The Ultimate Guide to Chemipakhsh Net Caustic Soda Flake (2025)

Introduction: Navigating the Global Market for chemipakhsh net caustic soda flake

In today’s competitive landscape, sourcing high-quality chemipakhsh net caustic soda flake can pose significant challenges for international B2B buyers. With varying supplier standards, fluctuating prices, and an ever-evolving regulatory environment, making informed purchasing decisions is crucial. This guide aims to address these challenges by providing a comprehensive overview of caustic soda flakes, covering essential topics such as types, applications, supplier vetting processes, and cost considerations.

For businesses in Africa, South America, the Middle East, and Europe—including emerging markets like Vietnam and Thailand—understanding the nuances of this chemical is vital for optimizing production and ensuring compliance with local regulations. Whether you’re in the manufacturing, chemical processing, or cleaning industries, the insights presented here will empower you to navigate the global market effectively.

By exploring various applications of caustic soda flakes and identifying reputable suppliers, this guide serves as a valuable resource for making strategic procurement decisions. Additionally, we will delve into cost factors and negotiation tactics, equipping you with the knowledge needed to secure the best deals without compromising quality. Ultimately, this comprehensive guide is designed to enhance your purchasing strategy, minimize risks, and foster successful international partnerships in the chemical supply chain.

Understanding chemipakhsh net caustic soda flake Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Caustic Soda Flake | High purity (≥ 99%), versatile, commonly used | Soap and detergent manufacturing | Pros: Cost-effective, readily available; Cons: Risk of impurities if sourced from unreliable suppliers |

| Food Grade Caustic Soda Flake | Meets stringent food safety standards | Food processing, pH regulation | Pros: Safe for food applications; Cons: Higher cost due to compliance requirements |

| Industrial Caustic Soda Flake | Tailored for heavy-duty industrial processes | Chemical manufacturing, textiles | Pros: High efficiency for large-scale operations; Cons: May require additional handling precautions |

| Pharmaceutical Grade Caustic Soda Flake | Extremely high purity and stringent quality control | Pharmaceutical production | Pros: Essential for drug formulation; Cons: Limited availability and high price point |

| Reagent Grade Caustic Soda Flake | Ultra-pure, used for analytical purposes | Laboratory applications | Pros: Reliable for precise measurements; Cons: Not suitable for large-scale manufacturing |

What are the Characteristics of Standard Caustic Soda Flake?

Standard caustic soda flakes are known for their high purity, typically exceeding 99%. They are versatile and widely used across various industries, particularly in the production of soaps and detergents. When purchasing, buyers should consider the supplier’s reliability, as impurities can significantly affect product quality. This type is cost-effective, making it a popular choice for many B2B applications, but sourcing from reputable suppliers is crucial to avoid potential quality issues.

How Does Food Grade Caustic Soda Flake Differ from Other Types?

Food grade caustic soda flakes adhere to strict safety standards, making them suitable for food processing and pH regulation. This type is essential in industries where product safety is paramount. Buyers should be aware that the compliance with food safety regulations often results in a higher price point compared to standard options. Additionally, sourcing food grade caustic soda from certified suppliers ensures that the product meets necessary health regulations, which is critical for maintaining consumer trust.

What are the Key Features of Industrial Caustic Soda Flake?

Industrial caustic soda flakes are designed for heavy-duty applications, such as chemical manufacturing and textile production. They offer high efficiency and performance in large-scale operations. Buyers should consider the specific requirements of their processes, including concentration levels and handling precautions, as this type may necessitate additional safety measures due to its potency. While they provide excellent results in industrial applications, the need for careful handling can be a drawback for smaller operations.

Why is Pharmaceutical Grade Caustic Soda Flake Important?

Pharmaceutical grade caustic soda flakes are characterized by their ultra-high purity and stringent quality control measures. They play a crucial role in drug formulation and pharmaceutical production processes. For B2B buyers in the pharmaceutical sector, sourcing this type is essential for compliance with regulatory standards. However, due to its limited availability and higher price, buyers must evaluate their needs carefully and consider long-term supplier relationships to ensure consistent quality and supply.

How is Reagent Grade Caustic Soda Flake Used in Laboratories?

Reagent grade caustic soda flakes are used primarily for analytical purposes in laboratories. They are ultra-pure and provide reliable results for precise measurements. While this grade is not suitable for large-scale manufacturing, it is indispensable for research and development activities. Buyers should focus on the supplier’s certifications and quality assurance processes to ensure they receive a product that meets the necessary analytical standards. The limited application scope and higher costs can be a consideration for those looking for bulk purchases.

Related Video: Caustic Soda Flakes: Overview and Uses

Key Industrial Applications of chemipakhsh net caustic soda flake

| Industry/Sector | Specific Application of chemipakhsh net caustic soda flake | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pulp and Paper | Used in the pulping process to break down lignin | Enhances pulp quality and increases production efficiency | Ensure consistent quality and availability of supply |

| Textile Manufacturing | Serves as a dyeing agent and for fabric treatment | Improves dye uptake and fabric durability | Look for suppliers with reliable logistics and certifications |

| Water Treatment | Acts as a pH regulator in water purification systems | Ensures compliance with environmental regulations | Verify supplier’s adherence to international standards |

| Chemical Manufacturing | Utilized in the production of various chemicals | Facilitates the synthesis of essential industrial chemicals | Assess technical support and product specifications |

| Food Processing | Employed in food processing for pH adjustment | Enhances product safety and shelf life | Confirm food-grade certifications and safety compliance |

How is chemipakhsh net caustic soda flake used in the pulp and paper industry?

In the pulp and paper industry, chemipakhsh net caustic soda flake is critical for the pulping process, where it helps to break down lignin, facilitating the separation of cellulose fibers. This application not only enhances the quality of the pulp produced but also increases production efficiency by enabling faster processing times. International buyers should focus on sourcing from suppliers who guarantee consistent quality and reliable supply chains to maintain uninterrupted production cycles.

What role does chemipakhsh net caustic soda flake play in textile manufacturing?

In textile manufacturing, chemipakhsh net caustic soda flake is used as a dyeing agent and for fabric treatments. It plays a vital role in improving dye uptake, which enhances color vibrancy and fabric durability. For buyers in regions like Africa and South America, it is essential to partner with suppliers who offer reliable logistics and possess the necessary industry certifications to ensure product quality and compliance with local regulations.

Why is chemipakhsh net caustic soda flake important for water treatment?

In water treatment applications, chemipakhsh net caustic soda flake acts as a pH regulator, crucial for maintaining optimal water quality in purification systems. This application ensures compliance with environmental regulations and improves the effectiveness of treatment processes. B2B buyers in the Middle East and Europe should verify that their suppliers adhere to international standards, ensuring that the caustic soda flake meets all necessary regulatory requirements for safety and efficacy.

How does chemipakhsh net caustic soda flake facilitate chemical manufacturing?

In the chemical manufacturing sector, chemipakhsh net caustic soda flake is utilized in the production of various essential chemicals, acting as a key reagent in numerous chemical reactions. This versatility allows manufacturers to streamline their production processes and reduce costs. Buyers should assess suppliers for technical support and detailed product specifications to ensure that the caustic soda flake meets the specific needs of their chemical processes.

What benefits does chemipakhsh net caustic soda flake provide in food processing?

In the food processing industry, chemipakhsh net caustic soda flake is used for pH adjustment, which is crucial for enhancing product safety and extending shelf life. This application is particularly important for ensuring that food products meet safety standards and maintain quality during storage. International buyers must confirm that their suppliers provide food-grade certifications and comply with safety regulations to guarantee the integrity of their food products.

3 Common User Pain Points for ‘chemipakhsh net caustic soda flake’ & Their Solutions

Scenario 1: Inconsistent Quality of Caustic Soda Flakes

The Problem:

International B2B buyers often struggle with sourcing caustic soda flakes that meet their specific quality standards. Inconsistent quality can lead to production delays, increased costs, and even compromised product integrity. Buyers in regions like Africa and South America may encounter challenges in verifying the quality of ‘chemipakhsh net caustic soda flake’ before it reaches their facilities, especially when dealing with multiple suppliers or navigating complex supply chains.

The Solution:

To mitigate quality inconsistencies, buyers should establish stringent quality assurance protocols. First, request comprehensive documentation from suppliers, including certificates of analysis (CoA) that detail the chemical composition and purity of the product. Engaging in a thorough vetting process for suppliers based in regions such as the Middle East or Europe can also help ensure that they adhere to international standards. Additionally, consider implementing a pilot testing phase where a small batch of ‘chemipakhsh net caustic soda flake’ is evaluated in your production process before committing to larger orders. This approach allows buyers to assess the product’s performance in real-world conditions, ensuring that it aligns with their operational needs.

Scenario 2: Difficulty in Sourcing Reliable Suppliers

The Problem:

Finding reliable suppliers for ‘chemipakhsh net caustic soda flake’ can be particularly challenging for B2B buyers, especially in developing markets in Africa and South America. Many businesses face issues with supplier reliability, including delays in shipment, unexpected price changes, and insufficient communication. This uncertainty can disrupt production schedules and impact overall business operations.

The Solution:

To address this pain point, buyers should leverage technology to streamline the sourcing process. Utilizing B2B marketplaces and supplier directories can help identify reputable manufacturers and distributors. Engage in thorough background checks, including reviews and testimonials from previous clients, to gauge supplier reliability. Establishing long-term relationships with a select few suppliers can also foster better communication and transparency. Buyers should negotiate terms that include penalties for delays, ensuring that suppliers are held accountable. Furthermore, consider diversifying your supplier base to mitigate risks, allowing for greater flexibility in sourcing while maintaining competitive pricing.

Scenario 3: Challenges in Proper Handling and Storage

The Problem:

Caustic soda flakes, while highly effective, require specific handling and storage conditions to ensure safety and maintain quality. B2B buyers in industries such as manufacturing or chemical processing often face challenges related to the safe storage and handling of these materials. Mishandling can lead to safety hazards and potential damage to the product, causing financial losses and regulatory compliance issues.

The Solution:

To overcome these challenges, buyers should implement comprehensive training programs for employees involved in the handling and storage of ‘chemipakhsh net caustic soda flake.’ This training should cover safe handling practices, emergency response protocols, and proper storage techniques to minimize risks. Additionally, invest in appropriate storage solutions, such as corrosion-resistant containers and climate-controlled environments, to protect the product from moisture and contamination. Establishing clear labeling and safety signage in storage areas can further enhance safety awareness. Regular audits and reviews of handling procedures can also ensure ongoing compliance with safety regulations and best practices, ultimately protecting both personnel and product integrity.

Strategic Material Selection Guide for chemipakhsh net caustic soda flake

What Are the Key Materials for chemipakhsh net caustic soda flake?

When selecting materials for chemipakhsh net caustic soda flake, it is crucial to consider the properties, advantages, and limitations of various materials. This analysis will focus on four common materials used in the production and application of caustic soda flakes, providing actionable insights for international B2B buyers.

How Do Polyethylene and Polypropylene Compare in Terms of Performance?

Polyethylene (PE) and Polypropylene (PP) are two widely used polymers in the packaging and storage of caustic soda flakes.

- Key Properties: Both materials exhibit excellent chemical resistance, with PE being suitable for temperatures up to 80°C and PP handling slightly higher temperatures, around 100°C. They are also lightweight, making them easy to transport.

- Pros & Cons: PE is generally more cost-effective, while PP offers better durability and strength. However, PE can become brittle at lower temperatures, and PP is more expensive to produce.

- Impact on Application: Both materials are compatible with caustic soda, but their differing temperature ratings may influence storage solutions in hotter climates, particularly in regions like the Middle East and Africa.

- Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding material safety and environmental impact. Standards such as ASTM for the US or EN for Europe should be adhered to.

What Role Does Stainless Steel Play in Storing Caustic Soda Flakes?

Stainless Steel, particularly grades 316 and 304, is another common material for containers and processing equipment for caustic soda flakes.

- Key Properties: Stainless steel offers high corrosion resistance, especially in environments with high caustic concentrations. It can withstand temperatures up to 500°C and pressures of several bar, making it suitable for various industrial applications.

- Pros & Cons: The key advantage of stainless steel is its durability and long lifespan, which can reduce long-term costs. However, it is significantly more expensive than plastic options and may require specialized welding and fabrication techniques.

- Impact on Application: Stainless steel is ideal for high-purity applications where contamination must be minimized, such as in pharmaceuticals or food processing.

- Considerations for International Buyers: Buyers from Europe and South America should verify compliance with standards like DIN and ISO, ensuring that the material meets industry-specific requirements.

How Does Glass Reinforced Plastic (GRP) Enhance Chemical Resistance?

Glass Reinforced Plastic (GRP) is increasingly popular for tanks and piping systems used in caustic soda applications.

- Key Properties: GRP combines the lightweight nature of plastics with the strength of glass fibers, providing excellent chemical resistance and temperature stability up to 120°C.

- Pros & Cons: The primary advantage of GRP is its resistance to corrosion and low maintenance requirements. However, it can be more expensive than traditional plastics and may not be as durable as metals under extreme conditions.

- Impact on Application: GRP is particularly suited for environments where chemical exposure is high, making it ideal for processing plants in Africa and the Middle East.

- Considerations for International Buyers: Compliance with safety standards is crucial, and buyers should look for certifications that reflect local regulations.

What Are the Advantages of Using Carbon Steel in Caustic Soda Applications?

Carbon Steel is often used in the construction of large storage tanks and pipelines for caustic soda.

- Key Properties: Carbon steel is strong and can handle high pressures and temperatures, but it is susceptible to corrosion when exposed to caustic environments.

- Pros & Cons: While carbon steel is cost-effective and widely available, its susceptibility to corrosion means that it often requires protective coatings or linings, increasing maintenance costs.

- Impact on Application: In humid or corrosive environments, carbon steel may not be the best choice without adequate protection, making it less suitable for buyers in tropical regions.

- Considerations for International Buyers: Buyers should ensure that carbon steel products comply with local corrosion resistance standards and consider the implications of maintenance and lifespan.

Summary Table of Material Selection for chemipakhsh net caustic soda flake

| Material | Typical Use Case for chemipakhsh net caustic soda flake | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene (PE) | Packaging and storage containers | Cost-effective | Brittle at low temperatures | Low |

| Polypropylene (PP) | Durable storage solutions | Better durability | Higher production cost | Med |

| Stainless Steel | High-purity processing equipment | Long lifespan | High initial cost | High |

| Glass Reinforced Plastic (GRP) | Tanks and piping systems | Excellent chemical resistance | Higher cost than traditional plastics | Med |

| Carbon Steel | Large storage tanks and pipelines | Cost-effective | Susceptible to corrosion | Low |

This guide aims to equip international B2B buyers with the essential knowledge needed to make informed decisions regarding material selection for chemipakhsh net caustic soda flakes, ensuring compliance with local standards and optimizing performance for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for chemipakhsh net caustic soda flake

What Are the Main Stages in the Manufacturing Process of Chemipakhsh Net Caustic Soda Flake?

The manufacturing process of Chemipakhsh net caustic soda flake involves several critical stages, each designed to ensure the production of high-quality caustic soda that meets international standards. The key stages include:

-

Material Preparation: This initial stage involves sourcing raw materials, primarily sodium chloride and water. Purity is crucial; thus, suppliers must ensure that the salt is free from impurities that could affect the final product’s quality. Advanced filtration and purification techniques are often employed to achieve this.

-

Electrolysis: The heart of caustic soda production lies in the electrolysis of brine (saltwater). This process separates sodium ions from chloride ions, producing chlorine gas and sodium hydroxide. The method used—such as membrane cell, diaphragm cell, or mercury cell—can significantly affect the purity and properties of the caustic soda produced. Each method has its advantages, and buyers should understand which is employed to gauge the product’s suitability for their applications.

-

Concentration and Crystallization: After electrolysis, the sodium hydroxide solution undergoes concentration to reach desired specifications. This is typically done through evaporation processes. Following concentration, the caustic soda is crystallized and then cooled to form flakes. The control of temperature and humidity during this stage is vital to prevent clumping and ensure uniform flake size.

-

Drying and Packaging: The final stage involves drying the flakes to remove any remaining moisture, which can affect shelf-life and usability. The dried caustic soda flakes are then packaged in moisture-proof bags or containers to ensure they remain stable during storage and transport. Packaging methods may vary, and buyers should inquire about the packaging practices to ensure they meet local regulations and standards.

How Is Quality Assurance Implemented in the Production of Chemipakhsh Net Caustic Soda Flake?

Quality assurance (QA) is integral to the production of caustic soda flakes, ensuring that the product meets both international and industry-specific standards. Key aspects of the QA process include:

-

International Standards Compliance: Manufacturers often adhere to ISO 9001, which outlines a framework for quality management systems. This certification demonstrates a commitment to consistent quality and continual improvement. For B2B buyers, verifying this certification can provide confidence in the supplier’s processes.

-

Industry-Specific Certifications: In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may apply, depending on the intended use of the caustic soda. These certifications indicate that the product meets specific safety and performance criteria relevant to various industries.

-

Quality Control Checkpoints: The QA process includes several checkpoints:

– Incoming Quality Control (IQC): Raw materials are tested upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Continuous monitoring during production helps identify any deviations from standards.

– Final Quality Control (FQC): The finished product undergoes rigorous testing for purity, flake size, and moisture content before packaging. -

Common Testing Methods: Various analytical methods are employed to assess the quality of caustic soda flakes. These may include titration for concentration, spectrophotometry for impurities, and moisture analysis using Karl Fischer titration. Buyers should request detailed testing reports to verify compliance with quality standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is crucial. Here are some actionable steps:

-

Conduct Audits: Regular supplier audits can provide insights into their manufacturing processes and quality assurance practices. Buyers should establish a schedule for audits and communicate expectations clearly to suppliers.

-

Request Documentation: Suppliers should provide comprehensive documentation, including quality control reports, certifications, and product specifications. This transparency allows buyers to assess compliance with industry standards and their own quality requirements.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes. These inspectors can verify that products meet the required specifications before shipment.

-

Understand Certification Nuances: Different regions may have varying requirements for certifications. For instance, while ISO 9001 is widely recognized, specific industries may require additional certifications like REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in Europe. Understanding these nuances can help buyers make informed decisions.

What Challenges Do International B2B Buyers Face Regarding Quality Assurance?

International B2B buyers face several challenges when it comes to ensuring quality in the procurement of caustic soda flakes:

-

Regulatory Variations: Different countries may have distinct regulations regarding chemical imports. Buyers must stay informed about these regulations to ensure compliance, which can be a complex and time-consuming process.

-

Cultural Differences: Variations in business practices and communication styles across cultures can lead to misunderstandings regarding quality expectations. Establishing clear lines of communication and setting mutual expectations can mitigate these issues.

-

Logistics and Supply Chain Risks: The transportation of chemical products can introduce risks related to quality degradation. Buyers should consider the entire supply chain, from production to delivery, and ensure that suppliers have robust logistics practices to protect product integrity.

-

Technological Advancements: As manufacturing technology evolves, suppliers may adopt new processes that could impact product quality. Buyers should stay updated on industry trends and advancements to assess whether their suppliers are keeping pace with best practices.

By understanding the manufacturing processes and quality assurance protocols associated with Chemipakhsh net caustic soda flake, B2B buyers can make informed decisions that align with their operational needs and quality standards. Engaging actively with suppliers and leveraging quality assurance practices will enhance supply chain reliability and product performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘chemipakhsh net caustic soda flake’

Introduction

Sourcing Chemipakhsh net caustic soda flake requires careful consideration of technical specifications, supplier reliability, and regulatory compliance. This guide provides a structured checklist to help international B2B buyers streamline their procurement process, ensuring that they make informed decisions that align with their operational needs and compliance requirements.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the product meets your operational requirements. Consider the purity level, moisture content, and flake size that are optimal for your processes. Additionally, specify any industry standards that the product must meet, such as ISO or ASTM certifications.

- Purity Level: Determine the acceptable range of impurities based on your application.

- Moisture Content: Specify the maximum moisture percentage to avoid operational disruptions.

Step 2: Conduct Market Research

Before engaging suppliers, conduct thorough market research to understand pricing trends, availability, and potential suppliers in your region. This will help you set realistic budget expectations and identify competitive offers.

- Price Trends: Analyze historical price data to gauge market fluctuations.

- Supplier Availability: Identify reliable suppliers from Africa, South America, the Middle East, and Europe who can consistently meet your demand.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; a comprehensive evaluation can reveal their reliability and reputation.

- Company Profile: Look for details about their operational history and market presence.

- References: Ask for testimonials from existing clients to understand their experience with the supplier.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers possess the necessary certifications and compliance documents. This step is essential to mitigate risks associated with quality and regulatory compliance.

- Quality Certifications: Confirm that suppliers hold relevant certifications, such as ISO 9001 or specific industry certifications.

- Safety Standards: Check for compliance with environmental and safety regulations pertinent to caustic soda production.

Step 5: Request Samples for Testing

Before finalizing your order, request samples of the caustic soda flakes for quality testing. This allows you to assess the product’s performance in your specific applications.

- Testing Criteria: Evaluate the samples based on your defined technical specifications.

- Performance Evaluation: Conduct tests to ensure that the product meets your operational needs without compromising quality.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations regarding pricing, delivery timelines, payment terms, and warranty policies. Clear agreements can prevent misunderstandings and ensure smooth transactions.

- Pricing Structure: Discuss bulk purchase discounts and payment options.

- Delivery Terms: Clarify shipping responsibilities and timelines to avoid delays.

Step 7: Establish a Long-term Relationship

After successful procurement, focus on building a long-term relationship with your supplier. This can lead to better pricing, priority service, and insights into future product innovations.

- Regular Communication: Schedule periodic meetings to discuss performance and expectations.

- Feedback Loop: Provide constructive feedback to help the supplier improve their offerings.

By following this checklist, B2B buyers can effectively navigate the sourcing process for Chemipakhsh net caustic soda flakes, ensuring they secure the best product for their needs while mitigating risks associated with procurement.

Comprehensive Cost and Pricing Analysis for chemipakhsh net caustic soda flake Sourcing

What are the Key Cost Components in Sourcing Chemipakhsh Net Caustic Soda Flake?

When analyzing the cost structure for sourcing Chemipakhsh net caustic soda flakes, several key components must be considered. The primary cost components include:

-

Materials: The price of raw materials significantly influences the final cost of caustic soda flakes. Fluctuations in the price of sodium hydroxide and other chemicals used in production can lead to variations in pricing.

-

Labor: Labor costs encompass wages, benefits, and training for employees involved in the manufacturing process. Regions with lower labor costs may offer more competitive pricing.

-

Manufacturing Overhead: This includes indirect costs such as utilities, maintenance, and administrative expenses. Efficient production processes can help minimize these costs.

-

Tooling: Investment in specialized equipment for the production of caustic soda flakes can impact overall costs. Buyers should inquire about the supplier’s tooling capabilities and any associated costs.

-

Quality Control (QC): Ensuring high-quality standards often requires rigorous testing and inspection processes, which can add to the cost. Certifications for quality standards may also affect pricing.

-

Logistics: Transportation and storage costs are crucial in determining the total cost of ownership. Buyers should consider the distance from the supplier and the efficiency of the logistics network.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market conditions and competition can help buyers negotiate better terms.

How Do Price Influencers Affect Chemipakhsh Net Caustic Soda Flake Costs?

Several factors can influence the pricing of Chemipakhsh net caustic soda flakes, including:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to lower per-unit costs. Negotiating favorable terms based on order volume can significantly reduce expenses.

-

Specifications and Customization: Customized products tailored to specific requirements can incur additional charges. Buyers should clearly communicate their needs to avoid unexpected costs.

-

Materials and Quality Certifications: Higher quality materials and certifications (like ISO or REACH compliance) may increase costs but can enhance product reliability and safety.

-

Supplier Factors: The supplier’s reputation, experience, and location can impact pricing. Established suppliers with a track record of reliability may charge a premium.

-

Incoterms: Understanding the International Commercial Terms (Incoterms) is essential as they dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect total costs.

What Negotiation Strategies Can Help in Sourcing Caustic Soda Flakes?

Effective negotiation is crucial for securing the best pricing and terms when sourcing Chemipakhsh net caustic soda flakes. Here are some actionable tips:

-

Research Market Prices: Familiarize yourself with current market prices to establish a baseline for negotiations. This knowledge empowers buyers to negotiate effectively.

-

Leverage Volume Discounts: If your business can commit to larger orders, use this leverage to negotiate better pricing and terms.

-

Build Relationships with Suppliers: Long-term relationships can lead to better pricing, priority service, and favorable payment terms. Consider establishing partnerships rather than one-off transactions.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also logistics, storage, and quality assurance costs. A lower initial price may not always equate to better value.

-

Explore Alternative Suppliers: Don’t hesitate to explore multiple suppliers. This competitive approach can lead to better offers and insights into industry pricing trends.

What Should International Buyers Consider Regarding Pricing Nuances?

International buyers, especially from Africa, South America, the Middle East, and Europe, should be aware of specific pricing nuances:

-

Currency Fluctuations: Exchange rate volatility can impact pricing and should be factored into budgeting.

-

Import Duties and Tariffs: Understand the tariffs applicable to caustic soda flakes in your region. These can add to the overall cost and should be included in the TCO analysis.

-

Shipping and Handling Fees: International shipping can introduce additional costs. Ensure that you account for these when negotiating with suppliers.

-

Cultural Considerations: Different regions may have varying negotiation styles and expectations. Adapting your approach can foster better relationships and outcomes.

Disclaimer on Pricing

Prices for Chemipakhsh net caustic soda flakes are subject to fluctuation based on market conditions, raw material costs, and supplier pricing strategies. It is advisable for buyers to conduct thorough market research and seek multiple quotations to ensure competitive pricing.

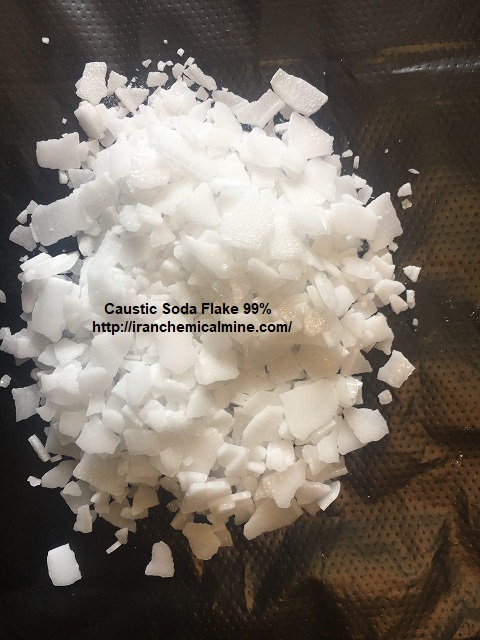

A stock image related to chemipakhsh net caustic soda flake.

Alternatives Analysis: Comparing chemipakhsh net caustic soda flake With Other Solutions

Introduction: Why Consider Alternatives to Chemipakhsh Net Caustic Soda Flake?

In the competitive landscape of industrial chemicals, B2B buyers often seek to optimize their procurement strategies by exploring various alternatives to established products like Chemipakhsh Net Caustic Soda Flake. Understanding these alternatives allows buyers to make informed decisions based on performance, cost, and application suitability. This analysis aims to compare Chemipakhsh Net Caustic Soda Flake with other viable solutions, helping international buyers from Africa, South America, the Middle East, and Europe identify the best fit for their needs.

| Comparison Aspect | Chemipakhsh Net Caustic Soda Flake | Alternative 1: Sodium Hydroxide Pellets | Alternative 2: Liquid Caustic Soda |

|---|---|---|---|

| Performance | High purity and consistent quality | Similar purity, slower dissolution | High reactivity, easy to use |

| Cost | Competitive pricing | Generally lower cost | Higher transport costs |

| Ease of Implementation | Requires special handling | Simple to handle | Requires careful storage |

| Maintenance | Minimal maintenance | Low maintenance needs | Higher maintenance due to corrosion |

| Best Use Case | Industrial cleaning, chemical synthesis | Laboratory applications, small-scale use | Large-scale industrial processes |

What Are the Advantages and Disadvantages of Sodium Hydroxide Pellets?

Sodium hydroxide pellets are a popular alternative due to their lower cost and ease of handling. They are often used in laboratory settings and for smaller-scale applications where precise measurements are necessary. However, their slower dissolution rate can pose challenges in processes requiring rapid reactions. Additionally, while they share similar purity levels, the consistency and performance of Chemipakhsh Net Caustic Soda Flake may be superior in more demanding industrial applications.

How Does Liquid Caustic Soda Compare?

Liquid caustic soda is favored in large-scale industrial processes due to its high reactivity and ease of use. It dissolves quickly, making it suitable for applications requiring immediate results. However, the transport costs associated with liquid forms can significantly increase overall expenses, especially for international buyers. Moreover, it necessitates careful storage to prevent corrosion and ensure safety, which can complicate logistics compared to the more stable Chemipakhsh Net Caustic Soda Flake.

Conclusion: How Can B2B Buyers Make the Right Choice?

When selecting the appropriate chemical solution, B2B buyers should assess their specific requirements, including application type, budget constraints, and handling capabilities. Chemipakhsh Net Caustic Soda Flake excels in consistency and performance, making it ideal for demanding industrial applications. However, alternatives like sodium hydroxide pellets and liquid caustic soda may offer cost benefits or operational advantages depending on the context. By carefully weighing these factors, international buyers can optimize their procurement strategies to achieve both efficiency and cost-effectiveness in their operations.

Essential Technical Properties and Trade Terminology for chemipakhsh net caustic soda flake

What Are the Key Technical Properties of Chemipakhsh Net Caustic Soda Flake?

A stock image related to chemipakhsh net caustic soda flake.

Understanding the essential technical properties of Chemipakhsh net caustic soda flake is crucial for B2B buyers, particularly those in industries such as chemicals, textiles, and food processing. Here are several critical specifications to consider:

1. Material Grade

Material grade refers to the purity level of the caustic soda flake. Chemipakhsh net caustic soda typically boasts a purity of 99% or higher, which is essential for industrial applications requiring stringent quality standards. A higher grade means fewer impurities, resulting in better performance and fewer complications during manufacturing processes.

2. Bulk Density

Bulk density measures the mass of caustic soda flake per unit volume, typically expressed in kilograms per cubic meter (kg/m³). For Chemipakhsh products, bulk density generally ranges from 400 to 600 kg/m³. This property is crucial for logistics and shipping, as it affects storage requirements and transportation costs. Buyers should ensure that the bulk density aligns with their storage capabilities and handling equipment.

3. Moisture Content

Moisture content indicates the percentage of water present in the caustic soda flake. Ideally, this should be less than 1% for optimal performance. Excess moisture can lead to clumping and reduced efficacy in chemical reactions. For international buyers, especially in humid climates, understanding moisture content is vital to avoid degradation during storage and transit.

4. Solubility

Solubility defines how readily caustic soda dissolves in water, impacting its effectiveness in various applications. Chemipakhsh caustic soda flake is highly soluble, making it suitable for processes requiring rapid dissolution. This property is particularly important for industries that rely on quick chemical reactions, such as pulp and paper manufacturing.

5. Particle Size Distribution

The particle size distribution of caustic soda flake affects its dissolution rate and handling characteristics. Chemipakhsh caustic soda typically has a consistent flake size, which enhances uniformity in applications. Buyers should consider how particle size influences their specific processes, as finer flakes dissolve more rapidly but may be more challenging to handle.

What Are Common Trade Terms in the Caustic Soda Industry?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are several important trade terms relevant to Chemipakhsh net caustic soda flake:

1. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of product that a supplier is willing to sell. For caustic soda flake, MOQs can vary based on supplier policies and market demand. Understanding the MOQ is essential for international buyers to manage inventory effectively and ensure cost-efficiency in procurement.

2. OEM (Original Equipment Manufacturer)

OEM denotes a company that produces products or components that are marketed by another company. In the context of caustic soda, buyers may seek OEM partnerships for customized formulations or private labeling. Knowing the OEM landscape can open doors to tailored solutions that meet specific business needs.

3. RFQ (Request for Quotation)

An RFQ is a document soliciting price quotes from suppliers for specific quantities and specifications of products. Issuing an RFQ for Chemipakhsh caustic soda flake allows buyers to compare offers and negotiate better terms. Crafting a detailed RFQ can lead to advantageous pricing and improved supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized terms that define the responsibilities of buyers and sellers in global trade. They clarify who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for international B2B transactions to minimize misunderstandings and ensure clear agreements.

5. Lead Time

Lead time refers to the time taken from placing an order to its delivery. Understanding lead times for Chemipakhsh caustic soda flake is critical for supply chain management. Buyers should factor lead times into their production schedules to avoid delays and ensure timely project completion.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, streamline procurement processes, and foster stronger supplier relationships in the caustic soda market.

Navigating Market Dynamics and Sourcing Trends in the chemipakhsh net caustic soda flake Sector

What Are the Key Market Dynamics Affecting the Chemipakhsh Net Caustic Soda Flake Sector?

The chemipakhsh net caustic soda flake market is significantly influenced by global economic conditions and evolving industrial demands. Key drivers include the rising need for caustic soda in diverse applications such as textiles, paper, and aluminum production. The demand for high-purity caustic soda flakes is particularly prominent among manufacturers seeking to meet stringent quality standards. Furthermore, fluctuations in raw material prices, particularly for sodium carbonate and sodium hydroxide, can impact pricing strategies, making it essential for international B2B buyers to stay informed about market trends and forecasts.

Emerging B2B technologies are reshaping sourcing practices within the chemipakhsh net caustic soda flake sector. Digital procurement platforms and supply chain management tools enable buyers to access real-time data on inventory levels and pricing, facilitating more informed purchasing decisions. Additionally, the integration of AI and machine learning in supply chain analytics is enhancing demand forecasting and inventory optimization. Buyers from Africa, South America, the Middle East, and Europe must leverage these technologies to improve sourcing efficiency and reduce lead times.

How Do Sustainability and Ethical Sourcing Influence the Caustic Soda Flake Market?

Sustainability is becoming increasingly critical for B2B buyers in the chemipakhsh net caustic soda flake sector. The environmental impact of caustic soda production—particularly its contribution to water and air pollution—has prompted a shift towards more sustainable practices. Buyers are now prioritizing suppliers who demonstrate a commitment to minimizing their ecological footprint through cleaner production methods and waste reduction strategies.

Ethical sourcing is another vital aspect for international buyers. Companies are increasingly seeking suppliers with transparent supply chains that adhere to ethical labor practices and regulatory compliance. Certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) are becoming essential criteria in supplier evaluations. By aligning with suppliers who prioritize sustainability and ethical practices, B2B buyers can enhance their brand reputation and meet the growing consumer demand for environmentally responsible products.

What Is the Historical Context of the Chemipakhsh Net Caustic Soda Flake Sector?

The chemipakhsh net caustic soda flake sector has evolved significantly over the past few decades, driven by industrial advancements and regulatory changes. Historically, caustic soda was primarily produced through the electrolysis of brine, a method that remains prevalent today. However, the sector has witnessed a shift toward more environmentally friendly production processes, influenced by rising regulatory pressures and sustainability initiatives.

In recent years, the market has expanded due to increased demand from emerging economies, particularly in Africa and South America. This growth has prompted suppliers to innovate and enhance their production capabilities, ultimately leading to a more competitive landscape. For B2B buyers, understanding this evolution provides crucial context for current market dynamics and sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of chemipakhsh net caustic soda flake

-

How do I ensure the quality of chemipakhsh net caustic soda flakes before purchasing?

To guarantee the quality of caustic soda flakes, request a Certificate of Analysis (CoA) from the supplier. This document provides detailed information on the product’s chemical composition and purity levels. Additionally, consider conducting third-party lab tests to validate the supplier’s claims. Establishing a clear quality assurance process and aligning on specifications before the transaction can mitigate risks associated with inferior products. -

What are the typical minimum order quantities (MOQ) for chemipakhsh net caustic soda flakes?

Minimum order quantities can vary based on the supplier’s policies and your specific requirements. Generally, for caustic soda flakes, MOQs may range from 1 to 5 tons. It’s advisable to discuss your needs with potential suppliers to negotiate favorable terms that align with your procurement strategy. Understanding the MOQ can also help in managing inventory and optimizing shipping costs. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms in international trade can differ widely but commonly include options such as letter of credit (LC), advance payment, or open account terms. For initial transactions, suppliers may prefer advance payments or LCs to mitigate risks. Clarifying payment conditions upfront and ensuring they are documented in your purchase agreement can help in maintaining smooth financial transactions. -

How can I vet suppliers of chemipakhsh net caustic soda flakes effectively?

To vet suppliers, start by researching their business history, customer reviews, and industry certifications. Request references from other businesses that have purchased from them. Additionally, consider visiting their facilities if feasible or utilizing third-party inspection services. Engaging in thorough due diligence will help ensure you partner with a reliable supplier that meets your quality and service expectations. -

What logistics considerations should I keep in mind when importing caustic soda flakes?

When importing caustic soda flakes, consider transportation methods, customs regulations, and potential duties or tariffs. Collaborate with a freight forwarder experienced in handling chemical products to navigate these complexities effectively. Ensure that the supplier provides appropriate packaging to comply with safety standards during transit. Understanding lead times and delivery schedules will also help in planning your supply chain efficiently. -

Can I customize the specifications of chemipakhsh net caustic soda flakes for my business needs?

Many suppliers are open to customization based on your specific requirements, such as purity levels or packaging options. Discuss your needs clearly with the supplier to determine what modifications are feasible. Customization can enhance product performance in your applications, but be mindful of potential impacts on pricing and lead times. Ensure that any agreed-upon specifications are documented in your contract. -

What are the common applications for chemipakhsh net caustic soda flakes in various industries?

Chemipakhsh net caustic soda flakes are widely used in industries such as chemical manufacturing, textiles, and food processing. They serve as a strong alkali for pH adjustment, a cleaning agent, and a raw material in producing soaps and detergents. Understanding these applications can help you identify how the product fits into your processes and inform your purchasing decisions. -

What regulatory compliance should I consider when sourcing caustic soda flakes internationally?

When importing caustic soda flakes, ensure compliance with both local and international regulations regarding chemical handling and safety. Familiarize yourself with the regulations set forth by entities such as the REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) in Europe or local environmental agencies. Proper documentation, including Safety Data Sheets (SDS), is essential to demonstrate compliance and ensure safe handling in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for chemipakhsh net caustic soda flake

In navigating the complexities of sourcing chemipakhsh net caustic soda flakes, international B2B buyers must prioritize strategic partnerships and robust supply chain management. Understanding local market dynamics in regions such as Africa, South America, the Middle East, and Europe is crucial for mitigating risks and optimizing procurement processes. Buyers should leverage insights into production capabilities and market trends to secure favorable pricing and ensure product quality.

What are the long-term benefits of strategic sourcing for caustic soda flakes? By establishing strong relationships with suppliers, companies can enhance their negotiation power and achieve better alignment with their operational needs. Moreover, diversifying supply sources can protect against market volatility, ensuring consistent availability of this critical chemical.

As the global demand for caustic soda continues to rise, it is essential for international buyers to stay informed about emerging market trends and regulatory changes. Engaging in proactive sourcing strategies will not only enhance operational efficiency but also contribute to sustainable growth.

In conclusion, seize the opportunity to refine your sourcing strategy for chemipakhsh net caustic soda flakes today. By doing so, you position your business for success in an increasingly competitive landscape.