Unlock Cost Savings with PU Ard: The Complete Guide (2025)

Introduction: Navigating the Global Market for pu ard

In today’s dynamic global market, sourcing PU (polyurethane) materials presents unique challenges for B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe. With a myriad of suppliers and applications ranging from automotive components to consumer goods, understanding the nuances of PU materials can significantly impact procurement decisions. This comprehensive guide is designed to illuminate the complexities of the PU market, offering insights into various types of PU products, their specific applications, and the critical factors to consider when vetting suppliers.

Buyers will gain valuable knowledge on cost structures, quality assurance, and logistics that affect the overall procurement process. Additionally, the guide addresses common pitfalls and best practices for making informed purchasing decisions, ensuring that international buyers can navigate the market landscape effectively. By focusing on regional considerations—such as local regulations and market trends in countries like Kenya and Egypt—this resource empowers businesses to optimize their sourcing strategies and enhance their competitive edge.

Ultimately, this guide serves as a vital tool for B2B buyers seeking to harness the full potential of PU materials, fostering successful partnerships with suppliers and driving innovation within their industries.

Understanding pu ard Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Remote Desktop | Allows control of a remote computer; supports various OS | IT support, remote work | Pros: Easy access, cost-effective; Cons: Latency issues can affect performance. |

| Cloud Computing | Utilizes cloud infrastructure for storage and processing | Data storage, application hosting | Pros: Scalability, reduced IT costs; Cons: Dependency on internet connectivity. |

| Virtual Private Network (VPN) | Secures internet connection, encrypts data | Secure remote access, secure communications | Pros: Enhanced security, privacy; Cons: May slow down internet speed. |

| Cloud Rendering | Leverages cloud resources for rendering graphics and animations | Media production, game development | Pros: High processing power, cost-effective for large projects; Cons: Requires internet for access. |

| Collaboration Tools | Combines communication and project management features | Team projects, remote collaboration | Pros: Improves team productivity, easy to use; Cons: May require training for effective use. |

What are the Key Characteristics of Remote Desktop Solutions?

Remote desktop solutions enable users to access and control a computer from a distant location. They are particularly suitable for IT support and remote work scenarios, where quick access to a workstation is crucial. When considering a remote desktop solution, B2B buyers should evaluate the ease of use, compatibility with different operating systems, and the level of support offered. Latency can be a concern, especially in high-demand environments, so assessing network requirements is essential.

How Does Cloud Computing Benefit B2B Operations?

Cloud computing provides businesses with scalable resources for data storage and application hosting. This model allows companies to adjust their resources based on current needs, making it an attractive option for organizations with fluctuating workloads. Buyers should consider the reliability of the cloud provider, data security measures, and potential costs associated with data transfer and storage. While cloud computing reduces IT infrastructure costs, it also creates a dependency on stable internet connectivity.

Why Choose a Virtual Private Network (VPN) for Business Security?

VPNs are essential for securing internet connections, especially for businesses that require remote access to sensitive information. By encrypting data, VPNs protect against unauthorized access and enhance user privacy. B2B buyers should assess the level of encryption offered, ease of setup, and whether the VPN service can maintain performance without significant speed reductions. While VPNs improve security, they may introduce latency, which can affect user experience.

What are the Advantages of Cloud Rendering in Media Production?

Cloud rendering allows businesses in media production to utilize powerful cloud resources for rendering graphics and animations, which can significantly reduce project timelines. This is particularly beneficial for industries like film and gaming, where high-quality visual output is essential. Buyers should evaluate the processing power available, the pricing model, and the provider’s reliability. While cloud rendering is cost-effective for large projects, it requires consistent internet access for optimal performance.

How Do Collaboration Tools Enhance Team Productivity?

Collaboration tools integrate various communication and project management features to facilitate teamwork, especially in remote settings. These tools are designed to streamline workflows, improve communication, and enhance overall productivity. When selecting a collaboration tool, B2B buyers should consider user-friendliness, integration with existing systems, and the level of training required for teams. Although these tools can enhance productivity, they may require time investment for effective implementation and usage.

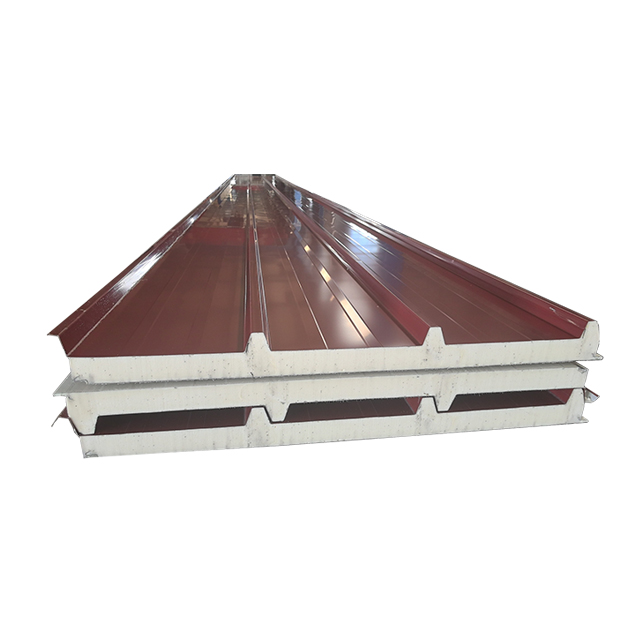

A stock image related to pu ard.

Related Video: Heat Pump Thermostat O, B, and C Terminal Variations Explained

Key Industrial Applications of pu ard

| Industry/Sector | Specific Application of pu ard | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Real-time monitoring and control | Enhances operational efficiency and reduces downtime | Need for reliable connectivity and robust security |

| Healthcare | Remote patient monitoring | Improves patient outcomes and reduces hospital visits | Compliance with health regulations and data privacy |

| Education | Virtual classrooms and remote learning | Expands access to education and reduces costs | Scalability and ease of integration with existing tools |

| Financial Services | Secure transaction processing | Increases security and customer trust | Strong encryption standards and regulatory compliance |

| Energy | Remote site management | Increases operational efficiency and reduces costs | Robust connectivity in remote locations and scalability |

How is pu ard Used in Manufacturing for Real-Time Monitoring and Control?

In the manufacturing sector, pu ard is pivotal for real-time monitoring and control of production lines. By integrating advanced remote access solutions, businesses can oversee equipment performance and troubleshoot issues instantly, minimizing production downtime. For international B2B buyers, especially in regions like Africa and South America, sourcing reliable connectivity solutions is critical to ensure seamless operations. Additionally, security features must be robust to protect sensitive production data from cyber threats.

What are the Benefits of Remote Patient Monitoring in Healthcare with pu ard?

In healthcare, pu ard enables remote patient monitoring, allowing healthcare providers to track vital signs and patient conditions in real-time. This application not only enhances patient care but also significantly reduces the need for in-person visits, thereby optimizing resource allocation. For buyers in the Middle East and Europe, understanding compliance with health regulations and data privacy laws is essential when sourcing these technologies. The ability to integrate with existing health IT systems can also be a critical factor for successful implementation.

How Does pu ard Facilitate Virtual Classrooms in Education?

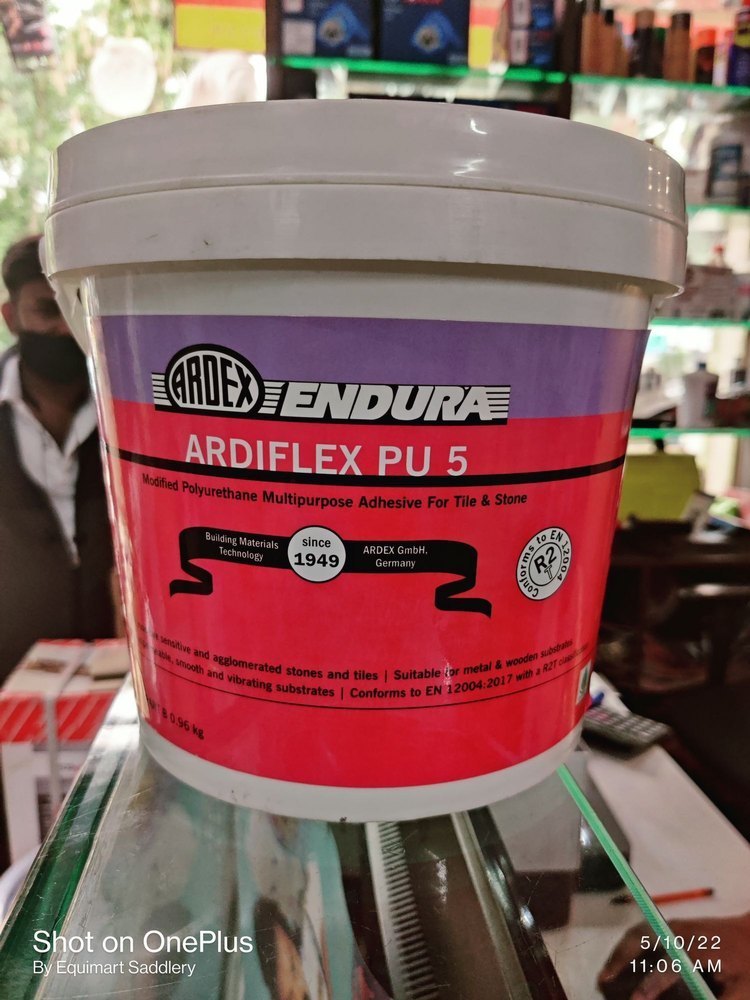

A stock image related to pu ard.

Pu ard supports virtual classrooms and remote learning environments, providing educational institutions with tools to deliver lessons effectively to students regardless of their location. This application is particularly beneficial in regions with limited access to physical schools, such as rural areas in Africa. International buyers should consider the scalability of the solution and its compatibility with existing educational technologies. Ease of use for both educators and students is also a vital factor in ensuring successful adoption.

Why is Secure Transaction Processing Important in Financial Services with pu ard?

In the financial services sector, pu ard plays a crucial role in secure transaction processing. By utilizing advanced encryption and secure remote access technologies, financial institutions can enhance security and build customer trust. For B2B buyers in South America and Europe, understanding the regulatory landscape and ensuring compliance with financial regulations is essential when sourcing these solutions. Strong encryption standards and the ability to conduct audits are key considerations for maintaining security and compliance.

How Does pu ard Improve Remote Site Management in the Energy Sector?

In the energy sector, pu ard is instrumental in remote site management, enabling companies to monitor and control operations from distant locations. This capability leads to increased operational efficiency and significant cost savings, particularly in remote areas. Buyers from regions like Africa and the Middle East should focus on sourcing solutions that offer robust connectivity options to ensure reliable communication across vast distances. Additionally, scalability is important for accommodating future growth in energy operations.

Related Video: What are all the Laboratory Apparatus and their uses?

3 Common User Pain Points for ‘pu ard’ & Their Solutions

Scenario 1: Navigating Connectivity Issues in Remote Access

The Problem: For B2B buyers, particularly in regions like Africa and South America, consistent internet connectivity can be a significant hurdle when implementing ‘pu ard’ solutions for remote access. Businesses often face challenges with intermittent connectivity or slow speeds, which can severely hinder productivity and affect the reliability of remote operations. This situation can lead to frustrations among employees who rely on seamless access to critical systems and data, ultimately impacting overall business efficiency.

The Solution: To address connectivity issues, it is crucial to invest in robust network infrastructure and consider solutions that offer adaptive bandwidth management. Buyers should look for ‘pu ard’ services that provide features like adaptive streaming and auto-adjusting resolution based on available bandwidth. Engaging local ISPs to ensure reliable service or considering satellite internet options could also be viable solutions. Additionally, buyers should implement a hybrid approach by combining cloud-based access with on-premises systems, allowing critical operations to continue even when internet connectivity is compromised. Regularly scheduled maintenance and updates to the software can also enhance performance and stability, ensuring a smoother user experience.

Scenario 2: Ensuring Data Security and Compliance

The Problem: In the realm of B2B transactions, data security and compliance with local regulations are paramount. Buyers from the Middle East and Europe often struggle with ensuring that their ‘pu ard’ solutions comply with stringent data protection laws, such as GDPR in Europe or various local data sovereignty laws. The challenge is compounded by the risk of data breaches, which can lead to severe financial penalties and reputational damage.

The Solution: To navigate these complexities, it is essential for buyers to select ‘pu ard’ solutions that prioritize security features such as end-to-end encryption, multi-factor authentication, and robust access controls. Conducting thorough due diligence on vendors is critical; this includes reviewing their compliance certifications and understanding how they manage data. Buyers should also establish a clear data governance framework that outlines data handling processes and compliance checks. Regular audits and training for employees on data security best practices can further mitigate risks. Partnering with legal experts to stay updated on regulatory changes can also help businesses remain compliant while leveraging ‘pu ard’ technologies effectively.

Scenario 3: Managing User Experience and Technical Support

The Problem: As businesses increasingly adopt ‘pu ard’ solutions, user experience becomes a critical factor. B2B buyers often face challenges with the technical onboarding of employees and ongoing support, especially in regions where technical expertise may be limited. Users may encounter difficulties in navigating the software, leading to decreased productivity and increased frustration.

The Solution: To enhance user experience, buyers should prioritize solutions that offer comprehensive onboarding and training programs. This includes access to user-friendly documentation, video tutorials, and dedicated customer support channels. Engaging in proactive communication with vendors about the availability of localized support can also be beneficial. Implementing a feedback loop where users can report issues and suggest improvements can lead to continuous enhancements in usability. Additionally, considering solutions that provide customizable user interfaces can help cater to the specific needs of different teams, ultimately leading to higher satisfaction and more effective use of the ‘pu ard’ technology.

Strategic Material Selection Guide for pu ard

When selecting materials for pu ard applications, international B2B buyers must consider various factors that influence product performance, compliance, and overall suitability for specific markets. Below, we analyze four common materials used in pu ard, providing insights into their properties, advantages, disadvantages, and implications for buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Polyurethane (PU) in pu ard Applications?

Polyurethane (PU) is a versatile material known for its excellent flexibility, durability, and resistance to abrasion. It is often used in applications requiring cushioning and insulation. PU can withstand a wide range of temperatures, typically from -30°C to 80°C, making it suitable for various environmental conditions. Additionally, PU exhibits good chemical resistance, particularly against oils and solvents, which is crucial for applications in industrial settings.

Pros: The primary advantages of PU include its lightweight nature, high resilience, and excellent mechanical properties. It can also be molded into complex shapes, allowing for customization in design.

Cons: However, PU can be more expensive than other materials like rubber or polyethylene, and it may degrade under prolonged exposure to UV light unless treated.

How Does Polypropylene (PP) Perform in pu ard Applications?

Polypropylene (PP) is another popular choice for pu ard due to its chemical resistance and low density. It is commonly used in applications requiring good impact resistance and thermal stability, with a temperature range of -20°C to 100°C. PP is also lightweight and has a relatively high melting point, making it suitable for various manufacturing processes.

Pros: The key benefits of PP include its cost-effectiveness and ease of processing. It can be easily molded and recycled, which is an advantage for companies focusing on sustainability.

Cons: On the downside, PP has lower tensile strength compared to PU and may not perform well in high-stress applications. Its compatibility with certain chemicals should also be assessed to avoid degradation.

What Are the Benefits of Using Stainless Steel in pu ard?

Stainless steel is often selected for pu ard applications that require high strength and corrosion resistance. It can withstand extreme temperatures and pressures, making it ideal for industrial environments. Stainless steel is also known for its longevity and minimal maintenance requirements.

Pros: The primary advantage of stainless steel is its durability and resistance to rust and corrosion, which is essential for applications exposed to harsh conditions.

Cons: However, stainless steel is heavier and more expensive than plastic alternatives, which may not be suitable for all applications. Its manufacturing complexity can also lead to higher production costs.

Why Choose Aluminum for pu ard Applications?

Aluminum is favored in pu ard for its lightweight and high strength-to-weight ratio. It is resistant to corrosion and can be anodized for additional protection. Aluminum is suitable for a range of temperatures, typically from -50°C to 150°C, making it versatile for various applications.

Pros: The advantages of aluminum include its excellent machinability and recyclability, making it an attractive option for companies focused on sustainability.

Cons: However, aluminum can be more susceptible to scratching and denting compared to other materials, which may affect its aesthetic and functional properties over time.

Summary Table of Material Selection for pu ard

| Material | Typical Use Case for pu ard | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane | Cushioned components, insulation | Excellent flexibility and durability | Can degrade under UV exposure | Medium |

| Polypropylene | Lightweight structural parts | Cost-effective and easy to process | Lower tensile strength | Low |

| Stainless Steel | High-strength components in harsh environments | Superior corrosion resistance | Heavier and more expensive | High |

| Aluminum | Lightweight frames and structural supports | High strength-to-weight ratio | Susceptible to scratching | Medium |

In conclusion, selecting the appropriate material for pu ard applications involves careful consideration of each material’s properties, advantages, and limitations. International B2B buyers should also factor in compliance with regional standards and preferences to ensure successful integration into their supply chains.

In-depth Look: Manufacturing Processes and Quality Assurance for pu ard

What Are the Main Stages in the Manufacturing Process of PU Ard?

The manufacturing process for PU (polyurethane) products, such as PU ard, typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial for ensuring that the final product meets the required specifications and quality standards.

-

Material Preparation: The first stage involves sourcing high-quality raw materials, including polyols and isocyanates. Suppliers must ensure that these materials comply with international standards, such as REACH in Europe or other regional regulations, to avoid any legal issues during importation. Buyers should request Material Safety Data Sheets (MSDS) to verify compliance.

-

Forming: In this stage, the prepared materials are mixed and poured into molds. Techniques such as reaction injection molding (RIM) or casting are commonly used. The choice of technique can significantly affect the physical properties of the final product, such as its density, hardness, and flexibility. It is essential for B2B buyers to understand these techniques to ensure they select the right products for their specific applications.

-

Assembly: After forming, components may require assembly. This can include joining different PU parts or integrating other materials such as metals or fabrics. The assembly process often employs adhesives or mechanical fastening methods. Buyers should inquire about the assembly techniques used, as they can impact the durability and performance of the final product.

-

Finishing: The final stage includes processes like trimming, surface treatment, and coating. These processes not only enhance the aesthetic appeal but also improve the functional properties of the PU product, such as resistance to abrasion or UV light. B2B buyers should look for suppliers who offer finishing options that align with their product requirements.

How Is Quality Assurance Implemented in PU Ard Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process for PU ard. It ensures that the products meet both customer expectations and regulatory requirements. Here are the key components of a robust QA system:

-

International Standards: Many manufacturers adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards is crucial for international B2B buyers, as it indicates a commitment to quality and continuous improvement.

-

Industry-Specific Standards: Depending on the application, additional certifications may be required. For instance, products used in construction might need to comply with CE marking in Europe, while those used in oil and gas may require API certification. Buyers should verify the relevant certifications based on their industry and region.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, various checks are conducted to monitor critical parameters and ensure they remain within defined limits.

– Final Quality Control (FQC): Before shipment, finished products undergo final inspections and testing to confirm they meet all specifications. -

Common Testing Methods: Various tests are performed at different stages, including:

– Physical Testing: Evaluates properties like tensile strength, elongation, and hardness.

– Chemical Testing: Assesses the composition and reactivity of materials.

– Durability Testing: Simulates conditions to predict product lifespan and performance.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential. Here are some actionable strategies:

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. This includes reviewing their quality management systems, production capabilities, and compliance with relevant standards.

-

Requesting Quality Reports: Buyers should request documentation that outlines the supplier’s quality control processes, including test results and compliance certifications. These reports can provide assurance that the supplier maintains high-quality standards.

-

Third-Party Inspections: Engaging third-party inspection services can help validate a supplier’s claims regarding quality. These inspectors can perform random checks on raw materials, in-process products, and finished goods, ensuring compliance with quality standards.

-

Certifications and Accreditations: Buyers should verify that suppliers possess the necessary certifications and accreditations relevant to their industry. This can include ISO certifications, CE marking, or specific industry-related certifications. Checking the validity of these certifications can help ensure the supplier’s credibility.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers must navigate various challenges when it comes to quality control. Here are some nuances to consider:

-

Regulatory Compliance: Each region has its own regulatory requirements, and understanding these can be complex. Buyers from Africa and South America, for instance, may face different challenges compared to their European counterparts. It is vital to stay informed about local regulations to ensure compliance.

-

Cultural Differences: Cultural perceptions of quality can vary significantly across regions. Buyers should be aware of these differences when establishing quality expectations and communicating with suppliers.

-

Supply Chain Transparency: Ensuring transparency in the supply chain is crucial for quality assurance. Buyers should establish clear communication channels and demand regular updates from suppliers regarding their quality control processes and any issues that may arise.

-

Technological Advancements: Embracing technology, such as IoT and AI, can enhance quality control processes. Buyers should inquire whether suppliers utilize advanced technologies for monitoring and maintaining quality standards.

In conclusion, understanding the manufacturing processes and quality assurance measures for PU ard is essential for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with implementing robust quality control measures, buyers can ensure they source high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pu ard’

In the competitive landscape of international B2B procurement, especially for buyers from regions like Africa, South America, the Middle East, and Europe, having a structured approach to sourcing ‘pu ard’ can streamline operations and enhance decision-making. This practical sourcing guide provides a step-by-step checklist to aid B2B buyers in effectively procuring ‘pu ard’, ensuring they make informed choices.

Step 1: Define Your Technical Specifications

Clearly articulating your technical requirements is crucial. This includes understanding the specific functionalities of ‘pu ard’ that meet your business needs. Outline parameters such as performance metrics, compatibility with existing systems, and any customization requirements.

- Why it Matters: Clear specifications help avoid misunderstandings with suppliers and ensure that the products meet your operational needs.

- What to Look For: Detail aspects like software scalability, user interface, and system integration capabilities.

Step 2: Conduct Market Research

Dive into market analysis to identify potential suppliers and their offerings. Research their market presence, reputation, and product reviews.

- Why it Matters: A thorough understanding of the market landscape allows you to gauge which suppliers are reliable and competitive.

- What to Look For: Use platforms that compare suppliers and read reviews from other businesses, particularly those in similar industries or regions.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to vet suppliers rigorously. Request comprehensive company profiles, case studies, and references from existing clients.

- Why it Matters: This step helps to ensure that the supplier has a proven track record and can deliver on their promises.

- What to Look For: Focus on their experience in your industry, customer support capabilities, and any certifications that validate their expertise.

Step 4: Assess Compliance and Certifications

Verify that potential suppliers comply with industry standards and possess relevant certifications. This may include ISO certifications or other quality assurance marks.

- Why it Matters: Compliance ensures that the product meets safety and quality standards, which is crucial for operational integrity.

- What to Look For: Request documentation of certifications and check their validity with the issuing bodies.

Step 5: Request Samples or Trials

Where applicable, ask for samples or trial versions of the product. This allows you to evaluate the quality and functionality firsthand.

- Why it Matters: Experiencing the product in action can reveal insights that specifications alone may not provide.

- What to Look For: Assess usability, performance under load, and how well the product integrates with your existing systems.

Step 6: Negotiate Terms and Conditions

Engage in negotiations to establish clear terms regarding pricing, delivery timelines, payment options, and warranty provisions.

- Why it Matters: Clear agreements protect both parties and set expectations for the procurement process.

- What to Look For: Ensure that terms are documented and that you understand any penalties or fees associated with breaches of contract.

Step 7: Plan for Post-Purchase Support

Ensure that the supplier offers robust post-purchase support, including training, maintenance, and customer service.

- Why it Matters: Ongoing support is crucial for troubleshooting and optimizing the use of ‘pu ard’.

- What to Look For: Verify the supplier’s response times, support channels, and availability of technical assistance.

By following this checklist, B2B buyers can navigate the complexities of sourcing ‘pu ard’ effectively, ensuring they select suppliers that align with their business objectives and operational requirements.

Comprehensive Cost and Pricing Analysis for pu ard Sourcing

What Are the Key Cost Components in pu ard Sourcing?

When sourcing pu ard, understanding the cost structure is crucial for effective budgeting and price negotiation. The primary cost components include:

-

Materials: The quality and type of materials used in pu ard significantly impact costs. Opting for premium materials will naturally increase the price but may offer better durability and performance.

-

Labor: Labor costs can vary by region. In countries with lower labor costs, such as some in Africa or South America, you might find more competitive pricing. However, ensure that the quality of craftsmanship is not compromised.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Suppliers with higher overheads may pass these costs onto buyers.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. It’s essential to factor in these costs when determining the total price.

-

Quality Control (QC): Investing in rigorous QC processes can add to the overall cost but ensures that the pu ard meets specified standards, thereby reducing the risk of defects.

-

Logistics: Shipping costs vary depending on the distance and method of transport. International logistics can introduce additional fees, including tariffs and customs duties.

-

Margin: Supplier profit margins can differ widely. Understand the typical margins in your industry to gauge whether the offered price is competitive.

How Do Price Influencers Impact pu ard Costs?

Several factors influence the final price of pu ard:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for larger orders. Assess your needs carefully to take advantage of bulk pricing without overcommitting.

-

Specifications and Customization: Custom designs or specifications can increase costs due to additional design time and tooling. Clearly define your requirements to avoid unexpected charges.

-

Materials and Quality Certifications: The choice of materials, especially those with certifications (e.g., ISO, CE), can affect pricing. Higher-quality materials generally lead to higher prices but offer better long-term value.

-

Supplier Factors: Supplier reputation, reliability, and experience can impact pricing. Established suppliers may charge more but often provide better service and quality assurance.

-

Incoterms: Understanding the shipping terms agreed upon (like FOB, CIF) is crucial as they dictate who bears the cost of shipping and insurance, which can significantly affect the total price.

What Are Some Essential Buyer Tips for Cost-Efficiency in pu ard Sourcing?

International B2B buyers should consider the following strategies to enhance cost-efficiency in pu ard sourcing:

-

Negotiation: Always negotiate pricing, especially if you are making a large purchase or are a repeat customer. Suppliers may be willing to lower prices for long-term partnerships.

-

Total Cost of Ownership (TCO): Assess not just the purchase price but the TCO, including logistics, maintenance, and potential disposal costs. A lower initial price may not always equate to better value.

-

Pricing Nuances for International Buyers: Be aware of local market conditions and currency fluctuations. Prices can vary significantly based on regional demand and economic factors, particularly in diverse markets like Africa and South America.

-

Research and Compare Suppliers: Conduct thorough research on potential suppliers. Compare prices, quality, and service levels to make informed decisions. Utilize trade shows and online platforms to gather insights.

-

Seek Out Local Suppliers: Whenever possible, consider sourcing from local suppliers to reduce logistics costs and support local economies. This can also lead to quicker turnaround times and improved communication.

Disclaimer on Indicative Prices

Please note that the prices mentioned throughout this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always seek formal quotations and conduct due diligence before making purchasing decisions.

Alternatives Analysis: Comparing pu ard With Other Solutions

In the landscape of B2B solutions, exploring alternatives to ‘pu ard’ is essential for international buyers seeking the most effective technology for their operational needs. This section will compare ‘pu ard’ with two viable alternatives, providing actionable insights for businesses, particularly those operating in Africa, South America, the Middle East, and Europe.

Comparison Table of ‘Pu Ard’ and Alternatives

| Comparison Aspect | ‘Pu Ard’ | Alternative 1: ToDesk | Alternative 2: TeamViewer |

|---|---|---|---|

| Performance | High stability and speed | Excellent remote connection | Good performance with latency |

| Cost | Moderate pricing | Free for basic, tiered pricing | Subscription-based, higher cost |

| Ease of Implementation | Requires training for advanced features | User-friendly, easy setup | Simple to install and use |

| Maintenance | Regular updates needed | Low maintenance, auto-updates | Requires manual updates |

| Best Use Case | Remote management in enterprise | Remote desktop support and gaming | Remote support and access |

Detailed Breakdown of Alternatives

What are the Advantages and Disadvantages of ToDesk?

ToDesk is a robust remote desktop solution designed for both personal and enterprise use. One of its major advantages is the cost-effectiveness it offers, especially for small businesses, as it provides a free tier that allows basic functionality without any financial commitment. Its user-friendly interface makes it accessible for teams with varying technical skills. However, users may find that its performance can be affected during peak hours, leading to occasional latency issues, which could be a drawback for businesses requiring high-speed connections.

How Does TeamViewer Compare?

TeamViewer stands out as a well-known remote support tool, recognized for its extensive features, including file transfer and remote printing capabilities. Its ease of use and straightforward installation process make it a popular choice for businesses that need immediate remote access solutions. However, the subscription-based pricing model can be a disadvantage for smaller enterprises or startups, as costs can accumulate quickly, especially with multiple users. Additionally, TeamViewer’s performance may lag compared to ‘pu ard’ during high-demand periods, affecting critical operations.

How to Choose the Right Solution for Your Business Needs?

When selecting the appropriate solution for your business, consider your specific operational requirements, budget constraints, and the technical expertise of your team. For companies focused on cost-efficiency with basic remote access needs, ToDesk might be the ideal choice. On the other hand, if your operations require advanced features and robust support capabilities, TeamViewer could be more suitable despite its higher costs. Ultimately, evaluating the performance, ease of implementation, and maintenance requirements will guide you in making an informed decision that aligns with your business objectives.

Essential Technical Properties and Trade Terminology for pu ard

What Are the Essential Technical Properties of pu ard?

When dealing with pu ard, understanding its technical properties is crucial for making informed purchasing decisions. Below are some key specifications that buyers should consider:

-

Material Grade

Material grade indicates the quality and composition of the pu ard. Different grades can affect durability, flexibility, and resistance to environmental factors. For international buyers, selecting the right grade is vital to ensure that the product meets industry standards and specific application needs. -

Tolerance Levels

Tolerance levels refer to the permissible limits of variation in dimensions and physical properties. This specification is critical in B2B transactions, as precise tolerances ensure compatibility with existing systems or components. Understanding tolerance can help avoid costly adjustments or rework in manufacturing processes. -

Thermal Stability

The ability of pu ard to maintain its properties under varying temperatures is essential, particularly in industries like automotive and electronics. Buyers should evaluate thermal stability to prevent failure or degradation in high-temperature environments, which can lead to operational downtime and financial loss. -

Chemical Resistance

This property indicates how well the pu ard can withstand exposure to various chemicals, including solvents and oils. For sectors such as manufacturing and pharmaceuticals, selecting a pu ard with excellent chemical resistance is crucial to maintain product integrity and safety. -

Mechanical Strength

Mechanical strength encompasses the material’s ability to withstand forces without breaking. This is particularly important for applications requiring high durability. Buyers should assess the mechanical strength to ensure the pu ard can handle operational stresses, contributing to longevity and reliability. -

Surface Finish

The surface finish of pu ard can affect its aesthetic appeal and functionality, influencing adhesion properties and wear resistance. Understanding the surface finish is essential for applications where appearance and interaction with other materials are critical, like in consumer goods or medical devices.

What Are Common Trade Terms Used in the pu ard Industry?

Familiarity with industry jargon can enhance communication and streamline negotiations. Here are essential trade terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, knowing whether a supplier is an OEM can assure them of the product’s quality and compatibility with branded systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity a supplier is willing to sell. This term is significant for budgeting and inventory management. Buyers should ensure that the MOQ aligns with their needs to avoid excess inventory costs or supply shortages. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and terms for specific products or services. It is a crucial step in the procurement process, enabling buyers to compare offers and negotiate better terms. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, risk, and insurance. Understanding Incoterms is vital for international buyers to clarify delivery conditions and avoid disputes. -

Lead Time

Lead time refers to the amount of time from placing an order to receiving it. This term is crucial for supply chain management, as longer lead times can impact project timelines and inventory levels. Buyers should inquire about lead times to plan their operations effectively. -

Certification

Certification indicates that a product meets specific standards set by regulatory bodies. For buyers, ensuring that pu ard has the necessary certifications can be a critical factor in compliance and quality assurance, especially in regulated industries.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of purchasing pu ard more effectively, ensuring they make informed decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the pu ard Sector

What Are the Key Trends Influencing the Global PU Ard Market?

The global PU (Polyurethane) ard market is experiencing significant transformation driven by various factors, including technological advancements, shifting consumer preferences, and increasing regulatory pressures. One of the primary drivers is the growing demand for lightweight, durable materials in industries such as automotive, construction, and furniture. For B2B buyers in Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for strategic sourcing and procurement.

Emerging trends include the rise of digital platforms that facilitate B2B transactions, making it easier for international buyers to connect with suppliers. The adoption of advanced manufacturing technologies, such as 3D printing and automation, is also reshaping sourcing strategies, allowing for greater customization and efficiency. Furthermore, the integration of IoT (Internet of Things) in supply chains is enhancing transparency and traceability, which is particularly beneficial for buyers looking to optimize their procurement processes.

Another critical aspect is the increasing focus on sustainability. As regulations tighten around environmental impact, buyers are increasingly seeking suppliers who can demonstrate adherence to eco-friendly practices. This shift is influencing sourcing decisions, as companies prioritize partnerships with manufacturers committed to reducing their carbon footprints and using sustainable materials.

How Is Sustainability Shaping Sourcing Decisions in the PU Ard Sector?

The importance of sustainability in the PU ard sector cannot be overstated. B2B buyers are under growing pressure to ensure their supply chains are not only efficient but also environmentally responsible. The environmental impact of PU products, from production to disposal, has led to a rising demand for ethical sourcing practices. Buyers are now looking for suppliers who can provide transparency about their sourcing methods and environmental policies.

A stock image related to pu ard.

Green certifications and materials are becoming essential criteria in the sourcing process. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are indicators of a supplier’s commitment to sustainability. Additionally, the use of bio-based polyurethanes, which utilize renewable resources, is gaining traction among environmentally conscious buyers.

B2B buyers should also consider the lifecycle of PU products when evaluating suppliers. This includes understanding the recyclability of products and the potential for circular economy practices, where materials are reused or repurposed at the end of their life cycle. Engaging with suppliers who prioritize sustainability not only mitigates environmental risks but can also enhance brand reputation and consumer trust.

What Is the Evolution of the PU Ard Sector?

The PU ard sector has evolved significantly over the past few decades. Initially developed in the 1930s, polyurethane technology has advanced rapidly, leading to a wide range of applications in various industries. Early uses of PU were primarily in insulation and cushioning materials. However, as the technology improved, its applications expanded into coatings, adhesives, sealants, and flexible foams, making it a versatile material in the manufacturing landscape.

The introduction of environmentally friendly formulations in the 1990s marked a turning point in the industry, responding to growing environmental concerns and consumer demand for sustainable products. Today, the PU ard sector continues to innovate, with a focus on creating more efficient, durable, and eco-friendly materials. This ongoing evolution presents significant opportunities for international B2B buyers to leverage advancements in PU technology for competitive advantage in their respective markets.

Frequently Asked Questions (FAQs) for B2B Buyers of pu ard

-

How can I determine the reliability of a supplier for pu ard?

To assess the reliability of a supplier, start by reviewing their business history and customer testimonials. Check their certifications and compliance with international standards, especially in your region, such as ISO certifications. Engage in direct communication to gauge their responsiveness and professionalism. Utilizing platforms like Alibaba or Global Sources can provide insights into supplier ratings and transaction histories. Additionally, consider requesting samples to evaluate product quality before making larger commitments. -

What are the common minimum order quantities (MOQ) for pu ard?

Minimum order quantities (MOQ) for pu ard can vary significantly depending on the supplier and the specific product type. Generally, MOQs can range from 50 to 500 units for custom orders. It’s essential to discuss your needs with potential suppliers, as many are flexible, especially for new customers or bulk orders. Always clarify the MOQ upfront to avoid unexpected costs and ensure it aligns with your purchasing strategy. -

What payment terms should I expect when sourcing pu ard internationally?

International payment terms can vary, but common practices include letters of credit, advance payments, and net 30 or 60-day terms after delivery. When engaging with suppliers, ensure you discuss and agree upon payment terms that protect both parties. Consider using secure payment methods such as PayPal or Escrow services for initial orders to mitigate risks. Always confirm the currency and any potential transaction fees that may apply. -

How can I customize pu ard products to meet my specifications?

Customizing pu ard products typically involves discussing your specific requirements with the supplier. Provide detailed specifications, including dimensions, materials, and design elements. Most suppliers have a process for handling custom orders, which may include prototypes or samples before full production. Be prepared for potential additional costs and longer lead times for customized products, and ensure that you have a written agreement on the terms of customization. -

What quality assurance processes should I expect from suppliers of pu ard?

Reputable suppliers should have defined quality assurance (QA) processes in place. This includes initial inspections of raw materials, in-process quality checks, and final product evaluations. Request documentation of their QA procedures and certifications, such as ISO 9001. Additionally, consider conducting third-party inspections, especially for large orders, to ensure that products meet your quality standards before shipment. -

What logistics considerations should I keep in mind when importing pu ard?

When importing pu ard, consider the shipping methods (air vs. sea), delivery timelines, and associated costs. Work with logistics providers who understand the regulations and customs processes in your country. Ensure you account for potential duties and taxes upon arrival. It’s beneficial to establish a clear logistics plan with your supplier, including tracking shipments and expected delivery dates to manage inventory effectively. -

What are the key trade regulations I should be aware of when sourcing pu ard from different regions?

Trade regulations can vary by country and region. Familiarize yourself with import/export regulations in your country, including tariffs, product safety standards, and documentation required for customs clearance. For instance, importing into the European Union may require CE marking for certain products. Consulting with a trade compliance expert or using a freight forwarder can help navigate these complexities and ensure compliance with local laws. -

How can I establish a long-term relationship with my pu ard supplier?

Building a long-term relationship with your pu ard supplier involves consistent communication, transparency, and mutual respect. Regularly engage with them to provide feedback on products and services. Consider negotiating longer contracts or agreements that benefit both parties. Showing loyalty, making timely payments, and discussing future needs can enhance trust and lead to better pricing and service terms over time.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for pu ard

Why is Strategic Sourcing Crucial for International B2B Buyers?

In today’s dynamic global market, strategic sourcing is not just an operational necessity but a pivotal component for enhancing competitive advantage. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding local market dynamics while leveraging global suppliers can lead to significant cost savings and improved supply chain resilience. Adopting a strategic sourcing approach allows businesses to align their procurement processes with overarching organizational goals, ensuring that they are well-positioned to respond to market fluctuations.

How Can Buyers Prepare for Future Sourcing Trends?

As we look to the future, the importance of data-driven decision-making in sourcing will only grow. Buyers should invest in technology that provides insights into supplier performance, market trends, and risk assessment. Emphasizing sustainability and ethical sourcing practices will also become essential, as consumers increasingly demand transparency in supply chains.

What Steps Should B2B Buyers Take Now?

International B2B buyers are encouraged to actively engage with suppliers who prioritize innovation and adaptability. Building strong relationships with suppliers, exploring diverse sourcing options, and continuously evaluating market trends will enable businesses to navigate uncertainties effectively.

In conclusion, as the landscape of global trade continues to evolve, strategic sourcing will be a key differentiator. Embrace these insights and take proactive steps to secure your position in the market. The future is bright for those who adapt and innovate in their sourcing strategies.