The Ultimate Guide to 12 Volt Plastic Dc Contactor Part No. 852-1251-210-50 (2025)

Introduction: Navigating the Global Market for 12 volt plastic dc contactor part no. 852-1251-210-50

In today’s rapidly evolving global marketplace, sourcing high-quality components like the 12 volt plastic DC contactor part no. 852-1251-210-50 can be a daunting task for international B2B buyers. The challenge lies not only in identifying reliable suppliers but also in understanding the various applications and specifications that meet industry standards. This comprehensive guide addresses these hurdles by offering in-depth insights into the different types of DC contactors, their applications across various sectors, and essential criteria for supplier vetting.

Buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Colombia and South Africa, will find actionable information tailored to their unique sourcing needs. The guide covers critical aspects such as pricing strategies, quality assurance measures, and logistical considerations, empowering businesses to make informed purchasing decisions.

By navigating through this resource, you will gain a thorough understanding of how to effectively source the 12 volt plastic DC contactor part no. 852-1251-210-50, ensuring that your procurement process is efficient and cost-effective. Whether you are looking to enhance your supply chain or streamline your manufacturing processes, this guide serves as an essential tool for achieving your business objectives in a competitive landscape.

Understanding 12 volt plastic dc contactor part no. 852-1251-210-50 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard 12V Plastic Contactor | Basic design, suitable for general DC applications. | Automotive systems, small machinery | Pros: Cost-effective; Cons: Limited load handling capacity. |

| Heavy-Duty 12V Contactor | Enhanced durability, higher load capacity, and thermal resistance. | Industrial automation, HVAC systems | Pros: Reliable under heavy loads; Cons: Higher upfront cost. |

| Miniature 12V Contactor | Compact size, ideal for space-constrained applications. | Consumer electronics, robotics | Pros: Space-saving; Cons: Limited current ratings. |

| Waterproof 12V Contactor | Sealed design to resist moisture and contaminants. | Marine applications, outdoor equipment | Pros: Excellent for harsh environments; Cons: More expensive. |

| Dual-Coil 12V Contactor | Features two coils for enhanced control options. | Automation systems, control panels | Pros: Improved efficiency; Cons: More complex installation. |

What are the Characteristics of Standard 12V Plastic Contactors?

The Standard 12V Plastic Contactor is designed for general-purpose applications, making it a versatile choice for various industries. It features a straightforward design that allows for easy installation and integration into existing systems. This type of contactor is widely used in automotive systems and small machinery due to its cost-effectiveness. However, it has limitations in load handling capacity, which may not suit applications requiring higher power.

How Do Heavy-Duty 12V Contactors Stand Out?

Heavy-Duty 12V Contactors are built to withstand demanding environments, offering enhanced durability and a higher load capacity. These contactors are ideal for industrial automation and HVAC systems, where reliability under heavy loads is crucial. The robust construction ensures longevity, making them a worthwhile investment despite their higher initial cost. Buyers should consider their specific load requirements and operational conditions when opting for this type.

What Makes Miniature 12V Contactors Suitable for Certain Applications?

Miniature 12V Contactors are designed for applications where space is at a premium. Their compact size makes them ideal for consumer electronics and robotics, where efficient use of space is essential. These contactors typically have lower current ratings, which may restrict their use in high-power applications. Businesses should evaluate their power needs carefully when selecting this type to ensure compatibility with their systems.

In What Situations Should You Choose Waterproof 12V Contactors?

Waterproof 12V Contactors are specifically designed to resist moisture and contaminants, making them perfect for marine applications and outdoor equipment. The sealed design enhances their reliability in harsh environments, ensuring consistent performance. While they come at a higher price point, the benefits of durability and performance in adverse conditions can justify the investment for businesses operating in such environments.

What Are the Benefits of Dual-Coil 12V Contactors?

Dual-Coil 12V Contactors offer enhanced control options due to their two-coil design, allowing for improved efficiency in automation systems and control panels. This feature can lead to reduced energy consumption and better performance in dynamic applications. However, the complexity of installation may be a drawback for some buyers. Companies should weigh the benefits of increased control against the installation requirements when considering this option.

Key Industrial Applications of 12 volt plastic dc contactor part no. 852-1251-210-50

| Industry/Sector | Specific Application of 12 volt plastic dc contactor part no. 852-1251-210-50 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Electric vehicle (EV) charging systems | Enables efficient power distribution, enhancing charging speed and safety | Ensure compatibility with EV specifications and safety standards. |

| Renewable Energy | Solar power systems | Facilitates the control of solar panel outputs, improving energy efficiency | Look for durability in harsh outdoor environments and regulatory compliance. |

| Industrial Automation | Robotics and automated machinery | Improves reliability and safety in automated processes | Assess integration with existing systems and support for international standards. |

| Marine and Offshore Applications | Control systems for boats and offshore equipment | Enhances safety and efficiency in marine operations | Evaluate corrosion resistance and compliance with maritime regulations. |

| Telecommunications | Power supply systems for telecom equipment | Ensures stable operation of critical communication infrastructure | Confirm voltage and load requirements, along with long-term availability. |

How is the 12 Volt Plastic DC Contactor Used in Electric Vehicle Charging Systems?

In the automotive industry, the 12 volt plastic DC contactor part no. 852-1251-210-50 plays a crucial role in electric vehicle (EV) charging systems. It is responsible for controlling the flow of electricity from the charging station to the vehicle’s battery. By enabling efficient power distribution, this contactor enhances charging speed and ensures safety during the charging process. For international B2B buyers, especially from regions like Africa and South America, it is essential to ensure that the contactor meets specific safety standards and is compatible with local EV specifications.

What Role Does This Contactor Play in Renewable Energy Systems?

In renewable energy applications, particularly solar power systems, the 12 volt plastic DC contactor is integral for managing the output of solar panels. It helps in controlling the energy flow from the panels to the inverter and ultimately to the grid or storage systems. This capability not only improves energy efficiency but also contributes to the reliability of the entire solar setup. Buyers from the Middle East and Europe should focus on sourcing contactors that are durable enough to withstand harsh outdoor conditions and comply with regional energy regulations.

How Does the Contactor Enhance Industrial Automation?

Within industrial automation, this contactor is utilized in robotics and automated machinery to enhance operational reliability. It acts as a switch that can handle high current loads, ensuring that machinery operates smoothly and safely. By improving the reliability of automated processes, businesses can reduce downtime and maintenance costs. International buyers must consider the contactor’s compatibility with existing systems and its support for international automation standards, especially when sourcing from different regions.

Why is the Contactor Important for Marine and Offshore Applications?

In marine and offshore applications, the 12 volt plastic DC contactor is vital for controlling power systems on boats and offshore equipment. It enhances safety by preventing electrical faults and improving the efficiency of power management systems. Given the challenging marine environment, buyers should prioritize contactors that offer corrosion resistance and comply with maritime regulations to ensure long-lasting performance.

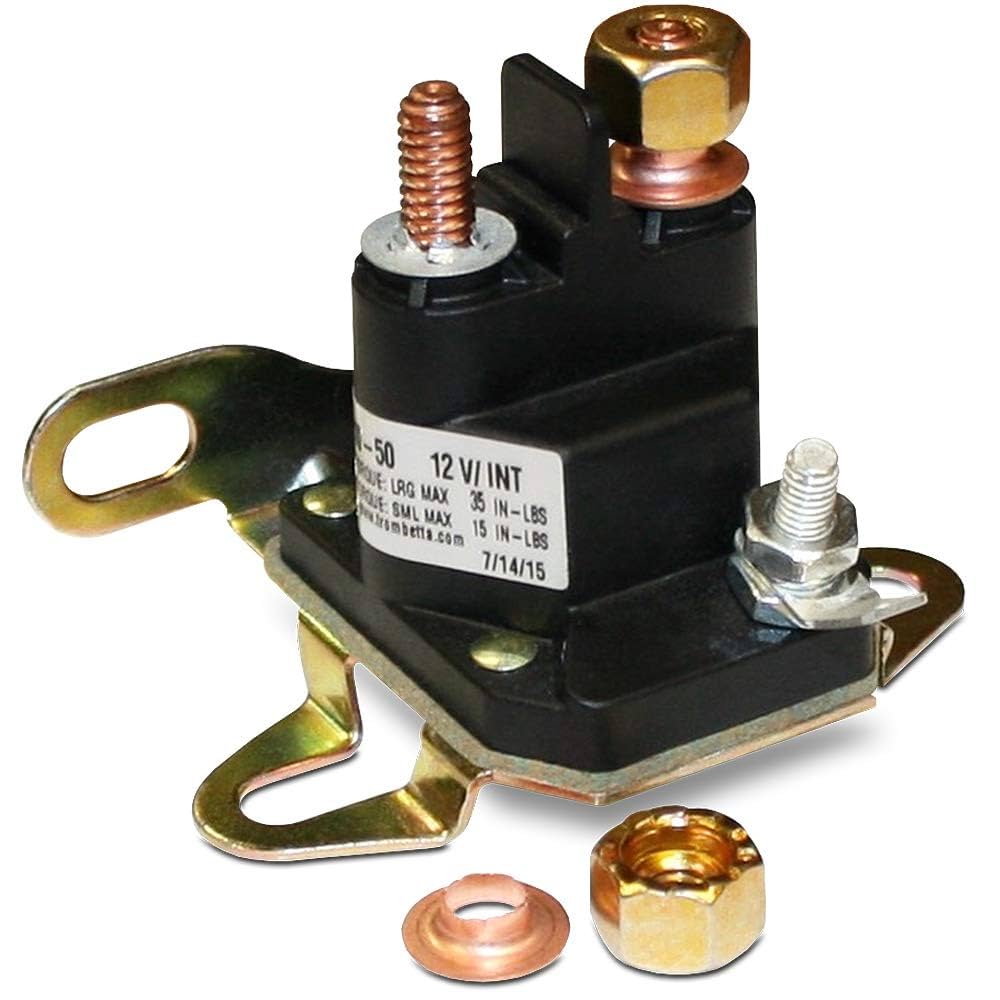

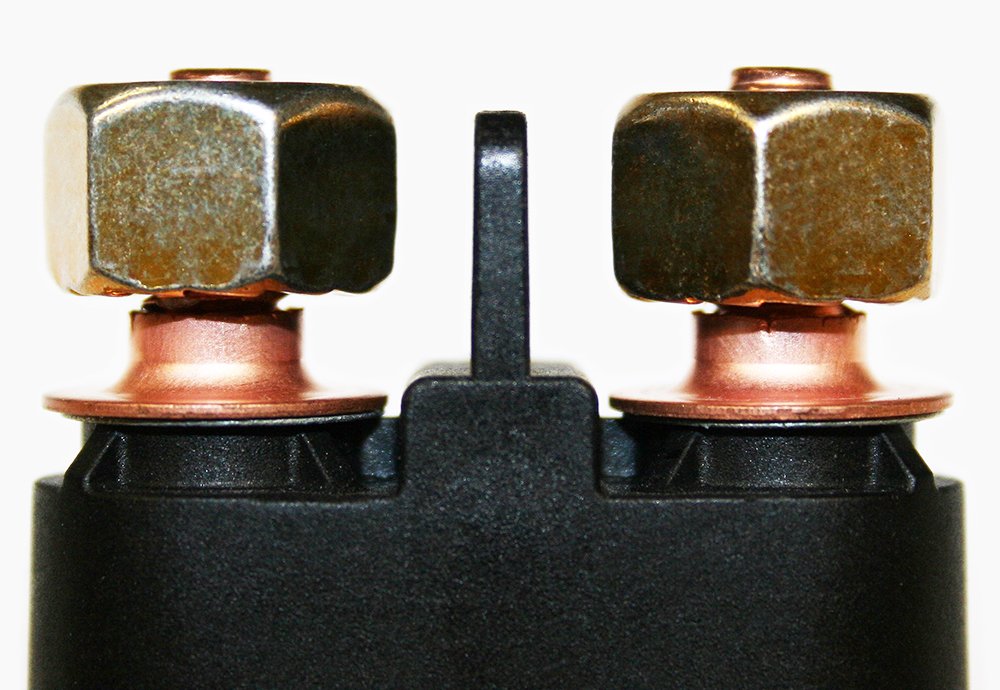

A stock image related to 12 volt plastic dc contactor part no. 852-1251-210-50.

How is This Contactor Used in Telecommunications?

In the telecommunications sector, the 12 volt plastic DC contactor is essential for power supply systems that support critical communication infrastructure. It ensures stable operation, which is crucial for maintaining connectivity and service reliability. For international B2B buyers, confirming the contactor’s voltage and load requirements, along with ensuring long-term availability, is key to securing a reliable power solution for telecom applications.

Related Video: Jason Mantzoukas Uses His Celebrity Lookalike | Taskmaster Series 19 | Channel 4 Entertainment

3 Common User Pain Points for ’12 volt plastic dc contactor part no. 852-1251-210-50′ & Their Solutions

Scenario 1: Sourcing Quality Components for Reliability in Operations

The Problem: For B2B buyers in industries such as renewable energy or automotive, sourcing reliable components like the 12 volt plastic DC contactor part no. 852-1251-210-50 can be a daunting task. Many suppliers may offer similar products, but the variations in quality and performance can lead to operational failures, increased downtime, and ultimately, financial losses. This is particularly critical for companies in regions like Africa and South America, where supply chain disruptions can hinder timely project completion and result in significant penalties.

The Solution: To overcome this challenge, buyers should conduct thorough research on suppliers, focusing on their reputation, product certifications, and customer reviews. It is beneficial to request samples of the 852-1251-210-50 contactor to evaluate its quality firsthand. Establishing relationships with reputable distributors who have a track record in the industry ensures access to high-quality components. Additionally, consider leveraging local suppliers who understand the specific operational challenges in your region, thereby reducing lead times and enhancing support.

Scenario 2: Navigating Technical Specifications and Compatibility Issues

The Problem: Another common pain point for B2B buyers is the complexity of technical specifications and ensuring compatibility with existing systems. The 12 volt plastic DC contactor part no. 852-1251-210-50 may have specific electrical ratings, mounting requirements, and operational features that need to align with other components in a project. Mismatched specifications can lead to system failures, operational inefficiencies, and increased costs due to re-engineering or retrofitting systems.

The Solution: To address this issue, buyers should invest time in understanding the detailed technical specifications of the contactor. Creating a compatibility checklist that includes voltage ratings, current capacity, and physical dimensions can aid in comparing the 852-1251-210-50 with other components. Collaborating with engineers or technical consultants during the sourcing phase can help ensure that all parts work seamlessly together. Additionally, utilizing simulation software can allow for virtual testing of the contactor within the intended system before purchase, reducing the risk of compatibility issues.

Scenario 3: Managing Lifecycle and Maintenance Concerns

The Problem: Maintenance and lifecycle management are critical considerations for buyers of electrical components. The 12 volt plastic DC contactor part no. 852-1251-210-50 must not only meet current operational needs but also be reliable over time. Buyers often face challenges in predicting when components will need replacement or maintenance, which can disrupt operations and lead to unexpected costs. In regions with limited access to replacement parts, this issue becomes even more pressing.

The Solution: To mitigate lifecycle and maintenance concerns, B2B buyers should develop a proactive maintenance schedule based on the operational context and expected wear and tear of the contactor. Engaging with suppliers who offer extended warranties or maintenance support can provide additional security. Implementing a tracking system for component performance can help in forecasting replacement needs, ensuring that the 852-1251-210-50 is replaced before failures occur. Furthermore, maintaining an inventory of critical spare parts can minimize downtime during maintenance activities, particularly in remote areas where logistics can be a challenge.

Strategic Material Selection Guide for 12 volt plastic dc contactor part no. 852-1251-210-50

What are the Common Materials Used in 12 Volt Plastic DC Contactors?

When selecting materials for the 12 volt plastic DC contactor part no. 852-1251-210-50, it’s essential to consider the properties, advantages, and limitations of common materials. This guide will analyze four prevalent materials: Polycarbonate (PC), Nylon (PA), Polypropylene (PP), and Thermoplastic Elastomer (TPE). Each material offers unique characteristics that can significantly affect the performance and suitability of the contactor in various applications.

How Does Polycarbonate (PC) Perform in DC Contactors?

Key Properties: Polycarbonate is known for its excellent impact resistance and transparency. It has a high heat deflection temperature of around 130°C (266°F) and good electrical insulation properties, making it suitable for electrical applications.

Pros & Cons: The primary advantage of polycarbonate is its durability and resistance to impact and heat. However, it can be more expensive than other plastics and may require specialized manufacturing processes, which can increase overall costs.

Impact on Application: Polycarbonate’s high-temperature resistance makes it ideal for applications that might experience thermal cycling. Its electrical insulating properties ensure safe operation in electrical environments.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure compliance with local standards, such as ASTM or ISO, as polycarbonate may not be as readily available in all markets.

What About Nylon (PA) as a Material Choice?

Key Properties: Nylon is a versatile material known for its strength, flexibility, and resistance to abrasion. It can withstand temperatures up to 120°C (248°F) and offers good chemical resistance.

Pros & Cons: The advantages of nylon include its excellent mechanical properties and relatively low cost. However, it can absorb moisture, which may affect its dimensional stability and performance in humid environments.

Impact on Application: Nylon’s flexibility and strength make it suitable for applications requiring durability and resistance to wear. However, its moisture absorption can limit its use in high-humidity regions.

Considerations for International Buyers: Buyers in the Middle East and Europe should consider the moisture content in their environments when selecting nylon. Compliance with standards like DIN or JIS is also crucial for ensuring product safety and reliability.

Is Polypropylene (PP) a Viable Option?

Key Properties: Polypropylene offers excellent chemical resistance and a temperature tolerance of around 100°C (212°F). It is lightweight and has a low density, making it a cost-effective option.

Pros & Cons: The main advantage of polypropylene is its resistance to a wide range of chemicals, which makes it suitable for various applications. However, it has lower impact resistance compared to polycarbonate and nylon.

Impact on Application: Polypropylene’s chemical resistance makes it ideal for environments where exposure to corrosive substances is expected. However, its lower impact resistance may limit its use in applications requiring high durability.

Considerations for International Buyers: In regions like South Africa, where chemical exposure is common, polypropylene’s properties can be beneficial. Ensuring compliance with local standards is essential for safety and performance.

How Does Thermoplastic Elastomer (TPE) Compare?

Key Properties: TPE combines the properties of rubber and plastic, offering flexibility and resilience. It can withstand temperatures ranging from -40°C to 120°C (-40°F to 248°F).

Pros & Cons: TPE provides excellent flexibility and is resistant to wear and tear. However, it can be more expensive than traditional plastics and may require specific processing techniques.

Impact on Application: The flexibility of TPE makes it suitable for applications requiring a soft touch or vibration dampening. Its resilience ensures a longer lifespan in dynamic environments.

Considerations for International Buyers: Buyers from Europe should evaluate the processing requirements for TPE, as it may not be as widely available as other materials. Compliance with EU regulations is also a critical factor.

Summary Table of Material Selection for 12 Volt Plastic DC Contactor

| Material | Typical Use Case for 12 volt plastic dc contactor part no. 852-1251-210-50 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate (PC) | High-temperature electrical applications | Excellent impact resistance | Higher manufacturing costs | High |

| Nylon (PA) | General-purpose applications requiring strength | Good mechanical properties | Moisture absorption issues | Medium |

| Polypropylene (PP) | Chemical exposure environments | Excellent chemical resistance | Lower impact resistance | Low |

| Thermoplastic Elastomer (TPE) | Applications needing flexibility and resilience | High flexibility and durability | Higher cost and processing needs | High |

This material selection guide provides actionable insights for international B2B buyers, ensuring they make informed decisions based on the specific requirements of their applications and the characteristics of each material.

In-depth Look: Manufacturing Processes and Quality Assurance for 12 volt plastic dc contactor part no. 852-1251-210-50

What Are the Main Stages in the Manufacturing Process of the 12 Volt Plastic DC Contactor Part No. 852-1251-210-50?

The manufacturing process for the 12 volt plastic DC contactor part no. 852-1251-210-50 is intricate and involves several critical stages, ensuring that each component meets high standards of quality and performance.

1. Material Preparation

The first step involves selecting and preparing high-quality raw materials, typically thermoplastics and conductive metals. Manufacturers often source materials that comply with international standards to guarantee durability and reliability. Materials are subjected to various tests to ensure they meet specifications, including tensile strength and thermal stability.

2. Forming Techniques

Once the materials are prepared, the next stage is forming. This can involve several techniques, including injection molding for plastic components and stamping or machining for metal parts. Injection molding is particularly favored for its efficiency in producing complex shapes with high precision. This stage is crucial, as any defects in forming can lead to failures in later assembly or performance.

3. Assembly

The assembly phase combines all individual components into a complete contactor. This may involve manual labor or automated assembly lines, depending on the manufacturer’s capabilities. Workers or machines ensure that components fit together seamlessly, and any electronic parts are correctly connected. This stage may also include initial functional testing to identify any assembly-related issues.

4. Finishing Processes

Finishing processes include surface treatments such as coating, painting, or polishing to enhance aesthetics and protect against corrosion or wear. For DC contactors, coatings may also improve electrical insulation and overall safety. This stage is essential for ensuring the longevity and reliability of the product, particularly in harsh environments.

What Quality Assurance Standards Should B2B Buyers Expect?

Quality assurance (QA) is paramount in the manufacturing of the 12 volt plastic DC contactor. B2B buyers should look for compliance with international standards and specific industry certifications.

International Standards

ISO 9001 is a widely recognized standard for quality management systems. Manufacturers adhering to ISO 9001 are required to demonstrate a consistent ability to provide products that meet customer and regulatory requirements. This standard emphasizes continuous improvement and customer satisfaction, ensuring that the manufacturing processes are regularly reviewed and optimized.

Industry-Specific Certifications

In addition to ISO standards, specific certifications such as CE (Conformité Européenne) for products sold in the European market and API (American Petroleum Institute) standards for use in oil and gas applications may also be relevant. These certifications ensure that the contactor meets specific safety, health, and environmental requirements, which can be crucial for buyers in regulated industries.

How Are Quality Control Checkpoints Implemented in the Manufacturing Process?

Quality control (QC) is integrated throughout the manufacturing process, with specific checkpoints established to maintain product integrity.

Incoming Quality Control (IQC)

The first checkpoint occurs during Incoming Quality Control (IQC), where raw materials are inspected upon arrival. This step ensures that only materials meeting predetermined specifications are used in production. Any substandard materials are rejected, thus preventing defects in the final product.

In-Process Quality Control (IPQC)

During the manufacturing stages, In-Process Quality Control (IPQC) involves continuous monitoring and testing of components at various stages of production. This may include dimensional checks, functional tests, and visual inspections. By identifying issues early, manufacturers can mitigate risks and reduce waste.

Final Quality Control (FQC)

Final Quality Control (FQC) is conducted once the contactors are fully assembled. This stage involves rigorous testing to ensure the product meets all functional and safety specifications. Tests may include electrical performance tests, thermal cycling tests, and environmental testing to simulate real-world conditions.

What Common Testing Methods Are Used for Quality Assurance?

B2B buyers should be aware of the common testing methods employed to ensure the reliability and performance of the 12 volt plastic DC contactor.

-

Electrical Testing: This includes checking the contact resistance, insulation resistance, and dielectric strength to ensure the contactor operates efficiently under specified electrical loads.

-

Mechanical Testing: Mechanical durability tests assess the strength and resilience of the contactor under various stress conditions, including vibration and shock tests.

-

Environmental Testing: Products are subjected to extreme temperature, humidity, and corrosive environments to ensure they can withstand harsh operating conditions.

-

Lifecycle Testing: This simulates the operational lifespan of the contactor to ensure it performs effectively throughout its intended life.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential.

Conducting Audits

Buyers should request to conduct regular audits of the manufacturing facilities. This provides an opportunity to assess the implementation of quality management systems and adherence to international standards.

Reviewing Quality Reports

Requesting access to quality reports, including IQC, IPQC, and FQC results, can give buyers insights into the supplier’s quality assurance practices.

Third-Party Inspections

Engaging third-party inspection agencies can provide an unbiased evaluation of the manufacturer’s quality processes. These agencies can conduct tests and audits to verify compliance with international standards.

What Nuances Should International B2B Buyers Consider Regarding Quality Control and Certification?

Understanding the nuances of quality control and certification is critical for international B2B buyers. Each region may have specific regulatory requirements, and manufacturers must adapt to these standards. Buyers should be aware of:

-

Local Regulations: Different countries may have unique certifications or standards that must be met, so it’s essential to verify that the manufacturer complies with local regulations in the buyer’s region.

-

Cultural Differences in Quality Expectations: Perceptions of quality can vary by region. Buyers should communicate their quality expectations clearly and ensure the supplier understands them.

-

Supply Chain Transparency: Ensuring transparency in the supply chain can help buyers understand the origins of materials and components, which is critical for quality assurance.

By comprehensively understanding the manufacturing processes and quality assurance for the 12 volt plastic DC contactor part no. 852-1251-210-50, international B2B buyers can make informed decisions and select reliable suppliers that meet their quality standards and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ’12 volt plastic dc contactor part no. 852-1251-210-50′

Introduction

Navigating the procurement of specialized components like the 12 volt plastic DC contactor part no. 852-1251-210-50 requires a structured approach. This checklist will guide international B2B buyers—particularly from Africa, South America, the Middle East, and Europe—through the critical steps of sourcing this essential electrical component. By following these steps, you can ensure a successful procurement process that meets your technical needs and aligns with your operational goals.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for the 12 volt plastic DC contactor is crucial. This includes understanding the electrical ratings, operational temperature ranges, and physical dimensions required for your application. Specific details such as coil voltage, contact ratings, and mounting options should be documented to avoid mismatches later.

- Example Specifications:

- Voltage: 12V DC

- Maximum current rating: 30A

- Type of contacts: Normally open (NO) or normally closed (NC)

Step 2: Conduct Market Research

Research potential suppliers and manufacturers of the 852-1251-210-50 contactor. Look for reputable suppliers that have a history of providing quality products. Utilize industry directories, trade shows, and online platforms to gather information about potential vendors.

- Key Considerations:

- Supplier’s market presence and experience in the industry

- Reviews and ratings from previous clients

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; check their credibility through third-party reviews or industry certifications.

- What to Look For:

- ISO certifications or other relevant quality standards

- Client testimonials or case studies demonstrating successful partnerships

Step 4: Request Samples for Testing

Once you’ve shortlisted potential suppliers, request samples of the 12 volt plastic DC contactor. Testing samples allows you to evaluate their performance under your specific conditions. This is an essential step to ensure the product meets your technical requirements and quality expectations.

- Testing Parameters:

- Electrical performance under load

- Physical durability and resistance to environmental factors

Step 5: Check Compliance and Certifications

Ensure that the contactor complies with relevant safety and quality standards. This is particularly important for international procurement, as regulations may vary by region. Verify that the product meets industry standards such as CE, UL, or RoHS, depending on your market.

- Key Compliance Aspects:

- Safety certifications relevant to your industry

- Environmental regulations, especially for electronic components

Step 6: Negotiate Terms and Conditions

Before finalizing your order, negotiate favorable terms with your chosen supplier. This includes pricing, payment terms, delivery schedules, and warranty conditions. Having clear agreements in place can help mitigate risks and ensure a smooth procurement process.

- Negotiation Tips:

- Aim for bulk order discounts if applicable

- Clarify the return policy in case of defective products

Step 7: Establish a Communication Plan

Set up a communication plan with your supplier to ensure ongoing support and updates throughout the procurement process. This is vital for addressing any issues that may arise during production or shipping, and it fosters a good working relationship.

- Effective Communication Channels:

- Regular updates via email or project management tools

- Scheduled check-ins to discuss progress and any potential issues

By adhering to this structured sourcing checklist, B2B buyers can effectively navigate the complexities of procuring the 12 volt plastic DC contactor part no. 852-1251-210-50, ensuring they meet their operational needs while minimizing risks.

Comprehensive Cost and Pricing Analysis for 12 volt plastic dc contactor part no. 852-1251-210-50 Sourcing

What Are the Key Cost Components for 12 Volt Plastic DC Contactor Part No. 852-1251-210-50?

When sourcing the 12 volt plastic DC contactor part no. 852-1251-210-50, it’s essential to understand the breakdown of its cost structure. Key components include:

-

Materials: The primary materials for manufacturing this contactor typically include high-quality plastics and copper for the contacts. The choice of materials affects durability and performance, influencing overall cost.

-

Labor: Labor costs can vary significantly depending on the manufacturing region. Regions with higher labor costs, such as parts of Europe, may see increased pricing compared to countries in Africa or South America, where labor might be less expensive.

-

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and administrative expenses. Overhead can also be affected by the scale of production; larger volumes generally lead to lower per-unit overhead costs.

-

Tooling: Initial tooling costs for molds and machinery can be significant, particularly for custom designs or adaptations. These costs are usually amortized over large production runs, which can help lower the unit price.

-

Quality Control (QC): Ensuring the product meets industry standards is vital. QC costs can include testing and certification fees, which vary based on the required certifications for specific markets.

-

Logistics: Transportation costs, including shipping and customs duties, can greatly influence the final price, especially for international buyers. These costs can fluctuate based on the shipping method and destination.

-

Margin: Manufacturers will apply a profit margin on top of the total production costs, which can vary widely depending on market demand and competition.

How Do Price Influencers Affect the Sourcing of DC Contactors?

Several factors influence the pricing of the 12 volt plastic DC contactor, including:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes typically lead to lower per-unit prices. B2B buyers should negotiate for better rates based on their purchasing commitments.

-

Specifications and Customization: Custom features or specific specifications can significantly increase costs. Buyers should evaluate whether these customizations are essential for their applications.

-

Material Quality and Certifications: Products with superior materials or additional certifications (like ISO or UL) often come at a premium. Buyers should weigh the benefits of these certifications against their budget.

-

Supplier Factors: The supplier’s reputation, location, and reliability can also influence pricing. Established suppliers may command higher prices due to their proven quality and service.

-

Incoterms: Understanding the shipping terms (Incoterms) is crucial for international buyers. They define who is responsible for costs and risks during shipping, affecting total landed cost.

What Are the Best Negotiation Tips for International B2B Buyers?

B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider the following strategies for effective negotiation:

-

Research and Compare: Gather multiple quotes and analyze different suppliers’ offerings. Understanding the market price can help in negotiations.

-

Emphasize Long-Term Relationships: Suppliers may be more willing to offer discounts to buyers who show potential for ongoing business. Highlighting long-term partnership intentions can leverage better pricing.

-

Focus on Total Cost of Ownership (TCO): Buyers should evaluate not only the purchase price but also the long-term costs associated with maintenance, energy consumption, and disposal. This broader view can justify higher upfront costs if quality and durability are assured.

-

Be Aware of Pricing Nuances: Currency fluctuations, import tariffs, and local economic conditions can affect pricing. Buyers should factor these into their negotiations and budget planning.

-

Leverage Local Knowledge: Engaging local experts or consultants can provide insights into supplier reliability and market conditions, helping buyers make informed decisions.

Conclusion

Understanding the comprehensive cost structure and pricing influencers for the 12 volt plastic DC contactor part no. 852-1251-210-50 is crucial for international B2B buyers. By focusing on these elements, buyers can make more informed sourcing decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing 12 volt plastic dc contactor part no. 852-1251-210-50 With Other Solutions

Understanding the Importance of Alternative Solutions for 12 Volt Plastic DC Contactors

In the realm of industrial applications, selecting the right DC contactor is crucial for ensuring operational efficiency and reliability. The 12 volt plastic DC contactor part no. 852-1251-210-50 is a popular choice, but B2B buyers should also consider viable alternatives that may better suit their specific requirements. This section will compare the 852-1251-210-50 with two alternative solutions: the 12 Volt Metal DC Contactor and the Solid State Relay (SSR).

Comparison Table of 12 Volt Plastic DC Contactor and Alternatives

| Comparison Aspect | 12 Volt Plastic DC Contactor Part No. 852-1251-210-50 | 12 Volt Metal DC Contactor | Solid State Relay (SSR) |

|---|---|---|---|

| Performance | Good for moderate loads; rated for continuous duty | Excellent for high-load applications | Very high switching speed; no mechanical wear |

| Cost | Generally lower cost | Higher cost due to materials | Moderate cost but higher than plastic contactors |

| Ease of Implementation | Easy to install with standard connectors | Slightly more complex installation | Requires some knowledge of circuit design |

| Maintenance | Low maintenance; durable plastic housing | Moderate maintenance; metal fatigue over time | Virtually maintenance-free |

| Best Use Case | Suitable for light to moderate industrial applications | Ideal for heavy machinery and high current applications | Excellent for fast switching applications like automation systems |

Detailed Breakdown of Alternatives

12 Volt Metal DC Contactor

The 12 Volt Metal DC Contactor is a robust alternative known for its durability and ability to handle higher currents. Its metal construction allows it to manage heavier loads effectively, making it suitable for applications involving heavy machinery. However, the cost is generally higher due to the materials used, and installation can be slightly more complex compared to plastic variants. Maintenance is required to address potential metal fatigue over time, especially in high-use environments.

Solid State Relay (SSR)

Solid State Relays represent a modern solution for controlling electrical loads without mechanical contacts. They offer rapid switching capabilities, making them ideal for automation and control applications where speed is critical. One of the significant advantages of SSRs is their maintenance-free operation; there are no mechanical parts to wear out. However, they typically come at a higher initial cost and may require more expertise for proper integration into existing systems. They are best suited for applications that demand high reliability and fast response times.

Conclusion: Making an Informed Decision for Your Business Needs

When selecting a DC contactor, B2B buyers must consider various factors such as performance, cost, ease of implementation, and maintenance. The 12 volt plastic DC contactor part no. 852-1251-210-50 is a solid choice for moderate applications, but for those requiring higher load capabilities or faster switching times, exploring alternatives like the 12 Volt Metal DC Contactor or Solid State Relay may be beneficial. By evaluating the unique demands of their operations, buyers can make informed decisions that align with their operational goals and budgetary constraints.

Essential Technical Properties and Trade Terminology for 12 volt plastic dc contactor part no. 852-1251-210-50

What are the Key Technical Properties of the 12 Volt Plastic DC Contactor Part No. 852-1251-210-50?

When evaluating the 12 volt plastic DC contactor part no. 852-1251-210-50, understanding its technical specifications is crucial for B2B buyers. Here are some essential properties to consider:

1. Material Grade

The part is typically made from high-quality plastic and conductive metals. The material grade is critical as it affects durability, resistance to environmental conditions, and overall performance. Buyers should ensure that the materials meet industry standards to guarantee reliability in various applications.

2. Current Rating

This specification indicates the maximum current the contactor can handle without overheating or failing. For the 852-1251-210-50, the current rating is often around 10-30 Amps. Understanding this rating is essential for ensuring the part is suitable for the intended electrical load, which directly impacts system efficiency and safety.

3. Voltage Rating

The voltage rating defines the maximum voltage the contactor can safely operate at, which, for this model, is 12 volts. Selecting a contactor with the correct voltage rating is vital to prevent electrical failures and ensure compatibility with the system’s power supply.

4. Tolerance Levels

Tolerance levels are crucial for ensuring the contactor operates within specified limits. For example, a tolerance of ±10% in current or voltage ratings can impact performance. Buyers should consider these levels to avoid operational inefficiencies and potential damage to connected devices.

5. Operating Temperature Range

This specification describes the temperature extremes within which the contactor can function effectively. The 852-1251-210-50 typically operates within -40°C to 85°C. Understanding this range helps buyers ensure that the contactor will perform reliably in their specific environmental conditions.

6. Mechanical Life

The mechanical life of the contactor refers to the number of operations it can perform before failure, typically expressed in cycles. A higher mechanical life translates to reduced maintenance costs and increased uptime for the system. Buyers should prioritize contactors with a mechanical life that meets their operational requirements.

What Common Trade Terms Should B2B Buyers Know?

Familiarizing oneself with industry jargon can enhance communication and negotiation in B2B transactions. Here are some key terms relevant to the procurement of the 12 volt plastic DC contactor:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in another company’s end products. Understanding OEM relationships is important for buyers looking to source parts that meet specific quality and performance standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchases and manage inventory effectively, ensuring they meet supplier requirements without overstocking.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products. This is a critical step in the procurement process, allowing buyers to compare costs and terms from different suppliers to make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risks associated with the transport of goods, ensuring smoother transactions.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is crucial for buyers to ensure timely delivery and maintain their production schedules.

6. Warranty Terms

Warranty terms outline the conditions under which a product can be returned or replaced if it fails. Knowing warranty terms helps buyers assess risk and potential costs associated with product failure, which is especially important for critical components like contactors.

By understanding these technical properties and trade terms, international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can make informed purchasing decisions regarding the 12 volt plastic DC contactor part no. 852-1251-210-50.

Navigating Market Dynamics and Sourcing Trends in the 12 volt plastic dc contactor part no. 852-1251-210-50 Sector

What Are the Current Market Dynamics for 12 Volt Plastic DC Contactors?

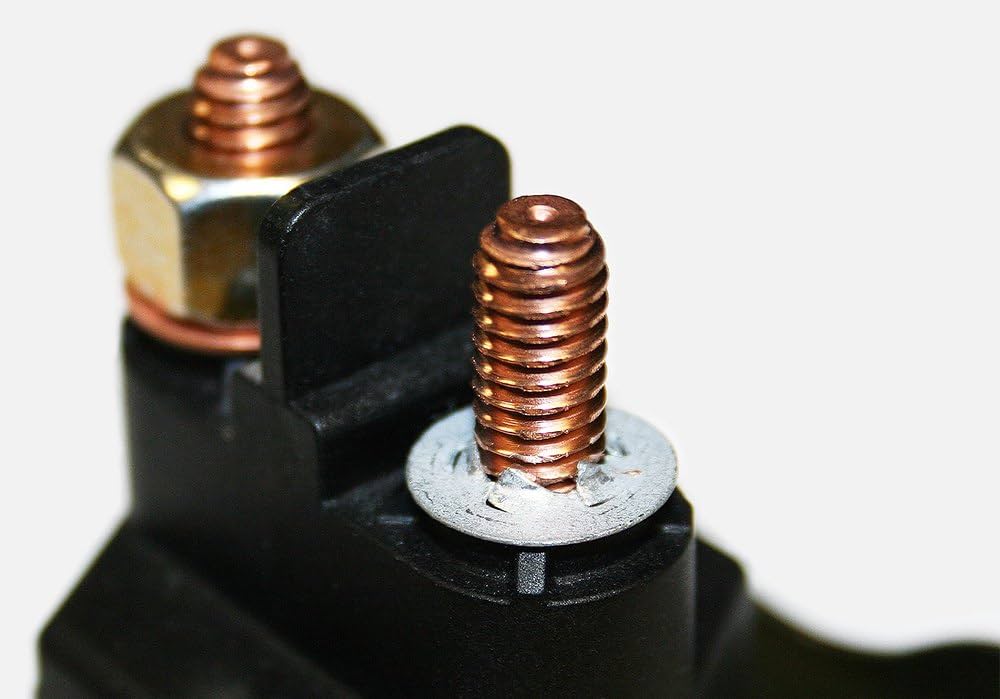

A stock image related to 12 volt plastic dc contactor part no. 852-1251-210-50.

The market for 12 volt plastic DC contactors, particularly part number 852-1251-210-50, is shaped by several global trends that B2B buyers should be aware of. One of the primary drivers is the increasing demand for automation in various industries such as automotive, renewable energy, and industrial applications. This demand is particularly pronounced in emerging markets across Africa, South America, and the Middle East, where industrialization and urbanization are rapidly evolving.

Moreover, technological advancements are leading to the development of more efficient and compact contactor designs. This trend is driven by the need for energy efficiency and cost reduction, which is crucial for businesses looking to optimize their operations. For instance, smart technologies that integrate IoT (Internet of Things) capabilities are becoming more prevalent, allowing for remote monitoring and control of electrical systems.

In Europe, regulatory frameworks focusing on energy efficiency and sustainability are influencing market dynamics. The EU’s Green Deal is pushing manufacturers to innovate and produce environmentally friendly products. B2B buyers in this region are increasingly prioritizing suppliers that can demonstrate compliance with these standards, indicating a shift towards sustainable sourcing practices.

How Is Sustainability Impacting Sourcing Decisions for 12 Volt Plastic DC Contactors?

Sustainability has become a crucial factor in B2B sourcing decisions for the 12 volt plastic DC contactor sector. The environmental impact of manufacturing processes, particularly in terms of plastic waste and energy consumption, is under scrutiny. Buyers are increasingly looking for suppliers who can provide transparency in their supply chains and demonstrate a commitment to reducing their carbon footprints.

Ethical sourcing practices are also gaining traction. Buyers are seeking manufacturers that adhere to labor rights, fair trade practices, and responsible sourcing of materials. Certifications such as ISO 14001 (Environmental Management) and other ‘green’ certifications are becoming essential for suppliers aiming to attract international buyers, especially from regions like Europe and North America, where such standards are expected.

Moreover, the use of recyclable materials in the production of 12 volt plastic DC contactors is a growing trend. Suppliers that offer products made from recycled plastics or those that incorporate eco-friendly materials are more likely to appeal to buyers who prioritize sustainability. This shift not only addresses environmental concerns but also aligns with the corporate social responsibility (CSR) goals of many organizations.

What Is the Historical Context of 12 Volt Plastic DC Contactors?

The evolution of 12 volt plastic DC contactors can be traced back to the growing demand for reliable and efficient electrical control systems in the mid-20th century. Initially, contactors were primarily made from metal, which posed challenges in terms of weight and corrosion resistance. The introduction of plastic as a primary material for contactor housings in the 1980s marked a significant turning point.

This shift allowed for lighter, more compact designs while enhancing resistance to environmental factors. Over the years, technological advancements have led to the incorporation of advanced materials and manufacturing processes, resulting in improved performance and longevity. As industries continue to evolve, the 12 volt plastic DC contactor has adapted to meet the demands of modern applications, ensuring its relevance in today’s market.

Conclusion

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding the market dynamics, sustainability trends, and historical context of 12 volt plastic DC contactors is essential. By prioritizing suppliers who are innovative, sustainable, and compliant with ethical standards, businesses can secure reliable partnerships that enhance their operational efficiency and support their corporate social responsibility goals.

Frequently Asked Questions (FAQs) for B2B Buyers of 12 volt plastic dc contactor part no. 852-1251-210-50

-

How do I choose the right 12 volt plastic DC contactor for my application?

When selecting a 12 volt plastic DC contactor, consider the specific requirements of your application, such as the load current, voltage rating, and the type of control circuit. Evaluate the contactor’s specifications, including its switching capacity and environmental ratings, to ensure it meets your operational needs. Additionally, check for compatibility with your existing systems, and consider the operating conditions, such as temperature and humidity, which may affect performance. -

What are the advantages of using a plastic DC contactor over metal options?

Plastic DC contactors offer several advantages, including lightweight construction, corrosion resistance, and lower manufacturing costs. They are typically easier to install and handle, making them ideal for applications where weight and space are critical factors. Additionally, plastic contactors often provide better insulation and are less prone to rust, which enhances their longevity in various environments. -

What is the minimum order quantity (MOQ) for 12 volt plastic DC contactors?

The minimum order quantity for 12 volt plastic DC contactors can vary significantly by supplier and manufacturer. Typically, the MOQ may range from 100 to 1,000 units, depending on production capabilities and pricing structures. It’s advisable to discuss your specific requirements with potential suppliers to negotiate terms that suit your procurement needs while ensuring competitive pricing. -

How do I vet suppliers for 12 volt plastic DC contactors?

To effectively vet suppliers, start by researching their reputation in the industry. Look for reviews, testimonials, and case studies from previous customers. Ensure the supplier has relevant certifications and quality assurance processes in place, such as ISO certifications. Additionally, request samples and assess their communication responsiveness and willingness to provide after-sales support, which are vital for long-term partnerships. -

What payment terms should I expect when sourcing DC contactors internationally?

Payment terms for international orders can vary widely, but common practices include advance payments, letters of credit, or payment upon delivery. Many suppliers may request a deposit (often 30% to 50%) before production, with the balance due upon shipment or receipt. It’s crucial to clarify these terms upfront to avoid misunderstandings and ensure smooth transactions. -

What quality assurance measures should I consider when sourcing contactors?

Quality assurance is paramount when sourcing 12 volt plastic DC contactors. Ensure that the supplier conducts rigorous testing, including electrical and mechanical performance tests, to meet industry standards. Inquire about their quality control processes, such as incoming material inspections and final product evaluations. Additionally, consider requesting a third-party quality inspection before shipment to verify compliance with your specifications.

A stock image related to 12 volt plastic dc contactor part no. 852-1251-210-50.

-

How can I ensure timely logistics for my order of DC contactors?

To ensure timely logistics, establish clear communication with your supplier regarding lead times and shipping schedules. Choose a reliable shipping method that aligns with your delivery needs, whether air freight for speed or sea freight for cost-efficiency. Additionally, consider working with logistics providers experienced in international shipping to navigate customs regulations and potential delays, ensuring your order arrives on time. -

What customization options are available for 12 volt plastic DC contactors?

Many manufacturers offer customization options for 12 volt plastic DC contactors, including modifications to dimensions, terminal types, and specific electrical ratings. You can also request branding on the products or specific packaging requirements. When discussing customization, provide detailed specifications and quantities to facilitate accurate quotations and ensure that the modifications align with your application needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 12 volt plastic dc contactor part no. 852-1251-210-50

In summary, the strategic sourcing of the 12 volt plastic DC contactor part no. 852-1251-210-50 offers international B2B buyers significant advantages, particularly in optimizing supply chain efficiency and reducing operational costs. By engaging with reliable suppliers and leveraging local partnerships, businesses in regions such as Africa, South America, the Middle East, and Europe can enhance their procurement processes. The demand for high-quality components like the 852-1251-210-50 is on the rise, driven by advancements in electrical systems across various industries.

As you consider your sourcing strategy, focus on the long-term benefits of establishing relationships with manufacturers who prioritize quality and sustainability. This not only ensures compliance with international standards but also supports the growth of local economies.

Looking ahead, now is the time to act. Evaluate your current suppliers and explore new partnerships that can provide you with the innovative solutions necessary for your business’s growth and success. By investing in strategic sourcing today, you position your company for a competitive edge tomorrow.