Unlock Cost Savings with 4.00 16: The Complete Guide (2025)

Introduction: Navigating the Global Market for 4.00 16

In the rapidly evolving landscape of international trade, sourcing the right tires—such as the 4.00 16—can pose significant challenges for B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe. The importance of selecting high-quality, reliable tires cannot be overstated; they are crucial for the performance and safety of various vehicles, from light trucks to agricultural machinery. This guide aims to simplify the process of navigating the global market for 4.00 16 tires, providing buyers with essential insights into types, applications, and the critical factors influencing purchasing decisions.

Throughout this comprehensive guide, you will discover the various types of 4.00 16 tires available, including their specific applications in different industries. We will also delve into supplier vetting processes, helping you identify reputable manufacturers and distributors that align with your business needs. Understanding cost structures and the factors influencing pricing will empower you to make informed financial decisions that contribute to your bottom line.

By equipping international B2B buyers with actionable insights and strategies, this guide serves as a valuable resource for navigating the complexities of the tire market. Whether you are in France, Spain, or any other part of the globe, our aim is to help you source the best 4.00 16 tires effectively, ensuring your operations run smoothly and efficiently.

Understanding 4.00 16 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bias Ply Tires | Made with layers of fabric, flexible sidewalls | Agriculture, construction, and industrial | Pros: Cost-effective, good durability; Cons: Less stable at high speeds. |

| Radial Tires | Steel belts and flexible sidewalls, better traction | Transportation, logistics, and retail | Pros: Superior fuel efficiency, longer lifespan; Cons: Higher initial cost. |

| Tubeless Tires | No inner tube, reduces risk of punctures | Heavy-duty vehicles, mining, and forestry | Pros: Lower maintenance, improved safety; Cons: More complex installation. |

| All-Terrain Tires | Designed for various surfaces, rugged tread patterns | Off-road vehicles, construction equipment | Pros: Versatile performance, enhanced grip; Cons: Can wear out faster on pavement. |

| Specialty Tires | Tailored for specific applications (e.g., snow, mud) | Agricultural, military, and emergency services | Pros: Optimized performance for niche uses; Cons: Limited availability and higher costs. |

What Are Bias Ply Tires and Their B2B Suitability?

Bias ply tires consist of layers of fabric arranged diagonally, providing flexibility and a smoother ride. These tires are commonly used in agricultural and construction applications due to their durability and cost-effectiveness. When purchasing bias ply tires, B2B buyers should consider their operational environment and the expected load, as these tires excel in situations requiring resilience but may not perform as well at high speeds. The lower initial investment can be appealing, particularly for businesses with tight budgets.

How Do Radial Tires Compare for B2B Applications?

Radial tires feature steel belts and flexible sidewalls, which enhance traction and fuel efficiency. They are ideal for transportation and logistics sectors, where long-distance travel is common. B2B buyers should evaluate their fleet’s performance needs, as the higher upfront cost of radial tires can be offset by their longer lifespan and reduced fuel consumption. Choosing radial tires can lead to significant savings over time, making them a wise investment for businesses focused on efficiency.

What Are the Benefits of Tubeless Tires for Heavy-Duty Applications?

Tubeless tires eliminate the need for an inner tube, significantly reducing the risk of punctures and improving safety. They are particularly suited for heavy-duty vehicles in mining and forestry sectors, where rugged conditions are prevalent. B2B buyers should consider the complexity of installation and maintenance when opting for tubeless tires. While they may require a higher initial investment, the benefits of lower maintenance costs and increased safety can offer substantial long-term value.

Why Choose All-Terrain Tires for Versatile Performance?

All-terrain tires are designed to handle various surfaces, making them ideal for off-road vehicles and construction equipment. Their rugged tread patterns provide enhanced grip, which is essential for businesses operating in diverse environments. When selecting all-terrain tires, B2B buyers should assess their specific operational needs and terrain types. While these tires offer versatility, they may wear out faster on paved surfaces, so understanding the typical use case is critical for maximizing investment.

What Makes Specialty Tires a Consideration for Niche Markets?

Specialty tires are engineered for specific applications, such as snow or mud, and are often used in agricultural, military, and emergency services. B2B buyers in niche markets should prioritize performance optimization when selecting these tires. Although they may come with higher costs and limited availability, the tailored performance can significantly enhance operational efficiency. Businesses should carefully evaluate their unique requirements to ensure they invest in the right specialty tires for their needs.

Key Industrial Applications of 4.00 16

| Industry/Sector | Specific Application of 4.00 16 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Precision Farming Equipment | Increases crop yield and optimizes resource use | Ensure compatibility with local regulations and climate conditions. |

| Manufacturing | Automated Assembly Lines | Enhances efficiency and reduces labor costs | Look for suppliers with a strong track record in automation technology. |

| Construction | Heavy Machinery and Equipment | Improves project timelines and reduces operational costs | Verify certifications and compliance with safety standards. |

| Transportation & Logistics | Fleet Management Systems | Optimizes route planning and reduces fuel consumption | Assess integration capabilities with existing systems. |

| Energy | Renewable Energy Solutions | Supports sustainability goals and reduces costs | Evaluate the technology’s adaptability to local energy regulations. |

How is ‘4.00 16’ Used in Agriculture for Precision Farming Equipment?

In the agriculture sector, ‘4.00 16’ is utilized in precision farming equipment such as GPS-guided tractors and drones. This technology enables farmers to monitor crop health, soil conditions, and optimize resource allocation. By implementing ‘4.00 16’, businesses can achieve higher crop yields while minimizing waste and environmental impact. International buyers should consider local soil types, climate conditions, and regulatory compliance when sourcing these technologies to ensure they meet regional agricultural needs.

What Role Does ‘4.00 16’ Play in Manufacturing Automated Assembly Lines?

Within manufacturing, ‘4.00 16’ is pivotal for the development of automated assembly lines that enhance operational efficiency. These systems utilize advanced robotics and AI to streamline production processes, reduce labor costs, and improve product quality. For B2B buyers, it’s crucial to evaluate the supplier’s experience in automation, the scalability of the technology, and the availability of local support services to ensure seamless integration and operation.

Why is ‘4.00 16’ Important for Heavy Machinery in Construction?

In the construction industry, ‘4.00 16’ is vital for heavy machinery and equipment, enabling better performance and reliability on job sites. Equipment such as excavators, bulldozers, and cranes benefit from this technology by enhancing fuel efficiency and operational safety. Buyers in this sector should focus on sourcing equipment that meets local safety regulations and standards while considering the availability of spare parts and after-sales support to minimize downtime.

How Can ‘4.00 16’ Enhance Fleet Management in Transportation & Logistics?

For transportation and logistics, ‘4.00 16’ is integrated into fleet management systems that help companies optimize their operations. This technology facilitates real-time tracking of vehicles, route optimization, and fuel management, leading to significant cost savings. When sourcing these systems, B2B buyers should assess the compatibility with existing logistics platforms and the robustness of data analytics capabilities to drive informed decision-making.

What Benefits Does ‘4.00 16’ Offer for Renewable Energy Solutions in the Energy Sector?

In the energy sector, ‘4.00 16’ is instrumental in the development of renewable energy solutions such as solar panels and wind turbines. This technology supports sustainability initiatives by improving energy efficiency and reducing operational costs. Buyers should evaluate the adaptability of these solutions to local energy regulations and infrastructure, ensuring they align with regional energy goals and market demands.

3 Common User Pain Points for ‘4.00 16’ & Their Solutions

Scenario 1: Sourcing Quality Materials for ‘4.00 16’

The Problem:

B2B buyers often struggle with sourcing high-quality materials for ‘4.00 16’ applications. Whether in Africa, South America, the Middle East, or Europe, the challenge lies in finding suppliers who can guarantee consistent quality and compliance with international standards. Buyers may encounter subpar materials that lead to product failures, impacting their reputation and bottom line. Additionally, fluctuating supply chain dynamics can make it difficult to maintain a steady supply of reliable materials.

The Solution:

To overcome this challenge, B2B buyers should establish a robust supplier evaluation process. Begin by creating a checklist that includes quality certifications, past performance reviews, and compliance with international standards such as ISO. Engage in direct communication with potential suppliers, requesting samples for testing. Additionally, leveraging platforms like Alibaba, TradeIndia, or local B2B marketplaces can help connect with reputable suppliers. Forming long-term partnerships with a select few suppliers can also ensure consistency in quality and delivery, thereby reducing risks associated with sourcing.

Scenario 2: Navigating Compliance and Regulatory Standards for ‘4.00 16’

The Problem:

Navigating the complex landscape of compliance and regulatory standards can be daunting for international B2B buyers, particularly those importing ‘4.00 16’ products into regions with stringent regulations. Buyers may face unexpected delays, fines, or even product recalls due to non-compliance with local laws. This is especially pertinent for regions like Europe, where regulations can vary significantly between countries.

The Solution:

To mitigate compliance risks, B2B buyers should invest time in understanding the regulatory framework of their target markets. Consult with legal experts or compliance consultants who specialize in international trade. Create a comprehensive compliance checklist that outlines necessary certifications, labeling requirements, and safety standards specific to ‘4.00 16’. Additionally, consider utilizing compliance management software that can help track and manage documentation and updates on regulations. Engaging with local trade associations can also provide valuable insights and resources for navigating these complexities.

Scenario 3: Ensuring Product Compatibility and Performance with ‘4.00 16’

The Problem:

Another common pain point for B2B buyers is ensuring that ‘4.00 16’ products are compatible with existing systems and meet performance expectations. This concern is particularly prevalent in industries such as automotive or machinery, where even slight discrepancies can lead to operational inefficiencies or safety hazards. Buyers often find themselves investing in products that do not integrate well with their current infrastructure.

The Solution:

To address compatibility issues, B2B buyers should conduct a thorough compatibility analysis before finalizing any purchase. This involves engaging with technical teams to assess existing systems and identify specific requirements for ‘4.00 16’ products. Request detailed specifications and performance data from suppliers, and don’t hesitate to ask for case studies or references demonstrating successful integrations. If possible, conduct pilot tests to evaluate product performance in real-world conditions. Collaboration with suppliers on product development can also lead to tailored solutions that better fit your operational needs, ultimately enhancing efficiency and reducing the likelihood of performance-related issues.

Strategic Material Selection Guide for 4.00 16

When selecting materials for the 4.00 16 specifications, international B2B buyers must consider various factors that influence performance, cost, and application suitability. Below is a detailed analysis of four common materials used in the manufacturing of products adhering to the 4.00 16 standards.

What Are the Key Properties of Rubber for 4.00 16 Applications?

Rubber is a popular choice for 4.00 16 applications due to its excellent flexibility and resilience. It typically exhibits good temperature resistance, withstanding a range from -40°C to 100°C. Its inherent properties also provide decent abrasion resistance and shock absorption, making it suitable for applications that require damping and cushioning.

Pros and Cons of Using Rubber:

– Pros: Rubber is generally low-cost, easy to manufacture, and provides excellent sealing capabilities. It is also lightweight, which can contribute to overall product efficiency.

– Cons: However, rubber can degrade over time due to exposure to UV light and certain chemicals, which may limit its lifespan in harsh environments. Additionally, it may not perform well under extreme pressure conditions.

Impact on Application:

Rubber is compatible with various media, including air and water, but it may not be suitable for aggressive chemicals. Buyers should ensure that the specific type of rubber selected is appropriate for the intended media.

How Does Steel Compare as a Material for 4.00 16?

Steel is known for its strength and durability, making it a common choice for structural applications. It typically offers high tensile strength and can withstand significant pressure and temperature variations, often rated for high-stress environments.

Pros and Cons of Using Steel:

– Pros: Steel is highly durable and resistant to deformation, making it ideal for heavy-duty applications. It also has excellent machinability and can be easily welded or fabricated.

– Cons: On the downside, steel can be susceptible to corrosion if not properly treated or coated. It is also heavier than other materials, which may not be ideal for all applications.

Impact on Application:

Steel is suitable for applications involving high pressure and temperature, but buyers must consider corrosion-resistant coatings or alloys for environments where moisture or chemicals are present.

What Are the Benefits and Limitations of Polyurethane in 4.00 16 Products?

Polyurethane is a versatile material known for its elasticity and durability. It offers a good balance of hardness and flexibility, making it suitable for various applications that require both properties. Polyurethane can typically withstand temperatures ranging from -30°C to 80°C.

Pros and Cons of Using Polyurethane:

– Pros: It exhibits excellent abrasion resistance and can be formulated to meet specific hardness requirements. Polyurethane is also resistant to oil and chemicals, making it a suitable choice for diverse applications.

– Cons: However, it can be more expensive than rubber and may require specialized manufacturing processes, which can increase overall production costs.

Impact on Application:

Polyurethane’s compatibility with various media, including oils and fuels, makes it a strong contender for applications in automotive and industrial sectors. Buyers should ensure that the formulation aligns with their specific use case.

What Role Does PVC Play in 4.00 16 Applications?

Polyvinyl Chloride (PVC) is another material often used in the 4.00 16 specifications due to its versatility and cost-effectiveness. It is known for its good chemical resistance and can withstand temperatures up to 60°C.

Pros and Cons of Using PVC:

– Pros: PVC is relatively low-cost and easy to manufacture, making it a popular choice for many applications. It is also resistant to moisture and many chemicals, enhancing its durability in various environments.

– Cons: However, PVC can become brittle over time, especially when exposed to UV light, which may limit its application in outdoor settings. It also has lower tensile strength compared to metals.

Impact on Application:

PVC is suitable for applications involving water and certain chemicals but may not be appropriate for high-pressure environments. Buyers should consider the specific requirements of their applications when selecting PVC.

Summary Table of Material Selection for 4.00 16

| Material | Typical Use Case for 4.00 16 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Seals and gaskets | Excellent flexibility and sealing | Degrades under UV exposure | Low |

| Steel | Structural components | High strength and durability | Susceptible to corrosion | Medium |

| Polyurethane | Automotive parts | Good abrasion resistance | Higher manufacturing costs | High |

| PVC | Pipes and fittings | Cost-effective and moisture-resistant | Becomes brittle with UV exposure | Low |

This strategic material selection guide provides international B2B buyers with essential insights into the materials commonly used for 4.00 16 applications, enabling informed decisions that align with their specific operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 4.00 16

What Are the Key Manufacturing Processes for 4.00 16?

Manufacturing 4.00 16 involves several critical stages that ensure both functionality and durability of the final product. Understanding these processes is essential for B2B buyers seeking reliable suppliers.

How Is Material Prepared for 4.00 16 Production?

The first step in manufacturing 4.00 16 is material preparation. High-quality raw materials, typically rubber or synthetic compounds, are sourced and tested for compliance with international standards. This involves assessing physical properties like tensile strength, elasticity, and durability. Suppliers often utilize advanced software for material selection to optimize performance characteristics. Buyers should ensure that their suppliers provide documentation on material specifications and certifications to validate quality.

What Forming Techniques Are Commonly Used in 4.00 16 Manufacturing?

Once materials are prepared, forming techniques come into play. The most common methods for producing 4.00 16 components include:

- Molding: This is a prevalent technique where rubber is heated and injected into molds to achieve the desired shape.

- Extrusion: Used for creating long, continuous profiles, extrusion allows for uniform thickness and is effective for items with consistent cross-sections.

- Stamping and Cutting: These techniques are utilized for precision parts that require tight tolerances.

Buyers should inquire about the forming methods employed by their suppliers, as this can significantly impact the quality and cost of the final product.

What Does the Assembly Process Entail for 4.00 16 Components?

Following the forming stage, the assembly process integrates various components to create the final product. This often involves:

- Joining Techniques: Adhesives, vulcanization, or mechanical fastening are used to assemble parts securely.

- Alignment and Fitting: Precision tools are used to ensure components fit together seamlessly, which is critical for performance.

B2B buyers should ensure that suppliers follow standardized assembly protocols to minimize defects.

How Is Finishing Handled in the Production of 4.00 16?

Finishing processes enhance the appearance and functionality of 4.00 16 products. Techniques such as surface treatment, painting, or coating are applied to improve durability and resistance to environmental factors. Buyers should ask for details about the finishing processes and the chemicals used to ensure compliance with environmental regulations, particularly for buyers in Europe and other regions with strict environmental laws.

What International Quality Assurance Standards Are Relevant for 4.00 16?

Quality assurance is crucial in the manufacturing of 4.00 16 to ensure that products meet both safety and performance criteria. International standards such as ISO 9001 provide a framework for quality management systems, which is vital for maintaining consistent quality throughout production.

How Do Industry-Specific Certifications Impact Quality Assurance for 4.00 16?

In addition to ISO standards, industry-specific certifications like CE marking for the European market or API standards for the oil and gas industry can impact product quality. These certifications often require rigorous testing and compliance checks, which can serve as a benchmark for B2B buyers assessing supplier reliability.

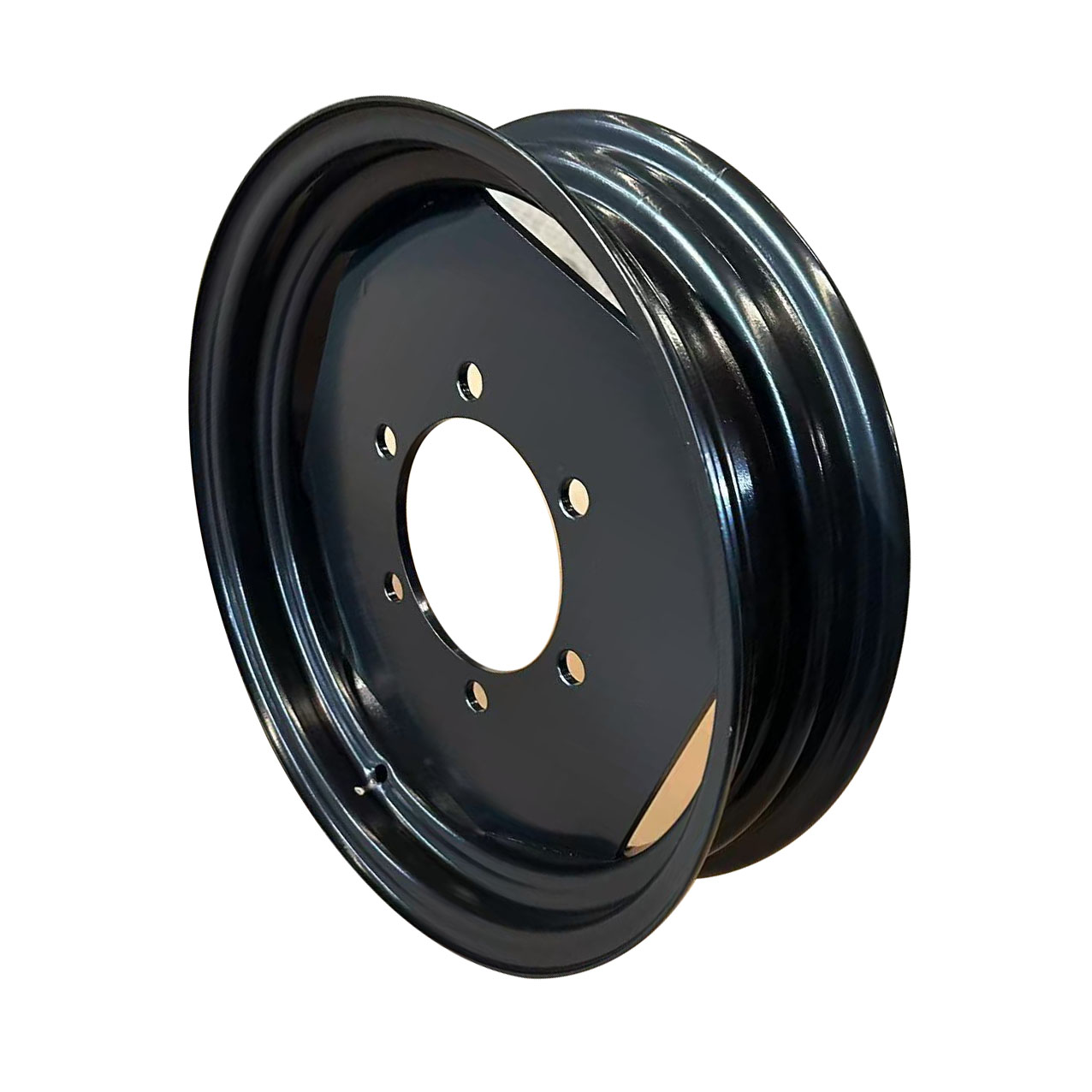

A stock image related to 4.00 16.

What Are the Key Quality Control Checkpoints in 4.00 16 Manufacturing?

Quality control (QC) checkpoints are essential throughout the manufacturing process to ensure product integrity. The main checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival at the manufacturing facility to verify compliance with specifications.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC helps identify defects early, allowing for corrective actions before final assembly.

- Final Quality Control (FQC): This final inspection ensures that the finished product meets all quality standards before shipment.

B2B buyers should verify that their suppliers have robust QC processes in place, including documentation of inspection results.

What Common Testing Methods Are Used in Quality Assurance for 4.00 16?

Testing methods can vary depending on the application but typically include:

- Tensile Testing: Measures the material’s strength and elasticity.

- Hardness Testing: Determines the material’s resistance to deformation.

- Thermal Testing: Assesses performance under temperature variations.

Buyers should request details about testing methodologies and results from their suppliers to ensure compliance with industry standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of suppliers:

- Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and QC measures.

- Request Quality Reports: Suppliers should be able to provide detailed reports on QC checks, including any non-conformities and corrective actions taken.

- Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance regarding product quality.

What Nuances Should International Buyers Consider Regarding QC and Certifications?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certifications is vital. Different regions may have varying regulations and standards, which can affect product acceptance and marketability.

- Regional Compliance: Buyers should be aware of local regulations, such as REACH in Europe, which governs chemical safety.

- Cultural Considerations: Communication and relationship-building with suppliers can impact the effectiveness of quality assurance. Understanding cultural nuances can facilitate better partnerships.

By paying close attention to manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing 4.00 16 products, ensuring they receive high-quality, reliable components that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘4.00 16’

In the competitive landscape of B2B procurement, sourcing the right products is crucial for operational efficiency and cost-effectiveness. This guide provides a step-by-step checklist specifically tailored for international buyers looking to procure ‘4.00 16’ products. By following these actionable insights, you can ensure a smooth and successful sourcing process.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it’s essential to clearly define your technical specifications for ‘4.00 16’ products. This includes understanding the dimensions, materials, and performance standards required for your application. A well-defined specification helps narrow down potential suppliers and reduces the risk of receiving substandard products.

- Consider the application: Is it for automotive use, industrial machinery, or another sector?

- Identify compliance standards: Are there industry-specific regulations or certifications that the product must meet?

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in ‘4.00 16’ products. Utilize online platforms, trade directories, and industry networks to compile a list of candidates. This step is vital as it sets the foundation for your sourcing strategy.

- Look for established suppliers: Focus on those with a proven track record in your industry.

- Check for regional presence: Suppliers with local representation can offer better support and quicker response times.

Step 3: Evaluate Supplier Capabilities

Once you have a shortlist of suppliers, assess their capabilities to ensure they can meet your needs. Request detailed information about their production processes, quality control measures, and lead times. This evaluation is crucial to avoid disruptions in your supply chain.

- Inquire about production capacity: Can they handle your volume requirements?

- Examine quality assurance practices: Do they have ISO certifications or similar quality standards?

Step 4: Verify Supplier Certifications

Verification of supplier certifications is a critical step in the sourcing process. Ensure that potential suppliers hold the necessary certifications relevant to ‘4.00 16’ products, such as ISO 9001 or industry-specific standards. This step is essential for mitigating risk and ensuring product quality.

- Request documentation: Ask for copies of relevant certifications and ensure they are up to date.

- Consider third-party audits: Suppliers who undergo regular audits demonstrate a commitment to quality.

Step 5: Request Samples for Testing

Before finalizing any purchase, request samples of the ‘4.00 16’ products you intend to procure. Testing samples allows you to evaluate the quality, performance, and suitability of the products for your specific needs. This step can save you from costly mistakes down the line.

- Conduct thorough testing: Ensure the samples meet your defined specifications.

- Involve your technical team: Get feedback from engineers or product managers who will use the products.

Step 6: Negotiate Terms and Pricing

Once you are satisfied with the supplier’s capabilities and product quality, it’s time to negotiate terms and pricing. Effective negotiation can lead to better pricing, favorable payment terms, and improved delivery schedules. This is a crucial step for maximizing your procurement budget.

- Discuss volume discounts: Can you secure better pricing based on order size?

- Clarify payment terms: Understand the implications of different payment options.

Step 7: Establish a Clear Communication Plan

Effective communication is key to successful sourcing. Establish a clear communication plan with your chosen supplier to ensure alignment on expectations, timelines, and any potential issues. This step fosters a strong partnership and helps prevent misunderstandings.

- Define communication channels: Specify how you will communicate (email, phone, etc.) and set regular check-in points.

- Document all agreements: Ensure that all terms discussed are documented for future reference.

By following this checklist, international B2B buyers can streamline their sourcing process for ‘4.00 16’ products, ensuring they make informed decisions that align with their operational needs and strategic goals.

Comprehensive Cost and Pricing Analysis for 4.00 16 Sourcing

What Are the Key Cost Components in 4.00 16 Sourcing?

When sourcing 4.00 16 products, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The type of materials used significantly impacts the overall cost. High-quality rubber and steel, which are standard in 4.00 16 tires, tend to be more expensive but can provide better durability and performance.

-

Labor: Labor costs vary by region. For instance, countries in South America may offer lower labor costs compared to Europe. Understanding local labor rates can help you gauge potential savings.

-

Manufacturing Overhead: This encompasses utilities, rent, and administrative expenses. Manufacturers in regions with higher operational costs will likely pass these expenses onto buyers.

-

Tooling: The initial investment in molds and machinery for production can be substantial, especially for customized products. Buyers should inquire about tooling costs when considering customization options.

-

Quality Control (QC): Ensuring product quality often requires additional investment in QC processes. Certifications such as ISO or specific industry standards can add to costs but are essential for ensuring product reliability.

-

Logistics: Transportation costs play a vital role, especially for international shipping. Factors like distance, shipping method, and customs duties can significantly affect the final price.

-

Margin: Suppliers will factor in their profit margins, which can vary widely based on competition and perceived value.

How Do Price Influencers Affect 4.00 16 Sourcing?

Several factors can influence the pricing of 4.00 16 products, making it essential for buyers to understand these dynamics:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can lead to significant discounts. Understanding a supplier’s MOQ can help you negotiate better prices.

-

Specifications and Customization: Custom specifications can increase costs. Buyers should evaluate the necessity of customization against potential price increases.

-

Material Quality and Certifications: Higher quality materials and certifications will increase costs but can lead to better performance and longevity. Buyers should weigh the long-term benefits against initial expenses.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: The terms of shipping and delivery can affect total costs. Familiarizing yourself with Incoterms (like FOB, CIF) can help you understand your responsibilities and potential costs.

What Are the Best Buyer Tips for Cost-Efficient Sourcing of 4.00 16 Products?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negotiate Wisely: Leverage volume purchasing to negotiate better prices. Always be prepared to discuss your long-term sourcing needs to encourage suppliers to offer competitive pricing.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, consider logistics, maintenance, and potential downtime when evaluating suppliers. A cheaper product might lead to higher costs in the long run.

-

Understand Pricing Nuances: Regional differences in pricing can be significant. For instance, tariffs and import duties may apply when sourcing from outside the EU, impacting your total cost.

-

Stay Informed About Market Trends: Keep abreast of market conditions and material availability, as these can influence pricing. For example, fluctuations in rubber prices can directly affect the cost of 4.00 16 tires.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing and terms over time. Suppliers are often more willing to negotiate with buyers who demonstrate commitment and reliability.

Disclaimer for Indicative Prices

Prices for 4.00 16 products can vary widely based on the factors mentioned above. It’s essential to conduct thorough research and obtain multiple quotes to ensure you are getting a fair price tailored to your specific needs.

Alternatives Analysis: Comparing 4.00 16 With Other Solutions

Understanding the Importance of Alternatives in B2B Solutions

In today’s competitive landscape, B2B buyers must evaluate multiple solutions before making a commitment. This is especially crucial for buyers in regions like Africa, South America, the Middle East, and Europe, where market dynamics and operational needs vary significantly. When considering the ‘4.00 16’, exploring alternatives can provide valuable insights into performance, cost-efficiency, and adaptability to specific business environments.

Comparison Table: Evaluating ‘4.00 16’ Against Alternatives

| Comparison Aspect | ‘4.00 16’ | Alternative 1: ‘5.00 16’ | Alternative 2: ‘3.50 16’ |

|---|---|---|---|

| Performance | High | Very High | Moderate |

| Cost | Mid-range | High | Low |

| Ease of Implementation | Easy | Moderate | Easy |

| Maintenance | Low | Moderate | Low |

| Best Use Case | General use in agriculture and transportation | Heavy-duty applications | Light-duty applications |

What Are the Benefits and Drawbacks of ‘5.00 16’?

A stock image related to 4.00 16.

The ‘5.00 16’ is a robust alternative that excels in performance, making it suitable for heavy-duty applications. Its high-performance capabilities mean it can handle more demanding tasks, which is particularly beneficial for industries like construction and mining. However, this comes at a higher cost, which may be a deterrent for budget-conscious buyers. Additionally, while installation is moderately easy, it requires more training and resources compared to the ‘4.00 16’. Maintenance is also a consideration, as it may necessitate more frequent checks to ensure optimal functionality.

How Does ‘3.50 16’ Compare in Terms of Cost and Use Cases?

The ‘3.50 16’ presents a cost-effective solution for businesses seeking a budget-friendly option. Its lower price point makes it appealing for smaller enterprises or projects with limited resources. The ease of implementation further enhances its attractiveness, as companies can quickly integrate it into their operations without extensive training. However, its performance is moderate, making it less suitable for heavy-duty tasks. It is best utilized in light-duty applications, such as small-scale agricultural operations or local transportation, where high performance is not a critical requirement.

Conclusion: Which Solution Should You Choose?

Choosing the right solution requires a careful assessment of your specific needs and operational context. If your business demands high performance and can accommodate a higher budget, the ‘5.00 16’ may be the optimal choice. For businesses with limited budgets or lighter operational needs, the ‘3.50 16’ offers a compelling alternative. Ultimately, the ‘4.00 16’ serves as a versatile middle ground, balancing performance and cost-effectiveness. By understanding these alternatives and their respective advantages, B2B buyers can make informed decisions that align with their strategic goals.

Essential Technical Properties and Trade Terminology for 4.00 16

What Are the Essential Technical Properties of 4.00 16?

When dealing with the 4.00 16 specification, understanding its technical properties is crucial for making informed purchasing decisions. Here are the key specifications that international B2B buyers should consider:

-

Material Grade

The material grade typically defines the quality and characteristics of the product. For 4.00 16, this often refers to the type of rubber or compound used in manufacturing. Buyers need to assess the material grade to ensure it meets durability and performance requirements, especially in varying climates prevalent in regions like Africa and the Middle East. -

Tolerance Levels

Tolerance refers to the allowable deviation from specified dimensions. In the context of 4.00 16, it is essential to understand the tolerance levels for both diameter and width. Precise tolerances are vital for ensuring compatibility with existing equipment, reducing the risk of operational failures, and minimizing waste during installation. -

Load Capacity

Load capacity indicates the maximum weight the 4.00 16 can support. It is particularly important for buyers in industries such as agriculture and construction, where heavy machinery is involved. Understanding load capacity helps in selecting the right components that can withstand operational demands without compromising safety. -

Temperature Resistance

This property measures how well the 4.00 16 can perform under varying temperature conditions. For buyers operating in regions with extreme temperatures, such as parts of South America and the Middle East, it is vital to choose products that maintain their integrity and performance in high or low-temperature environments. -

Abrasion Resistance

Abrasion resistance refers to the ability of the material to withstand wear and tear. For B2B buyers, especially in mining or transportation sectors, selecting a 4.00 16 with high abrasion resistance can lead to longer service life and reduced replacement costs, thereby enhancing overall operational efficiency.

What Common Trade Terms Should B2B Buyers Know for 4.00 16?

Familiarity with trade terminology is essential for effective communication and negotiations in international B2B transactions. Here are some key terms that are relevant to the 4.00 16 sector:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking for specific quality standards and compatibility with existing machinery. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. For international buyers, especially from Europe and Africa, knowing the MOQ helps in budgeting and inventory management, ensuring that procurement aligns with operational needs without excessive surplus. -

RFQ (Request for Quotation)

An RFQ is a document that invites suppliers to bid on providing specific products or services. For B2B buyers, issuing an RFQ for 4.00 16 allows for competitive pricing and helps in evaluating supplier capabilities, which is vital for making cost-effective decisions. -

Incoterms (International Commercial Terms)

These are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for understanding shipping responsibilities, cost allocations, and risk management in the supply chain. -

Lead Time

Lead time refers to the time taken from placing an order to its delivery. Understanding lead times is critical for B2B buyers to plan their inventory and production schedules effectively, particularly in industries with tight deadlines and seasonal demands.

By grasping these technical properties and trade terms, international B2B buyers can enhance their procurement strategies for 4.00 16, ensuring they make informed, strategic decisions that align with their operational needs and market conditions.

Navigating Market Dynamics and Sourcing Trends in the 4.00 16 Sector

What Are the Current Market Dynamics and Key Trends in the 4.00 16 Sector?

The 4.00 16 sector is undergoing significant transformations influenced by global economic shifts and technological advancements. International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should note that the demand for high-quality, cost-effective solutions is driving market dynamics. Key trends include increased digitization of the supply chain, where technologies such as blockchain and IoT are enhancing transparency and efficiency. The rise of e-commerce platforms tailored for B2B transactions is making it easier for buyers to source products from diverse suppliers across the globe.

Moreover, sustainability is becoming a pivotal aspect of purchasing decisions. Buyers are increasingly favoring suppliers who can demonstrate eco-friendly practices and compliance with international standards. In regions like Europe, stringent regulations concerning product sustainability are shaping sourcing strategies. Additionally, geopolitical factors, including trade policies and tariffs, are influencing market accessibility and pricing. B2B buyers must stay informed about these trends to make strategic decisions that align with their business objectives.

How Important Is Sustainability and Ethical Sourcing in the 4.00 16 Sector?

Sustainability and ethical sourcing are not just buzzwords; they are essential components of modern B2B operations in the 4.00 16 sector. The environmental impact of manufacturing and distributing products is under increasing scrutiny. Buyers are expected to prioritize suppliers who actively engage in reducing their carbon footprint and utilize sustainable materials. For instance, sourcing products with certifications such as ISO 14001 or those made from recycled materials can significantly enhance a company’s reputation and appeal to eco-conscious consumers.

In addition, the importance of ethical supply chains is becoming paramount. B2B buyers should consider the labor practices of their suppliers, ensuring that they comply with international labor standards and promote fair treatment of workers. Transparency in sourcing can build trust and foster long-term partnerships. Engaging with suppliers who prioritize sustainability and ethics can lead to better compliance with regulations and improved market positioning, particularly in regions like Europe, where consumer demand for responsible business practices is on the rise.

What Is the Evolution of the 4.00 16 Sector and Its Implications for B2B Buyers?

A stock image related to 4.00 16.

The 4.00 16 sector has seen notable evolution over the past few decades, driven by technological advancements and changing consumer preferences. Initially dominated by traditional manufacturing methods, the sector has shifted towards more innovative approaches, including automation and smart manufacturing. This evolution has led to improvements in product quality and reductions in lead times, enabling B2B buyers to respond more effectively to market demands.

As the sector continues to evolve, the implications for B2B buyers are significant. Buyers must adapt to rapidly changing technologies and market conditions, ensuring they are sourcing from suppliers who are not only technologically adept but also aligned with sustainable practices. Understanding this evolution will equip buyers with the knowledge to navigate the complexities of the market and leverage new opportunities for growth and collaboration.

Frequently Asked Questions (FAQs) for B2B Buyers of 4.00 16

-

How do I solve supply chain disruptions when sourcing 4.00 16?

Supply chain disruptions can significantly impact your procurement of 4.00 16 products. To mitigate these risks, establish a diversified supplier base across different regions, including Africa, South America, and Europe. Utilize technology to enhance visibility in your supply chain, enabling you to quickly identify and address potential issues. Additionally, consider implementing a just-in-case inventory strategy, which allows for maintaining extra stock to buffer against unexpected delays. -

What is the best sourcing strategy for purchasing 4.00 16 products?

The best sourcing strategy for 4.00 16 products involves a comprehensive approach that includes supplier vetting, competitive pricing analysis, and understanding local market conditions. Start by conducting thorough market research to identify reliable suppliers in your target regions. Establish strong relationships with suppliers through regular communication and visits, if possible. Lastly, leverage bulk purchasing to negotiate better terms, ensuring you receive quality products at competitive prices. -

What should I consider when evaluating suppliers for 4.00 16?

When evaluating suppliers for 4.00 16, consider their industry experience, production capabilities, and quality assurance processes. Request certifications and references to verify their compliance with international standards. It’s also important to assess their financial stability and ability to meet your minimum order quantities (MOQs). Conducting site visits can provide deeper insights into their operations and reliability, helping you make informed decisions. -

What are the typical minimum order quantities (MOQs) for 4.00 16 products?

Minimum order quantities (MOQs) for 4.00 16 products can vary significantly depending on the supplier and the type of product. Generally, MOQs can range from 100 to 1,000 units. It’s important to discuss these terms upfront to ensure they align with your purchasing needs. Some suppliers may offer flexibility on MOQs for established clients or bulk orders, so don’t hesitate to negotiate terms that work for your business. -

What payment terms are common for international purchases of 4.00 16?

Common payment terms for international purchases of 4.00 16 typically include options like Letters of Credit (LC), wire transfers, or payment upon delivery. Some suppliers may require a deposit upfront, especially for larger orders. It’s essential to clarify these terms before finalizing any agreements to avoid misunderstandings. Consider using escrow services for added security, particularly when dealing with new suppliers. -

How can I ensure quality assurance when sourcing 4.00 16 products?

To ensure quality assurance when sourcing 4.00 16 products, implement a robust quality control process. This may involve specifying quality standards in your purchase agreements and conducting regular audits of your suppliers. Request samples before placing large orders to evaluate product quality firsthand. Additionally, consider partnering with third-party inspection services to verify compliance with your specifications prior to shipment. -

What logistics considerations should I keep in mind when importing 4.00 16?

When importing 4.00 16, logistics considerations include shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder experienced in handling your specific products and regions. Familiarize yourself with import duties and compliance requirements in your country to avoid delays. Establish a clear timeline for delivery to ensure your supply chain remains uninterrupted, allowing for contingencies in case of delays. -

How can I navigate customs regulations when importing 4.00 16 products?

Navigating customs regulations requires thorough preparation and understanding of the import laws in your country. Ensure all documentation, including invoices and packing lists, is accurate and complete. Work with a customs broker to facilitate the process and stay updated on any changes in regulations. Familiarize yourself with tariff codes specific to 4.00 16 products to ensure compliance and avoid unexpected fees or delays during clearance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 4.00 16

What Are the Key Takeaways for B2B Buyers in Strategic Sourcing?

In conclusion, the strategic sourcing of 4.00 16 presents a significant opportunity for international B2B buyers, especially from Africa, South America, the Middle East, and Europe. By leveraging data-driven decision-making and supplier relationships, organizations can enhance their procurement processes and minimize costs. Key takeaways include the importance of understanding local market dynamics, the necessity of fostering long-term partnerships with suppliers, and the benefits of adopting technology for better sourcing efficiency.

How Can Strategic Sourcing Drive Competitive Advantage?

Strategic sourcing not only streamlines procurement but also contributes to sustainability and innovation, making it a vital component in today’s global market. For businesses aiming to thrive in competitive landscapes, implementing a robust sourcing strategy can lead to enhanced product quality, improved service delivery, and ultimately, customer satisfaction.

What Should B2B Buyers Do Next?

As you move forward, consider how your organization can integrate these insights into your sourcing strategies. Engage with local suppliers to tap into regional advantages and explore collaborative opportunities. The future of sourcing is not just about cost but also about building resilient supply chains that can adapt to changing market conditions. Now is the time to act—evaluate your current sourcing practices and embrace a strategic approach to ensure your business remains competitive in the evolving global marketplace.