The Ultimate Guide to Honeycomb For Lights (2025)

Introduction: Navigating the Global Market for honeycomb for lights

Navigating the global market for honeycomb for lights presents unique challenges for international B2B buyers, particularly those hailing from Africa, South America, the Middle East, and Europe. As demand for high-quality lighting solutions rises, sourcing the right honeycomb materials that ensure optimal light diffusion and aesthetics becomes crucial. This guide serves as a comprehensive resource, detailing the various types of honeycomb structures available, their applications across different industries, and key considerations for supplier vetting.

Understanding the nuances of honeycomb technology is essential for making informed purchasing decisions. Buyers will find insights into the latest advancements in honeycomb materials, cost considerations, and the impact of regional regulations on sourcing. This knowledge empowers businesses to not only select the best products but also negotiate favorable terms with suppliers.

Moreover, the guide emphasizes the importance of quality assurance and sustainable practices in the procurement process. By focusing on these aspects, international B2B buyers can enhance their competitive edge and align their sourcing strategies with global standards. Whether you’re in the lighting industry or related fields, this guide is designed to equip you with the insights necessary to navigate the complexities of the honeycomb market effectively.

Understanding honeycomb for lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hexagonal Honeycomb | Standard pattern, excellent light diffusion | Photography, Film Production | Pros: Effective light control; Cons: Limited color options. |

| Square Honeycomb | Compact design, versatile for various fixtures | Retail Displays, Exhibitions | Pros: Space-efficient; Cons: May not diffuse light as effectively. |

| Circular Honeycomb | Round shape, ideal for soft light effects | Stage Lighting, Event Venues | Pros: Creates a soft lighting effect; Cons: Limited to specific fixtures. |

| Adjustable Honeycomb | Customizable aperture sizes for light intensity | Architectural Lighting | Pros: Flexibility in light control; Cons: Higher cost. |

| Color Filter Honeycomb | Integrated color filters for colored lighting | Theatrical Productions | Pros: Enhanced creativity; Cons: Filters may require replacement. |

What Are the Characteristics of Hexagonal Honeycomb?

Hexagonal honeycomb is the most common type, characterized by its six-sided cells that provide excellent light diffusion. This type is particularly suitable for photography and film production, where controlled lighting is critical. B2B buyers should consider the specific light output and diffusion qualities required for their projects, as hexagonal honeycombs are known for their effective light control but may have limited color options.

How Does Square Honeycomb Differ From Other Types?

Square honeycomb features a compact design, making it versatile for various lighting fixtures. It is widely used in retail displays and exhibitions, where space efficiency is crucial. Buyers should weigh the benefits of its compactness against the potential downside of less effective light diffusion compared to hexagonal options. This type is ideal for applications where direct lighting is preferred.

In What Situations is Circular Honeycomb Most Effective?

Circular honeycomb is designed for fixtures that require soft light effects, making it popular in stage lighting and event venues. Its round shape allows for more uniform light distribution, which can enhance the ambiance of a setting. B2B buyers should consider whether their lighting needs demand a softer touch, as this type may not be as versatile in terms of fixture compatibility.

Why Choose Adjustable Honeycomb for Lighting Solutions?

Adjustable honeycomb offers customizable aperture sizes, allowing users to control light intensity more effectively. This type is particularly beneficial in architectural lighting, where varying light levels may be necessary. While the flexibility is a significant advantage, buyers should note that adjustable honeycombs typically come at a higher cost, which may impact budget considerations.

What Are the Benefits of Color Filter Honeycomb?

Color filter honeycombs integrate color filters directly into the design, enabling users to create colored lighting effects. This type is especially popular in theatrical productions, where creative lighting plays a crucial role. B2B buyers should be aware of the ongoing maintenance required, as filters may need to be replaced periodically, impacting long-term costs and planning.

Related Video: THREE WAYS TO INSTALL LIGHTS ON AN OUTDOOR TREE

Key Industrial Applications of honeycomb for lights

| Industry/Sector | Specific Application of honeycomb for lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Honeycomb light diffusers in vehicle interiors | Enhanced aesthetic appeal and uniform lighting | Durability, heat resistance, and compliance with safety standards |

| Aerospace | Honeycomb structures for aircraft lighting | Weight reduction and improved energy efficiency | Certification for aviation use and material specifications |

| Architectural Lighting | Honeycomb panels for ambient lighting | Energy savings and improved light distribution | Customization options and compatibility with existing fixtures |

| Film and Television Production | Honeycomb grids for stage and set lighting | Precise light control and reduced glare | Flexibility in sizes and adaptability to different lighting setups |

| Industrial Facilities | Honeycomb filters for factory lighting | Improved visibility and reduced energy consumption | Compliance with industrial safety regulations and maintenance requirements |

How is Honeycomb Used in Automotive Lighting Applications?

In the automotive industry, honeycomb light diffusers are employed in vehicle interiors to create a more aesthetically pleasing environment. These diffusers help in achieving uniform lighting, which enhances the overall passenger experience. For B2B buyers, sourcing honeycomb products for automotive applications requires an understanding of durability and heat resistance, as these components must withstand varying temperatures and conditions within a vehicle. Compliance with safety standards is also crucial, especially in regions with stringent automotive regulations.

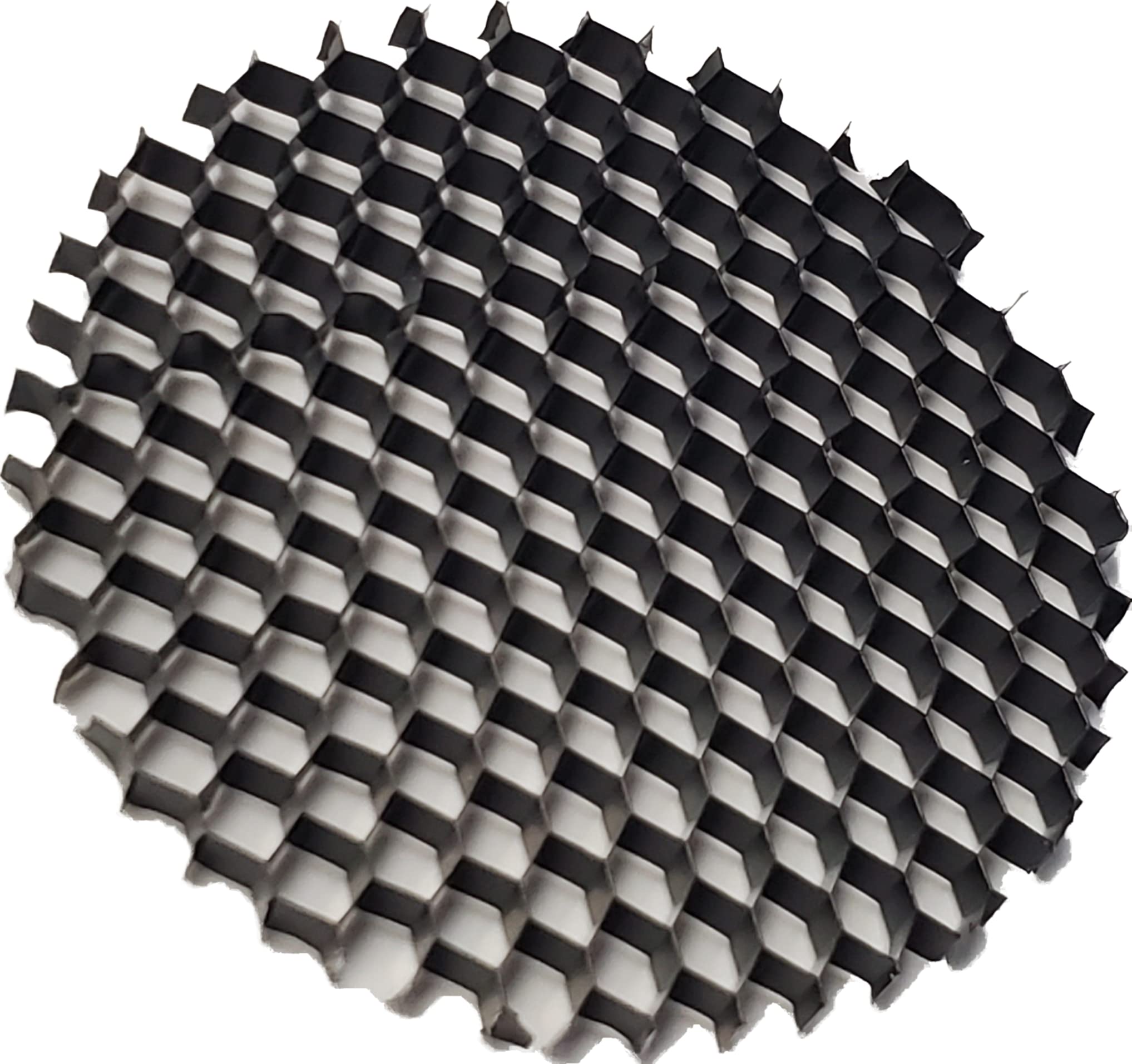

A stock image related to honeycomb for lights.

What Role Does Honeycomb Play in Aerospace Lighting Solutions?

In aerospace, honeycomb structures are utilized in aircraft lighting systems to reduce weight and improve energy efficiency. The lightweight nature of honeycomb materials allows for significant fuel savings, which is a critical factor for airlines looking to reduce operational costs. Buyers in this sector must consider certification for aviation use, as well as specific material specifications that meet industry standards, particularly in regions like Europe and the Middle East where regulations can be stringent.

How Does Honeycomb Enhance Architectural Lighting Designs?

Honeycomb panels are increasingly used in architectural lighting to create ambient lighting solutions that are both functional and visually appealing. These panels can diffuse light effectively, reducing harsh glare while enhancing energy savings. For international B2B buyers, customization options are vital, as they may need to integrate these panels into existing lighting fixtures. Compatibility with various lighting technologies is also a key consideration, especially in diverse markets across Africa and South America.

What Advantages Do Honeycomb Grids Offer in Film and Television Production?

A stock image related to honeycomb for lights.

In the film and television production industry, honeycomb grids are essential for stage and set lighting, providing precise control over light distribution and reducing glare. This is particularly important in settings where lighting plays a crucial role in visual storytelling. B2B buyers should look for flexibility in sizes and adaptability to various lighting setups to ensure that they can meet the specific needs of different productions, especially in the dynamic environments found in South America and Europe.

How Do Honeycomb Filters Improve Lighting in Industrial Facilities?

Honeycomb filters are used in industrial facilities to enhance visibility and reduce energy consumption in factory lighting. By improving light distribution, these filters help create a safer working environment, which is critical in industries with high safety standards. Buyers in this sector need to ensure that the products comply with industrial safety regulations and consider maintenance requirements to minimize downtime, particularly in regions with rigorous operational standards such as the Middle East and Europe.

Related Video: Thermoplastic Honeycomb Composite Panel

3 Common User Pain Points for ‘honeycomb for lights’ & Their Solutions

Scenario 1: Challenges in Light Diffusion Control for Events

The Problem: B2B buyers in the event planning industry often struggle with achieving optimal light diffusion using honeycomb grids. These grids are essential for controlling light spill and creating the desired ambiance, but they can sometimes lead to uneven lighting or insufficient diffusion, especially in large venues. This inconsistency not only affects the aesthetics of the event but can also impact the overall experience for attendees, leading to dissatisfaction and negative feedback.

The Solution: To address this issue, buyers should carefully assess the specifications of the honeycomb grids they are sourcing. Opt for honeycomb grids with adjustable cell sizes; this feature allows for greater flexibility in light diffusion. Additionally, it is crucial to conduct pre-event tests using different setups to determine the most effective grid configuration. Investing in a variety of honeycomb grids can enable event planners to customize their lighting solutions based on the specific requirements of each venue, ensuring consistent and pleasing results. Collaborating with experienced lighting designers can also provide valuable insights and recommendations tailored to each event’s unique needs.

Scenario 2: Compatibility Issues with Existing Lighting Equipment

The Problem: Many B2B buyers face compatibility issues when integrating honeycomb grids with their existing lighting systems. This can occur when the dimensions or mounting methods of the grids do not align with the specifications of their lights, leading to inefficient setups and wasted resources. Such challenges can result in delays in project timelines and increased costs as buyers are forced to invest in new equipment or make modifications.

The Solution: To mitigate these compatibility issues, buyers should engage in thorough research before purchasing honeycomb grids. They should evaluate the dimensions, mounting styles, and material compatibility of the grids in relation to their existing lighting fixtures. When selecting honeycomb grids, opting for modular designs can provide added versatility and ease of integration. Additionally, consulting with manufacturers or suppliers who offer customization options can ensure that the grids fit seamlessly with current equipment. Establishing a clear communication channel with suppliers can also facilitate obtaining detailed product specifications and installation guidance.

Scenario 3: Durability and Maintenance Concerns in Harsh Environments

The Problem: Buyers in industries such as film production or outdoor events frequently encounter issues with the durability of honeycomb grids, particularly in harsh environments. Exposure to elements like moisture, extreme temperatures, or heavy usage can lead to wear and tear, diminishing the effectiveness of the grids and necessitating frequent replacements. This not only impacts the budget but can also disrupt project schedules and overall operational efficiency.

The Solution: To combat durability concerns, B2B buyers should prioritize sourcing honeycomb grids made from robust, weather-resistant materials suitable for their specific environment. Look for grids that are treated to withstand moisture and extreme temperatures. Regular maintenance routines, including cleaning and inspection, can prolong the lifespan of the grids. Additionally, consider investing in protective cases for transport and storage, which can safeguard the grids from damage. Collaborating with suppliers who specialize in durable lighting solutions can provide buyers with options that are specifically designed for demanding conditions, ensuring long-term reliability and performance.

Strategic Material Selection Guide for honeycomb for lights

When selecting materials for honeycomb structures used in lighting applications, international B2B buyers must consider various factors, including performance characteristics, cost implications, and compliance with regional standards. Below, we analyze four common materials used in honeycomb designs, highlighting their properties, advantages, disadvantages, and specific considerations for buyers in Africa, South America, the Middle East, and Europe.

What are the Key Properties of Aluminum Honeycomb for Lights?

Aluminum honeycomb is a popular choice due to its lightweight nature and strength. It typically has a high-temperature rating, making it suitable for applications exposed to heat. Aluminum also offers excellent corrosion resistance, which is essential for outdoor lighting fixtures.

Pros: Aluminum honeycomb is durable, lightweight, and easy to manufacture, making it suitable for a variety of lighting designs. Its recyclability is an added advantage, appealing to environmentally conscious buyers.

Cons: The initial cost can be higher than other materials, and it may require additional treatments to enhance corrosion resistance in harsh environments.

Impact on Application: Aluminum honeycomb is compatible with various media, including LED lighting systems, and can withstand high temperatures without deforming.

Considerations for International Buyers: Compliance with ASTM and DIN standards is crucial, particularly for buyers in Europe and the Middle East. Buyers should also consider the availability of aluminum in local markets to avoid supply chain disruptions.

How Does Polycarbonate Honeycomb Compare for Lighting Applications?

Polycarbonate honeycomb is increasingly used for its impact resistance and lightweight properties. It has a moderate temperature rating, making it suitable for indoor lighting applications.

Pros: This material is highly durable and offers excellent thermal insulation, which can enhance energy efficiency in lighting applications.

Cons: Polycarbonate may not withstand high temperatures as well as aluminum, limiting its use in high-heat environments. It is also more prone to scratching, which can affect aesthetic appeal.

Impact on Application: Polycarbonate honeycomb is compatible with various lighting technologies, including fluorescent and LED. Its transparency allows for effective light diffusion.

Considerations for International Buyers: Buyers should ensure that polycarbonate products meet local safety standards, particularly in regions with stringent regulations like Europe.

What are the Benefits and Limitations of Steel Honeycomb for Lights?

Steel honeycomb structures offer exceptional strength and durability, making them suitable for heavy-duty lighting applications. They have high-temperature ratings and good corrosion resistance when treated.

Pros: Steel honeycomb is incredibly strong and can support heavy fixtures, making it ideal for industrial applications. It is also relatively cost-effective compared to aluminum.

Cons: The weight of steel can be a disadvantage in applications where lightweight materials are preferred. Additionally, manufacturing processes can be more complex.

Impact on Application: Steel honeycomb is suitable for high-intensity lighting setups, such as in warehouses or manufacturing facilities, where durability is paramount.

Considerations for International Buyers: Compliance with JIS standards is critical for buyers in Japan and other Asian markets. Buyers should also consider the availability of treated steel to ensure corrosion resistance.

Why Choose Composite Honeycomb for Lighting Solutions?

Composite honeycomb materials, often made from a combination of fiberglass and resin, offer unique benefits for lighting applications. They are lightweight and provide excellent thermal insulation.

Pros: Composite honeycomb is resistant to moisture and chemicals, making it suitable for various environments. Its lightweight nature allows for easy installation.

Cons: The manufacturing process can be more complex and costly, which may deter some buyers. Additionally, composites may have lower structural strength compared to metals.

Impact on Application: Composite honeycomb is often used in specialized lighting applications, such as in marine or chemical environments, where moisture resistance is critical.

Considerations for International Buyers: Buyers should verify that composite materials meet ASTM standards for fire resistance and chemical compatibility, especially in industries with strict safety regulations.

Summary Table of Material Selection for Honeycomb in Lights

| Material | Typical Use Case for honeycomb for lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Outdoor LED fixtures | Lightweight, corrosion-resistant | Higher initial cost | High |

| Polycarbonate | Indoor lighting applications | Impact-resistant, good thermal insulation | Limited high-temperature resistance | Medium |

| Steel | Industrial lighting setups | Exceptional strength | Heavier, complex manufacturing | Medium |

| Composite | Marine or chemical environments | Moisture and chemical resistance | Higher manufacturing complexity | High |

This guide provides international B2B buyers with essential insights into the strategic selection of honeycomb materials for lighting applications, ensuring informed decisions that align with regional standards and market requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for honeycomb for lights

What Are the Key Stages in the Manufacturing Process of Honeycomb for Lights?

The manufacturing process of honeycomb for lights involves several critical stages, each designed to ensure the final product meets stringent quality and performance standards. The main stages include material preparation, forming, assembly, and finishing.

A stock image related to honeycomb for lights.

Material Preparation: What Raw Materials Are Used?

The primary materials for honeycomb structures typically include aluminum, plastic, or composite materials. Each of these materials has unique properties that affect the performance of the honeycomb when used in lighting applications. For instance, aluminum honeycombs are lightweight, durable, and provide excellent thermal conductivity, making them ideal for lighting fixtures.

During the material preparation stage, suppliers must ensure that the raw materials meet specific industry standards. This includes verifying the material specifications through documentation and certifications, which can be crucial for international B2B buyers who need to ensure compliance with local regulations.

How Is the Forming Process Conducted?

The forming stage involves shaping the raw materials into the desired honeycomb structure. This can be achieved through various techniques, including extrusion, die cutting, or molding.

-

Extrusion: This technique is often used for aluminum honeycombs, where the aluminum is forced through a die to create a continuous honeycomb sheet.

-

Die Cutting: For plastic or composite materials, die cutting allows for precise shapes and sizes to be achieved, which is essential for fitting into lighting fixtures.

-

Molding: This method is typically employed for creating complex shapes and is particularly useful when using thermoplastic materials.

Each technique has its advantages and is selected based on the specific requirements of the lighting application, including weight, thermal resistance, and cost-effectiveness.

What Does the Assembly Stage Involve?

Once the honeycomb panels are formed, they undergo assembly, where components are combined to create the final product. This may involve:

-

Bonding: Adhesives or mechanical fasteners are used to secure the honeycomb panels to other structural elements of the lighting fixture.

-

Integration: Electrical components, such as LED strips or sockets, may be integrated into the honeycomb structure, enhancing functionality.

The assembly process is crucial, as it directly impacts the durability and performance of the lighting product. B2B buyers should inquire about the assembly techniques used and whether they align with industry best practices.

What Finishing Techniques Are Commonly Applied?

The finishing stage enhances the aesthetics and functionality of the honeycomb for lights. Common finishing techniques include:

-

Coating: Applying protective or decorative coatings, such as powder coating or anodizing, improves corrosion resistance and visual appeal.

-

Trimming: Edges are trimmed for a clean finish, which is especially important in consumer-facing products.

-

Quality Checks: Final inspections are conducted to ensure that the product meets specified tolerances and quality standards.

How Is Quality Assurance Implemented in Honeycomb Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of honeycomb for lights, ensuring that the products meet international and industry-specific standards.

What International Standards Should Buyers Be Aware Of?

For B2B buyers, understanding the relevant international standards is crucial. Key certifications include:

-

ISO 9001: This standard focuses on quality management systems, ensuring that the manufacturer has consistent processes in place to meet customer and regulatory requirements.

-

CE Marking: This certification is essential for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

-

API Standards: For applications that may involve harsh environments or specific performance criteria, adherence to American Petroleum Institute (API) standards may be required.

B2B buyers should request documentation that verifies compliance with these standards, as it reflects the manufacturer’s commitment to quality.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch defects early. Common checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint ensures that all raw materials meet specified standards before production begins.

-

In-Process Quality Control (IPQC): Monitoring during the manufacturing process helps identify any deviations from the established protocols.

-

Final Quality Control (FQC): A comprehensive inspection of the finished product ensures that it meets all specifications before shipment.

How Can B2B Buyers Verify Supplier Quality Control?

Verification of a supplier’s quality control processes is essential for B2B buyers to ensure product reliability. Here are some actionable steps:

-

Request Audits and Certifications: Ask for documentation of quality audits conducted by third-party organizations. This can provide insight into the supplier’s adherence to industry standards.

-

Review Quality Reports: Suppliers should provide detailed quality reports that outline their QC processes and any issues encountered during production.

-

Conduct On-Site Inspections: Whenever feasible, conducting on-site inspections can provide a deeper understanding of the supplier’s manufacturing capabilities and quality practices.

-

Engage Third-Party Inspectors: Hiring independent inspectors to assess the manufacturing process can offer an unbiased view of the supplier’s quality control measures.

What Are the Nuances of QC and Certification for International B2B Buyers?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, it is vital to understand the nuances of quality control and certification. Different regions may have specific requirements or standards that need to be adhered to.

-

Local Regulations: Familiarize yourself with local regulations that may affect product compliance and safety.

-

Cultural Considerations: In some regions, business practices may vary, influencing how quality control is perceived and implemented.

-

Language Barriers: Ensure that all documentation is available in a language that you and your team understand to avoid misinterpretations.

By taking these factors into account, B2B buyers can better navigate the complexities of sourcing honeycomb for lights from international suppliers, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘honeycomb for lights’

To successfully procure honeycomb for lights, international B2B buyers must navigate a series of critical steps. This guide provides a structured checklist to ensure you make informed decisions throughout the sourcing process.

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications required for the honeycomb for lights. This includes dimensions, materials, and performance characteristics such as light diffusion and heat resistance.

– Why It Matters: Having precise specifications helps in filtering suppliers who can meet your needs, reducing the risk of costly mistakes.

– What to Look For: Documentation or product datasheets that detail the physical and performance parameters of the product.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers with a proven track record in manufacturing honeycomb for lights. Use industry-specific directories, trade shows, and online platforms to gather a list of potential vendors.

– Why It Matters: The quality of your honeycomb directly impacts the performance of your lighting systems, making supplier reputation crucial.

– What to Look For: Reviews, ratings, and case studies from other businesses, especially those in your region or industry.

Step 3: Evaluate Supplier Certifications

Before proceeding with any supplier, verify their certifications and compliance with international standards, such as ISO or CE marking.

– Why It Matters: Certifications ensure that the products meet safety and quality standards, which is essential for reliability and longevity.

– What to Look For: Request copies of certifications and check their validity through the issuing bodies.

Step 4: Request Samples for Testing

Always request samples of the honeycomb for lights before making a bulk purchase. This allows you to assess the product’s quality and suitability for your specific application.

– Why It Matters: Testing samples can reveal potential issues that may not be apparent in product descriptions or marketing materials.

– What to Look For: Evaluate the samples for durability, light transmission, and overall aesthetic to ensure they meet your project requirements.

Step 5: Assess Pricing and Terms of Sale

Compare pricing structures from different suppliers while considering terms of sale, including payment options, delivery timelines, and return policies.

– Why It Matters: Understanding the financial implications and terms can help you avoid hidden costs and ensure a smooth procurement process.

– What to Look For: Detailed quotations that outline pricing, delivery schedules, and any additional fees for shipping or customs.

Step 6: Check After-Sales Support and Warranty

Inquire about the after-sales support and warranty offered by the suppliers. A reliable supplier should provide support for installation, maintenance, and troubleshooting.

– Why It Matters: Good after-sales support can significantly reduce downtime and maintenance costs in the long term.

– What to Look For: Warranty duration, terms of service, and availability of technical support.

Step 7: Finalize the Contract

Once you are satisfied with the supplier’s offerings, finalize the contract. Ensure that all specifications, pricing, delivery dates, and after-sales support terms are clearly documented.

– Why It Matters: A well-drafted contract protects both parties and minimizes misunderstandings that could arise later.

– What to Look For: Clear clauses regarding liability, payment schedules, and conditions for termination or modification of the contract.

By following this checklist, B2B buyers can streamline their sourcing process for honeycomb for lights, ensuring that they make informed decisions that align with their business objectives.

Comprehensive Cost and Pricing Analysis for honeycomb for lights Sourcing

What Are the Key Cost Components in Honeycomb for Lights Sourcing?

When sourcing honeycomb for lights, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

- Materials: The choice of materials significantly influences the cost. High-quality aluminum or plastic may be more expensive but offer better durability and performance.

- Labor: Labor costs vary by region. Countries with higher wages will naturally have higher production costs, impacting overall pricing.

- Manufacturing Overhead: This includes indirect costs like utilities, rent, and equipment depreciation, which are allocated across production.

- Tooling: Custom tooling for specific designs can be a significant upfront cost, particularly for unique or non-standard honeycomb structures.

- Quality Control (QC): Ensuring that products meet international standards requires investment in QC processes, which adds to the overall cost.

- Logistics: Shipping costs depend on the distance, shipping method, and weight of the product. For international buyers, these costs can escalate quickly, especially for bulk orders.

- Margin: Suppliers often add a profit margin based on their cost structure and market positioning.

How Do Price Influencers Affect Honeycomb for Lights Pricing?

Several factors can influence the pricing of honeycomb for lights:

- Volume/MOQ (Minimum Order Quantity): Suppliers often provide tiered pricing based on order volume. Larger orders can lead to significant discounts, making it essential for buyers to assess their needs.

- Specifications and Customization: Custom specifications can drive up costs. Standardized products typically have lower prices, while bespoke designs require more resources.

- Materials and Quality Certifications: Products with certifications (e.g., ISO, CE) may cost more due to the rigorous testing and quality assurance processes involved.

- Supplier Factors: The supplier’s reputation, location, and production capacity can affect pricing. Established suppliers may charge a premium for reliability.

- Incoterms: Understanding shipping terms is critical. FOB (Free on Board) pricing may differ from CIF (Cost, Insurance, and Freight), impacting the total cost.

What Buyer Tips Can Help Optimize Costs in Honeycomb for Lights Sourcing?

International B2B buyers can adopt several strategies to enhance cost efficiency:

- Negotiate Effectively: Always approach negotiations with a clear understanding of your budget and the market rates for honeycomb products. Leverage volume to negotiate better terms.

- Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Factor in shipping, installation, maintenance, and potential replacement costs to understand the TCO fully.

- Seek Multiple Quotes: Obtain quotes from various suppliers to compare prices and terms. This competitive approach can reveal more favorable conditions.

- Evaluate Long-term Partnerships: Building relationships with suppliers can lead to better pricing, reliability, and preferential treatment on future orders.

- Stay Informed on Market Trends: Keep abreast of material costs and industry trends that may impact pricing. Economic shifts can affect supply chains and prices.

Disclaimer on Indicative Prices

Prices for honeycomb for lights can vary widely based on the factors mentioned above. It is essential for buyers to conduct thorough market research and obtain tailored quotes to ensure they receive the best value for their specific needs. Always verify current pricing and terms directly with suppliers to avoid potential discrepancies.

Alternatives Analysis: Comparing honeycomb for lights With Other Solutions

Understanding the Alternatives to Honeycomb for Lights

When considering lighting solutions, it’s essential for international B2B buyers to evaluate various technologies that can fulfill their needs effectively. Honeycomb for lights has gained popularity due to its unique properties, but it’s crucial to compare it with alternative solutions to make informed purchasing decisions. Below, we explore two viable alternatives: LED panels and diffusion filters, assessing their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Honeycomb For Lights | LED Panels | Diffusion Filters |

|---|---|---|---|

| Performance | Excellent light control; reduces glare and hotspots | High light output; energy-efficient | Softens light; reduces harsh shadows |

| Cost | Moderate investment | Varies (generally higher initial cost) | Low-cost option |

| Ease of Implementation | Relatively easy | Requires electrical setup | Simple to install |

| Maintenance | Low maintenance | Moderate (bulb replacements) | Low (cleaning required) |

| Best Use Case | Cinematic lighting, photography | General lighting, commercial spaces | Stage lighting, photography |

What Are the Pros and Cons of Using LED Panels?

LED panels are a modern lighting solution known for their energy efficiency and high light output. They are particularly suitable for commercial spaces and general lighting applications. The primary advantage of LED panels is their longevity and low power consumption, which can lead to significant cost savings over time. However, they often come with a higher initial investment compared to honeycomb solutions. Additionally, installation may require professional electrical work, which can complicate the implementation process for some buyers.

How Do Diffusion Filters Compare to Honeycomb for Lights?

Diffusion filters serve as an economical alternative to honeycomb for lights, primarily used in photography and stage lighting to soften harsh light and reduce shadows. They are inexpensive and easy to implement, making them accessible for small businesses or individual projects. However, diffusion filters may not provide the same level of control over light direction and intensity as honeycomb solutions. Their effectiveness is largely dependent on the existing lighting setup, which can limit their versatility in some applications.

Conclusion: Which Lighting Solution is Right for Your Business?

When selecting the right lighting solution, B2B buyers should consider their specific needs and applications. Honeycomb for lights excels in providing controlled lighting for professional settings, making it ideal for photography and cinematography. In contrast, LED panels offer a high-output, energy-efficient solution suitable for larger commercial spaces, albeit at a higher cost. Diffusion filters present a budget-friendly option for those needing soft lighting effects without extensive installations. Ultimately, the choice will depend on the balance between performance, cost, and the specific lighting requirements of the business.

Essential Technical Properties and Trade Terminology for honeycomb for lights

What Are the Key Technical Properties of Honeycomb for Lights?

When sourcing honeycomb for lighting applications, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are some critical specifications:

1. Material Grade

Honeycomb panels are typically made from various materials, including aluminum, plastic, and cardboard. The material grade affects durability, weight, and thermal insulation properties. For example, aluminum honeycomb is favored for its strength and lightweight characteristics, making it suitable for portable lighting solutions. Buyers should assess the material properties based on the intended application to ensure optimal performance.

2. Cell Size and Configuration

The cell size refers to the dimensions of the individual cells in the honeycomb structure. Common sizes range from 6mm to 25mm, and the configuration can impact light diffusion and beam control. Smaller cells provide finer control over light direction, while larger cells may enhance light diffusion. Understanding cell size is essential for buyers seeking specific lighting effects or energy efficiency.

3. Tolerance Levels

Tolerance levels indicate the permissible limits of variation in the dimensions of the honeycomb panels. High tolerance levels ensure that the panels fit seamlessly into lighting fixtures, which is critical for maintaining aesthetic appeal and functionality. Buyers should confirm the manufacturer’s tolerance specifications to avoid compatibility issues during installation.

4. Weight Load Capacity

The weight load capacity of honeycomb panels is a vital consideration, especially in applications where the panels will support other lighting components. This specification is usually expressed in pounds per square foot (PSF) and determines how much weight the panel can bear without compromising structural integrity. For B2B buyers, understanding this property helps in selecting the right panels for their specific lighting setups.

5. Thermal Resistance

Thermal resistance is an important property for honeycomb materials used in lighting applications. It indicates how well the material can withstand heat without deforming or losing performance. This is particularly relevant for LED lights, which generate heat. Ensuring that the honeycomb material has adequate thermal resistance can prolong the lifespan of lighting installations.

What Common Trade Terms Should B2B Buyers Know When Purchasing Honeycomb for Lights?

Familiarity with industry terminology can significantly enhance B2B transactions. Here are some key terms related to honeycomb for lights:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. In the context of honeycomb for lights, buyers may source panels from OEMs that specialize in producing high-quality honeycomb materials tailored for specific lighting applications. Understanding OEM relationships can help buyers ensure they are getting reliable products.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as it affects inventory management and cost efficiency. Buyers should negotiate MOQs to align with their project needs while keeping costs manageable.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific quantities and specifications of honeycomb panels. Submitting an RFQ allows buyers to compare prices and terms from multiple suppliers, fostering competitive pricing and informed decision-making.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping. Understanding Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for B2B buyers to clarify shipping costs, risks, and logistics responsibilities when importing honeycomb materials from different regions.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. This term is critical for project planning and should be clearly communicated between buyers and suppliers to ensure timely delivery of honeycomb panels for lighting applications.

Conclusion

In summary, understanding the key technical properties and trade terminology related to honeycomb for lights is essential for B2B buyers. By familiarizing themselves with material grades, tolerance levels, and industry jargon, buyers can make more informed decisions that enhance the efficiency and effectiveness of their lighting solutions.

Navigating Market Dynamics and Sourcing Trends in the honeycomb for lights Sector

What Are the Key Market Dynamics in the Honeycomb for Lights Sector?

The honeycomb for lights sector is witnessing significant growth driven by advancements in LED technology and increasing demand for energy-efficient lighting solutions. Global trends indicate a shift towards customizable lighting systems that enhance aesthetic appeal while maintaining functionality. Key markets in Africa, South America, the Middle East, and Europe are adapting to these changes, with particular emphasis on sustainability and cost-effectiveness.

B2B buyers are increasingly looking for suppliers who offer innovative designs and materials that comply with international standards. For instance, honeycomb panels that allow for diffused lighting are becoming popular, as they not only improve light quality but also reduce glare. Additionally, the rise of smart lighting systems, integrated with IoT technology, is influencing sourcing trends. Buyers are encouraged to invest in suppliers who are at the forefront of these technological advancements, as they will likely offer competitive pricing and superior products.

Emerging markets, particularly in Africa and South America, are experiencing a surge in construction and urban development, which propels the demand for honeycomb lighting solutions. In Europe, regulatory frameworks promoting energy efficiency are pushing manufacturers towards more sustainable practices. As international B2B buyers navigate these dynamics, aligning with suppliers who embrace innovation and sustainability will be crucial for long-term success.

How Can Sustainability and Ethical Sourcing Impact Your B2B Decisions?

Sustainability is no longer just a trend but a necessity in the sourcing of honeycomb for lights. Environmental impacts from traditional manufacturing processes raise concerns among consumers and businesses alike, prompting a shift towards greener alternatives. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint through sustainable practices.

Ethical sourcing is vital in establishing a responsible supply chain. This includes ensuring that raw materials used in honeycomb production are sourced from certified sustainable forests, thereby minimizing deforestation and habitat destruction. Additionally, buyers should seek suppliers who have acquired ‘green’ certifications, such as ISO 14001, which indicates adherence to environmental management standards.

Investing in sustainable honeycomb materials can also enhance a company’s brand image, attracting environmentally-conscious customers. As market demand grows for eco-friendly products, aligning with suppliers who prioritize sustainability not only meets regulatory requirements but also positions businesses favorably in an increasingly competitive marketplace.

What Is the Historical Context of Honeycomb for Lights?

The honeycomb structure has been utilized in various industries for decades, originally gaining traction in aerospace and automotive applications due to its lightweight and strong properties. The transition of honeycomb technology into the lighting sector began in the late 20th century when designers started to explore ways to enhance light diffusion and reduce glare.

As lighting technology evolved, particularly with the introduction of LEDs, the versatility of honeycomb materials became more apparent. The ability to create intricate designs while maintaining functionality appealed to architects and designers alike. This historical evolution laid the groundwork for the current trends in customizable, energy-efficient lighting solutions that continue to shape the market today.

By understanding the market dynamics, sustainability imperatives, and historical context, international B2B buyers can make informed decisions that align with current trends and future growth opportunities in the honeycomb for lights sector.

Frequently Asked Questions (FAQs) for B2B Buyers of honeycomb for lights

-

How do I choose the right honeycomb for lighting applications?

When selecting honeycomb for lighting applications, consider factors such as the material composition, cell size, and light diffusion properties. Materials like aluminum or polycarbonate offer durability and effective light management. Assess the specific requirements of your project, including size constraints and desired light quality, to ensure the honeycomb aligns with your lighting goals. Always request samples to evaluate how the honeycomb performs in real-world conditions before making a bulk purchase. -

What is the best honeycomb design for LED lights?

The best honeycomb design for LED lights typically features a cell structure that enhances light diffusion while minimizing glare. A smaller cell size can provide finer control over light distribution, making it ideal for applications requiring focused illumination. Polycarbonate honeycomb panels are often preferred for LED setups due to their lightweight nature and excellent thermal resistance. When sourcing, inquire about customization options to tailor the design to your specific lighting needs. -

What are the minimum order quantities (MOQs) for honeycomb products?

Minimum order quantities for honeycomb products vary by supplier and depend on factors like manufacturing capabilities and material costs. Typically, MOQs can range from a few hundred to several thousand units. It’s advisable to communicate your requirements directly with potential suppliers to negotiate MOQs that fit your budget and project timelines. Some suppliers may offer flexibility for first-time orders or pilot projects, so explore these options. -

What payment terms should I expect when purchasing honeycomb for lights internationally?

Payment terms for international purchases of honeycomb products can vary widely. Common arrangements include advance payment, partial payment upon order confirmation, and the balance upon shipment. Letters of credit are also frequently used to secure transactions. It’s essential to discuss and agree upon payment terms upfront to avoid misunderstandings. Ensure that the payment method chosen is secure and offers some level of buyer protection. -

How do I vet suppliers of honeycomb for lighting products?

Vetting suppliers is critical to ensuring product quality and reliability. Start by researching their industry reputation through reviews and testimonials. Verify their certifications and compliance with international standards, such as ISO or ASTM. Request references from previous clients and inquire about their experience with product quality and delivery timelines. A factory visit or a third-party inspection can also provide valuable insights into their manufacturing processes. -

What are the logistics considerations when importing honeycomb products?

Logistics is a key factor when importing honeycomb products. Consider shipping methods, lead times, and customs regulations in your target market. Ensure that the supplier can provide detailed packaging and labeling to facilitate smooth customs clearance. It’s advisable to work with a freight forwarder familiar with your region to navigate any complexities in international shipping. Understanding local import duties and taxes can also help you better plan your budget. -

How can I ensure quality assurance (QA) for honeycomb products?

To ensure quality assurance for honeycomb products, establish clear specifications and standards with your supplier before production begins. Request regular updates during the manufacturing process and consider implementing a pre-shipment inspection. Many suppliers offer QA documentation, including test reports and certifications, which should be reviewed thoroughly. Building a strong relationship with your supplier can facilitate open communication regarding any potential quality issues. -

What customization options are available for honeycomb lighting products?

Customization options for honeycomb lighting products can include variations in cell size, material type, color, and thickness. Many manufacturers are willing to work with clients to develop bespoke solutions that meet specific project requirements. Discuss your needs with potential suppliers to explore the range of customization available. Providing detailed specifications and even design prototypes can help ensure that the final product aligns with your vision.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for honeycomb for lights

In the rapidly evolving market for honeycomb products used in lighting applications, strategic sourcing emerges as a critical factor for international B2B buyers. By leveraging local suppliers from regions like Africa and South America, as well as established manufacturers in Europe and the Middle East, businesses can enhance their supply chain resilience and reduce costs. Understanding the unique characteristics of honeycomb materials, such as their lightweight properties and durability, allows buyers to make informed decisions that align with their operational needs and sustainability goals.

Furthermore, fostering strong relationships with suppliers can unlock opportunities for innovation and customization, catering to specific market demands. As the competition intensifies, buyers must prioritize not only cost but also quality and service reliability when selecting partners.

Looking ahead, the demand for honeycomb solutions in lighting is expected to grow, driven by advancements in technology and an increasing focus on energy efficiency. International B2B buyers are encouraged to explore diverse sourcing options and stay attuned to market trends. By embracing a proactive sourcing strategy, businesses can position themselves for success and capitalize on emerging opportunities within this dynamic sector.