Sn Labels Guide: Type,Cost,Material…

Introduction: Navigating the Global Market for sn labels

In today’s fast-paced global market, sourcing high-quality serial number labels (SN labels) poses a significant challenge for international B2B buyers. With the increasing need for precise product tracking, warranty management, and counterfeit prevention, businesses must navigate a complex landscape of materials, applications, and suppliers. This guide aims to demystify the world of SN labels by providing a comprehensive overview of various types, including metal tags, barcode labels, and custom stickers. It also delves into their applications across diverse industries, ensuring that buyers understand where and how these labels can enhance their operations.

Moreover, the guide emphasizes the importance of supplier vetting, offering actionable insights into evaluating potential vendors based on quality, reliability, and cost-effectiveness. By addressing common concerns and questions, we empower buyers from Africa, South America, the Middle East, and Europe—such as those in Saudi Arabia and Brazil—to make informed purchasing decisions. Whether you’re looking to streamline inventory management or enhance product security, this resource will equip you with the knowledge and tools necessary to select the right SN labels for your business needs. Ultimately, understanding the nuances of SN labels will not only improve operational efficiency but also safeguard your brand’s integrity in a competitive marketplace.

Understanding sn labels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Metal ID Tags | Made from anodized aluminum; highly durable; resistant to extreme conditions. | Industrial equipment, manufacturing, asset tracking. | Pros: Long-lasting, withstands harsh environments. Cons: Higher initial cost compared to paper labels. |

| Barcode Serial Number Labels | Incorporate barcodes for automated tracking; suitable for high-volume operations. | Inventory management, logistics, retail. | Pros: Streamlines asset management, reduces manual errors. Cons: Requires barcode scanners for optimal use. |

| Tamper-Evident Labels | Features that indicate unauthorized removal; enhances security. | Product authentication, supply chain management. | Pros: Prevents fraud and counterfeiting. Cons: May be more expensive than standard labels. |

| Custom Sequential Number Labels | Personalized numbering; can include logos and specific designs. | Product tracking, warranty management, marketing. | Pros: Enhances brand visibility, tailored to specific needs. Cons: Longer lead times for production. |

| Weather-Resistant Labels | Resistant to moisture, UV light, and extreme temperatures; durable materials. | Outdoor equipment, agricultural products, logistics. | Pros: Ensures legibility in challenging environments. Cons: Limited to specific applications where weather resistance is necessary. |

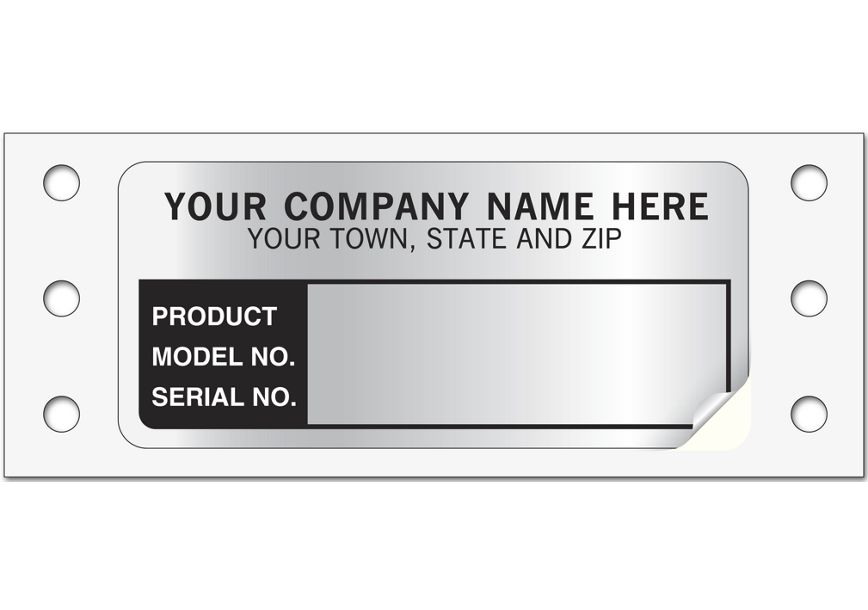

What Are the Key Characteristics of Metal ID Tags?

Metal ID tags are designed for maximum durability and strength, making them ideal for industrial applications. Crafted from high-quality anodized aluminum, these tags resist bending, tearing, corrosion, and extreme temperatures, ensuring they remain readable over time. They are particularly suitable for environments where exposure to chemicals or physical wear is common. When purchasing, consider the specific conditions your labels will face and the importance of longevity versus initial costs.

How Do Barcode Serial Number Labels Enhance Inventory Management?

Barcode serial number labels integrate unique barcodes that enable automated tracking of assets, making them essential for inventory management and logistics. These labels are particularly beneficial for businesses handling high volumes of products, as they streamline the process of checking in and out inventory. When selecting barcode labels, ensure compatibility with your existing scanning systems and assess the potential return on investment through improved efficiency.

Why Are Tamper-Evident Labels Important for Product Security?

Tamper-evident labels are crucial for enhancing product security and preventing counterfeiting. These labels are designed to show visible signs of tampering, providing assurance to buyers about the authenticity of the product. Ideal for supply chain management, they are commonly used in industries where product integrity is paramount. When considering tamper-evident labels, assess the balance between security features and cost implications for your business.

What Benefits Do Custom Sequential Number Labels Offer?

Custom sequential number labels provide a unique identifier for each product, often accompanied by company branding or logos. This personalization not only aids in tracking and warranty management but also enhances brand visibility. Businesses looking to differentiate their products in competitive markets will find these labels particularly beneficial. However, buyers should factor in potential lead times for customization when planning their orders.

How Do Weather-Resistant Labels Perform in Challenging Environments?

Weather-resistant labels are specifically designed to withstand exposure to moisture, UV light, and extreme temperatures, making them suitable for outdoor applications. These labels ensure that important information remains legible in harsh conditions, which is vital for businesses in agriculture, outdoor equipment, and logistics. When selecting weather-resistant labels, consider the specific environmental challenges they will face and ensure that the materials used meet your durability requirements.

Key Industrial Applications of sn labels

| Industry/Sector | Specific Application of sn labels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Asset Tracking and Management | Enhances inventory accuracy, reduces losses, and improves operational efficiency. | Choose durable materials that withstand manufacturing environments. |

| Logistics and Supply Chain | Shipment Tracking | Streamlines logistics, improves traceability, and enhances customer satisfaction. | Ensure labels are compatible with various surfaces and weather conditions. |

| Electronics | Product Authentication and Warranty Claims | Protects brand integrity and facilitates warranty services. | Opt for labels that allow for unique serialization and are resistant to wear. |

| Pharmaceuticals | Compliance and Regulatory Tracking | Ensures adherence to safety regulations and facilitates recalls if necessary. | Consider labels that meet industry-specific standards and are tamper-evident. |

| Retail | Inventory Management and Loss Prevention | Reduces shrinkage and improves stock management. | Look for customizable options that integrate with existing inventory systems. |

How Are Serial Number Labels Used in Manufacturing?

In the manufacturing sector, serial number labels are critical for asset tracking and management. They enable companies to assign unique identifiers to machinery and equipment, facilitating real-time inventory updates and reducing the risk of loss or misplacement. International buyers, particularly from Africa and South America, should focus on sourcing labels made from durable materials that can withstand harsh manufacturing environments, ensuring they remain legible despite exposure to chemicals and mechanical wear.

What Role Do SN Labels Play in Logistics and Supply Chain?

In logistics, serial number labels are vital for tracking shipments from origin to destination. They provide a clear identifier for each package, enhancing traceability and allowing companies to quickly locate items within the supply chain. For businesses operating in the Middle East and Europe, it is essential to select labels that adhere securely to various surfaces and can endure diverse weather conditions to maintain their integrity throughout transit.

How Do SN Labels Benefit the Electronics Industry?

The electronics industry relies heavily on serial number labels for product authentication and warranty claims. These labels help manufacturers verify the authenticity of their products, which is crucial in combating counterfeiting. Buyers in regions such as Europe and South America should prioritize labels that allow for unique serialization and are resistant to wear, ensuring they remain intact throughout the product’s lifecycle.

Why Are SN Labels Important in Pharmaceuticals?

In the pharmaceutical sector, serial number labels are essential for compliance and regulatory tracking. They help companies maintain accurate records of production batches and ensure adherence to safety regulations. International buyers, especially those in Africa and the Middle East, need to consider labels that are tamper-evident and meet stringent industry standards, as these features are vital for maintaining product integrity and facilitating recalls if necessary.

How Do Retailers Use SN Labels for Inventory Management?

Retailers utilize serial number labels for effective inventory management and loss prevention. By assigning unique identifiers to products, businesses can reduce shrinkage and improve stock management practices. Buyers from regions like Brazil should look for customizable options that can seamlessly integrate with existing inventory systems, allowing for enhanced operational efficiency and improved customer satisfaction.

3 Common User Pain Points for ‘sn labels’ & Their Solutions

Scenario 1: Inconsistent Label Durability Leads to Asset Mismanagement

The Problem: Many B2B buyers encounter challenges with the durability of serial number labels, especially in harsh environments. For instance, a manufacturing plant may use labels that quickly degrade due to exposure to moisture, chemicals, or extreme temperatures. This can result in unreadable labels, leading to lost assets, difficulties in inventory tracking, and ultimately, financial losses. Buyers may find that the labels they initially chose do not withstand the operational demands, forcing them to frequently replace them.

The Solution: To combat this issue, it’s essential to select serial number labels specifically designed for durability in tough conditions. Buyers should look for labels made from materials like anodized aluminum or high-quality vinyl that can resist bending, tearing, and corrosion. When sourcing, consider suppliers who offer extensive customization options, allowing for features such as tamper-resistance and UV protection. Additionally, conducting a thorough assessment of the operational environment will help identify the most appropriate label materials and adhesive options. This proactive approach not only enhances asset management but also reduces the frequency of label replacements, leading to long-term cost savings.

Scenario 2: Complicated Customization Processes Slow Down Production

The Problem: B2B buyers often face delays in production due to complicated customization processes for serial number labels. Companies may require specific serial formats, barcodes, or logos, but many suppliers lack the flexibility to accommodate these needs efficiently. This can lead to extended lead times and hinder the overall production schedule, causing frustration among buyers who need their labels promptly to maintain workflow continuity.

The Solution: To streamline the customization process, buyers should seek suppliers who provide robust online tools for designing and ordering custom serial number labels. Look for companies that allow for easy uploads of logos, selection of font styles, and input of serial number formats directly through their websites. Additionally, establishing a clear communication channel with the supplier can facilitate faster approvals and adjustments to label designs. By working with a supplier that prioritizes flexibility and efficiency, buyers can ensure that their customization needs are met swiftly, minimizing production downtime and maintaining operational flow.

Scenario 3: Difficulties in Asset Tracking Lead to Regulatory Compliance Issues

The Problem: In sectors like manufacturing and logistics, accurate asset tracking is crucial for compliance with industry regulations. Many B2B buyers struggle with implementing effective tracking systems due to poorly designed serial number labels that fail to integrate with their existing inventory management software. This can result in inaccurate record-keeping and potential legal repercussions if regulatory standards are not met.

The Solution: To enhance asset tracking and ensure compliance, buyers should opt for serial number labels that are compatible with their inventory management systems. This includes selecting labels that can easily accommodate barcodes or QR codes, which allow for seamless scanning and data input. When sourcing these labels, it’s important to collaborate with suppliers who understand the specific needs of your industry and can provide insights on label formats that work best with your software. Regular training for staff on how to use the labeling system effectively can also prevent tracking errors. By investing in the right labeling solutions and ensuring proper integration, businesses can maintain compliance and improve overall operational efficiency.

Strategic Material Selection Guide for sn labels

What Are the Key Materials for Serial Number Labels?

When selecting materials for serial number (SN) labels, it is crucial to consider their properties, advantages, and limitations to ensure they meet specific application requirements. Here, we analyze four common materials used in the production of SN labels: vinyl, polyester, aluminum, and paper.

How Does Vinyl Perform as a Material for SN Labels?

Vinyl is a popular choice for SN labels due to its versatility and durability. It is resistant to moisture, UV rays, and chemicals, making it suitable for both indoor and outdoor applications. Vinyl labels can withstand temperatures ranging from -40°F to 180°F (-40°C to 82°C), providing reliable performance in various environments.

Pros: Vinyl labels are cost-effective and can be produced in high volumes. They are also flexible, allowing them to adhere well to curved surfaces.

Cons: While vinyl is durable, it may not be suitable for extreme conditions, such as high heat or exposure to harsh chemicals over extended periods. Additionally, vinyl labels may not be as environmentally friendly as other options.

Impact on Application: Vinyl labels are ideal for industries like logistics and retail, where durability and visibility are essential. However, they may not be the best choice for applications involving extreme temperatures or corrosive substances.

What Advantages Does Polyester Offer for SN Labels?

Polyester is another widely used material for SN labels, known for its exceptional durability. It can endure high temperatures (up to 300°F or 149°C) and is resistant to chemicals, moisture, and abrasion. This makes polyester an excellent choice for industrial applications.

Pros: Polyester labels are highly durable and can maintain their integrity in harsh environments. They also offer excellent print quality, ensuring that barcodes and text remain legible over time.

Cons: The production cost of polyester labels is typically higher than that of vinyl. Additionally, they may require specific adhesives to ensure proper adhesion to various surfaces.

Impact on Application: Polyester is well-suited for applications in manufacturing, automotive, and electronics industries where durability and resistance to environmental factors are critical.

Why Choose Aluminum for SN Labels?

Aluminum labels offer a rugged solution for SN labeling, particularly in demanding environments. They are resistant to bending, tearing, and corrosion, making them ideal for heavy-duty applications. Anodized aluminum can withstand exposure to chemicals and extreme temperatures, ensuring long-lasting readability.

Pros: Aluminum labels provide unmatched durability and are tamper-resistant, which is crucial for security and asset tracking.

Cons: The initial cost of aluminum labels is generally higher than that of plastic options. Additionally, they may require specialized printing techniques, such as laser engraving, which can complicate the manufacturing process.

Impact on Application: Aluminum labels are commonly used in industries such as aerospace, military, and outdoor equipment, where label integrity is paramount.

When Is Paper a Viable Option for SN Labels?

Paper labels are often considered for low-cost applications where durability is less critical. They can be coated for moisture resistance, but they are generally not suitable for harsh environments. Paper labels are best used in indoor settings or for short-term applications.

Pros: Paper labels are inexpensive and can be produced quickly, making them ideal for temporary labeling needs.

Cons: They lack the durability of synthetic materials and can degrade quickly when exposed to moisture, heat, or chemicals.

Impact on Application: Paper labels are suitable for retail environments, inventory management, and temporary asset tracking where cost efficiency is a priority.

Summary of Material Selection for SN Labels

| Material | Typical Use Case for SN Labels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vinyl | Retail, logistics | Cost-effective and flexible | Less durable in extreme conditions | Low |

| Polyester | Manufacturing, automotive | High durability and print quality | Higher production cost | Medium |

| Aluminum | Aerospace, military, outdoor | Unmatched durability and security | Higher initial cost and complexity | High |

| Paper | Retail, inventory management | Inexpensive and quick production | Lacks durability in harsh conditions | Low |

This guide provides a comprehensive overview of the materials used in SN labels, allowing international B2B buyers to make informed decisions based on their specific needs and application environments.

In-depth Look: Manufacturing Processes and Quality Assurance for sn labels

What Are the Key Stages in the Manufacturing Process of Serial Number Labels?

The manufacturing process of serial number labels (SN labels) is a meticulous endeavor that ensures both quality and functionality. This process typically involves several main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves selecting appropriate materials that meet the specific requirements of durability and environmental resistance. Common materials for SN labels include vinyl, polyester, and anodized aluminum. Each material is chosen based on factors such as intended use, exposure to chemicals, moisture, and temperature extremes. Proper material preparation includes cutting the raw materials to required dimensions and ensuring they are free from defects.

-

Forming: In this stage, the prepared materials undergo various forming techniques. This can involve printing or etching unique serial numbers, barcodes, and other identifiers onto the label surface. Advanced printing technologies such as thermal transfer and laser engraving are often employed to ensure precision and durability. The choice of technology can affect the label’s longevity and readability, especially in harsh environments.

-

Assembly: After forming, the labels are assembled, which may include applying adhesives or coatings. For labels requiring tamper resistance, additional security features are integrated during this phase. This might involve special adhesives that prevent removal without damage or unique holographic elements that verify authenticity.

-

Finishing: The final stage encompasses quality checks and the application of protective finishes. These finishes could include UV coatings, laminates, or anodized coatings that enhance the label’s resistance to wear and tear. Finishing techniques are crucial as they help in prolonging the label’s life, ensuring that the serial numbers remain legible over time.

How Is Quality Assurance Implemented in the Manufacturing of SN Labels?

Quality assurance (QA) is a critical component in the production of SN labels, ensuring that they meet both international standards and customer specifications. The QA process encompasses various checkpoints and testing methods.

-

International Standards for Quality Control: Many manufacturers adhere to ISO 9001 standards, which provide a framework for quality management systems. Compliance with these standards ensures that the manufacturing processes are continuously monitored and improved. Additionally, industry-specific certifications like CE (for products sold in Europe) and API (for oil and gas industry products) might also be required depending on the application of the labels.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): Before production begins, raw materials are inspected to confirm they meet specified standards. This helps prevent defects from entering the production process.

– In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections are conducted to ensure that processes are being followed and that products meet quality specifications. This includes checks on printing accuracy, adhesion strength, and any other critical characteristics.

– Final Quality Control (FQC): Once the labels are finished, they undergo a final inspection. This includes checking for proper serial number sequencing, legibility, and adherence to any custom specifications requested by the client. -

Testing Methods for SN Labels: Common testing methods include:

– Durability Testing: Labels are subjected to conditions they will encounter in their intended environments, such as exposure to chemicals, UV light, and extreme temperatures.

– Adhesion Testing: Ensures that the labels will remain affixed to their surfaces under various conditions.

– Readability Testing: Confirms that printed information, including serial numbers and barcodes, can be easily read by both humans and automated scanning systems.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring the reliability of SN labels.

-

Supplier Audits: Conducting on-site audits allows buyers to directly assess a manufacturer’s adherence to quality standards. This includes reviewing their processes, equipment, and quality control documentation. During the audit, buyers should look for evidence of compliance with international standards such as ISO 9001.

-

Quality Control Reports: Reputable suppliers should provide detailed QC reports that outline their testing methods, results, and any corrective actions taken in response to quality issues. This transparency helps buyers understand the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes. These inspections can cover material sourcing, production processes, and final product assessments, offering additional assurance to buyers.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing SN labels internationally, B2B buyers should be aware of certain nuances that can affect quality control and product integrity.

-

Regulatory Compliance: Different regions may have specific regulations regarding labeling, especially in industries like pharmaceuticals or food and beverage. Buyers must ensure that suppliers comply with these regulations to avoid legal complications.

-

Cultural and Language Barriers: Communication with suppliers across different regions can pose challenges. It’s essential to establish clear channels of communication and ensure that technical specifications are understood and adhered to by the supplier.

-

Logistics and Supply Chain Considerations: The quality of SN labels can be affected by their storage and handling during transportation. Buyers should ensure that suppliers have robust logistics practices that safeguard the quality of labels from production to delivery.

-

After-Sales Support: Consider suppliers who offer comprehensive after-sales support, including warranty management and customer service. This can be particularly important for resolving issues related to product defects or compliance post-purchase.

In summary, the manufacturing processes and quality assurance measures for SN labels are integral to ensuring that these products meet the high standards required in various industries. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers for their labeling needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sn labels’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure serial number (SN) labels. These labels are essential for product tracking, inventory management, and ensuring regulatory compliance. By following this step-by-step guide, you can make informed purchasing decisions that enhance your operational efficiency and product integrity.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the specifications you need for your SN labels. Consider factors such as size, material, durability, and whether you require features like barcodes or QR codes. Defining these details upfront helps streamline the sourcing process and ensures you receive products that meet your exact requirements.

- Material Considerations: Look for materials that withstand environmental factors relevant to your industry, such as heat, moisture, or chemical exposure.

- Label Size and Shape: Ensure that the labels fit your products properly and can be affixed securely.

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers who specialize in SN labels. Investigate their reputation within the industry by reading reviews, testimonials, and case studies. A reliable supplier will have a proven track record of delivering quality products and excellent customer service.

- Supplier Background: Look for suppliers with extensive experience in your specific industry to ensure they understand your unique needs.

- Certifications and Compliance: Verify that the supplier adheres to relevant industry standards and regulations, which can affect product quality and safety.

Step 3: Evaluate Product Customization Options

Customization is key when sourcing SN labels. Assess the extent to which suppliers can tailor their labels to meet your specific needs, such as custom numbering, logos, or additional security features. This step is crucial for branding and ensuring that your labels fulfill their functional requirements.

- Tamper-Resistant Features: Inquire about options that prevent unauthorized removal or counterfeiting, which is particularly important for high-value items.

- Design Flexibility: Ensure the supplier can accommodate unique design requests that align with your branding.

Step 4: Request Samples and Prototypes

Before finalizing your order, request samples or prototypes of the SN labels. Testing samples allows you to assess the quality, durability, and visual appeal of the labels firsthand. This step is essential to avoid potential issues after the full production run.

- Testing in Real Conditions: Evaluate how the labels perform in the environments they will be used in, such as temperature extremes or exposure to moisture.

- Feedback from Stakeholders: Involve relevant team members in the evaluation process to gather diverse insights on label functionality and design.

Step 5: Discuss Pricing and Payment Terms

Engage in discussions about pricing structures and payment terms with your chosen suppliers. Understanding the cost per unit, bulk pricing options, and payment flexibility can help you manage your budget effectively. Transparent pricing can also prevent misunderstandings later in the procurement process.

- Bulk Order Discounts: Inquire about discounts for larger orders, which can significantly reduce your costs.

- Payment Flexibility: Assess payment options such as net terms or installment plans that could ease cash flow concerns.

Step 6: Verify Production and Delivery Timelines

Clarify production timelines and delivery schedules with the supplier to ensure that your labels are produced and delivered on time. Reliable timelines are crucial for maintaining your inventory levels and avoiding disruptions in your operations.

- Lead Times: Understand the standard lead times for your order size and any expedited options that may be available.

- Shipping Methods: Discuss shipping options and costs to ensure they align with your delivery requirements.

Step 7: Establish a Communication Plan

Develop a communication plan for ongoing interactions with the supplier. Establishing clear lines of communication helps address any issues quickly and ensures a smooth procurement process. Regular updates on order status and any potential challenges can foster a strong supplier relationship.

- Point of Contact: Identify a specific contact person within the supplier organization for efficient communication.

- Regular Check-ins: Schedule periodic updates to discuss progress, address concerns, and plan for future orders.

By following this checklist, B2B buyers can effectively navigate the sourcing process for SN labels, ensuring they meet their operational needs while maintaining product integrity and compliance.

Comprehensive Cost and Pricing Analysis for sn labels Sourcing

What Are the Key Cost Components in Sourcing SN Labels?

When sourcing serial number (SN) labels, understanding the cost structure is vital for international B2B buyers. The primary components influencing costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly affects pricing. Common materials for SN labels include paper, vinyl, and anodized aluminum. Durable options, such as metal ID tags, typically come at a higher cost due to their robustness and longevity. Customization, such as adding barcodes or QR codes, may also increase material expenses.

-

Labor: Labor costs encompass the workforce required for the design, printing, and assembly of labels. Custom jobs usually demand more skilled labor, leading to higher costs. For high-volume orders, the labor cost per unit may decrease, making bulk orders more economical.

-

Manufacturing Overhead: This includes indirect costs related to production, such as utilities, rent, and equipment depreciation. Suppliers with efficient production processes can offer more competitive pricing, emphasizing the importance of selecting a manufacturer with streamlined operations.

-

Tooling: Custom tooling for label production can add to initial costs but is essential for unique designs. This one-time expense may be amortized over larger order quantities, lowering the overall cost per unit.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the labels meet specific standards and durability requirements. Although this adds to the cost, it can prevent costly errors and returns, ultimately benefiting buyers.

-

Logistics: Shipping and handling costs can vary based on the destination, shipment size, and logistics provider. International buyers need to consider these costs in their total budget, as they can significantly impact the overall pricing.

-

Margin: Suppliers typically mark up costs to cover their expenses and profit. Understanding the market rates can help buyers negotiate better deals.

How Do Price Influencers Impact SN Label Costs?

Several factors influence the pricing of SN labels, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Higher volumes usually lead to lower per-unit costs. Suppliers often provide tiered pricing, incentivizing bulk purchases. Buyers should assess their needs to take advantage of these savings.

-

Specifications and Customization: Custom features, such as unique sizes, colors, or designs, will increase costs. Buyers should clearly communicate their requirements to avoid unexpected charges.

-

Material Quality and Certifications: Labels that meet specific industry standards or certifications can be more expensive. However, investing in high-quality labels can enhance brand reputation and compliance.

-

Supplier Factors: Supplier reliability, experience, and geographic location can affect pricing. International buyers should consider local suppliers to minimize shipping costs and potential tariffs.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They determine the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, directly impacting the total cost.

What Are Some Effective Buyer Tips for Negotiating SN Label Prices?

-

Negotiate Terms: Engage suppliers in discussions about pricing, especially for large orders. Don’t hesitate to ask for discounts or additional value, such as free samples or expedited shipping.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership rather than just the initial purchase price. Consider factors like durability, replacement frequency, and potential savings from efficient inventory management.

-

Understand Pricing Nuances: Familiarize yourself with regional pricing trends, as costs can vary significantly across different markets. For example, sourcing from suppliers in Europe may have different pricing structures than those in South America or Africa.

-

Plan for Currency Fluctuations: International buyers should be aware of exchange rate variations, which can affect overall costs. Locking in prices or establishing contracts in stable currencies can mitigate these risks.

-

Request Detailed Quotes: Ask suppliers for itemized quotes that break down costs by component. This transparency allows for better comparison across suppliers and aids in identifying areas for negotiation.

Disclaimer on Indicative Prices

Prices for SN labels can vary widely based on the factors discussed above. Buyers should conduct thorough market research and obtain multiple quotes to ensure they receive competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing sn labels With Other Solutions

Introduction to Alternative Solutions for SN Labels

In the realm of product identification and asset management, businesses often seek the most effective solutions to meet their operational needs. While serial number (SN) labels provide unique identifiers for products, there are alternative technologies and methods available. This analysis will compare SN labels against two viable alternatives: QR codes and RFID tags, highlighting their respective strengths and weaknesses to help B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | SN Labels | QR Codes | RFID Tags |

|---|---|---|---|

| Performance | High durability and readability | Moderate durability; dependent on print quality | High speed and accuracy in data retrieval |

| Cost | Moderate initial investment; bulk pricing available | Low cost for printing; additional costs for scanning devices | Higher costs for tags and readers |

| Ease of Implementation | Simple to apply; requires no special tools | Easy to print and apply; requires scanner | More complex setup; requires specialized equipment |

| Maintenance | Low; minimal upkeep required | Low; only requires scanning devices to be maintained | Moderate; periodic checks may be needed |

| Best Use Case | Asset tracking in industrial settings | Consumer products, marketing materials | High-volume inventory tracking, logistics |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of QR Codes?

QR codes serve as a versatile alternative to SN labels, allowing for the encoding of significant amounts of information in a compact format. They are cost-effective and easy to produce, requiring only a printer and scanner. However, their durability can be an issue; poor printing quality or damage to the code can hinder scanning capabilities. QR codes are best suited for consumer-facing applications, such as product packaging and marketing campaigns, where quick access to information is essential.

How Do RFID Tags Compare in Functionality?

RFID (Radio Frequency Identification) tags provide a high-tech alternative to SN labels, offering rapid data retrieval without the need for direct line-of-sight scanning. This technology excels in environments where speed and efficiency are paramount, such as warehouse management and logistics. However, RFID systems involve higher initial costs due to the need for specialized readers and infrastructure. Furthermore, while RFID tags can store more information than SN labels, their complexity can require additional training for staff. They are ideal for organizations managing large inventories and requiring real-time tracking capabilities.

Conclusion: Choosing the Right Solution for Your Business Needs

When selecting between SN labels and alternative solutions like QR codes or RFID tags, B2B buyers should consider their specific operational requirements, budget constraints, and the environments in which these solutions will be implemented. SN labels are best for industries needing durable and simple asset tracking, while QR codes excel in consumer engagement and information dissemination. RFID tags are suitable for businesses focused on efficiency and speed in inventory management. By aligning the choice of technology with business goals, organizations can enhance their asset management strategies effectively.

Essential Technical Properties and Trade Terminology for sn labels

What Are the Key Technical Properties of SN Labels?

Understanding the critical specifications of serial number (SN) labels is essential for B2B buyers who need durable and effective solutions for asset tracking and product identification. Here are some key properties that define the quality and functionality of SN labels:

1. Material Grade

The material used for SN labels can significantly impact their durability and application. Common materials include vinyl, polyester, and anodized aluminum. Each material offers varying levels of resistance to environmental factors such as moisture, chemicals, and extreme temperatures. For instance, anodized aluminum is ideal for rugged industrial environments due to its corrosion resistance and longevity. Selecting the appropriate material grade ensures that the labels will withstand the conditions they will face in their intended use.

2. Adhesive Strength

The adhesive used to affix SN labels is critical for ensuring they remain securely attached to products or assets over time. High-performance adhesives can resist peeling and lifting, even in challenging environments. This property is particularly important for labels used in logistics or manufacturing, where exposure to various substances and mechanical wear is common. Strong adhesive performance minimizes the risk of losing valuable tracking information.

3. Printing Technology

The method used to print serial numbers and other identifying information affects both the readability and durability of the labels. Techniques such as thermal transfer, laser etching, or direct thermal printing provide varying levels of quality and longevity. For B2B buyers, understanding the implications of these technologies is vital; for example, thermal transfer labels may offer better resistance to fading compared to those printed by other methods.

4. Tamper Resistance

Tamper-resistant SN labels are designed to prevent unauthorized removal or alteration, which is essential for maintaining product integrity and security. These labels often feature destructible materials that break apart when someone attempts to remove them. This property is crucial for industries where counterfeiting and fraud are concerns, as it helps ensure that only authentic products are in circulation.

5. Customizability

The ability to customize SN labels with unique serial numbers, barcodes, or QR codes is a significant advantage for B2B buyers. Customization allows businesses to tailor labels to their specific tracking and inventory management needs. This flexibility can enhance operational efficiency by facilitating easier asset management and product identification.

6. Temperature Tolerance

SN labels must often perform under extreme conditions, including high heat or severe cold. Understanding the temperature tolerance of a label material is essential, especially for industries such as manufacturing and logistics, where assets may be exposed to fluctuating temperatures. Selecting labels that can withstand these conditions ensures continuous readability and functionality.

What Are Common Trade Terms Related to SN Labels?

Familiarity with industry jargon can help B2B buyers navigate the procurement process more effectively. Here are some common terms associated with SN labels:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of SN labels, OEMs often require customized labeling solutions for their products to ensure proper identification and tracking throughout the supply chain.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it impacts inventory management and budget considerations. Buyers should negotiate MOQs to align with their operational needs while minimizing excess inventory.

3. RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers for specific products or services. In the case of SN labels, an RFQ can help buyers compare pricing, materials, and customization options from different manufacturers, enabling informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and liability. Familiarity with Incoterms is essential for B2B buyers engaged in global trade, as it helps clarify shipping costs and risks associated with the delivery of SN labels.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times for SN labels is vital for supply chain planning and ensuring that products are available when needed, especially in industries where timing is critical.

6. Durability Rating

A durability rating provides insight into how well a label will withstand environmental stressors over time. This rating is important for B2B buyers as it helps gauge the longevity and reliability of SN labels in various applications, influencing overall cost-effectiveness.

By comprehending these technical properties and trade terms, B2B buyers can make informed decisions when selecting SN labels that best meet their operational requirements.

Navigating Market Dynamics and Sourcing Trends in the sn labels Sector

What Are the Current Market Dynamics and Key Trends Affecting SN Labels?

The global market for serial number labels (SN labels) is witnessing significant growth driven by several key factors. Increasing demand for product traceability and accountability across various industries, including manufacturing, logistics, and retail, is propelling the adoption of SN labels. In regions like Africa, South America, the Middle East, and Europe, buyers are increasingly focusing on solutions that enhance operational efficiency and streamline inventory management. The integration of advanced technologies such as QR codes and RFID into SN labels is emerging as a notable trend, facilitating real-time tracking and improved asset management.

Emerging B2B tech trends also indicate a shift towards customization and personalization in label solutions. International buyers are increasingly seeking SN labels that can be tailored to specific operational needs, including unique branding and varied materials to withstand diverse environmental conditions. The rise of e-commerce has further accelerated the need for efficient labeling systems that can support quick inventory turnover and accurate order fulfillment. Additionally, the growing emphasis on data-driven decision-making in supply chain management underscores the importance of labels that can be integrated into larger asset management systems.

How Is Sustainability and Ethical Sourcing Impacting SN Labels?

Sustainability and ethical sourcing are becoming paramount concerns for B2B buyers in the SN labels sector. The environmental impact of traditional labeling materials, particularly plastic, has prompted a shift towards sustainable alternatives. Buyers are increasingly seeking SN labels made from eco-friendly materials that are recyclable or biodegradable, aligning with broader corporate social responsibility (CSR) goals.

Furthermore, ethical supply chains are gaining traction as businesses recognize the importance of transparency and accountability in sourcing practices. This trend is particularly pronounced in regions with stringent regulatory frameworks, where compliance with environmental standards is essential. Buyers are advised to look for suppliers that hold certifications such as FSC (Forest Stewardship Council) or ISO 14001, which indicate a commitment to sustainable practices.

Incorporating ‘green’ materials not only enhances brand reputation but also contributes to long-term cost savings. By investing in sustainable SN labels, businesses can reduce waste, lower their carbon footprint, and appeal to an increasingly environmentally-conscious consumer base.

What Is the Evolution of SN Labels and Their Relevance Today?

The evolution of serial number labels has been marked by advancements in technology and a growing understanding of their critical role in supply chain management. Initially, SN labels were simple printed tags used primarily for inventory tracking. However, as businesses began to recognize the importance of product authenticity and traceability, the functionality of these labels expanded significantly.

Today, SN labels incorporate sophisticated features such as QR codes and tamper-evident designs, enhancing their utility in combating counterfeiting and improving product security. This evolution is particularly relevant for international B2B buyers who require robust solutions for product tracking, warranty management, and compliance with regulatory standards. As the market continues to evolve, businesses that leverage innovative labeling solutions will be better positioned to meet consumer demands and navigate the complexities of global trade.

Frequently Asked Questions (FAQs) for B2B Buyers of sn labels

-

How do I ensure the durability of serial number labels in harsh environments?

To guarantee the durability of serial number labels in challenging conditions, select materials specifically designed for resilience, such as anodized aluminum or high-performance vinyl. These materials can withstand extreme temperatures, moisture, chemicals, and physical abrasion. Additionally, consider labels with tamper-resistant features to enhance security and prevent unauthorized removal. Always consult with your supplier about the environmental factors your labels will face and request samples to test their performance under your specific conditions. -

What customization options are available for serial number labels?

Customization options for serial number labels can vary significantly by supplier, but typically include features like custom serial numbering, barcodes, QR codes, and company logos. You can also specify label size, shape, and material to suit your particular needs. Discuss your requirements with potential suppliers to ensure they can accommodate your specifications, and don’t hesitate to ask for mock-ups or proofs before finalizing your order to ensure everything meets your expectations. -

What are the minimum order quantities (MOQs) for serial number labels?

Minimum order quantities for serial number labels can differ based on the manufacturer and the complexity of your order. Many suppliers offer flexible MOQs, especially for standard products, while custom labels might require higher quantities to justify production costs. When sourcing, inquire about bulk pricing and potential discounts for larger orders, as this can significantly impact your overall budget and procurement strategy. -

How can I verify the authenticity of a supplier for serial number labels?

To verify a supplier’s authenticity, conduct thorough research by checking their business credentials, customer reviews, and industry certifications. Request references from past clients and review their portfolio of work to assess quality and reliability. Additionally, consider visiting their facility if possible or engaging in a video call to discuss your requirements directly. Utilizing platforms that facilitate international trade can also provide insights into supplier ratings and reliability. -

What payment terms should I expect when ordering serial number labels internationally?

Payment terms for international orders can vary, but common practices include upfront payment, deposits, or payment upon delivery. Negotiate terms that provide a balance of security and flexibility, especially if you are working with a new supplier. Be aware of currency exchange rates and potential transaction fees. Using secure payment methods like letters of credit or escrow services can protect both parties and ensure a smoother transaction process. -

How do serial number labels enhance inventory management?

Serial number labels significantly improve inventory management by providing unique identifiers for each item, allowing for precise tracking and auditing. They facilitate real-time inventory checks, reduce the risk of errors, and streamline the process of stock replenishment. By integrating these labels into an asset management system, businesses can enhance accountability, manage warranties more effectively, and reduce losses due to theft or misplacement. -

What quality assurance measures should be in place for serial number labels?

Quality assurance measures for serial number labels should include material inspection, print quality checks, and adherence to specifications during production. It’s essential to establish clear standards with your supplier regarding durability, adhesion, and readability. Request a batch sample before full-scale production to evaluate the labels’ performance in your intended application. Additionally, consider implementing a system for ongoing quality checks to ensure consistency in future orders. -

What logistics considerations should I keep in mind for international shipping of serial number labels?

When planning the logistics for international shipping of serial number labels, consider factors such as shipping methods, lead times, and customs regulations in your destination country. Choose a reliable shipping partner experienced in international trade to handle documentation and ensure compliance with import/export laws. It’s also wise to factor in potential delays and additional costs such as tariffs or taxes, which can impact your overall budget and timelines.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Sn Labels Manufacturers & Suppliers List

1. Maverick Label – Serial Number Labels

Domain: mavericklabel.com

Registered: 2000 (25 years)

Introduction: Product: Serial Number Labels

Price: Starting at $168.75

Key Features:

– Highly Durable: Built to withstand extreme heat, moisture, chemicals, and mechanical wear.

– Customizable: Personalize with barcodes, QR codes, logos, custom serial numbers, or company branding.

– Tamper-Resistant Options: Prevents fraud, counterfeiting, and unauthorized label removal.

Applications: Ideal for industrial, comm…

2. Case Badges – Customizable Number Labels

Domain: case-badges.com

Registered: 2002 (23 years)

Introduction: Number labels are customizable for various purposes including product identification, inventory tracking, asset accounting, and security tags. Available in multiple shapes and sizes, they can include barcodes, serial numbers, company names, and logos. Materials offered include white, silver, metallic, clear, and specialty options. Minimum order quantity is 100 labels, with no setup fees and free p…

3. Coast Label – Custom Serial Number Labels

Domain: coastlabel.com

Registered: 1997 (28 years)

Introduction: Custom serial number labels, also known as SN labels or serial number stickers, serve as unique identifiers for products, aiding in tracking, warranty management, and product authentication. They contain a combination of letters and numbers specific to each product, ensuring no two products share the same serial number. These labels can be found on various products, including electronic devices, a…

4. SN Labels – Custom Stickers & Labels

Domain: snlabels.com

Registered: 2019 (6 years)

Introduction: {“products”:[{“name”:”Paper Roll Form Stickers”,”price”:”₹ 180 / Roll”},{“name”:”Self Adhesive Barcode Sticker”,”price”:”₹ 175 / Roll”},{“name”:”3D Hologram Labels”,”price”:”₹ 0.25 / Piece”},{“name”:”Printed Barcode Sticker”,”price”:”₹ 260 / Roll”},{“name”:”Thermal Barcode Labels”,”price”:”₹ 195 / Roll”},{“name”:”Self Adhesive Barcode Labels”,”price”:”₹ 180 / Roll”},{“name”:”Roll Form Sticker Prin…

5. Shamrock – SN-50-PRE Nursing Labels

Domain: shamrocklabels.com

Registered: 1999 (26 years)

Introduction: {“Product Name”: “SN-50-PRE Nursing Labels for Instruction and Communication”, “Price”: “$21.67”, “Size”: “1” x 500″”, “Unit of Measure”: “Roll”, “Quantity per UOM”: “500”, “Material”: “Superstick”, “Adhesive”: “Removable”, “Core Size”: “1””, “Label Color”: “White”, “Ink Color”: “Black”, “Imprint”: “LAST RITES GIVEN”}

6. Clarion Safety – Custom Serial Number Labels

Domain: clarionsafety.com

Registered: 2007 (18 years)

Introduction: Custom Serial Number Labels designed for clear communication, traceability, and safety. Features unique information for asset tracking, warranty management, and access to manuals. Supports safety and informational use, reduces overhead, streamlines training, and enhances operational efficiency. Available in two sizes: 2.00″ x 0.50″ starting at $3.65 each and 2.75″ x 0.50″ starting at $4.59 each. M…

7. Aegis Adhesives – Direct Thermal Shipping Labels

Domain: walmart.com

Registered: 1995 (30 years)

Introduction: This company, Aegis Adhesives – Direct Thermal Shipping Labels, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. QC Labels – Serial Number Labels

Domain: qclabels.com

Registered: 2000 (25 years)

Introduction: Serial Number Labels Quality Assured, Clearly Labeled. Available in various sizes: 1″x2.25″ and 0.625″x1.5″. Each label features a write-on surface suitable for pen, pencil, or marker. Options include self-laminating and durable annealed aluminum labels for enhanced protection against wear and tear. Ideal for identifying and distinguishing products in manufacturing. Free shipping for US orders ove…

9. Advanced Barcode – Custom Serial Number Labels

Domain: ablt.com

Registered: 1997 (28 years)

Introduction: Custom Serial Number Labels from Advanced Barcode & Label Technologies are designed to help businesses track assets, models, and SKUs effectively. The labels can be customized with unique data for enhanced tracking and protection against theft and counterfeiting. A variety of materials, adhesives, and laminates are available to ensure label integrity in harsh environments. ABLT offers assistance i…

Strategic Sourcing Conclusion and Outlook for sn labels

How Can Strategic Sourcing Enhance Your SN Labels Procurement?

In today’s competitive landscape, strategic sourcing of serial number (SN) labels offers significant advantages for businesses across various sectors. The durability, customization, and security features of these labels make them essential tools for effective asset management, inventory control, and brand protection. By leveraging high-quality SN labels, companies can streamline their operations, enhance product traceability, and mitigate the risks of counterfeit goods, ultimately leading to improved customer trust and satisfaction.

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should prioritize partnerships with reliable suppliers who understand the unique needs of their markets. This collaboration not only ensures the procurement of superior products but also fosters innovation in labeling solutions tailored to specific industry requirements.

As you look to the future, consider how integrating advanced serial number labeling systems can transform your business operations. Start exploring your options today and embrace the benefits of strategic sourcing to stay ahead in a rapidly evolving marketplace. Connect with trusted suppliers to elevate your brand’s efficiency and security through high-quality SN labels tailored to your needs.