Unlock Cost Savings with C Channel 10: The Complete Guide (2025)

Introduction: Navigating the Global Market for c channel 10

In the ever-evolving landscape of global commerce, sourcing c channel 10 presents a unique challenge for international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. As industries increasingly rely on these versatile structural components, understanding the nuances of the c channel 10 market becomes crucial. This guide is designed to assist buyers in navigating the complexities of sourcing c channel 10 by offering insights into various types, applications, and supplier vetting processes.

From construction to manufacturing, c channel 10 plays a vital role in numerous applications, making it essential for buyers to grasp its specifications and performance characteristics. This comprehensive resource will delve into critical factors influencing purchasing decisions, including cost considerations, quality standards, and the importance of supplier reliability. By equipping buyers with the knowledge needed to make informed decisions, this guide aims to demystify the procurement process, ensuring that businesses can secure the right materials for their projects.

Whether you are a seasoned buyer or new to the international market, this guide empowers you to confidently navigate the c channel 10 landscape. With actionable insights tailored to the unique challenges and opportunities faced by B2B buyers in your region, you will be better positioned to optimize your procurement strategy and enhance your competitive edge in the global marketplace.

Understanding c channel 10 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard C Channel | Uniform thickness, typically made of steel or aluminum | Structural support in construction | Pros: Versatile, widely available; Cons: May require additional processing for specific uses. |

| Lip C Channel | Features a flange or lip on one or both edges | Framing, shelving, and support structures | Pros: Enhanced rigidity; Cons: Slightly heavier, which may affect shipping costs. |

| Punched C Channel | Contains punched holes for easy installation | Electrical and mechanical applications | Pros: Simplifies assembly; Cons: Limited load-bearing capacity compared to solid channels. |

| Galvanized C Channel | Coated with zinc for corrosion resistance | Outdoor and marine applications | Pros: Long-lasting, resistant to rust; Cons: Higher initial cost compared to non-galvanized options. |

| Custom C Channel | Tailored dimensions and specifications | Specialized industrial applications | Pros: Meets specific project requirements; Cons: Longer lead times and potentially higher costs. |

What Are the Characteristics of Standard C Channel?

Standard C Channels are characterized by their uniform thickness and are typically manufactured from steel or aluminum. They are widely used in various construction applications due to their strength and versatility. Buyers should consider the availability and stock sizes, as they are often readily accessible, which can lead to quicker project turnaround times. However, for specific applications requiring unique dimensions, additional processing may be necessary.

How Does Lip C Channel Differ from Standard Options?

Lip C Channels are distinguished by the presence of a flange or lip along one or both edges, which provides increased rigidity. This type is ideal for applications such as framing and shelving, where added strength is beneficial. While they offer enhanced structural integrity, buyers should note that the added weight may increase shipping costs. Evaluating the project’s weight tolerance and structural needs is essential when considering this option.

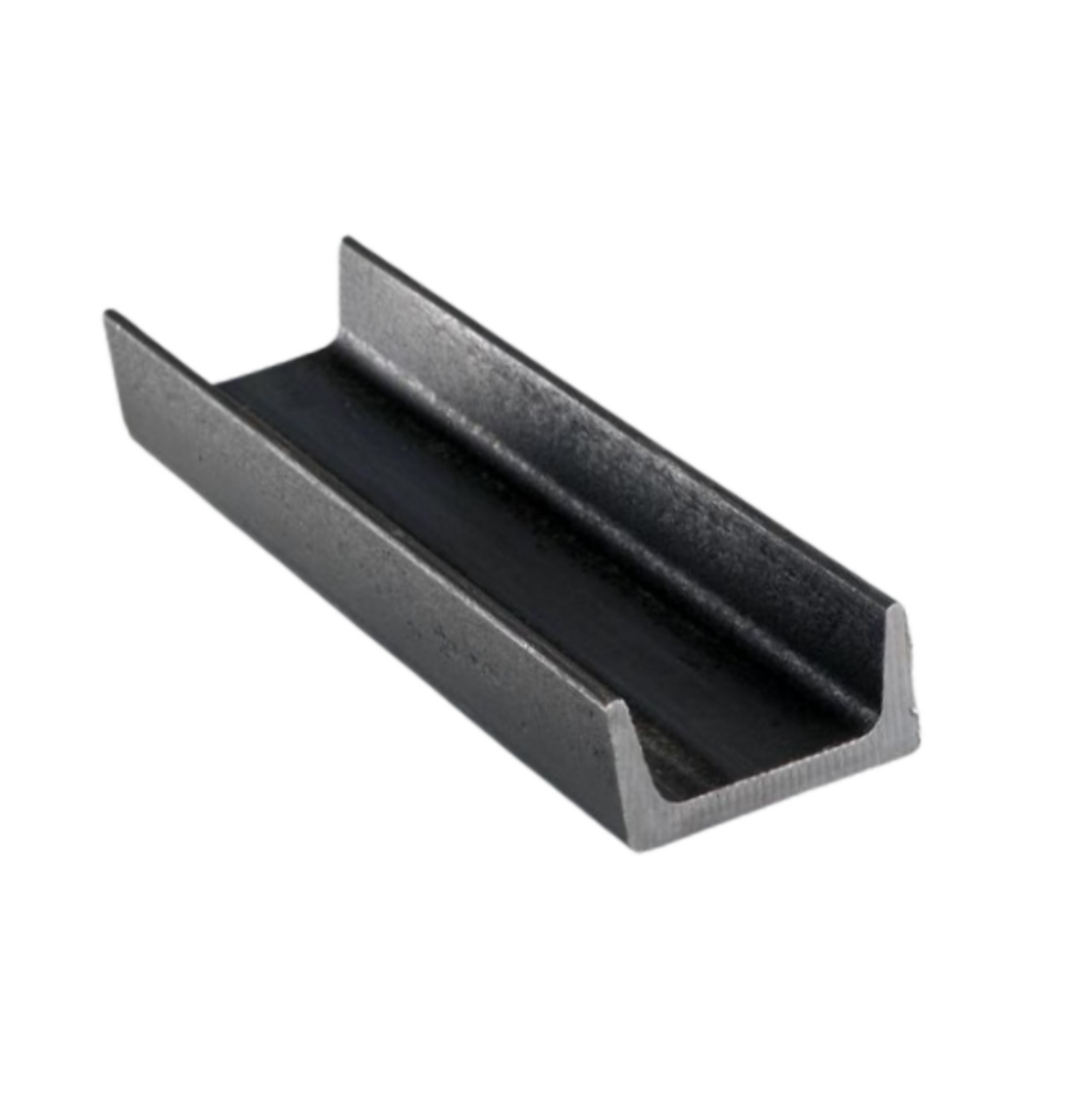

A stock image related to c channel 10.

What Are the Benefits of Punched C Channel?

Punched C Channels feature holes punched into the web of the channel, facilitating easy installation and integration into various systems. They are commonly used in electrical and mechanical applications where quick assembly is a priority. While they simplify the installation process, buyers must be aware that this design may limit the load-bearing capacity compared to solid channels. Assessing the specific load requirements is critical for ensuring safety and functionality.

Why Choose Galvanized C Channel for Outdoor Use?

Galvanized C Channels are coated with zinc, providing excellent corrosion resistance, making them suitable for outdoor and marine applications. Their longevity and ability to withstand harsh environmental conditions are significant advantages for B2B buyers operating in such settings. However, the initial cost is typically higher than that of non-galvanized channels, so businesses should weigh the long-term benefits of durability against upfront expenditures.

What Are the Advantages of Custom C Channel Solutions?

Custom C Channels are tailored to meet specific dimensions and specifications, making them ideal for specialized industrial applications. This flexibility allows businesses to address unique project requirements effectively. However, buyers should be prepared for longer lead times and potentially higher costs associated with custom fabrication. Understanding the balance between project needs and budget constraints is vital for making an informed purchasing decision.

Related Video: Heat Pump Thermostat O, B, and C Terminal Variations Explained

Key Industrial Applications of c channel 10

| Industry/Sector | Specific Application of c channel 10 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural framing for buildings and bridges | Provides strength and stability, reducing structural failures | Sourcing from reliable manufacturers with quality certifications |

| Transportation | Rail and road infrastructure support | Enhances durability and safety of transport networks | Consider local suppliers for cost-effectiveness and timely delivery |

| Manufacturing | Machinery and equipment support structures | Increases operational efficiency and machine longevity | Look for suppliers with experience in heavy-duty applications |

| Renewable Energy | Solar panel mounting systems | Optimizes energy capture and system reliability | Evaluate suppliers based on material specifications and environmental compliance |

| Automotive | Vehicle chassis and frame components | Improves vehicle strength and safety standards | Ensure compliance with industry safety regulations and standards |

How is c channel 10 Used in Construction?

In the construction industry, c channel 10 is predominantly utilized for structural framing in buildings and bridges. Its design offers superior strength and stability, crucial for load-bearing applications. By using c channel 10, construction firms can mitigate risks associated with structural failures, ensuring the safety and longevity of their projects. International buyers should prioritize sourcing from manufacturers with robust quality certifications and a proven track record in structural applications to meet local building codes and standards.

What Role Does c channel 10 Play in Transportation?

In the transportation sector, c channel 10 is essential for supporting rail and road infrastructure. It contributes to the durability and safety of transport networks, enabling effective load distribution across bridges and roadways. B2B buyers in this sector should consider sourcing from local suppliers to enhance cost-effectiveness and ensure timely delivery, which is critical for project schedules. Additionally, assessing the supplier’s ability to meet specific regional transportation standards is vital for compliance.

How is c channel 10 Applied in Manufacturing?

Within manufacturing, c channel 10 serves as a support structure for machinery and equipment. Its robust construction enhances operational efficiency and extends the lifespan of critical machinery, thus reducing downtime and maintenance costs. Buyers should seek suppliers with expertise in heavy-duty applications, ensuring that the c channel 10 can withstand the rigors of manufacturing environments. It’s also important to verify that the materials meet industry-specific standards for durability and performance.

In What Ways Does c channel 10 Support Renewable Energy Projects?

In the renewable energy sector, c channel 10 is commonly used for mounting solar panels. Its ability to provide a stable and reliable support structure optimizes energy capture while ensuring the longevity of solar installations. International buyers should evaluate suppliers based on their material specifications and environmental compliance, as these factors can affect the overall performance and sustainability of solar projects. Understanding local regulations regarding renewable energy infrastructure is also crucial for successful sourcing.

How is c channel 10 Integrated into Automotive Manufacturing?

In the automotive industry, c channel 10 is integral to the production of vehicle chassis and frame components. Its strength contributes to enhanced vehicle safety and performance, making it a preferred choice for manufacturers focused on meeting stringent safety standards. B2B buyers should ensure that their suppliers comply with industry regulations and quality standards, as this is essential for maintaining safety and performance in automotive applications. Additionally, evaluating the supplier’s capacity for timely delivery can significantly impact production schedules.

Related Video: Uses and Gratifications Theory – UGT

3 Common User Pain Points for ‘c channel 10’ & Their Solutions

Scenario 1: Navigating Quality Concerns in Sourcing ‘C Channel 10’

The Problem:

B2B buyers often struggle with ensuring the quality and reliability of ‘c channel 10’ products, especially when sourcing from international suppliers. This is particularly true for buyers in regions like Africa and South America, where supply chain inconsistencies can lead to significant delays and increased costs. Concerns about substandard materials or non-compliance with industry standards can create hesitance, resulting in lost business opportunities and diminished trust in supplier relationships.

The Solution:

To effectively manage quality concerns, buyers should implement a rigorous vendor evaluation process. Start by conducting thorough background checks on potential suppliers, including their certifications and quality assurance processes. Utilize third-party inspection services to verify product quality before shipment. Additionally, establish clear quality specifications and communicate them to suppliers upfront. This proactive approach not only mitigates risks but also fosters stronger partnerships, as suppliers appreciate working with buyers who prioritize quality.

Scenario 2: Understanding the Technical Specifications of ‘C Channel 10’

The Problem:

Many B2B buyers encounter difficulties in understanding the technical specifications associated with ‘c channel 10’. This lack of knowledge can lead to purchasing the wrong product or miscalculating the required dimensions, which can be particularly detrimental in projects that require precise measurements, such as construction or manufacturing. Buyers in Europe and the Middle East may face additional challenges due to varying standards and terminologies across regions.

The Solution:

To overcome this issue, buyers should invest time in educating themselves about the technical specifications of ‘c channel 10’. This can be achieved through industry seminars, webinars, or online courses focused on construction materials. Additionally, leveraging resources like detailed product catalogs or technical datasheets from manufacturers can provide essential information. Engage with sales representatives to clarify any doubts about specifications and applications. Lastly, consider forming a cross-functional team that includes engineers and procurement specialists to ensure that all technical aspects are thoroughly evaluated before purchasing decisions are made.

Scenario 3: Managing Delivery Timelines and Logistics for ‘C Channel 10’

The Problem:

Delivery delays and logistical challenges are common pain points for B2B buyers dealing with ‘c channel 10’. International shipping can be unpredictable, with factors such as customs regulations, transportation strikes, or unexpected demand fluctuations impacting timelines. Buyers in regions like Africa and South America may find these issues particularly pronounced, leading to project delays and increased costs.

The Solution:

To effectively manage delivery timelines, buyers should adopt a multi-faceted logistics strategy. Begin by selecting suppliers who have a proven track record of timely deliveries and who offer transparency regarding shipping processes. Utilize technology solutions such as supply chain management software to track shipments in real time. Building buffer periods into project timelines can also alleviate the stress of potential delays. Furthermore, consider establishing relationships with multiple suppliers to create redundancy; this ensures that if one supplier faces delays, alternatives can be quickly sourced. By proactively managing logistics, buyers can minimize disruptions and maintain project schedules.

Strategic Material Selection Guide for c channel 10

When selecting materials for c channel 10, international B2B buyers must consider various factors that influence performance, cost, and compliance with local standards. Here, we analyze four common materials used in the manufacturing of c channel 10, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Steel for c channel 10?

Steel is one of the most widely used materials for c channel 10 due to its excellent mechanical properties. It has high tensile strength, making it ideal for structural applications. Steel can withstand high temperatures and pressures, which is crucial for applications in construction and heavy machinery. Additionally, it can be treated for corrosion resistance, enhancing its longevity in various environments.

Pros & Cons: Steel’s durability and strength are significant advantages. However, it is susceptible to corrosion if not properly treated, which can lead to increased maintenance costs. The manufacturing complexity is moderate, as steel can be easily formed and welded, but the initial cost can be higher than other materials.

Impact on Application: Steel c channels are suitable for load-bearing applications and are often used in construction, automotive, and industrial sectors. Buyers need to consider local corrosion factors and whether additional protective coatings are necessary.

How Does Aluminum Compare as a Material for c channel 10?

Aluminum is another popular choice for c channel 10, particularly in applications where weight savings are essential. It has a lower density than steel, making it easier to handle and transport. Aluminum also exhibits excellent corrosion resistance due to its natural oxide layer, which protects it from environmental factors.

Pros & Cons: The lightweight nature of aluminum is a significant advantage, especially in aerospace and automotive applications. However, it has a lower tensile strength compared to steel, which may limit its use in heavy-load applications. The cost of aluminum is generally higher than steel, and its manufacturing process can be more complex, requiring specialized equipment.

Impact on Application: Aluminum c channels are ideal for applications where weight reduction is critical, such as in transportation and packaging. Buyers should consider the specific load requirements and potential need for additional structural support.

What Are the Benefits of Using Stainless Steel for c channel 10?

Stainless steel combines the strength of steel with enhanced corrosion resistance, making it suitable for applications exposed to harsh environments. It is particularly beneficial in industries such as food processing, pharmaceuticals, and marine applications where hygiene and corrosion resistance are paramount.

Pros & Cons: The key advantage of stainless steel is its resistance to rust and staining, which extends the life of the product. However, it is more expensive than both regular steel and aluminum, which can impact budget considerations. The manufacturing process is also more complex, requiring specialized welding techniques.

Impact on Application: Stainless steel c channels are often used in environments where cleanliness is essential, such as hospitals and food production facilities. Buyers must ensure compliance with industry standards like ASTM or FDA regulations.

Why Consider Composite Materials for c channel 10?

Composite materials, such as fiberglass reinforced plastic (FRP), are gaining popularity for c channel 10 applications due to their unique properties. Composites are lightweight, strong, and resistant to corrosion and chemicals, making them suitable for a variety of industries, including construction and marine.

Pros & Cons: The primary advantage of composites is their resistance to environmental degradation, which can result in lower maintenance costs over time. However, they can be more expensive to produce and may not have the same load-bearing capacity as metals. The manufacturing process can also be complex, requiring specialized techniques.

Impact on Application: Composite c channels are particularly effective in applications where weight and corrosion resistance are critical. Buyers should evaluate the specific environmental conditions and mechanical requirements of their applications.

Summary Table of Material Selection for c channel 10

| Material | Typical Use Case for c channel 10 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural applications in construction and machinery | High tensile strength | Susceptible to corrosion | Medium |

| Aluminum | Aerospace and automotive applications | Lightweight | Lower tensile strength | High |

| Stainless Steel | Food processing and marine applications | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Composite Materials | Construction and marine applications | Corrosion and chemical resistance | Higher production costs | Medium to High |

This comprehensive analysis provides international B2B buyers with actionable insights into material selection for c channel 10, ensuring informed decisions that align with performance requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for c channel 10

What Are the Key Manufacturing Processes for C Channel 10?

The manufacturing of C Channel 10 involves several critical stages, each requiring precision and quality control to ensure the final product meets industry standards. Understanding these processes is essential for international B2B buyers, particularly those sourcing from regions like Africa, South America, the Middle East, and Europe.

How is Material Prepared for C Channel 10 Manufacturing?

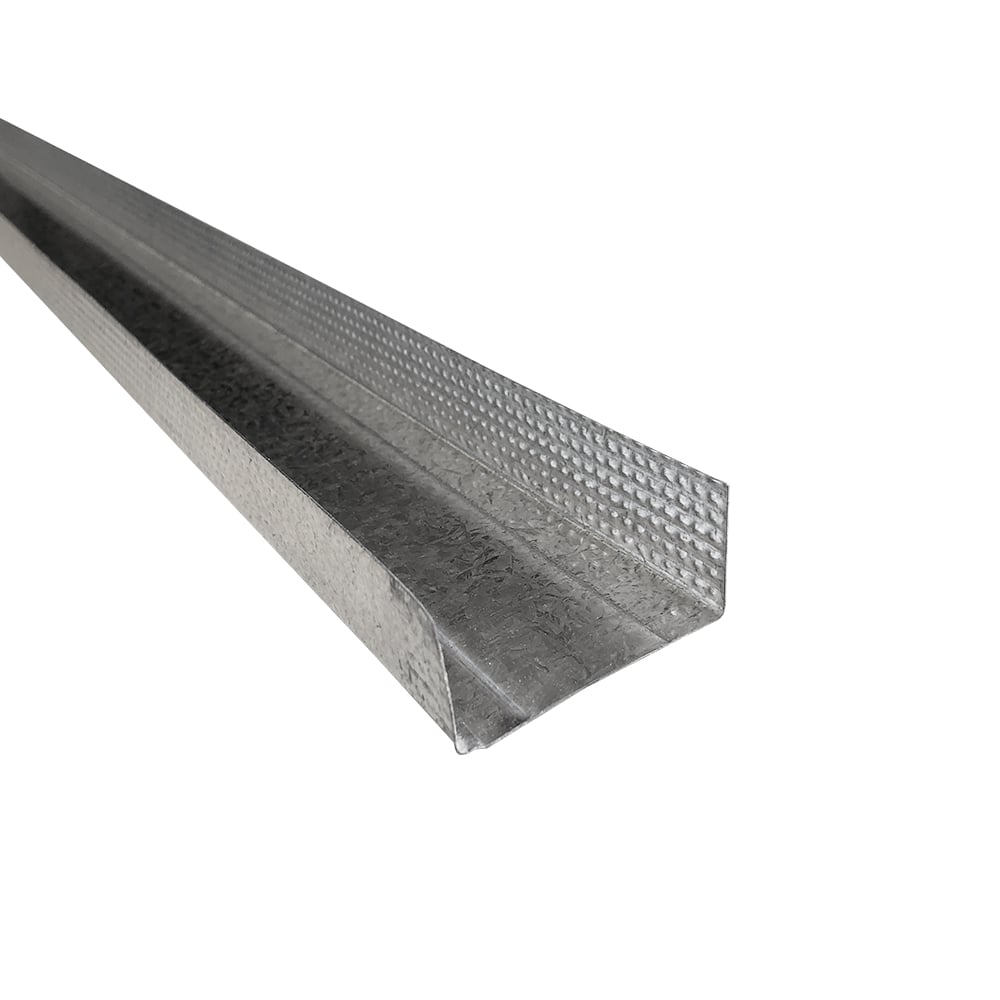

A stock image related to c channel 10.

The first stage in manufacturing C Channel 10 is material preparation, which typically involves selecting high-quality steel or aluminum based on the desired properties of the final product. Buyers should ensure that the supplier uses materials compliant with international standards, such as ASTM A36 for carbon steel or ASTM A572 for high-strength steel.

Once the materials are selected, they undergo cutting to the required dimensions. This process may utilize various methods, including shearing, sawing, or plasma cutting, depending on the thickness and type of material. It is crucial for buyers to verify that the materials are free from defects, as any imperfections can compromise the structural integrity of the final product.

What Forming Techniques Are Used in C Channel 10 Production?

Following material preparation, the next stage is forming, where the flat steel or aluminum sheets are transformed into the C channel shape. This typically involves processes such as:

- Roll Forming: Continuous forming technique where the material is passed through a series of rollers that progressively shape it into a C channel.

- Cold Bending: Involves bending the material at room temperature, which is suitable for thinner gauges and provides better dimensional accuracy.

Buyers should inquire about the specific forming techniques used by suppliers, as these can significantly affect the mechanical properties of the C channel. A reliable supplier will have the capability to adjust the forming process based on the material’s characteristics.

How Are C Channels Assembled and Finished?

After forming, the assembly process may involve welding or fastening sections of C channels together for specific applications. This stage requires skilled labor to ensure strong joints and structural integrity.

The finishing process is equally important and may include surface treatments such as galvanizing, powder coating, or painting to enhance corrosion resistance and aesthetic appeal. Buyers should confirm that suppliers follow established practices for finishing, as improper techniques can lead to premature wear and degradation.

What Quality Assurance Practices Should B2B Buyers Expect?

Quality assurance (QA) is integral to the manufacturing process of C Channel 10. Understanding the QA practices that suppliers implement is vital for international buyers to ensure they receive products that meet their specifications.

Which International Standards Should C Channel 10 Manufacturers Comply With?

Manufacturers of C Channel 10 should adhere to relevant international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards ensures that the manufacturer maintains consistent quality in their production processes.

Additionally, industry-specific standards like CE marking for European markets or API standards for applications in the oil and gas sector may also apply. Buyers should request documentation proving compliance with these standards, as this can indicate the manufacturer’s commitment to quality.

What Are the Key Quality Control Checkpoints in C Channel 10 Production?

Quality control (QC) checkpoints are essential at various stages of the manufacturing process. Key QC checkpoints include:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process, including dimensional checks and visual inspections.

- Final Quality Control (FQC): Comprehensive testing of the finished product, including load testing, dimensional accuracy, and surface finish assessments.

Buyers should engage with suppliers about their QC processes, including the frequency and nature of inspections performed at each checkpoint.

How Can B2B Buyers Verify Supplier Quality Assurance?

Verifying the quality assurance processes of suppliers is crucial for B2B buyers, especially when sourcing from international markets. Here are several strategies to ensure supplier reliability:

What Documentation Should Buyers Request from Suppliers?

International buyers should request documentation such as:

- Quality Management System Certificates: Proof of compliance with ISO 9001 or other relevant standards.

- Inspection Reports: Detailed reports from IQC, IPQC, and FQC stages.

- Test Certificates: Results from any relevant mechanical testing performed on the C channels.

These documents provide transparency into the supplier’s quality assurance practices and help mitigate risks associated with product quality.

How Can Buyers Conduct Supplier Audits?

Conducting supplier audits is an effective way to assess the quality control processes of potential manufacturers. Buyers can either perform these audits in person or hire third-party inspection agencies to conduct comprehensive evaluations.

During audits, it is essential to assess the manufacturing environment, production processes, and adherence to quality standards. This hands-on approach provides invaluable insights into the supplier’s capabilities and commitment to quality.

What Testing Methods Are Commonly Used for C Channel 10?

Common testing methods for C Channel 10 include:

- Ultrasonic Testing (UT): Used to detect internal flaws in the material.

- Magnetic Particle Testing (MT): Effective for identifying surface defects.

- Tensile Testing: Evaluates the material’s strength and ductility.

B2B buyers should ensure that suppliers employ these testing methods and provide corresponding test reports to verify the quality and safety of the products.

Conclusion

Understanding the manufacturing processes and quality assurance measures for C Channel 10 is essential for international B2B buyers. By focusing on material preparation, forming techniques, assembly, finishing, and rigorous quality control practices, buyers can ensure they partner with reliable suppliers who deliver high-quality products that meet their specific needs. Engaging with suppliers about their compliance with international standards and conducting thorough audits will further enhance confidence in the sourcing process.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘c channel 10’

In today’s global marketplace, sourcing ‘c channel 10’ effectively requires a strategic approach tailored to the unique needs of international B2B buyers. This guide provides a step-by-step checklist to ensure a streamlined procurement process, focusing on practical actions that can significantly enhance your sourcing outcomes.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of any successful procurement process. This step ensures that all stakeholders understand the exact requirements of ‘c channel 10’, such as material properties, dimensions, and performance standards.

- Key Details to Consider:

- What are the specific dimensions and tolerances required?

- Are there industry standards or certifications that must be met?

Step 2: Conduct Market Research

Thorough market research helps identify potential suppliers and understand the competitive landscape. This step allows you to assess the availability, pricing, and quality of ‘c channel 10’ across different regions, including Africa, South America, the Middle East, and Europe.

- Important Aspects:

- Analyze market trends and demand fluctuations.

- Investigate suppliers’ reputations through online reviews and industry forums.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it is crucial to conduct a thorough evaluation. This includes requesting company profiles, case studies, and references from other buyers in similar industries or regions.

- What to Look For:

- Supplier experience in manufacturing ‘c channel 10’.

- Customer testimonials or case studies that demonstrate reliability and quality.

Step 4: Verify Supplier Certifications

Ensuring that your suppliers have the necessary certifications is essential for maintaining quality standards and compliance with international regulations. This step helps mitigate risks associated with substandard products.

- Key Certifications to Check:

- ISO certifications relevant to manufacturing processes.

- Compliance with local and international safety standards.

Step 5: Request Samples for Testing

Before placing a large order, requesting samples of ‘c channel 10’ allows you to assess the quality and suitability of the product for your specific needs. This step is vital to avoid costly mistakes down the line.

- What to Test:

- Physical attributes such as strength and flexibility.

- Compatibility with existing systems or components.

Step 6: Negotiate Terms and Conditions

Effective negotiation can lead to better pricing, delivery schedules, and payment terms. This step is essential for establishing a mutually beneficial relationship with your supplier.

- Points to Negotiate:

- Payment terms (e.g., net 30, net 60).

- Delivery timelines and logistics arrangements.

Step 7: Establish a Communication Plan

Clear communication is crucial throughout the procurement process. Establishing a communication plan ensures that all parties are aligned on expectations, timelines, and any potential issues that may arise.

A stock image related to c channel 10.

- Communication Strategies:

- Set regular check-ins during the sourcing process.

- Use project management tools to track progress and updates.

By following this checklist, international B2B buyers can navigate the complexities of sourcing ‘c channel 10’ more effectively, ensuring that they secure the best products at the most favorable terms.

Comprehensive Cost and Pricing Analysis for c channel 10 Sourcing

What are the Key Cost Components in Sourcing C Channel 10?

When sourcing C Channel 10, international B2B buyers should understand the various cost components that contribute to the overall pricing. These include:

-

Materials: The type of steel used (e.g., mild steel, stainless steel) significantly impacts the cost. Prices can fluctuate based on global steel market conditions, so it’s wise to keep an eye on these trends.

-

Labor: Labor costs vary by region and affect the final price of C Channel 10. For instance, labor costs in Africa or South America may differ significantly from those in Europe or the Middle East.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, maintenance, and factory management. Buyers should inquire about how these costs are calculated by suppliers.

-

Tooling: If custom sizes or specifications are required, tooling costs can be substantial. Understanding the tooling setup and amortization can help buyers evaluate potential long-term savings.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but can increase costs. Buyers should weigh the importance of certifications (like ISO) against potential price increases.

-

Logistics: Shipping costs vary based on the Incoterms agreed upon and the geographical distance from the manufacturer. Buyers should factor in freight, insurance, and handling costs.

-

Margin: Supplier profit margins can vary widely. Negotiating favorable terms can help lower the overall cost, but it’s crucial to balance price with quality.

How Do Price Influencers Impact C Channel 10 Sourcing?

Several factors influence the pricing of C Channel 10 that buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically result in lower per-unit costs. Buyers should evaluate their purchasing strategy to optimize volume discounts.

-

Specifications and Customization: Custom dimensions or additional features (like coatings) can lead to higher prices. Clearly defining requirements upfront can mitigate unexpected costs.

-

Material Quality and Certifications: Higher-quality materials or additional certifications (such as ASTM standards) often come with increased costs. Buyers should assess whether these are necessary for their application.

-

Supplier Factors: Supplier reliability, reputation, and location play a crucial role in pricing. Establishing long-term relationships with reputable suppliers can lead to more favorable pricing over time.

-

Incoterms: The choice of Incoterms (like FOB, CIF, etc.) impacts logistics costs and risk allocation. Understanding these terms can help buyers manage total costs effectively.

What Buyer Tips Can Enhance Cost-Efficiency in C Channel 10 Sourcing?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, can adopt several strategies to improve cost-efficiency:

-

Negotiate Effectively: Engage suppliers in discussions about pricing, volume discounts, and payment terms. A well-prepared negotiation can lead to substantial savings.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, performance, and durability of the C Channel 10. This perspective can lead to better investment decisions.

-

Understand Pricing Nuances: Different regions may have varying pricing structures based on local market conditions. Awareness of these nuances can provide leverage during negotiations.

-

Build Strategic Partnerships: Establishing long-term relationships with suppliers can yield better pricing and service terms. Trust and communication can lead to mutually beneficial agreements.

Disclaimer on Pricing

Prices for C Channel 10 can vary widely based on market conditions, supplier capabilities, and specific order requirements. Buyers should request quotes from multiple suppliers and consider all cost components to make informed purchasing decisions. Regularly reviewing supplier performance and market trends will further enhance sourcing strategies.

Alternatives Analysis: Comparing c channel 10 With Other Solutions

When evaluating the effectiveness of ‘C Channel 10’, it is essential for B2B buyers to consider viable alternatives that could meet similar needs. This analysis will provide a structured comparison of ‘C Channel 10’ against two alternative solutions, helping international buyers make informed decisions based on performance, cost, and other critical factors.

| Comparison Aspect | ‘C Channel 10’ | Alternative 1: ‘C Channel 12’ | Alternative 2: ‘C Channel 8’ |

|---|---|---|---|

| Performance | High durability and load capacity | Moderate durability, better for lighter loads | Lower durability, primarily for non-structural uses |

| Cost | Moderate initial investment | Higher cost due to advanced materials | Lower cost, but may require more frequent replacements |

| Ease of Implementation | Straightforward installation with standard tools | Slightly more complex due to design features | Easy installation, but less versatile |

| Maintenance | Low maintenance requirements | Moderate maintenance due to wear | High maintenance due to frequent replacements |

| Best Use Case | Heavy-duty applications like construction and industrial use | Suitable for medium-duty applications | Ideal for light-duty applications or temporary structures |

What Are the Advantages and Disadvantages of ‘C Channel 12’ as an Alternative?

‘C Channel 12’ offers enhanced performance with advanced materials that provide greater resistance to corrosion and wear. This makes it suitable for applications requiring high durability, such as in marine environments or heavy machinery. However, the initial investment is higher, which may deter cost-sensitive buyers. The complexity of its design can also make installation slightly more challenging, necessitating specialized tools or skills.

How Does ‘C Channel 8’ Compare in Terms of Cost and Application?

‘C Channel 8’ is the most cost-effective option among the three, making it attractive for businesses with tight budgets or those needing temporary solutions. Its lightweight design allows for easy installation, which can save on labor costs. However, the trade-off is a significant reduction in durability, making it unsuitable for heavy-duty applications. Frequent replacements may lead to higher long-term costs, particularly in environments that demand robust structural support.

Conclusion: Which Solution Should B2B Buyers Choose?

When selecting between ‘C Channel 10’ and its alternatives, B2B buyers should assess their specific needs, including load requirements, budget constraints, and application environments. For heavy-duty applications, ‘C Channel 10’ remains a reliable choice due to its durability and low maintenance. In contrast, ‘C Channel 12’ may be ideal for specialized situations where performance outweighs cost, while ‘C Channel 8’ serves well for budget-conscious projects with lighter demands. Careful consideration of these factors will ensure that buyers choose the most appropriate solution for their operational needs.

Essential Technical Properties and Trade Terminology for c channel 10

What are the Key Technical Properties of C Channel 10?

When considering the purchase of C Channel 10, understanding its technical properties is essential for ensuring it meets your project requirements. Here are the critical specifications:

-

Material Grade

C Channel 10 is typically made from structural steel grades like ASTM A36 or A992. The choice of material affects strength, weight, and corrosion resistance. For B2B buyers, selecting the right material grade is crucial as it impacts both the durability and performance of the final product. -

Dimensions and Tolerances

C Channel 10 dimensions include height, flange width, and thickness, with common specifications being 10 inches in height and varying flange widths. Tolerances refer to the permissible limits of variation in these dimensions. Precise dimensions and tolerances ensure that the channels fit correctly in their intended applications, minimizing the need for adjustments during installation. -

Weight

The weight of C Channel 10 is a significant factor for shipping and handling. It is typically measured in pounds per foot (lb/ft). Knowing the weight helps in planning logistics and ensures that the structural support can handle the load it will bear in construction or manufacturing contexts. -

Yield Strength

Yield strength indicates the maximum stress a material can withstand without permanent deformation. For example, ASTM A36 steel has a yield strength of approximately 36,000 psi. Understanding yield strength is crucial for B2B buyers to ensure that the C Channel 10 can support the required loads without failure. -

Finish

The finish of C Channel 10 can vary from hot-rolled to galvanized or painted. The finish affects corrosion resistance and aesthetic appearance. Selecting the appropriate finish is essential, particularly in environments exposed to moisture or chemicals, as it can prolong the lifespan of the product.

What Trade Terms Should B2B Buyers Understand When Purchasing C Channel 10?

Familiarity with industry terminology can streamline the procurement process for C Channel 10. Here are several essential terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. Understanding this term helps buyers identify whether they are sourcing directly from the manufacturer or through a reseller, which can affect pricing and warranty conditions. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. It’s important for B2B buyers to know the MOQ as it impacts inventory management and cash flow. A high MOQ may require larger upfront investments. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. Submitting an RFQ can help buyers compare different suppliers’ offers, ensuring they get the best value for C Channel 10. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms like FOB (Free On Board) or CIF (Cost Insurance Freight) is crucial for understanding the total landed cost of C Channel 10. -

Lead Time

Lead time refers to the period between placing an order and receiving the goods. Understanding lead time is essential for project planning and can impact timelines, especially in construction or manufacturing projects where delays can be costly.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding their procurement of C Channel 10, ensuring they choose the right specifications and navigate the purchasing process effectively.

Navigating Market Dynamics and Sourcing Trends in the c channel 10 Sector

What Are the Current Market Dynamics and Key Trends in the C Channel 10 Sector?

The C channel 10 sector is experiencing significant transformations driven by technological advancements and changing consumer preferences. Globalization continues to play a pivotal role, allowing international B2B buyers from regions such as Africa, South America, the Middle East, and Europe to access a wider array of suppliers and products. One of the most prominent trends is the increased adoption of digital platforms for sourcing. This shift not only enhances efficiency but also allows for real-time data analysis, enabling buyers to make informed decisions quickly.

Additionally, the rise of automation and AI is reshaping supply chain dynamics. These technologies streamline operations and reduce costs, which is crucial for international buyers seeking competitive pricing. Furthermore, sustainability is becoming a core consideration, with buyers increasingly prioritizing suppliers who demonstrate a commitment to ethical practices and environmental responsibility. This trend is particularly resonant in Europe, where stringent regulations push companies to adopt more sustainable sourcing practices.

Another key dynamic is the fluctuation of global supply chains, influenced by geopolitical factors and economic shifts. Buyers must navigate these complexities by diversifying their supplier base and exploring alternative sourcing strategies to mitigate risks. Understanding local market conditions and cultural nuances in Africa and South America, for instance, can enhance negotiation tactics and foster stronger partnerships.

How Is Sustainability Shaping Ethical Sourcing in the C Channel 10 Sector?

Sustainability is no longer a mere buzzword; it has become a critical factor in the procurement processes of B2B buyers. The environmental impact of sourcing decisions can no longer be ignored, as stakeholders demand greater transparency and accountability from suppliers. In the C channel 10 sector, this shift has led to an increased emphasis on ethical supply chains that prioritize responsible sourcing practices.

International buyers must seek suppliers that comply with recognized sustainability certifications, such as ISO 14001 or Fair Trade. These certifications not only indicate a commitment to reducing environmental footprints but also ensure that labor practices are ethical and fair. By aligning with suppliers who embrace sustainable materials and processes, businesses can reduce their own environmental impact while appealing to eco-conscious consumers.

Moreover, the integration of ‘green’ materials in product offerings can enhance brand reputation and open doors to new markets. For instance, sourcing recycled or bio-based materials can differentiate products in a competitive marketplace. Buyers should engage in thorough due diligence to assess the sustainability practices of potential suppliers, ensuring that their sourcing strategies reflect their corporate values and meet the expectations of their stakeholders.

What Is the Historical Context of the C Channel 10 Sector in B2B Sourcing?

The C channel 10 sector has evolved significantly over the past few decades, transitioning from traditional sourcing methods to a more integrated, technology-driven approach. Historically, sourcing was heavily reliant on personal relationships and localized suppliers. However, the advent of the internet and digital platforms has revolutionized this landscape, providing B2B buyers with instant access to global markets.

In the early 2000s, the focus began to shift toward efficiency and cost reduction, prompting the adoption of e-procurement systems. This evolution allowed businesses to streamline their purchasing processes and leverage data analytics for better decision-making. As the market matured, the emphasis on sustainability and ethical sourcing emerged as a response to consumer demand for responsible business practices. Today, the C channel 10 sector stands at the intersection of technology, sustainability, and globalization, making it imperative for international B2B buyers to adapt to these ongoing changes to remain competitive.

Frequently Asked Questions (FAQs) for B2B Buyers of c channel 10

-

How do I choose the right supplier for c channel 10?

Selecting a supplier for c channel 10 involves assessing several key factors. Start by evaluating their industry experience and reputation. Look for suppliers with positive reviews and testimonials from other businesses, especially those in your region. Additionally, request samples to inspect the quality of the c channel 10. Ensure they can meet your specific customization requirements and confirm their ability to deliver on time. Lastly, consider their responsiveness to inquiries, as this reflects their customer service and commitment to B2B relationships. -

What customization options are available for c channel 10?

Many suppliers offer customization options for c channel 10, allowing you to tailor dimensions, materials, and finishes to suit your project needs. Discuss your specific requirements with potential suppliers, including any unique specifications that may be necessary for your application. Some suppliers may also provide design assistance to help optimize the product for your intended use. Be sure to inquire about minimum order quantities (MOQs) for customized orders, as these can vary significantly. -

What are the typical payment terms for sourcing c channel 10?

Payment terms for c channel 10 can vary based on the supplier and your relationship with them. Common terms include a deposit upfront (usually 30-50%) with the balance due upon delivery or after inspection. Some suppliers may offer net terms (e.g., net 30 or net 60) for established customers. It’s essential to clarify payment methods accepted, such as wire transfers, credit cards, or letters of credit, and to ensure these terms align with your company’s cash flow management. -

How can I ensure quality assurance when sourcing c channel 10?

To ensure quality assurance for c channel 10, request certifications and quality control documentation from the supplier. Inquire about their manufacturing processes and whether they adhere to international standards, such as ISO certifications. Consider conducting factory audits or hiring third-party inspectors to verify the quality of production before shipment. Establish clear inspection criteria and discuss these with the supplier to ensure that the final product meets your specifications. -

What logistics considerations should I keep in mind when importing c channel 10?

When importing c channel 10, it’s crucial to understand shipping logistics, including freight costs, delivery times, and customs regulations in your country. Work with a freight forwarder who can help you navigate these complexities. Ensure that you have all necessary documentation, such as commercial invoices and packing lists, to facilitate customs clearance. Additionally, consider the mode of transport (air vs. sea) based on urgency and budget constraints, as well as the need for insurance coverage during transit. -

What are the common challenges faced when sourcing c channel 10 internationally?

Common challenges include language barriers, differing quality standards, and varying lead times. Additionally, fluctuations in currency exchange rates can impact pricing. To mitigate these risks, establish clear communication channels with suppliers and negotiate contracts that outline expectations and responsibilities. Engaging with a local partner or an experienced sourcing agent can also help navigate cultural and logistical challenges, ensuring a smoother procurement process. -

How do I determine the minimum order quantity (MOQ) for c channel 10?

Minimum order quantities (MOQs) for c channel 10 can vary significantly among suppliers. Generally, larger manufacturers may have higher MOQs due to production efficiency, while smaller suppliers may be more flexible. To determine the MOQ that suits your needs, directly communicate with potential suppliers and explain your project requirements. If the MOQ is too high, consider negotiating or exploring options for joint orders with other businesses to meet the supplier’s requirements without excess inventory. -

What are the key factors to consider for after-sales support when sourcing c channel 10?

After-sales support is crucial in ensuring customer satisfaction and product performance. Key factors to consider include the supplier’s warranty policy, availability of replacement parts, and responsiveness to inquiries post-purchase. Discuss the support channels they offer, such as phone, email, or live chat. Additionally, verify if they provide technical assistance or training on product usage, which can enhance your operational efficiency and minimize downtime in your projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for c channel 10

In the evolving landscape of global trade, strategic sourcing for c channel 10 emerges as a pivotal factor in enhancing supply chain efficiency and competitive advantage. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding the nuances of c channel 10 can lead to significant cost reductions and improved procurement processes. By leveraging data-driven insights and technology, businesses can optimize their sourcing strategies, ensuring they stay ahead in an increasingly competitive market.

How Can International Buyers Maximize Their Strategic Sourcing Efforts?

The value of strategic sourcing extends beyond mere cost savings; it fosters stronger supplier relationships and enhances product quality. International buyers should prioritize collaboration with suppliers who demonstrate transparency and reliability, as this will pave the way for long-term partnerships. Furthermore, embracing sustainability practices in sourcing not only meets consumer demand but also positions companies favorably in the eyes of stakeholders.

As we look to the future, the importance of agility and responsiveness in sourcing strategies will only grow. Buyers must remain vigilant, adapting their approaches to emerging trends and market dynamics. This is an invitation for international B2B buyers to take proactive steps in refining their sourcing strategies, ensuring they are well-equipped to seize opportunities in the ever-changing global marketplace.