maintenance, and utilities. For suppliers managing older inventories of R-12, these costs can be significant due to the specialized nature of the refrigerant.

-

Tooling: Although R-12 is primarily sold in pre-filled cylinders, the tooling costs involved in manufacturing these containers can influence pricing. Suppliers must invest in appropriate cylinder technology to meet safety standards.

-

Quality Control (QC): Ensuring the purity and quality of refrigerant gas is essential. This may involve laboratory testing and certification processes that add to the overall cost.

-

Logistics: Transportation and storage logistics are pivotal, particularly for international buyers. The cost of shipping refrigerant can vary significantly based on distance, shipping method, and any regulatory compliance that must be met.

-

Margin: Suppliers typically apply a margin on top of their costs, which can vary based on market conditions, competition, and the supplier’s positioning.

What Factors Influence the Pricing of R-12 Refrigerant?

Several elements can impact the pricing of R-12 refrigerant:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower per-unit costs due to economies of scale. Buyers should consider their storage capabilities and future needs when negotiating order sizes.

-

Specifications/Customization: Custom requirements for purity levels or packaging can affect pricing. Buyers should communicate specific needs to ensure accurate quotes.

-

Material Quality/Certifications: The source of the refrigerant and its certifications can influence price. Higher-quality products with environmental certifications may command a premium.

-

Supplier Factors: Supplier reputation and reliability can affect pricing. Established suppliers with a track record of compliance and quality assurance may offer better terms.

-

Incoterms: Understanding the Incoterms applied to transactions is crucial. They define responsibilities and costs related to shipping and handling, impacting the total cost of ownership.

What Tips Can Help Buyers Negotiate Better Prices for R-12?

For international B2B buyers, particularly from regions like Africa and South America, effective negotiation and strategic sourcing are vital:

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and service. Regular communication and trust can result in favorable terms.

-

Total Cost of Ownership (TCO): Buyers should evaluate the TCO rather than just the initial purchase price. Consider factors such as shipping costs, potential environmental fees, and product lifespan.

-

Market Research: Staying informed about market trends and pricing fluctuations can provide leverage during negotiations. Understanding regional demands and supplier capabilities can lead to advantageous deals.

-

Explore Multiple Suppliers: Engaging with various suppliers can provide insights into competitive pricing and service offerings. Request quotes from multiple sources to gauge the market.

Conclusion

While sourcing R-12 refrigerant gas, international B2B buyers must navigate a complex landscape of costs and pricing factors. By understanding these dynamics and employing strategic negotiation techniques, buyers can optimize their purchasing decisions and achieve better value in their procurement processes. Prices may vary widely based on the aforementioned factors, so it is essential to approach sourcing with diligence and insight.

Alternatives Analysis: Comparing refrigerant gas r12 With Other Solutions

Exploring Alternatives to Refrigerant Gas R12

In the world of refrigeration, the choice of refrigerant is crucial for operational efficiency, environmental impact, and compliance with regulations. While R12 has been a staple in various applications, its ozone-depleting properties have led to a decline in its use. This analysis will compare R12 with two viable alternatives: R134a and R1234yf, both of which are widely adopted in modern refrigeration systems.

| Comparison Aspect | Refrigerant Gas R12 | Alternative 1: R134a | Alternative 2: R1234yf |

|---|---|---|---|

| Performance | Excellent cooling capacity; effective in low-temperature applications | Good performance; slightly lower efficiency than R12 in some cases | Comparable to R12, but with better energy efficiency |

| Cost | High due to scarcity; prices can vary significantly | Moderate; widely available with stable pricing | Higher initial cost but decreasing as adoption increases |

| Ease of Implementation | Requires specialized handling and certification | Easier to implement; compatible with many existing systems | May require system modifications for optimal performance |

| Maintenance | Requires careful handling due to environmental regulations | Lower maintenance needs; less hazardous | Similar maintenance requirements to R134a; minimal environmental impact |

| Best Use Case | Older systems (pre-1994 vehicles, some industrial applications) | Automotive and commercial refrigeration | Newer systems, particularly where low global warming potential is desired |

What Are the Benefits and Drawbacks of R134a?

R134a, a hydrofluorocarbon (HFC), has become a popular substitute for R12 due to its lower ozone depletion potential. It performs well in automotive and commercial refrigeration applications, making it a versatile choice. However, while R134a is generally easier to source and implement, it does have a higher global warming potential compared to R1234yf. B2B buyers should consider the environmental regulations in their region when selecting R134a, as some jurisdictions are moving towards more eco-friendly alternatives.

How Does R1234yf Compare as a Modern Refrigerant?

R1234yf is a next-generation refrigerant designed to replace R134a and is particularly favored for its low global warming potential. It is increasingly being adopted in the automotive sector and is seen as a sustainable option for new refrigeration systems. Although it may require modifications to existing equipment, its environmental benefits make it an attractive choice for companies looking to enhance their sustainability profile. However, the initial cost and the need for specific handling procedures may be a barrier for some B2B buyers.

How Can B2B Buyers Choose the Right Refrigerant Solution?

When selecting the appropriate refrigerant, B2B buyers must evaluate their specific operational needs, regulatory requirements, and long-term sustainability goals. For businesses operating older systems, R12 might still be viable but consider the costs and potential regulatory hurdles. For newer installations, R134a offers a balanced performance with accessibility, while R1234yf stands out for those prioritizing environmental impact. Ultimately, the decision should align with both immediate operational needs and future regulatory landscapes to ensure compliance and efficiency.

Essential Technical Properties and Trade Terminology for refrigerant gas r12

What Are the Key Technical Properties of Refrigerant Gas R12?

Refrigerant R12, also known as Dichlorodifluoromethane, is a chlorofluorocarbon (CFC) that has been widely used in various cooling applications. Understanding its technical properties is crucial for B2B buyers, especially those in the HVAC and refrigeration sectors.

-

Chemical Composition

R12 is composed of two carbon atoms, two chlorine atoms, and two fluorine atoms (CCl2F2). This specific molecular structure gives R12 its excellent thermodynamic properties, making it effective in heat exchange processes. For buyers, knowing the chemical makeup is essential for ensuring compatibility with existing systems and compliance with environmental regulations. -

Boiling Point

The boiling point of R12 is approximately -29.8°C (-21.6°F). This low boiling point allows it to evaporate at low temperatures, making it suitable for medium to low-temperature refrigeration applications. Understanding the boiling point helps buyers select R12 for specific cooling needs, especially in climates that may require efficient temperature management. -

Ozone Depletion Potential (ODP)

R12 has an ODP of 0.82, which means it contributes to ozone layer depletion. This property has led to its phasedown under international treaties such as the Montreal Protocol. For international buyers, awareness of ODP is critical for compliance with environmental regulations and for making informed decisions about refrigerant alternatives. -

Global Warming Potential (GWP)

The GWP of R12 is 10,680, indicating its significant impact on global warming compared to CO2. This high GWP underscores the need for responsible handling and disposal practices. Buyers must consider GWP when assessing the long-term environmental impacts of their refrigerant choices and explore alternatives that offer lower GWP. -

Cylinder Color and Packaging

R12 is typically stored in white or tan cylinders, which helps in easy identification. The refrigerant is available in various cylinder sizes, including 30 lb, 50 lb, and 145 lb, catering to different operational needs. Understanding packaging and labeling can aid buyers in efficient inventory management and compliance with safety regulations. -

Certification Requirements

In many regions, including the U.S., purchasing R12 requires specific certifications (e.g., EPA Section 608 certification). Buyers must ensure that their personnel are certified to handle refrigerants, which not only complies with legal requirements but also ensures safe and effective use of the refrigerant.

What Are the Common Trade Terms Associated with Refrigerant Gas R12?

Navigating the refrigerant marketplace also requires familiarity with industry-specific terminology, which can facilitate smoother transactions and negotiations.

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products that are sold under another company’s brand name. In the context of refrigerants, knowing the OEM can help buyers ensure they are sourcing high-quality and compatible products for their refrigeration systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers to manage their inventory effectively and negotiate favorable terms, especially when dealing with bulk purchases. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. For R12, an RFQ can help buyers compare prices and services from different suppliers, ensuring they secure the best deal for their refrigerant needs. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help buyers understand shipping logistics, risk management, and cost allocation when importing R12 from suppliers in different countries. -

Reclamation and Recovery

These terms refer to the processes of recycling and reusing refrigerants. Understanding these processes is essential for businesses looking to minimize waste and comply with environmental regulations regarding refrigerant disposal. -

Safety Data Sheet (SDS)

An SDS provides detailed information about the properties of a chemical substance, including hazards, handling, and emergency measures. For R12, reviewing the SDS is critical for ensuring safe handling and compliance with safety regulations in the workplace.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring compliance and optimizing their refrigeration systems.

Navigating Market Dynamics and Sourcing Trends in the refrigerant gas r12 Sector

What Are the Key Market Dynamics and Trends Impacting the R12 Refrigerant Sector?

The refrigerant gas R12, commonly known as Freon, has a rich history and a complex market landscape. Although the production of new R12 has been banned due to its environmental impact, the demand for recycled and reclaimed R12 continues to grow, driven by the substantial number of older refrigeration units still in operation worldwide. In regions such as Africa, South America, the Middle East, and parts of Europe, where older automotive and refrigeration technologies are prevalent, the sourcing of R12 remains critical. International B2B buyers are increasingly seeking suppliers who can provide high-quality reclaimed R12 to meet regulatory requirements and ensure operational efficiency.

Emerging technologies in the refrigerant market are also noteworthy. Innovations in refrigerant recovery and reclamation processes are enhancing the efficiency and safety of R12 sourcing. Furthermore, digital platforms are facilitating easier access to suppliers and improving transparency in pricing and availability. B2B buyers are advised to leverage these technologies, utilizing online marketplaces that specialize in refrigerant gases to identify reputable suppliers and compare prices effectively.

How Is Sustainability Influencing Sourcing Decisions for R12 Refrigerant?

The environmental impact of refrigerant gases, particularly those that deplete the ozone layer, has made sustainability a crucial consideration in the R12 market. The Montreal Protocol, which mandates the phase-out of ozone-depleting substances, has led to increased scrutiny of sourcing practices. B2B buyers are now prioritizing suppliers who demonstrate a commitment to sustainability through ethical sourcing and environmentally-friendly practices.

Certifications like the Environmental Protection Agency (EPA) certification for refrigerants are becoming essential for suppliers. Buyers should look for companies that are not only compliant with regulations but also actively engage in reclamation and recycling efforts. These practices minimize environmental harm and ensure that the refrigerants are handled responsibly. By partnering with suppliers who prioritize sustainability, international buyers can enhance their corporate social responsibility initiatives while ensuring compliance with global environmental standards.

What Is the Historical Context of R12 and Its Relevance Today?

The development of R12 dates back nearly a century, and it became one of the most widely used refrigerants in various applications, from automotive air conditioning to industrial chillers. However, due to its classification as a chlorofluorocarbon (CFC), R12 was phased out in many regions as part of global efforts to combat ozone depletion. Despite the ban on new production, the existing stock of R12 continues to play a vital role in servicing older equipment, particularly in developing markets where such technologies remain in use.

Today, the historical significance of R12 serves as a reminder of the need for responsible management of refrigerants. B2B buyers must navigate a landscape where they can still procure R12 legally and ethically, focusing on suppliers who specialize in the reclamation of existing stocks. Understanding the historical context of R12 not only informs sourcing decisions but also highlights the importance of transitioning towards more sustainable refrigerants in the future.

By staying informed about market dynamics, embracing sustainability, and recognizing the historical context of R12, international B2B buyers can make strategic sourcing decisions that align with both operational needs and environmental responsibilities.

Frequently Asked Questions (FAQs) for B2B Buyers of refrigerant gas r12

-

How do I ensure compliance when purchasing refrigerant gas R12?

To ensure compliance when purchasing refrigerant gas R12, you must first verify that your supplier adheres to local and international regulations regarding the sale and handling of refrigerants. In many regions, including the U.S. and Europe, a certification such as EPA Section 608 or 609 is required for the purchase of R12. Before making a purchase, confirm that you possess the necessary certifications and that the supplier provides proper documentation. Additionally, ensure that the refrigerant meets safety standards, and inquire about the supplier’s reclamation and recycling practices. -

What are the most common applications for refrigerant gas R12?

Refrigerant gas R12, commonly known as Freon, is widely used in various applications, particularly in older automotive air conditioning systems and refrigeration units manufactured before 1994. It serves effectively in medium to low-temperature refrigeration, including refrigerators, freezers, and commercial air conditioning systems. Other applications include medical refrigeration, industrial chillers, and aerosol propellants. Understanding these applications helps buyers determine whether R12 is the right choice for their specific needs. -

What should I consider when vetting suppliers for R12 refrigerant?

When vetting suppliers for R12 refrigerant, prioritize factors such as the supplier’s reputation, industry experience, and compliance with environmental regulations. Check customer reviews and testimonials to gauge reliability and service quality. Additionally, inquire about their sourcing practices and whether they offer reclamation services. Assess their ability to provide documentation, certifications, and safety data sheets (SDS) for the refrigerant. Establishing a relationship with a supplier that demonstrates transparency and accountability is crucial for long-term partnerships. -

What are the minimum order quantities (MOQ) for R12 refrigerant?

Minimum order quantities (MOQ) for R12 refrigerant can vary significantly by supplier and region. Typically, suppliers may set MOQs based on the packaging size, such as 30lb or 50lb cylinders. For wholesale buyers, MOQs may be more flexible, allowing for bulk purchases. It’s advisable to discuss your specific requirements with potential suppliers to understand their terms. Additionally, consider negotiating MOQs to align with your inventory needs and ensure cost-effectiveness. -

What are the payment terms commonly offered by suppliers of refrigerant gas R12?

Payment terms for refrigerant gas R12 can differ widely among suppliers. Common options include upfront payment, partial deposits, or credit terms, particularly for established business relationships. International buyers should also consider currency exchange rates and payment processing fees. It’s important to clarify payment methods accepted, such as wire transfers or letters of credit, and to ensure that the terms align with your financial capabilities and risk management strategies. -

How do I handle logistics and shipping for refrigerant gas R12?

Handling logistics and shipping for refrigerant gas R12 involves understanding the regulations surrounding the transport of hazardous materials. Ensure that your supplier complies with local and international shipping laws, including proper labeling and packaging standards. Discuss shipping options, costs, and delivery timelines with your supplier to avoid delays. Additionally, consider partnering with logistics providers experienced in transporting refrigerants to mitigate risks and ensure timely delivery to your location. -

What quality assurance measures should I look for in R12 refrigerant?

Quality assurance measures for R12 refrigerant include checking for certifications that confirm the refrigerant meets industry standards, such as ISO or ASTM certifications. Inquire if the supplier conducts regular quality checks and provides documentation for the refrigerant’s purity and composition. Additionally, ask about their reclamation processes and whether they recycle or reclaim R12, which can affect the refrigerant’s quality. Establishing a partnership with a supplier committed to quality control is essential for ensuring reliable performance in your applications. -

Can I still sell or dispose of R12 refrigerant after purchasing?

Yes, you can sell or dispose of R12 refrigerant after purchasing it, but it’s crucial to adhere to local regulations regarding the sale and disposal of refrigerants. While the production of new R12 is banned in many countries, existing supplies can still be legally sold. However, ensure you comply with any certification requirements for handling refrigerants. For disposal, consider working with certified reclamation services that can safely recycle or reclaim R12, minimizing environmental impact and ensuring compliance with regulations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Refrigerant Gas R12 Manufacturers & Suppliers List

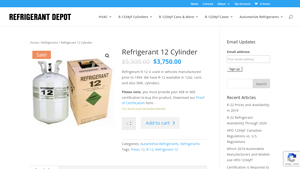

1. Refrigerant Depot – Refrigerant R-12 Cylinder

Domain: refrigerantdepot.com

Registered: 2012 (13 years)

Introduction: {“product_name”: “Refrigerant 12 Cylinder”, “price”: {“original”: “$5,500.00”, “sale”: “$3,750.00”}, “description”: “Refrigerant R-12 is used in vehicles manufactured prior to 1994. Available in 12oz. cans and 30lb. cylinders.”, “certification_required”: “608 or 609 certification is required to purchase this product.”, “stock_status”: “3 in stock (can be backordered)”, “categories”: [“Automotive R…

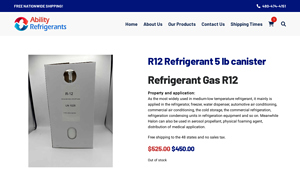

2. Ability Refrigerants – R12 Refrigerant 5 lb Canister

Domain: abilityrefrigerants.com

Registered: 2016 (9 years)

Introduction: {“product_name”: “R12 Refrigerant 5 lb canister”, “shipping”: “Free nationwide shipping to the 48 states”, “original_price”: “$525.00”, “current_price”: “$450.00”, “availability”: “Out of stock”, “applications”: [“refrigerator”, “freezer”, “water dispenser”, “automotive air conditioning”, “commercial air conditioning”, “cold storage”, “commercial refrigeration”, “refrigeration condensing units”], …

3. Multitanks – Duracool 12a Refrigerant

Domain: multitanks.com

Registered: 2003 (22 years)

Introduction: This company, Multitanks – Duracool 12a Refrigerant, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Refrigerant Supply – R12 Refrigerant

Domain: refrigerant-supply.com

Registered: 1999 (26 years)

Introduction: R12 Refrigerant, also known as Freon R-12, is a brand name for R-12 Dichlorodifluoromethane. It is marketed under names such as CFC-12, Genetron 12, and Forane 12. Ideal for auto air conditioning and medium to high temperature refrigeration, R12 is a colorless liquefied gas with a slight ethereal odor. It is packaged in pressurized white cylinders available in sizes of 30, 50, 145, 1000, and 2000 …

5. Reddit – R12 Replacement Gases

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – R12 Replacement Gases, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. CalGas Direct – R12 Refrigerant Calibration Gas

Domain: calgasdirect.com

Registered: 2013 (12 years)

Introduction: R12 Refrigerant Calibration Gas, made in the USA, available for online order or via toll-free call at 888-349-6042 (8AM-5PM PST). Free shipping on orders over $275. Part of the largest calibration gas selection in the USA with over 180,000 mixtures available.

7. Griffiths – R134a Refrigerant

Domain: griffiths.com

Registered: 1996 (29 years)

Introduction: R134a is the most widely accepted alternative automotive refrigerant used to replace R12. R12 is no longer produced, making its availability limited and more expensive than R134a. R134a is more efficient than R12, capable of removing more heat from a vehicle’s interior when properly matched with system components. The conversion process from R12 to R134a involves several steps, including removing …

Strategic Sourcing Conclusion and Outlook for refrigerant gas r12

As the global market for refrigerant gas R-12 continues to evolve, strategic sourcing remains essential for B2B buyers in Africa, South America, the Middle East, and Europe. Understanding the regulatory landscape and the implications of the production ban on new R-12 is crucial for maintaining operational efficiency in industries reliant on older refrigeration systems. Buyers should prioritize partnerships with reputable suppliers who can offer certified R-12, ensuring compliance with environmental regulations while accessing quality refrigerants at competitive prices.

Moreover, the demand for reclaimed and recycled R-12 presents an opportunity for cost savings and sustainability, aligning with global trends toward environmental responsibility. Organizations looking to source R-12 should focus on suppliers with robust reclamation programs and transparent sourcing practices.

Looking ahead, as markets adapt to changing regulations and environmental considerations, proactive sourcing strategies will enable businesses to navigate challenges effectively. B2B buyers are encouraged to stay informed about market trends and engage with suppliers who demonstrate a commitment to quality and compliance. By doing so, they can secure reliable access to R-12 and position their operations for future success in a competitive landscape.