Standard Wine Bottle Sizes In Cm Guide: Type,Cost,Material…

Introduction: Navigating the Global Market for standard wine bottle sizes in cm

Navigating the global market for standard wine bottle sizes in centimeters presents a significant challenge for international B2B buyers. As businesses seek to source wine bottles that align with both consumer preferences and regulatory standards, understanding the diverse range of bottle dimensions becomes essential. This guide provides a comprehensive overview of standard wine bottle sizes, detailing the various types such as Bordeaux, Burgundy, and Magnum bottles, along with their specific applications and typical dimensions.

By delving into critical aspects such as supplier vetting, cost considerations, and storage solutions, this resource equips buyers from regions like Africa, South America, the Middle East, and Europe—including key markets like Brazil and Nigeria—with the knowledge to make informed purchasing decisions. As the global wine industry continues to expand, recognizing the nuances of bottle sizing will not only enhance product offerings but also foster stronger partnerships with suppliers.

With actionable insights and a focus on industry best practices, this guide serves as a valuable tool for navigating the complexities of sourcing wine bottles, ensuring that businesses can meet their operational needs while catering to the evolving tastes of their customers.

Understanding standard wine bottle sizes in cm Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Split (Piccolo) | 187.5 ml, typically used for single servings; compact size | Airlines, events, gift shops | Pros: Convenient for single servings; Cons: Limited volume for larger gatherings. |

| Half (Demi) | 375 ml, slimmer bottle, often used for dessert wines | Restaurants, wine bars, catering | Pros: Ideal for tastings and smaller servings; Cons: Less popular than standard size. |

| Standard (Bordeaux) | 750 ml, classic shape with straight sides; most widely distributed | Retail, distribution, export | Pros: Universally recognized; Cons: High competition in the market. |

| Magnum | 1.5 L, double the standard size, requires specialized storage | High-end restaurants, events | Pros: Impressive presentation; Cons: Requires larger storage space. |

| Jeroboam | 3.0 L for sparkling wine, 4.5 L for still; large and bold design | Luxury events, weddings, celebrations | Pros: Suitable for large gatherings; Cons: High cost and storage challenges. |

What are the Characteristics of Split (Piccolo) Wine Bottles?

The Split or Piccolo wine bottle holds 187.5 ml, making it a compact choice ideal for single servings. This size is particularly popular in the airline industry and for events where individual servings are preferred. B2B buyers should consider this size for catering to clients looking for convenience and portion control. However, its limited volume may not suffice for larger gatherings, thus affecting its overall utility.

How Does the Half (Demi) Bottle Serve B2B Needs?

The Half or Demi bottle, which holds 375 ml, is a versatile option often used for dessert wines. Its size is ideal for restaurants and wine bars that wish to offer tastings or smaller servings without committing to a full bottle. This size caters to a growing trend of wine exploration among consumers. However, its lesser popularity compared to standard sizes may affect inventory turnover for businesses.

Why is the Standard (Bordeaux) Bottle the Most Recognized?

The Standard wine bottle, typically 750 ml, is the universal size for most wines globally. Its classic Bordeaux shape with straight sides makes it easily recognizable and widely distributed. B2B buyers should prioritize this size due to its high demand and versatility across various markets. However, the competitive landscape can make it challenging for new entrants to establish a foothold.

What Advantages Does a Magnum Bottle Offer for B2B Buyers?

Magnum bottles, holding 1.5 liters, are twice the standard size and are often favored for high-end dining experiences and special events. Their impressive presentation can elevate the customer experience, making them popular for luxury restaurants and celebrations. However, businesses must consider the need for specialized storage solutions, as well as the higher cost associated with purchasing and handling these larger bottles.

How Can Jeroboam Bottles Enhance Luxury Events?

Jeroboam bottles, with capacities of 3.0 L for sparkling wine and 4.5 L for still wine, are designed for grand occasions and large gatherings. Their bold design and substantial volume make them ideal for weddings and luxury events. B2B buyers should evaluate the potential return on investment, as these bottles can command higher prices. However, the challenges of storage and transportation must also be factored into purchasing decisions.

Key Industrial Applications of standard wine bottle sizes in cm

| Industry/Sector | Specific Application of standard wine bottle sizes in cm | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Wine Production | Bottling and packaging of wines | Ensures compliance with international standards and consumer preferences | Quality of glass, availability of sizes, and customization options |

| Retail and Distribution | Shelf display and merchandising | Maximizes retail space and enhances customer experience | Compatibility with existing shelving, durability, and aesthetics |

| Hospitality and Catering | Serving and storage of wine in restaurants | Enhances the dining experience and encourages wine sales | Volume requirements, ease of storage, and serving efficiency |

| E-commerce and Online Sales | Packaging for wine shipments | Protects products during transit and reduces breakage risks | Shipping regulations, packaging materials, and sizes for cost efficiency |

| Event Planning and Catering | Use in large-scale events and celebrations | Facilitates bulk serving and enhances event prestige | Sourcing of bulk quantities, customization for branding, and storage solutions |

How Are Standard Wine Bottle Sizes Used in Wine Production?

In the wine production sector, standard wine bottle sizes, particularly the 750 ml Bordeaux and Burgundy bottles, are crucial for bottling and packaging. These sizes comply with international norms, ensuring that producers meet consumer expectations and regulatory requirements. Buyers in this sector should focus on sourcing high-quality glass that maintains the integrity of the wine, as well as options for customization to enhance brand identity. This is especially pertinent for international buyers from regions such as Africa and South America, where local preferences may influence bottle design.

What Role Do Standard Wine Bottle Sizes Play in Retail and Distribution?

In retail and distribution, standard wine bottle sizes are essential for effective shelf display and merchandising. Retailers benefit from maximizing space while providing a visually appealing presentation. The 750 ml bottle is universally recognized, making it easier for consumers to make purchasing decisions. Buyers should consider the compatibility of bottles with existing shelving and display systems, as well as the durability of the packaging to withstand handling. This is particularly important for markets in the Middle East and Europe, where retail environments can vary significantly.

How Are Standard Wine Bottle Sizes Important for Hospitality and Catering?

In the hospitality and catering industry, standard wine bottle sizes are integral to serving and storing wine effectively in restaurants and events. The 750 ml bottle allows for efficient serving, while larger formats like magnums are ideal for special occasions, enhancing the overall dining experience. Buyers should prioritize bottles that are easy to store and serve, as well as those that align with their wine lists and customer preferences. For international buyers, understanding local dining customs can inform their sourcing decisions.

What is the Importance of Standard Wine Bottle Sizes in E-commerce and Online Sales?

In the e-commerce sector, standard wine bottle sizes are vital for packaging wine shipments. The 750 ml and larger formats must be adequately protected during transit to minimize breakage. Buyers need to consider shipping regulations and packaging materials that offer both protection and cost efficiency. This is particularly relevant for businesses targeting markets like Brazil and Nigeria, where logistics can pose unique challenges.

How Do Standard Wine Bottle Sizes Contribute to Event Planning and Catering?

For event planning and catering, standard wine bottle sizes facilitate bulk serving at large-scale events. Bottles such as magnums or jeroboams not only serve more guests but also add a touch of prestige to events. Buyers in this sector should focus on sourcing bottles in bulk, considering customization options for branding purposes, and ensuring adequate storage solutions to manage inventory efficiently. This is essential for catering businesses operating in diverse regions, as they often cater to various cultural preferences and expectations.

3 Common User Pain Points for ‘standard wine bottle sizes in cm’ & Their Solutions

Scenario 1: Managing Diverse Wine Bottle Sizes in Storage Solutions

The Problem: B2B buyers, such as restaurant owners and wine distributors, often face challenges in managing diverse wine bottle sizes. For instance, a buyer may have a collection that includes not only standard 750 ml Bordeaux bottles but also larger formats like magnums and Jeroboams. This variability can lead to inefficient use of storage space, as standard wine racks may not accommodate all bottle shapes and sizes. Additionally, buyers may struggle to find reliable suppliers who offer compatible storage solutions that fit their unique needs.

The Solution: To effectively manage this issue, B2B buyers should invest in customizable wine racking systems that cater to various bottle sizes and shapes. When sourcing these racks, it’s essential to specify the exact dimensions of the bottles in their inventory, particularly focusing on height and width variations. Suppliers should provide detailed product specifications and dimensions for their racks. Buyers can also consider modular racks that allow for easy adjustments and reconfigurations based on changing inventory. This not only maximizes storage efficiency but also enhances the overall presentation of the wine collection, making it easier for staff to access and manage inventory.

Scenario 2: Navigating Import Regulations and Standard Sizes

The Problem: International B2B buyers, particularly those in regions like Africa and South America, may encounter challenges related to import regulations and compliance when sourcing wine. Different countries have varied standards for wine bottle sizes, which can complicate shipments and increase costs if incorrect sizes are imported. For example, a buyer may order a shipment of 750 ml bottles only to find that their local regulations favor 375 ml bottles for certain types of wines, leading to potential fines or product returns.

The Solution: To navigate these complex regulations, buyers should conduct thorough research on the specific wine bottle size regulations in their target markets. Consulting with local import/export experts or trade associations can provide valuable insights into compliance requirements. Furthermore, establishing strong communication with suppliers to ensure that all orders are compliant with local standards is crucial. Buyers should also consider diversifying their suppliers to include those who are knowledgeable about international regulations. This proactive approach can help avoid costly mistakes and ensure a smooth import process.

Scenario 3: Understanding the Impact of Bottle Size on Wine Quality

The Problem: B2B buyers, such as restaurateurs and wine retailers, often struggle to understand how different bottle sizes can affect the quality and aging potential of wine. For instance, many may not realize that larger bottles, like magnums, provide a slower aging process due to a smaller ratio of oxygen exposure. This lack of knowledge can lead to poor purchasing decisions, affecting the quality of the wine served to customers and ultimately impacting sales.

The Solution: To overcome this knowledge gap, buyers should invest in educational resources that detail the effects of bottle size on wine characteristics. This could include attending wine seminars, engaging with sommeliers, or accessing online courses dedicated to wine education. Additionally, buyers should seek out suppliers who provide detailed information about their wines, including the benefits of various bottle sizes. By understanding these nuances, buyers can make informed decisions about which bottle sizes to stock, enhancing their offerings and providing better recommendations to customers, ultimately leading to increased sales and customer satisfaction.

Strategic Material Selection Guide for standard wine bottle sizes in cm

What Are the Key Materials Used for Standard Wine Bottles?

When selecting materials for standard wine bottles, several options are commonly considered by international B2B buyers. Each material has unique properties, advantages, and limitations that can significantly affect product performance and marketability. Below, we analyze four prevalent materials: glass, PET (polyethylene terephthalate), aluminum, and ceramic.

How Does Glass Perform as a Material for Wine Bottles?

Glass is the traditional choice for wine bottles, particularly for standard sizes like the 750ml Bordeaux bottle. Its key properties include excellent barrier protection against oxygen and light, which preserves the wine’s flavor and aroma. Glass is also highly resistant to corrosion and can withstand high pressures, making it suitable for sparkling wines.

Pros: Glass bottles are durable, recyclable, and provide an upscale aesthetic that appeals to consumers. They are also compliant with international standards, which is crucial for B2B buyers in regulated markets.

Cons: The primary drawbacks are the weight and fragility of glass, which can increase shipping costs and the risk of breakage. Additionally, the manufacturing process is complex and energy-intensive, leading to higher production costs.

Impact on Application: Glass bottles are compatible with various wine types, including reds, whites, and sparkling wines. However, their weight may be a disadvantage for markets with high shipping costs.

What Are the Benefits of Using PET for Wine Bottles?

PET is an increasingly popular alternative to glass, especially in markets looking for lightweight and shatterproof options. PET bottles are highly resistant to impact and can be produced in various shapes and sizes, including standard wine bottle dimensions.

Pros: The lightweight nature of PET reduces shipping costs, and its shatterproof quality minimizes breakage risk. PET also offers good barrier properties, although not as effective as glass.

Cons: PET is less suitable for long-term aging of wines due to its permeability to oxygen over time, which can affect wine quality. Additionally, it may not convey the same premium image as glass.

Impact on Application: PET bottles are ideal for casual or outdoor settings, making them popular in regions with a growing wine market, such as Africa and South America. However, they may not meet the expectations of traditional wine consumers in Europe.

How Does Aluminum Compare as a Material for Wine Bottles?

Aluminum bottles are gaining traction, particularly in the premium beverage market. They offer excellent barrier properties against light and oxygen, similar to glass.

Pros: Aluminum is lightweight, fully recyclable, and resistant to corrosion. It also provides a modern aesthetic that can appeal to younger consumers.

Cons: The initial production cost of aluminum bottles can be high, and they may not be suitable for all wine types, particularly those requiring aging. Additionally, some consumers may perceive aluminum as less premium compared to glass.

Impact on Application: Aluminum bottles are particularly popular in markets focused on sustainability and convenience, making them an attractive option for B2B buyers in environmentally conscious regions.

What Role Does Ceramic Play in Wine Bottle Production?

Ceramic bottles are less common but offer unique advantages. They provide excellent insulation and can maintain a stable temperature for the wine.

Pros: The aesthetic appeal of ceramic bottles can attract niche markets, and they are highly durable and resistant to UV light.

Cons: The weight and cost of ceramic bottles can be prohibitive, and they are not as widely accepted in the mainstream wine market.

Impact on Application: Ceramic is suitable for premium or artisanal wines, particularly in Europe, where consumers appreciate unique packaging. However, their limited use may restrict marketability in regions with price-sensitive consumers.

Summary Table of Material Selection for Wine Bottles

| Material | Typical Use Case for standard wine bottle sizes in cm | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Standard wines (Bordeaux, Burgundy) | Excellent barrier protection | Heavy and fragile, higher shipping costs | High |

| PET | Casual wines, outdoor events | Lightweight and shatterproof | Less suitable for aging wines | Medium |

| Aluminum | Premium beverages, eco-friendly markets | Modern aesthetic, fully recyclable | Higher production costs, perceived as less premium | Medium |

| Ceramic | Artisanal and niche wines | Unique aesthetic, UV resistance | Heavy and costly, limited market acceptance | High |

This strategic material selection guide provides essential insights for B2B buyers in diverse markets, enabling informed decisions that align with product performance and market expectations.

In-depth Look: Manufacturing Processes and Quality Assurance for standard wine bottle sizes in cm

What Are the Key Stages in the Manufacturing Process of Standard Wine Bottles?

The manufacturing of standard wine bottles involves several critical stages, each designed to ensure the bottles meet industry specifications while maintaining the integrity of the wine they will contain. Understanding these stages is essential for B2B buyers looking to source high-quality wine bottles.

Material Preparation: What Raw Materials Are Used?

The primary material used in wine bottle manufacturing is glass, typically made from silica sand, soda ash, and limestone. The glass must be of high quality to withstand the pressure from carbonated wines and maintain the aesthetic appeal desired by consumers. The raw materials undergo rigorous quality checks to ensure they meet purity standards before being mixed and melted at high temperatures.

In addition to traditional glass, some manufacturers may use recycled materials, which can lower production costs and environmental impact. B2B buyers should inquire about the percentage of recycled content and any certifications that validate the sustainability of these materials.

How Are Wine Bottles Formed?

Once the glass is melted, it is shaped into bottles through two primary techniques: blow molding and press molding.

- Blow Molding: This method involves inflating molten glass into a mold using air pressure, allowing for greater flexibility in bottle design and size.

- Press Molding: In this technique, a solid piece of glass is pressed into a mold, creating a more uniform shape that is ideal for mass production.

Both methods ensure the bottles achieve the desired dimensions, such as the standard 750ml size, which typically measures 30 cm in height and 7.5 cm in diameter.

What Are the Assembly and Finishing Processes?

After forming, the bottles are cooled in a controlled environment to prevent thermal shock. Once cooled, they undergo several finishing processes, including:

- Annealing: This step involves reheating the bottles in a furnace to relieve internal stresses.

- Surface Treatment: Bottles may be polished or treated to enhance clarity and finish.

- Labeling and Decoration: Depending on the buyer’s specifications, bottles may also undergo printing or labeling processes.

These finishing touches not only enhance the appearance of the bottles but also ensure they are ready for branding and marketing.

How Is Quality Assurance Integrated into Wine Bottle Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of wine bottles. International and industry-specific standards guide the QA processes to ensure that every bottle produced meets safety and quality criteria.

What International Standards Are Relevant for Wine Bottle Manufacturing?

ISO 9001 is the leading international standard for quality management systems. It focuses on ensuring that products consistently meet customer and regulatory requirements. In the context of wine bottles, compliance with ISO 9001 can assure B2B buyers that the manufacturer has a robust quality management system in place.

Additionally, certifications such as CE (European Conformity) and API (American Petroleum Institute) may be relevant depending on the markets in which the bottles will be sold. These certifications help validate the quality and safety of the bottles, particularly in regions where stringent regulations apply.

What Are the Key Quality Control Checkpoints in Production?

Quality control checkpoints are integrated throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to catch any deviations in real-time.

- Final Quality Control (FQC): A comprehensive inspection of finished bottles to ensure they meet dimensional and aesthetic specifications.

Each stage is crucial for maintaining the overall quality of the final product.

What Common Testing Methods Are Employed in Quality Control?

To ensure the bottles meet quality standards, various testing methods are utilized, including:

- Dimensional Checks: Automated systems measure the height, diameter, and weight of bottles to ensure they conform to specifications.

- Pressure Tests: For sparkling wines, bottles are tested under pressure to ensure they can withstand carbonation without breaking.

- Visual Inspections: Trained personnel inspect bottles for defects, such as bubbles, cracks, or irregularities.

B2B buyers should request documentation of these tests and any certifications obtained to verify the quality of the bottles they intend to purchase.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential.

What Steps Should Buyers Take to Ensure Quality?

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. This can include reviewing their compliance with international standards.

-

Requesting Quality Reports: Buyers should request detailed quality reports that outline the results of IQC, IPQC, and FQC procedures. This transparency helps build trust in the supplier’s capabilities.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes. These services can provide additional assurance that the products meet the required standards before shipment.

-

Certifications and Documentation: Buyers should verify that suppliers possess the necessary certifications (like ISO 9001, CE, etc.) and maintain proper documentation that outlines their quality control measures.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various regulatory environments and standards across different regions. For instance, bottles exported to the European Union must comply with EU directives, whereas those shipped to the United States may have different requirements.

Understanding these nuances is crucial, as it can affect everything from production practices to labeling and packaging. B2B buyers should be aware of these differences and ensure that their suppliers are equipped to meet the diverse standards required in their target markets.

In summary, the manufacturing process of standard wine bottles is intricate, involving multiple stages of production and stringent quality control measures. By understanding these processes and actively verifying supplier practices, B2B buyers can ensure they source high-quality products that meet international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘standard wine bottle sizes in cm’

Introduction

In the competitive landscape of the wine industry, understanding and sourcing standard wine bottle sizes is crucial for B2B buyers. This guide provides a practical checklist to ensure that your procurement process is efficient and aligned with industry standards. By following these steps, you can confidently select the right bottles to meet your business needs.

Step 1: Define Your Technical Specifications

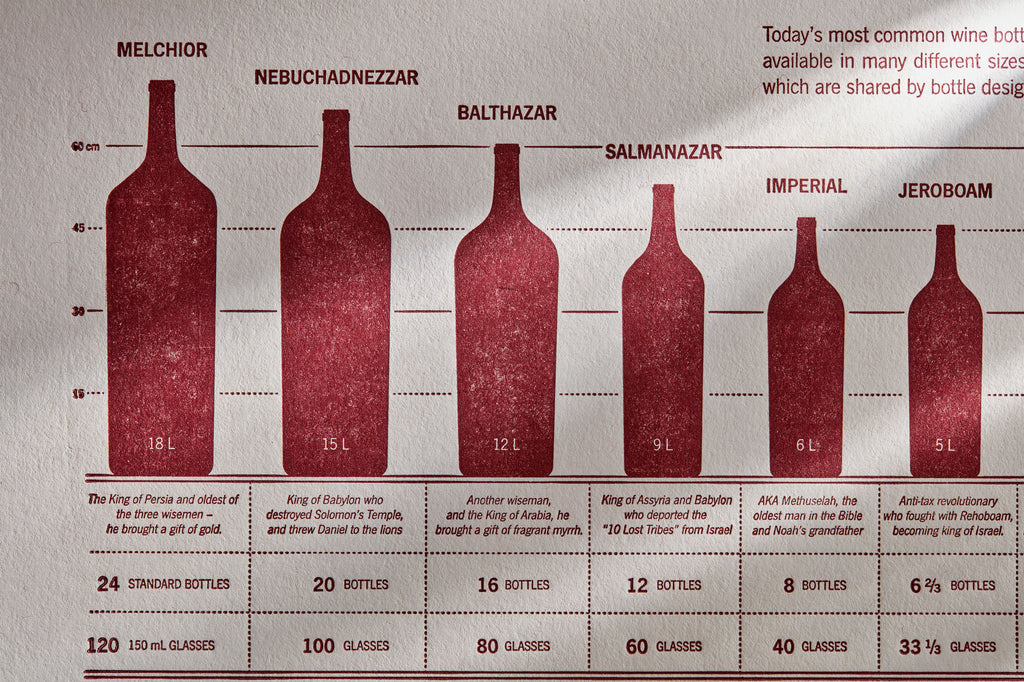

Before you begin sourcing, it’s essential to outline your technical requirements. This includes understanding the various standard wine bottle sizes, which typically range from 187 ml (Piccolo) to 15 liters (Nebuchadnezzar). Knowing the specific sizes you need will help narrow down potential suppliers and ensure they can meet your volume and storage requirements.

- Common sizes to consider: 750 ml (standard), 1.5 L (magnum), and larger formats like 3.0 L (Jeroboam).

- Consider your market: Different regions may favor specific bottle sizes based on consumer preferences.

Step 2: Research Reliable Suppliers

Identifying reputable suppliers is a critical step in the sourcing process. Look for suppliers with a proven track record in the wine industry and those who specialize in the bottle sizes you require.

- Check for industry certifications: Certifications such as ISO or those specific to the food and beverage sector can indicate quality and reliability.

- Read reviews and testimonials: These provide insights into the supplier’s reputation and customer service.

Step 3: Evaluate Product Quality

Quality assurance is paramount when procuring wine bottles. Ensure that the bottles meet industry standards for durability and design, as these factors affect both storage and presentation.

- Inspect samples: Request samples to evaluate the bottle thickness, weight, and overall finish.

- Confirm compatibility: Ensure that the bottles fit your existing wine racks or storage systems.

Step 4: Verify Compliance with International Standards

Different markets have varying regulations regarding packaging. It’s important to verify that the bottles comply with international standards, especially if you plan to export or import.

- Check labeling requirements: Ensure that the bottles can accommodate any labeling needs specific to your target market.

- Review safety regulations: Bottles should meet safety standards to prevent breakage during transport.

Step 5: Assess Cost and Payment Terms

Pricing can vary significantly between suppliers, so it’s essential to evaluate costs carefully. Consider both the upfront costs and any additional fees, such as shipping or import duties.

- Request detailed quotes: Ensure quotes include all potential costs to avoid unexpected expenses.

- Negotiate payment terms: Discuss flexible payment options that align with your cash flow and purchasing strategy.

Step 6: Establish Logistics and Delivery Timelines

The logistics of transporting wine bottles can be complex. Establish clear expectations regarding delivery timelines and logistics to prevent disruptions in your supply chain.

- Coordinate with suppliers: Discuss lead times and any potential delays.

- Plan for customs clearance: If importing, ensure that all documentation is in order to expedite the process.

Step 7: Build Long-Term Relationships

Once you’ve successfully sourced your wine bottles, focus on building long-term relationships with suppliers. This can lead to better pricing, priority service, and access to new products.

- Communicate regularly: Keep in touch to discuss future needs or any changes in your business model.

- Provide feedback: Share your experiences with suppliers to foster improvements and strengthen the partnership.

By following this checklist, B2B buyers can navigate the complexities of sourcing standard wine bottle sizes effectively, ensuring they meet their business objectives while maintaining quality and compliance.

Comprehensive Cost and Pricing Analysis for standard wine bottle sizes in cm Sourcing

What Are the Key Cost Components in Sourcing Standard Wine Bottle Sizes?

When sourcing standard wine bottles, several cost components come into play that can significantly influence the overall pricing structure. The primary components include:

-

Materials: The type of glass used, thickness, and any additional treatments (like UV protection or decorative finishes) directly affect costs. Higher quality glass or bespoke designs will increase material expenses.

-

Labor: The labor involved in bottle manufacturing can vary based on the complexity of the design and the production scale. Automated processes may reduce labor costs, but specialized craftsmanship for custom bottles can elevate expenses.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including facility costs, utilities, and equipment maintenance. Efficient production processes can minimize these overheads.

-

Tooling: Custom molds for unique bottle shapes or sizes require significant investment. For standard sizes, tooling costs are lower, but any customization will necessitate a larger upfront investment.

-

Quality Control (QC): Rigorous quality control processes ensure that bottles meet industry standards. The costs associated with QC can vary based on the level of scrutiny required, particularly for high-end or export markets.

-

Logistics: Transportation and handling costs are crucial, especially when shipping internationally. Factors such as distance, mode of transport, and packaging will influence logistics costs.

-

Margin: Suppliers will add a margin to cover their costs and ensure profitability. This margin can vary widely based on market conditions and competition.

How Do Price Influencers Impact the Cost of Wine Bottles?

Several price influencers can affect the final cost of wine bottles, particularly for international B2B buyers:

-

Volume/MOQ: Bulk orders generally lower the per-unit cost due to economies of scale. Minimum order quantities (MOQs) can affect pricing, especially for smaller buyers.

-

Specifications and Customization: Custom designs or specific sizes can lead to increased costs. Buyers should assess whether the added value justifies the higher price.

-

Materials: The choice of materials can drastically affect cost. Premium materials may enhance product appeal but will come at a higher price point.

-

Quality and Certifications: Certifications for food safety, environmental impact, or specific quality standards can influence costs. Buyers should consider whether certifications are necessary for their market.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may offer higher prices but provide better quality assurance and service.

-

Incoterms: Understanding the terms of trade can significantly affect total costs. Incoterms determine who is responsible for shipping, insurance, and tariffs, which can influence the overall price.

What Tips Can Help Buyers Negotiate Better Prices for Wine Bottles?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following tips to enhance their negotiation strategy:

-

Negotiate Volume Discounts: Leverage larger order sizes to negotiate better pricing. Suppliers are often more willing to offer discounts for significant commitments.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with quality, durability, and potential waste. A higher initial investment in quality may result in lower overall costs.

-

Understand Pricing Nuances for International Markets: Prices may vary based on regional demand, competition, and local regulations. Researching these factors can provide leverage during negotiations.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing and terms. Trust can encourage suppliers to offer favorable conditions.

-

Be Aware of Currency Fluctuations: International buyers should consider currency exchange rates when negotiating prices, as fluctuations can impact overall costs.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific order requirements. Buyers should conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing standard wine bottle sizes in cm With Other Solutions

Exploring Alternatives to Standard Wine Bottle Sizes in cm

When considering wine storage and distribution, standard wine bottle sizes in centimeters serve as a universal reference. However, various alternatives exist that can cater to different business needs, particularly for B2B buyers in international markets. This analysis compares standard wine bottle sizes against alternative packaging solutions, enabling buyers to make informed decisions based on performance, cost, and practicality.

| Comparison Aspect | Standard Wine Bottle Sizes In Cm | Bag-in-Box Packaging | Kegs |

|---|---|---|---|

| Performance | Universally accepted size (750ml, 1.5L, etc.) offers consistency. | Great for preserving wine quality over time; suitable for larger quantities. | Ideal for high-volume serving and events; maintains freshness. |

| Cost | Moderate manufacturing and shipping costs. | Generally lower cost per liter; initial packaging may be higher. | Higher upfront cost but reduces waste and improves cost per serving. |

| Ease of Implementation | Simple to implement with established infrastructure for bottling and storage. | Requires special equipment for dispensing; may need staff training. | Requires specialized kegs and dispensing systems; complex setup. |

| Maintenance | Requires regular inventory checks and proper storage. | Minimal maintenance; easier to manage inventory. | Needs regular cleaning and maintenance of dispensing equipment. |

| Best Use Case | Retail and direct sales; works well for wine shops and restaurants. | Ideal for catering events, festivals, and restaurants focusing on sustainability. | Best suited for bars, restaurants, and large events where rapid serving is needed. |

What are the Advantages and Disadvantages of Bag-in-Box Packaging?

Bag-in-box packaging offers a modern alternative to traditional wine bottles. This solution consists of a flexible bag housed within a cardboard box, allowing for easy dispensing of wine. One of the primary advantages is its ability to preserve wine quality for extended periods after opening, making it ideal for catering and restaurant use. Additionally, it typically has a lower cost per liter compared to bottled wine, appealing to budget-conscious buyers. However, the initial packaging costs can be higher, and the need for specialized dispensing equipment may complicate implementation for some businesses.

How Do Kegs Serve as an Alternative to Standard Wine Bottles?

Kegs represent a practical solution for high-volume wine serving, particularly in bars and restaurants. They maintain the freshness of wine for longer durations and facilitate quick serving, making them an attractive option for events and high-demand settings. The cost efficiency of kegs is notable, as they reduce waste and improve the cost per serving. However, the initial investment in kegs and dispensing systems can be significant, and businesses must ensure proper maintenance and cleaning to prevent contamination.

Conclusion: Which Wine Packaging Solution is Right for Your Business?

Selecting the appropriate wine packaging solution depends on the specific needs of the business. For B2B buyers focusing on retail and direct sales, standard wine bottle sizes provide a familiar and reliable option. Conversely, businesses looking to optimize cost and sustainability may find bag-in-box or keg solutions more advantageous, especially for large events or high-volume sales. Ultimately, understanding the unique requirements of your operation will guide you in choosing the right solution for effective wine storage and distribution.

Essential Technical Properties and Trade Terminology for standard wine bottle sizes in cm

What Are the Key Technical Properties of Standard Wine Bottle Sizes in cm?

Understanding the essential technical properties of wine bottles is crucial for B2B buyers, particularly when it comes to ensuring compatibility with storage solutions and transportation logistics. Here are several critical specifications to consider:

-

Material Grade

Wine bottles are typically made from glass, which can vary in thickness and quality. The standard glass used is soda-lime glass, known for its durability and ability to withstand pressure, especially in sparkling wine bottles. For B2B buyers, selecting bottles with the appropriate material grade is vital to prevent breakage during transport and storage, which can lead to financial losses. -

Height and Diameter

Standard wine bottles typically range in height from 30 cm to 32 cm, with diameters varying between 7.5 cm and 8.5 cm. These dimensions are crucial for compatibility with storage systems, such as wine racks and shipping containers. Buyers must ensure that their storage solutions can accommodate these dimensions to optimize space and efficiency. -

Volume Tolerance

Most wine bottles are designed to hold specific volumes, such as 375 ml, 750 ml, or larger formats like magnums (1.5 L) and jeroboams (3 L). Tolerance in volume is essential, as even slight deviations can affect labeling, pricing, and consumer expectations. For B2B transactions, confirming the exact volume specifications helps avoid discrepancies during shipping and inventory management. -

Closure Compatibility

Wine bottles typically utilize cork or screw cap closures. The choice of closure can affect the wine’s aging process and overall consumer experience. B2B buyers should consider the compatibility of closures with their bottling lines and storage conditions, as this impacts product quality and customer satisfaction. -

Labeling Area Dimensions

The area designated for labeling on wine bottles varies based on the bottle shape and size. Understanding these dimensions is crucial for ensuring that labels fit correctly and are visually appealing. Proper labeling not only complies with regulatory standards but also enhances brand recognition.

What Are Common Trade Terms Related to Wine Bottling?

Familiarizing oneself with industry jargon is essential for effective communication and negotiation in the wine bottling trade. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of wine bottles, an OEM might provide customized bottle designs for a winery. Understanding OEM relationships is critical for B2B buyers looking to differentiate their products in the market. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest number of units a supplier is willing to sell. This is significant for B2B buyers who must balance their inventory levels with production needs. Knowing the MOQ can help buyers plan their purchases and manage cash flow effectively. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing information for a specific quantity of goods. For wine bottling, submitting an RFQ can help buyers compare prices and terms from different suppliers, ensuring they secure the best deal for their needs. -

Incoterms (International Commercial Terms)

These are a set of predefined commercial terms published by the International Chamber of Commerce, which define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to clarify shipping responsibilities, costs, and risks, thereby facilitating smoother cross-border transactions. -

SKU (Stock Keeping Unit)

An SKU is a unique identifier for each distinct product and service that can be purchased. In the wine industry, SKUs help businesses manage inventory, track sales, and streamline order fulfillment. For B2B buyers, accurate SKU management ensures efficient stock control and enhances overall operational efficiency.

By comprehending these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement strategies and improve their bottom line in the competitive wine market.

Navigating Market Dynamics and Sourcing Trends in the standard wine bottle sizes in cm Sector

What Are the Key Market Dynamics Impacting Standard Wine Bottle Sizing?

The global wine bottle market is experiencing significant evolution, driven by various factors that international B2B buyers should consider. One of the main drivers is the increasing demand for premium and luxury wines, particularly from emerging markets in Africa and South America, where wine consumption is on the rise. Additionally, the trend towards unique packaging solutions is gaining traction, with buyers seeking customized bottle shapes and sizes to differentiate their products. Standard wine bottle sizes, particularly the widely accepted 750ml format, remain dominant, but there is a growing interest in smaller formats (like 375ml) and larger ones (like 1.5L magnums), catering to diverse consumer preferences.

Emerging B2B technologies, such as advanced inventory management systems and data analytics, are enabling suppliers to better track market trends and optimize their product offerings. Furthermore, the rise of e-commerce platforms has transformed the sourcing landscape, allowing international buyers to access a broader range of suppliers and negotiate better deals. In regions like the Middle East and Europe, where wine culture is deeply embedded, buyers are increasingly looking for suppliers that can offer not only competitive pricing but also unique bottle designs that align with their branding strategies.

How Does Sustainability Influence Sourcing Trends in the Wine Bottle Industry?

Sustainability is becoming a critical factor for B2B buyers in the wine bottle sector. The environmental impact of glass production and transportation is prompting many companies to adopt more sustainable practices, such as using recycled glass or lighter-weight bottles that reduce carbon emissions during shipping. The importance of ethical supply chains cannot be overstated; buyers are now more inclined to partner with suppliers who demonstrate a commitment to sustainable practices and transparency in their sourcing processes.

Certification for “green” materials is increasingly relevant. Many suppliers are obtaining certifications that validate their use of eco-friendly materials and processes, which can be a strong selling point for B2B buyers focused on corporate responsibility. By prioritizing suppliers that adhere to sustainable practices, buyers not only mitigate their environmental impact but also enhance their brand’s reputation in the marketplace.

What Is the Historical Context of Wine Bottle Sizing for B2B Buyers?

The evolution of wine bottle sizes has been shaped by both tradition and innovation. Historically, the standard 750ml bottle became the norm in the 19th century, primarily due to its compatibility with the corking process and ease of handling. Over time, variations emerged to cater to different wine types and serving occasions, such as the half bottle (375ml) for dessert wines and magnums (1.5L) for celebratory events.

For B2B buyers, understanding this historical context is essential as it informs current consumer preferences and market trends. The diverse range of bottle sizes not only reflects the wine’s character but also influences the consumer’s purchasing decision. As international markets continue to grow, buyers must remain informed about these historical developments to effectively navigate sourcing strategies and meet evolving consumer demands.

Conclusion

Navigating the complexities of the standard wine bottle sizes market requires an acute awareness of market dynamics, sustainability initiatives, and historical context. By aligning sourcing strategies with emerging trends and ethical practices, international B2B buyers can position themselves for success in an increasingly competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of standard wine bottle sizes in cm

-

How do I determine the right wine bottle size for my market?

To select the right wine bottle size, consider your target consumer preferences and purchasing trends in your region. For example, the 750ml standard bottle is widely accepted globally, but smaller formats like 375ml or 187ml might appeal to specific markets, especially for single-serving products. Analyze local consumption habits, competitor offerings, and storage capabilities to make an informed decision. Collaborating with local distributors can provide insights into popular bottle sizes in your target market. -

What are the most common wine bottle sizes in cm for international trade?

The most common wine bottle sizes for international trade include the 750ml standard bottle (approximately 30cm tall and 7.5cm in diameter), the 375ml half bottle (around 24cm tall), and the 187ml split bottle (approximately 18cm tall). Larger formats like magnums (1.5L) measure about 34cm tall, while Jeroboams (3L) can reach around 46cm. Understanding these dimensions is crucial for logistics, packaging, and ensuring compliance with import regulations in various countries. -

What should I consider when vetting suppliers for wine bottles?

When vetting suppliers, consider their experience in the wine industry, production capabilities, and quality assurance processes. Request samples to evaluate the bottle quality and dimensions. Investigate their compliance with international standards, including food safety regulations. Additionally, inquire about their ability to customize bottle designs and sizes to meet your specific needs, as well as their production lead times and capacity to handle your order volume. -

What is the minimum order quantity (MOQ) for wine bottles?

Minimum order quantities can vary significantly among suppliers, typically ranging from 500 to 5,000 units depending on the bottle size and customization options. It’s essential to discuss MOQ with potential suppliers, as larger orders may offer better pricing. For startups or smaller businesses, some suppliers might offer flexible terms, so it’s advisable to negotiate based on your specific needs and potential for future orders. -

How can I ensure the quality of wine bottles I source?

To ensure quality, request certifications from suppliers that demonstrate compliance with international quality standards, such as ISO or food safety regulations. Conduct thorough inspections of samples before placing bulk orders. Establish a quality assurance protocol that includes testing for durability, leakage, and dimensional accuracy. Additionally, consider working with third-party quality control firms to conduct inspections during production and prior to shipment. -

What are the typical payment terms for sourcing wine bottles internationally?

Payment terms can vary by supplier, but common practices include a deposit upon order confirmation (usually 30-50%) with the balance due before shipment. Some suppliers may also accept letters of credit or escrow services for larger transactions to mitigate risk. It’s crucial to clarify payment terms upfront and ensure they align with your cash flow management strategy. Negotiating favorable terms can enhance your financial flexibility. -

How do I manage logistics for importing wine bottles?

Managing logistics involves selecting a reliable freight forwarder experienced in handling glass products to minimize breakage during transit. Consider factors such as shipping methods (air vs. sea), customs clearance processes, and insurance for high-value shipments. It’s also essential to understand import duties and taxes in your destination country to accurately calculate total landed costs. Building strong relationships with logistics partners can streamline the process and improve delivery timelines. -

What customization options are available for wine bottles?

Customization options for wine bottles can include unique shapes, colors, and sizes, as well as embossed logos or labels. Many suppliers offer design services to help you create a bottle that aligns with your brand identity. Discussing your requirements early in the sourcing process is vital, as custom molds may involve higher costs and longer lead times. Ensure that your supplier can accommodate your design specifications while maintaining quality and compliance with industry standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Standard Wine Bottle Sizes In Cm Manufacturers & Suppliers List

1. Vigilant Inc – Piccolo Wine Bottle

Domain: vigilantinc.com

Registered: 1996 (29 years)

Introduction: Wine Bottle Sizes and Dimensions:

1. Piccolo or Split Wine Bottle:

– Size: 1/4 Bottle (187 ml / 6 oz.)

– Dimensions: 7″L x 2 — 2.5″W (178 x 50 mm)

– Fits Vigilant Kit Wine Racks: Diamond Bins, Diamond Cubes, Modular Cabinets, Solid Rectangular Bins, Wine Cubes

– Fits Vigilant Custom Wine Racks: Split Bins & Cases, Cabinetry, Cascades, Half Heights, Quarter Rounds

2. Demi or Half Wine …

2. Hillebrand Gori – Wine Bottle Dimensions Guide

Domain: hillebrandgori.com

Registered: 2021 (4 years)

Introduction: Wine bottle dimensions explained: A standard bottle holds about five glasses of wine. There are 17 sizes of wine bottles ranging from the quarter bottle (Split or Piccolo) at 187 ml to the 18-liter (L) Melchizedek (Midas) holding 200 glasses. Common wine bottle shapes include: 1. Alsace: 13.75″ height, 3.1″ width (349.25 x 78.74 mm) – used for Riesling and Muller Thurgau. 2. Bocksbeutel: Flattened…

3. Architecture Intérieure du Vin – Complete Guide to Wine Bottle Sizes

Domain: architectureinterieureduvin.com

Registered: 2020 (5 years)

Introduction: A Complete Guide to Different Wine Bottle Sizes: 1. Small Wine Bottles: Miniature (0.05 L), Piccolo (0.20 L), Chopine (0.25 L), Demi (0.375 L), Half-litre (0.5 L), Medium (0.5 L to 0.6 L). 2. Standard Wine Bottle Size: Standard bottle (0.75 L). 3. Large Wine Bottle Sizes: Magnum (1.5 L), Jeroboam (3 L), Rehoboam (4.5 L), Methuselah (6 L), Salmanazar (9 L), Balthazar (12 L), Nebuchadnezzar (15 L), …

4. Pinterest – Wine Bottle Guide

Domain: es.pinterest.com

Registered: 2009 (16 years)

Introduction: A wine bottle is a container used to hold wine. The height of a wine bottle can vary depending on the type and style of the bottle. The most common wine bottle size is the 750 milliliter (ml) bottle, also known as a ‘standard’ or ‘regular’ bottle. The height of a 750 ml wine bottle is typically between 9.5 and 11.5 inches (24 to 29 cm).

5. Wineracks America – Wood & Metal Wine Racks

Domain: wineracksamerica.com

Registered: 2003 (22 years)

Introduction: Wine Bottle Sizes | Explore Wine Bottle & Rack Dimensions for Different Types of Wine Racks

– Free Shipping For Wood & Metal Racks

– Industry-Leading Design, Build & Ship Timelines

– Contact Us | 1-888-373-6057

Wood Racks:

– Best Sellers: InstaCellar™, Living Series™, Floating Wine & Liquor Shelves, GrandCellar™

– Various styles including: The Vino Xclusive, The Alcove, The Diamond Display, The C…

6. Wine Folly – Wine Bottle Sizes Guide

Domain: winefolly.com

Registered: 2009 (16 years)

Introduction: Wine Bottle Sizes: 187.5 ml Piccolo or Split (single serving of Champagne), 375 ml Demi or Half (half of 750 ml), 750 ml Standard (common size), 1.5 L Magnum (2 x 750 ml), 3.0 L Double Magnum (4 x 750 ml), 4.5 L Jeroboam (6 x 750 ml), 4.5 L Rehoboam (6 x 750 ml sparkling), 6.0 L Methuselah (8 x 750 ml), 9.0 L Salmanazar (12 x 750 ml), 12.0 L Balthazar (16 x 750 ml), 15.0 L Nebuchadnezzar (20 x 750…

Strategic Sourcing Conclusion and Outlook for standard wine bottle sizes in cm

In the competitive landscape of the wine industry, understanding standard wine bottle sizes is essential for effective strategic sourcing. The predominant 750ml bottle serves as a universal standard, but variations such as the 375ml half-bottle and larger formats like magnums and jeroboams cater to diverse market preferences and occasions. As buyers from regions like Africa, South America, the Middle East, and Europe assess their sourcing strategies, it is crucial to consider not only the dimensions but also the associated storage solutions and market trends.

Investing in the right bottle sizes can enhance product appeal and meet consumer demand, particularly in emerging markets where premium experiences are gaining traction. By prioritizing strategic sourcing, B2B buyers can align their inventory with regional preferences, ensuring they capitalize on market opportunities.

Looking ahead, the global wine market is poised for growth, with a rising interest in unique and larger-format bottles that provide memorable experiences. Buyers are encouraged to explore suppliers who offer a diverse range of wine bottle sizes and innovative storage solutions, positioning themselves advantageously in a dynamic marketplace. Embrace the opportunity to refine your sourcing strategy today and unlock the potential of your wine offerings.