Unlocking Efficiency: Your Ultimate Guide to LED Lights for B2B Buyers

Introduction: Navigating the Global Market for led lights

In today’s rapidly evolving global marketplace, LED lights have emerged as a vital component for businesses aiming to enhance efficiency, sustainability, and cost-effectiveness. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the dynamics of the LED lighting market is essential. This guide aims to equip you with the knowledge necessary to make informed sourcing decisions, ensuring that you not only meet your operational needs but also align with global sustainability goals.

The LED lighting sector is characterized by a diverse array of products, suppliers, and technological advancements. Navigating this complexity requires a strategic approach to procurement, emphasizing quality, compliance, and innovation. By delving into this guide, you will gain insights into market trends, key players, and best practices for sourcing LED lights that are both environmentally friendly and economically viable.

This comprehensive resource will cover critical topics such as the latest advancements in LED technology, regulatory considerations, and the impact of regional market trends. Whether you are looking to upgrade your facilities, enhance product offerings, or reduce energy consumption, this guide serves as a roadmap to empower your purchasing strategy. Embrace the potential of LED lighting and position your business for success in a competitive landscape.

Understanding led lights Types and Variations

Standard LED Bulbs

Standard LED bulbs are widely used in various B2B applications, such as retail and office spaces. They offer energy efficiency and a long lifespan compared to traditional incandescent bulbs, making them a cost-effective option for businesses. The ability to choose from various wattages allows for customization based on specific lighting needs. However, their installation is limited to standard fixtures, which may restrict their use in more specialized applications.

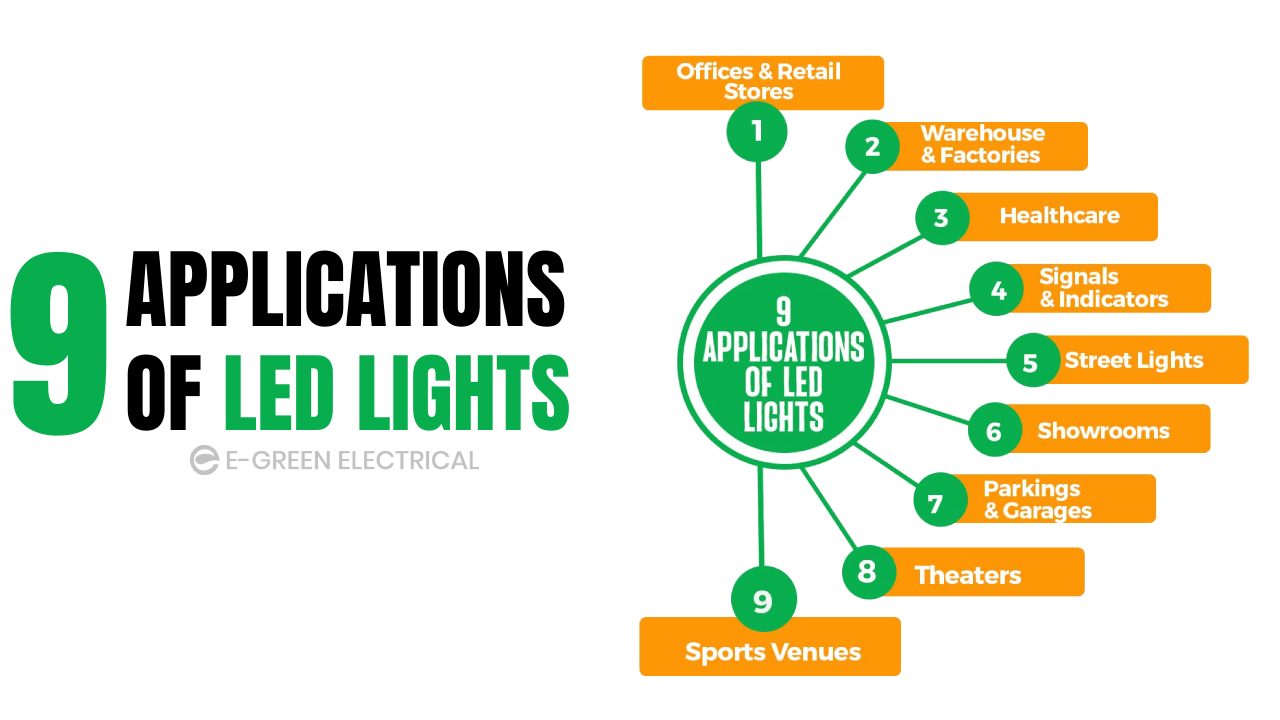

High Bay LED Lights

High bay LED lights are designed for spaces with high ceilings, such as warehouses and manufacturing facilities. They provide a high lumen output, ensuring ample illumination for large areas. Businesses benefit from their durability and low maintenance requirements, which can significantly reduce operational costs. The initial investment is higher than standard bulbs, but the long-term savings on energy and replacement costs justify the expense.

LED Strip Lights

LED strip lights offer versatility and flexibility, making them ideal for retail displays, interior design, and signage. They come in customizable lengths and a variety of colors, allowing businesses to create unique lighting effects. Their ease of installation makes them popular among designers and retailers. However, they may require additional power supplies or controllers, which can complicate installation in larger projects.

Smart LED Lights

Smart LED lights provide advanced features, such as app control and adjustable brightness and color settings. These lights are increasingly used in smart buildings, hospitality, and event spaces, allowing for enhanced control over the ambiance. The energy savings and convenience offered by smart lighting solutions can significantly reduce operational costs. However, the upfront costs can be higher than traditional options, which may deter some businesses from adopting this technology.

Outdoor LED Floodlights

Outdoor LED floodlights are engineered for high intensity and wide coverage, making them suitable for security applications, outdoor events, and sports facilities. Their weather-resistant design ensures reliability in various environmental conditions, enhancing safety and visibility. While they are energy-efficient and can reduce electricity bills, their use may be excessive in smaller areas, leading to unnecessary light pollution and increased costs.

Illustrative Image (Source: Google Search)

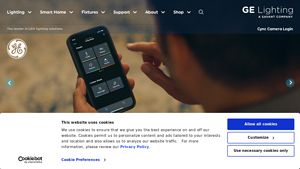

Key Industrial Applications of led lights

The adoption of LED lighting technology has significantly transformed several key industries, enhancing efficiency, sustainability, and cost-effectiveness. Below are some primary industries that utilize LED lights, along with specific applications, business value, and important sourcing considerations.

Illustrative Image (Source: Google Search)

Detailed Applications

Manufacturing

In the manufacturing sector, LED lights are extensively used for machine and workstation lighting. This application ensures that workers have adequate illumination, leading to improved visibility and reduced risk of accidents. The energy efficiency of LED lighting translates into lower electricity costs, which can significantly enhance operational margins. B2B buyers in this industry should focus on sourcing durable LED solutions that can withstand harsh environments and comply with safety standards.

Retail

Retail environments utilize LED lights for both display and ambient lighting. The vibrant colors and adjustable brightness of LED fixtures can highlight products effectively, enhancing the customer shopping experience and potentially increasing sales. Additionally, the energy efficiency of LEDs contributes to lower operational costs, making them an attractive option for retailers. Buyers should seek customizable lighting solutions that align with their brand identity and store aesthetics.

Agriculture

In agriculture, LED grow lights are revolutionizing indoor farming practices. These specialized lights promote photosynthesis, leading to increased crop yield and quality. Compared to traditional lighting systems, LED grow lights consume significantly less energy, providing a cost-effective solution for farmers. When sourcing these lights, B2B buyers should prioritize suppliers with expertise in agricultural applications to ensure optimal results.

Healthcare

Healthcare facilities rely on LED lights for surgical and examination room lighting. The clarity and consistency of LED illumination enhance patient safety and care, allowing healthcare professionals to perform their duties with precision. Moreover, the energy efficiency of LED lighting systems helps reduce operational costs in these facilities. Buyers should ensure that sourced products meet stringent health and safety regulations to maintain high standards of care.

Transportation

In the transportation sector, LED lights are widely used for street and highway lighting. This application improves visibility for drivers and pedestrians, contributing to safer urban environments. The long lifespan and energy efficiency of LED streetlights result in significant cost savings for municipalities. When sourcing these solutions, B2B buyers should consider options that integrate smart technology for enhanced efficiency and management capabilities.

Strategic Material Selection Guide for led lights

When selecting materials for LED lights, international B2B buyers must consider a variety of factors that can impact performance, durability, and cost. Below, we analyze four common materials used in the construction of LED lights, highlighting their properties, advantages, disadvantages, and applications.

1. Aluminum

Properties: Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity. It is a popular choice for heat sinks and housing components in LED lighting due to its ability to dissipate heat effectively.

Pros:

- Thermal Management: Excellent heat dissipation, prolonging LED life.

- Durability: Resistant to rust and corrosion, making it suitable for outdoor applications.

- Weight: Lightweight, which reduces shipping costs and installation complexity.

Cons:

- Cost: Generally more expensive than plastic materials.

- Aesthetic Limitations: Limited in color and finish options compared to other materials.

Application Impact: Aluminum is ideal for industrial and commercial LED fixtures where thermal management is crucial. Its durability makes it suitable for both indoor and outdoor environments.

2. Polycarbonate

Properties: Polycarbonate is a strong, transparent plastic known for its impact resistance and optical clarity. It is often used for lenses and diffusers in LED lighting.

Pros:

- Impact Resistance: Highly durable and resistant to shattering, making it safe for various applications.

- Light Transmission: Excellent optical properties allow for efficient light diffusion.

- Weight: Lightweight, which aids in reducing overall fixture weight.

Cons:

- UV Degradation: Can yellow and degrade over time when exposed to UV light without protective coatings.

- Thermal Sensitivity: Less effective in high-temperature environments compared to metals.

Application Impact: Polycarbonate is widely used in residential and commercial lighting where safety and aesthetics are important, such as in pendant lights and outdoor fixtures.

3. Glass

Properties: Glass offers superior optical clarity and can be treated for various properties like UV resistance and thermal stability. It is often used in high-end lighting applications.

Pros:

- Aesthetic Appeal: Provides a premium look and feel, enhancing design versatility.

- Thermal Resistance: Can withstand higher temperatures without deforming.

- Chemical Resistance: Resistant to many chemicals and environmental factors.

Cons:

- Fragility: More prone to breakage compared to plastic alternatives.

- Weight: Heavier than other materials, which can increase shipping and installation costs.

Application Impact: Glass is commonly found in decorative fixtures and high-end applications where appearance and durability are prioritized, such as chandeliers and wall sconces.

4. Steel

Properties: Steel is a strong and durable metal that can withstand significant physical stress. It is often used in the structural components of LED lighting fixtures.

Pros:

- Strength: Provides robust support for heavy fixtures.

- Longevity: Highly durable, making it suitable for long-term installations.

- Versatility: Can be coated or finished to enhance aesthetic appeal.

Cons:

- Corrosion: Prone to rust if not properly treated or coated.

- Weight: Heavier than aluminum and plastic, potentially complicating installation.

Application Impact: Steel is typically used in industrial and commercial applications, such as street lighting and warehouse fixtures, where durability and structural integrity are essential.

Summary Table

In conclusion, the choice of material for LED lights significantly impacts their performance, cost, and application suitability. B2B buyers should carefully evaluate these factors to ensure they select the best materials for their specific needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for led lights

Manufacturing LED lights involves a series of well-defined stages that ensure the final product meets the desired specifications and quality standards. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these processes is crucial for making informed purchasing decisions. Below is a detailed overview of the typical manufacturing processes, quality assurance standards, and methodologies involved in the production of LED lights.

Manufacturing Processes

1. Design and Prototyping

The manufacturing process begins with the design phase, where engineers and designers create detailed specifications and prototypes of the LED lights. This stage involves:

- Electrical Design: Circuit design for efficient power management.

- Thermal Management: Designing heat sinks to dissipate heat effectively.

- Optical Design: Creating lenses and reflectors to optimize light distribution.

Prototyping allows manufacturers to test the design, functionality, and aesthetics of the LED lights before mass production begins.

2. Component Sourcing

LED lights are composed of various components, including:

- LED Chips: The heart of the light source, typically sourced from reputable manufacturers.

- Drivers: Power supply units that regulate the electrical current to the LEDs.

- Housing Materials: Aluminum or plastic casings that provide durability and thermal management.

Sourcing high-quality components is essential for ensuring the longevity and performance of the final product.

3. Assembly

The assembly process includes several key stages:

- Soldering: LED chips are soldered onto circuit boards, often using surface mount technology (SMT). Automated pick-and-place machines are commonly used to ensure precision.

- Driver Installation: The LED driver is attached to the circuit board, ensuring proper electrical connections.

- Housing Assembly: The assembled circuit boards are placed into their respective housings, which may involve additional components like lenses or heat sinks.

4. Final Assembly and Packaging

Once the components are assembled, the final assembly involves:

- Quality Checks: Initial inspections are conducted to ensure all parts are correctly installed.

- Packaging: LED lights are carefully packaged to prevent damage during transportation. This stage often includes labeling and providing product information.

Quality Assurance

Quality assurance is a critical aspect of LED manufacturing, ensuring that products meet international standards and customer expectations.

International Standards

Several international standards govern the quality assurance processes in LED manufacturing:

- ISO 9001: This standard focuses on quality management systems and is applicable to any organization that aims to improve customer satisfaction and operational efficiency.

- IEC 60598: This standard pertains to the safety of luminaires and covers various aspects, including electrical safety and thermal performance.

- RoHS Compliance: Ensures that products do not contain hazardous substances, making them safer for consumers and the environment.

Quality Control Checkpoints

Quality control (QC) is integrated into the manufacturing process through various checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves inspecting the raw materials and components upon arrival. Components are checked for specifications, defects, and compliance with standards.

-

In-Process Quality Control (IPQC): During assembly, regular inspections are conducted to monitor the production process. This includes checking soldering quality, verifying component placements, and ensuring that assembly methods adhere to standards.

-

Final Quality Control (FQC): After the final assembly, LED lights undergo rigorous testing to ensure they meet performance criteria. This includes:

- Electrical Testing: Verifying voltage, current, and power consumption.

- Photometric Testing: Measuring light output (lumens) and efficacy (lumens per watt).

- Thermal Testing: Assessing heat dissipation and ensuring that the temperature remains within safe limits.

Common Testing Methods

Various testing methods are employed to validate the quality and performance of LED lights:

- Accelerated Life Testing (ALT): Simulating long-term usage in a short period to identify potential failures.

- Temperature Cycle Testing: Exposing products to extreme temperature variations to assess durability and performance under different environmental conditions.

- Ingress Protection Testing (IP Rating): Testing the product’s resistance to dust and moisture, which is essential for outdoor and industrial applications.

Verifying Quality Control

B2B buyers should take proactive steps to verify the quality control processes of manufacturers:

-

Request Documentation: Buyers should ask for certificates of compliance to relevant standards (e.g., ISO, IEC) and inspection reports from the manufacturer.

-

Factory Audits: Conducting audits of the manufacturing facilities can provide insights into the quality control measures and production capabilities.

-

Product Samples: Requesting samples for testing can help buyers assess the quality and performance of the LED lights before placing larger orders.

-

Third-Party Testing: Engaging third-party testing organizations can provide unbiased verification of product quality and compliance with international standards.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for LED lights is essential for B2B buyers seeking reliable and high-performance lighting solutions. By focusing on the key stages of manufacturing, adhering to international standards, and implementing robust quality control measures, manufacturers can deliver products that meet the rigorous demands of diverse markets. Buyers should leverage this knowledge to make informed purchasing decisions, ensuring they select reputable suppliers who prioritize quality and compliance.

Comprehensive Cost and Pricing Analysis for led lights Sourcing

Understanding the cost structure and pricing dynamics of LED lights is essential for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis will break down the key components of cost, the factors influencing pricing, and provide actionable insights for effective negotiation and procurement strategies.

Illustrative Image (Source: Google Search)

Cost Structure of LED Lights

-

Materials: The primary cost component in LED lights is the raw materials used in their production. This includes semiconductors, phosphors, and circuit boards. The prices of these materials can fluctuate based on global supply and demand dynamics, trade tariffs, and geopolitical factors. For instance, the price of gallium, a crucial element in LED manufacturing, can vary significantly, impacting overall production costs.

-

Labor: Labor costs can vary widely depending on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but this can sometimes come at the expense of quality. Conversely, manufacturers in higher-cost regions may provide superior craftsmanship and quality assurance, which can justify the higher price. Understanding the labor market in the manufacturing country is crucial for buyers.

-

Overhead: Overhead costs encompass all indirect costs associated with production, including factory maintenance, utilities, administrative expenses, and equipment depreciation. These costs can significantly influence the final price of LED lights. Buyers should consider how a manufacturer’s operational efficiency affects pricing.

-

Quality Control (QC): Effective quality control processes are essential for ensuring product reliability and longevity. Manufacturers that invest in rigorous QC protocols may have higher upfront costs, which could lead to a higher price point. However, this often results in lower total cost of ownership (TCO) for buyers, as high-quality products reduce the risk of failure and maintenance costs.

-

Logistics: Shipping and handling costs can vary based on the distance between the manufacturer and the buyer, as well as the mode of transportation. Buyers should be aware of potential additional costs associated with import duties, tariffs, and insurance. Efficient logistics management can mitigate these costs, making it a critical factor in pricing.

Price Influencers

Several factors can influence the pricing of LED lights:

-

Volume: Bulk purchasing typically results in lower per-unit costs. Manufacturers often offer discounts for larger orders, which can significantly affect the overall budget for buyers. Establishing a long-term relationship with suppliers may also yield better pricing through volume agreements.

-

Specifications: Customization of LED lights (e.g., specific brightness levels, color temperatures, and sizes) can lead to increased costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Quality: Higher quality standards often come with a premium price. Buyers must balance their need for quality with their budget constraints, considering the long-term benefits of investing in superior products.

Buyer Tips

-

Negotiation: Effective negotiation is crucial for securing favorable pricing. Buyers should come prepared with market research and be willing to discuss pricing based on volume, payment terms, and long-term contracts. Building rapport with suppliers can also facilitate more favorable negotiations.

-

Total Cost of Ownership (TCO): When evaluating LED lights, consider the TCO rather than just the upfront cost. This includes installation, maintenance, energy consumption, and potential replacement costs. Investing in high-quality products may lead to lower TCO over time, making it a wise financial decision.

-

Supplier Evaluation: Assess potential suppliers not only based on price but also on their production capabilities, quality assurance processes, and delivery reliability. A comprehensive evaluation will ensure that the chosen supplier aligns with your business needs and values.

By understanding these cost components and price influencers, B2B buyers can make informed decisions when sourcing LED lights, ultimately leading to better procurement outcomes and enhanced value for their businesses.

Spotlight on Potential led lights Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence.

Essential Technical Properties and Trade Terminology for led lights

When navigating the LED lights market, understanding key technical properties and industry terminology is crucial for international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe. This section outlines essential specifications and common trade terms that will enhance your purchasing decisions.

Key Technical Properties of LED Lights

-

Luminous Flux (lm): This measures the total amount of visible light emitted by a light source, expressed in lumens. Higher luminous flux indicates brighter light output, which is critical in applications requiring high visibility.

-

Color Temperature (K): Measured in Kelvin, this property defines the color appearance of the light emitted by the LED. Lower values (2700K-3000K) produce warm, yellowish light, while higher values (5000K-6500K) yield cooler, bluish light. This characteristic is vital in creating the desired ambiance in commercial spaces.

-

Efficacy (lm/W): This metric refers to the efficiency of the LED light in converting electrical energy into visible light, calculated as lumens per watt. A higher efficacy indicates a more energy-efficient product, which can significantly reduce operational costs over time.

-

Lifespan (hours): The operational life of an LED, typically rated between 15,000 to 50,000 hours. Understanding the lifespan is essential for assessing long-term value and maintenance needs, particularly for businesses that rely on consistent lighting.

-

CRI (Color Rendering Index): Ranging from 0 to 100, CRI measures how accurately a light source displays colors compared to natural light. A CRI of 80 or above is generally recommended for commercial applications to ensure true color representation.

-

Dimmability: This property indicates whether an LED light can be dimmed and to what extent. Dimmable LEDs offer flexibility in lighting design, allowing businesses to adjust brightness according to specific needs or times of day.

Common Trade Terminology in LED Lighting

-

OEM (Original Equipment Manufacturer): Refers to companies that produce components that are used in another company’s products. For LED buyers, partnering with an OEM can streamline sourcing and ensure product quality.

-

MOQ (Minimum Order Quantity): This term defines the smallest number of units that a supplier is willing to sell in a single order. Understanding MOQ is critical for budget planning and inventory management, especially for businesses with variable demand.

-

RFQ (Request for Quotation): A formalized process where buyers request pricing and terms from suppliers. An RFQ is essential for comparing costs and negotiating better deals, particularly in competitive markets.

-

Lead Time: The time taken from placing an order to delivery. Understanding lead times is crucial for project planning and ensuring timely availability of products, especially for large-scale installations.

-

Warranty: A guarantee provided by the manufacturer regarding the quality and lifespan of the LED product. A longer warranty often indicates confidence in the product’s durability, providing peace of mind for buyers.

-

Certification Standards: These are quality assurance benchmarks that LED products must meet to ensure safety and performance. Common certifications include CE (European Conformity), UL (Underwriters Laboratories), and RoHS (Restriction of Hazardous Substances). Familiarity with these standards is essential for compliance and market access.

By familiarizing yourself with these technical properties and trade terms, you can make informed purchasing decisions, ensuring that the LED lighting solutions you select meet your operational needs and regulatory requirements.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led lights Sector

The LED lights sector is experiencing a transformative period driven by technological advancements, changing consumer preferences, and regulatory pressures. The global market for LED lighting solutions is projected to grow significantly, with estimates suggesting a compound annual growth rate (CAGR) of around 10% through 2030. This growth is fueled by the increasing demand for energy-efficient lighting solutions that reduce operational costs while minimizing environmental impact.

In regions such as Africa and South America, rapid urbanization is propelling the demand for reliable and sustainable lighting solutions. Governments are also investing in infrastructure development, which creates opportunities for B2B buyers to engage with manufacturers and suppliers. In contrast, Europe and the Middle East are seeing a push towards smart lighting solutions that integrate IoT technology for enhanced control and energy management. Buyers in these regions should focus on suppliers who offer innovative, energy-efficient products that align with the latest technological trends.

Moreover, as countries tighten regulations on energy consumption and emissions, LED lighting becomes a necessity rather than an option. This regulatory landscape encourages companies to adopt LED solutions not only for compliance but also for brand differentiation in increasingly eco-conscious markets. Buyers should stay informed about local and international regulations to ensure their sourcing decisions align with compliance requirements and market demands.

Sustainability is no longer a mere trend; it has become a core component of business strategy in the LED lights sector. International B2B buyers must prioritize ethical sourcing and sustainability in their procurement practices. This involves evaluating suppliers based on their environmental impact, manufacturing processes, and material sourcing. For instance, many manufacturers are now focusing on using recyclable materials and reducing waste in production, which resonates well with environmentally conscious consumers.

Moreover, buyers should consider suppliers who embrace transparency in their supply chains. This includes providing information about the sourcing of raw materials, labor practices, and adherence to environmental regulations. By partnering with suppliers committed to sustainability, businesses can enhance their own brand reputation and appeal to a growing segment of eco-conscious customers.

Investing in LED technology has evolved significantly over the past few decades. Initially introduced in the 1960s as simple indicator lights, LEDs have undergone substantial advancements in efficiency, brightness, and application versatility. The transition from traditional incandescent bulbs to LED lighting began in earnest in the early 2000s, spurred by the need for energy conservation and advancements in semiconductor technology.

Today, LED lights are not only used in residential and commercial applications but also in specialized fields such as horticulture, automotive, and smart cities. This evolution reflects a broader trend toward energy-efficient solutions that meet diverse consumer needs. For B2B buyers, understanding this historical context is crucial for making informed sourcing decisions and aligning with suppliers who are at the forefront of innovation in the LED lighting industry.

As the market continues to evolve, staying abreast of technological advancements and sustainability trends will empower international buyers to make strategic decisions that benefit their businesses and contribute positively to the environment.

Frequently Asked Questions (FAQs) for B2B Buyers of led lights

-

How can I effectively vet suppliers of LED lights?

When vetting suppliers, start by checking their certifications and compliance with international standards (e.g., ISO, CE, RoHS). Request references from previous clients and examine their production capacity and technology. Conduct audits, either virtually or on-site, to assess quality control processes and labor practices. Additionally, consider their financial stability and the geographical location for logistical advantages. Leverage online reviews and industry forums to gather insights about their reputation and reliability in the market. -

Can LED lights be customized for my specific requirements?

Yes, many suppliers offer customization options for LED lights, including color temperature, lumens output, and design specifications. When discussing customization, clearly outline your requirements, including the intended application and any specific features needed. Request samples to evaluate the product’s performance and aesthetics before placing a larger order. Ensure that the supplier has the capability and experience in delivering customized solutions to meet your needs. -

What is the minimum order quantity (MOQ) for LED lights?

The MOQ for LED lights varies by supplier and can depend on factors like product type and customization options. Generally, it can range from a few dozen to several thousand units. When negotiating, inquire about flexibility in MOQs, especially if you are testing new products or entering a new market. Some suppliers may offer lower MOQs for initial orders to build a relationship, while others may have tiered pricing based on order volume. -

What quality assurance measures should I expect from LED light suppliers?

Reputable suppliers should implement comprehensive quality assurance (QA) protocols, including incoming material inspection, in-process testing, and final product evaluation. Expect to see certifications that demonstrate compliance with quality standards, such as ISO 9001. Request documentation related to testing procedures, including photometric, thermal, and electrical performance tests. Regular audits and third-party inspections can also serve as additional assurance of product quality. -

How do logistics and shipping impact my sourcing of LED lights?

Logistics play a crucial role in sourcing LED lights, affecting lead times, costs, and product availability. Assess the supplier’s shipping capabilities, including shipping options, delivery times, and freight costs. Consider the proximity of suppliers to major shipping routes or ports to minimize delays. It’s also important to understand import regulations and tariffs that could affect your total landed cost. Establish clear communication regarding shipping schedules and potential disruptions. -

What are the common payment terms when sourcing LED lights?

Payment terms can vary widely among suppliers, but common practices include deposits (often 30% upfront) with the balance due before shipment. Some suppliers may offer net terms (e.g., 30, 60, or 90 days) for established clients. Always negotiate terms that align with your cash flow and risk tolerance. Additionally, consider using secure payment methods and escrow services for larger orders to protect against fraud and ensure compliance with agreed terms. -

What certifications should I look for in LED lights?

Look for certifications that indicate compliance with safety, efficiency, and environmental standards. Common certifications include UL (Underwriters Laboratories), CE (Conformité Européenne), and Energy Star. These certifications ensure that the products meet rigorous testing for safety and performance. For markets in Africa and South America, check for local compliance marks that might be required for import. Always verify the authenticity of these certifications with the issuing authority. -

How can I ensure reliable after-sales support from my LED light supplier?

Reliable after-sales support is vital for maintaining product performance and customer satisfaction. Before finalizing a purchase, inquire about warranty terms, support channels, and response times for service requests. Ensure that the supplier has a dedicated customer service team and offers technical support for installation and troubleshooting. Request documentation on their return policy and procedures for handling defective products to avoid complications post-purchase.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide is for informational and educational purposes only. It does not constitute professional procurement, financial, or legal advice.

While we have made every effort to ensure accuracy, we are not responsible for any errors or omissions. Market conditions and company details are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions.

Strategic Sourcing Conclusion and Outlook for led lights

In summary, the strategic sourcing of LED lights presents a critical opportunity for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By embracing strategic sourcing practices, businesses can not only enhance operational efficiency but also significantly reduce costs associated with energy consumption and maintenance. The long lifespan and energy efficiency of LED technology make it a sustainable choice, aligning with the global push towards greener practices.

Buyers should prioritize partnerships with manufacturers that emphasize quality, compliance with international standards, and innovation in their product offerings. This approach not only mitigates risks related to supply chain disruptions but also fosters long-term relationships that can yield better pricing and product support.

Looking ahead, as the demand for energy-efficient lighting solutions continues to grow, engaging in strategic sourcing will be essential for staying competitive. B2B buyers are encouraged to actively seek out and evaluate potential suppliers, leveraging market intelligence and technological advancements to make informed decisions. The time to act is now; the future of lighting is bright, and your strategic choices today will pave the way for sustainable growth tomorrow.