Water Cap Dimensions Guide: Type,Cost,Material…

Introduction: Navigating the Global Market for water cap dimensions

Navigating the complexities of sourcing water cap dimensions can be a significant challenge for international B2B buyers. With varying standards and specifications across regions, understanding the nuances of neck finishes, thread sizes, and dimensions is essential for ensuring compatibility and functionality in your product offerings. This guide aims to illuminate the intricacies of water cap dimensions, covering everything from common types and applications to supplier vetting processes and cost considerations.

As you explore this resource, you will gain insights into the critical measurements that determine a secure fit, such as the “T,” “E,” “I,” “S,” and “H” dimensions, which are pivotal in selecting the right closures for your bottles. Additionally, we will delve into the implications of different thread finishes, including continuous and non-continuous options, to help you make informed decisions that enhance your product’s performance and marketability.

By equipping yourself with this comprehensive knowledge, you can confidently navigate the global market, particularly when engaging with suppliers from Africa, South America, the Middle East, and Europe, including Germany and Vietnam. This guide is designed to empower you with the expertise needed to streamline your purchasing processes and ultimately drive your business success in an increasingly competitive landscape.

Understanding water cap dimensions Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 60-400 | Standard neck finish with one thread turn; common size | Water bottles, personal drinkware | Pros: Widely available, easy to source. Cons: May not provide the tightest seal. |

| 38-400 | Versatile neck finish; suitable for various closures | Beverage packaging, food containers | Pros: Compatibility with many caps. Cons: Limited to standard applications. |

| 28-410 | Features a deeper thread for enhanced sealing capability | Cosmetic bottles, pharmaceutical containers | Pros: Better sealing for liquids. Cons: May require specialized caps. |

| 24-410 | Smaller neck finish; suitable for dispensing applications | Personal care products, oils | Pros: Ideal for controlled dispensing. Cons: Limited to smaller volume products. |

| 28-400 | Wider neck finish providing more stability and grip | Juices, sauces, and thicker liquids | Pros: Enhanced grip for easier handling. Cons: Less common, may have limited cap options. |

What Are the Key Characteristics of the 60-400 Neck Finish?

The 60-400 neck finish is characterized by its standard size and one complete thread turn, making it a prevalent choice for water bottles and personal drinkware. Its simplicity ensures compatibility with a wide range of closures, allowing manufacturers to easily source caps. However, while it is widely available, the seal may not be as tight as those found in more specialized finishes, which could be a consideration for products requiring higher leak resistance.

Why Is the 38-400 Neck Finish Popular Among B2B Buyers?

The 38-400 neck finish is highly versatile, accommodating various closures and making it suitable for numerous applications, including beverage and food packaging. Its compatibility with many cap types simplifies the procurement process for B2B buyers, allowing for streamlined production lines. However, its standardization may limit options for specialized sealing requirements, which could affect product integrity for certain liquid types.

How Does the 28-410 Neck Finish Enhance Product Sealing?

The 28-410 neck finish features a deeper thread design, providing superior sealing capabilities that are ideal for liquid products, including cosmetics and pharmaceuticals. This design allows for a more secure fit between the bottle and cap, minimizing the risk of leakage. While this finish enhances product safety, it may require buyers to source specialized caps, potentially complicating the supply chain.

In What Scenarios Is the 24-410 Neck Finish Most Effective?

The 24-410 neck finish is particularly well-suited for dispensing applications, often found in personal care products and oils. Its smaller diameter allows for precise pouring and dispensing, catering to consumer needs for control and convenience. However, the limited size may restrict its use to smaller volume products, which could be a drawback for manufacturers looking to package larger quantities.

What Advantages Does the 28-400 Neck Finish Provide?

The 28-400 neck finish is designed to provide stability and grip, making it an excellent choice for packaging thicker liquids such as juices and sauces. Its wider neck allows for easier handling and pouring, which is beneficial for consumer use. However, this finish is less common than others, which may lead to challenges in sourcing compatible caps, potentially impacting production timelines for B2B buyers.

Key Industrial Applications of water cap dimensions

| Industry/Sector | Specific Application of water cap dimensions | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Beverage Manufacturing | Designing custom water bottles with precise cap dimensions | Ensures product integrity and reduces leakage, enhancing consumer trust | Compliance with international standards, material compatibility |

| Chemical Packaging | Utilizing water cap dimensions for chemical containers | Provides secure sealing for volatile substances, ensuring safety | Chemical resistance of materials, threading specifications |

| Food and Beverage | Customizing caps for food-safe containers | Maintains freshness and prevents contamination, extending shelf life | Food-grade certification, compatibility with various dispensing systems |

| Personal Care Products | Tailoring caps for cosmetic and personal care bottles | Enhances user experience with easy dispensing and secure closures | Aesthetic design options, durability under various conditions |

| Industrial Equipment | Implementing water cap dimensions in industrial fluid containers | Ensures efficient handling and minimizes spillage during transport | Robustness of materials, compatibility with dispensing mechanisms |

How Are Water Cap Dimensions Used in Beverage Manufacturing?

In the beverage manufacturing sector, precise water cap dimensions are critical for designing custom water bottles. This ensures a secure fit between the cap and the bottle, preventing leakage and maintaining product integrity. Buyers must consider compliance with international standards, such as those set by the Society of Plastics Industry (SPI), to ensure that their products meet safety and quality requirements. Additionally, material compatibility is essential to avoid chemical reactions that could compromise the beverage.

What Role Do Water Cap Dimensions Play in Chemical Packaging?

In chemical packaging, water cap dimensions are vital for ensuring that containers provide a secure seal for volatile substances. This is particularly important for hazardous materials, where leaks can pose significant safety risks. Buyers in this sector need to prioritize sourcing caps that feature threading specifications capable of withstanding high pressures and chemical interactions. Furthermore, the materials used must demonstrate chemical resistance to ensure long-term reliability.

How Do Water Cap Dimensions Enhance Food and Beverage Safety?

Customizing caps for food-safe containers relies heavily on accurate water cap dimensions. These dimensions ensure that closures maintain product freshness and prevent contamination, which is essential for food safety. B2B buyers in the food and beverage industry should focus on sourcing caps that are certified food-grade, as well as compatible with various dispensing systems to enhance consumer convenience and satisfaction.

Why Are Water Cap Dimensions Important in Personal Care Products?

In the personal care sector, tailoring caps for cosmetic and personal care bottles using precise water cap dimensions enhances user experience. Secure closures prevent leaks and spills, while well-designed dispensing mechanisms facilitate ease of use. Buyers should consider aesthetic design options that align with brand identity while ensuring the durability of materials under various environmental conditions, such as humidity and temperature fluctuations.

How Do Water Cap Dimensions Contribute to Industrial Equipment Efficiency?

Water cap dimensions are crucial for implementing efficient handling in industrial fluid containers. Properly designed caps minimize spillage during transport, which is vital for maintaining operational efficiency and reducing waste. When sourcing these components, businesses need to focus on the robustness of materials and ensure compatibility with various dispensing mechanisms to meet the demands of industrial applications.

3 Common User Pain Points for ‘water cap dimensions’ & Their Solutions

Scenario 1: Incompatibility of Caps and Bottles

The Problem: One of the most common issues B2B buyers face is the incompatibility between caps and bottles due to incorrect water cap dimensions. When companies order bottles and caps based solely on visual design or branding without verifying the specific neck finish and thread sizes, they often discover that the closures do not fit. This oversight can lead to increased costs due to returns, wasted materials, and production delays, impacting the supply chain and customer satisfaction.

The Solution: To avoid this problem, buyers should implement a systematic approach to verify water cap dimensions before making purchases. First, ensure that all product specifications are clearly documented, including the “T” (outer diameter of the thread), “E” (outer diameter of the neck), and thread finish. Utilize standardized identifiers such as 60/400 or 38-400, which indicate both the neck width and the type of thread. Collaborate closely with manufacturers or suppliers to confirm compatibility by requesting samples for testing. Additionally, maintaining an updated database of dimensions for both caps and bottles can streamline the ordering process and prevent future mismatches.

Scenario 2: Difficulty in Customization for Unique Products

The Problem: Many businesses require custom water bottles for branding or specialized use, such as promotional events or unique product lines. However, the challenge often lies in accurately specifying the dimensions for custom caps. A lack of understanding of neck finishes and thread types can lead to poor-fitting caps that fail to seal properly, resulting in leaks and compromised product integrity. This situation not only diminishes brand reputation but also leads to costly recalls or returns.

The Solution: To effectively customize water bottles, buyers should engage in thorough research and development before finalizing their designs. This includes consulting with packaging experts who can provide insights on the best neck finishes and thread sizes for their specific requirements. Consider using CAD (Computer-Aided Design) software to create precise models of the bottle and cap, allowing for better visualization and adjustments. Furthermore, conducting pilot runs with prototypes can help identify any potential issues in sealing and usability, ensuring that the final product meets both functional and aesthetic standards.

Scenario 3: Regulatory Compliance and Safety Standards

The Problem: In regions like Africa and the Middle East, regulatory compliance for packaging can be stringent, with specific requirements regarding materials and closures. B2B buyers may struggle to navigate these regulations, particularly when it comes to ensuring that water cap dimensions align with safety standards. Non-compliance can lead to legal ramifications, financial penalties, or even bans on selling certain products, which can severely impact business operations.

The Solution: To mitigate compliance risks, buyers should stay informed about the relevant packaging regulations in their target markets. This includes understanding the specific standards for neck finishes and closures. Engaging with local regulatory bodies or consulting with compliance specialists can provide valuable guidance. Additionally, sourcing caps and bottles from manufacturers who are certified and familiar with international standards can streamline the compliance process. Implementing a quality assurance protocol that includes regular audits of both products and suppliers can further ensure adherence to safety standards, protecting the business from potential liabilities.

Strategic Material Selection Guide for water cap dimensions

What Are the Key Properties of Common Materials Used for Water Cap Dimensions?

When selecting materials for water cap dimensions, it’s essential to consider properties such as temperature and pressure ratings, corrosion resistance, and overall compatibility with the intended media. Below are analyses of four common materials utilized in the manufacturing of water caps.

How Do Different Plastic Materials Perform in Water Cap Applications?

1. Polyethylene (PE)

Polyethylene is a widely used plastic for water caps due to its excellent chemical resistance and low cost. It has a temperature rating of up to 80°C and is resistant to moisture and many chemicals, making it suitable for various applications.

Pros:

– Durability: Resistant to impact and wear.

– Cost-Effective: Low production costs make it ideal for large-scale manufacturing.

– Manufacturing Complexity: Simple to mold, allowing for efficient production processes.

Cons:

– Temperature Limitations: Not suitable for high-temperature applications.

– Environmental Concerns: Limited recyclability can impact sustainability efforts.

Impact on Application:

Polyethylene is compatible with a range of liquids but may not be suitable for high-temperature or aggressive chemical applications.

Considerations for International Buyers:

Buyers should ensure compliance with local regulations regarding plastic materials, especially in regions with stringent environmental laws. Standards such as ASTM D1248 may apply.

2. Polypropylene (PP)

Polypropylene is another popular choice for water caps, known for its higher temperature resistance (up to 100°C) and excellent chemical resistance compared to polyethylene.

Pros:

– Durability: Strong and resistant to fatigue.

– Versatile: Suitable for various applications, including hot-fill processes.

– Cost: Generally low to moderate, depending on the processing method.

Cons:

– UV Sensitivity: Can degrade when exposed to UV light unless treated.

– Brittleness at Low Temperatures: May become brittle in cold environments.

Impact on Application:

Polypropylene caps are ideal for water and beverages, especially in regions with higher ambient temperatures.

Considerations for International Buyers:

Ensure compliance with food safety standards such as FDA regulations and relevant European directives, especially when exporting to regions like Europe and the Middle East.

3. Stainless Steel

Stainless steel caps offer exceptional durability and corrosion resistance, making them suitable for applications involving aggressive chemicals or high temperatures.

Pros:

– Durability: Extremely robust and long-lasting.

– Corrosion Resistance: Ideal for a variety of media, including acidic and alkaline substances.

– Aesthetic Appeal: Often preferred for premium products.

Cons:

– Cost: Higher manufacturing costs compared to plastics.

– Weight: Heavier than plastic options, which may impact shipping costs.

Impact on Application:

Stainless steel caps are particularly suited for industrial applications and products requiring a high level of hygiene, such as in the food and beverage industry.

Considerations for International Buyers:

Buyers should be aware of compliance with standards such as ASTM A240 for stainless steel grades and ensure proper certification for food safety.

4. Glass

Glass caps are less common but are used for specific applications where chemical inertness and aesthetics are paramount.

Pros:

– Chemical Resistance: Excellent resistance to most chemicals.

– Recyclability: Glass is highly recyclable, aligning with sustainability goals.

– Aesthetic Quality: Provides a premium look and feel.

Cons:

– Fragility: Susceptible to breakage during handling and transport.

– Cost: Generally higher than plastic options.

Impact on Application:

Glass caps are ideal for high-end bottled beverages and products requiring a premium presentation.

Considerations for International Buyers:

Ensure compliance with local packaging regulations and standards, such as DIN 15490 in Europe, which governs glass containers.

Summary Table of Material Selection for Water Cap Dimensions

| Material | Typical Use Case for Water Cap Dimensions | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene (PE) | Bottled water and beverages | Cost-effective and durable | Limited temperature resistance | Low |

| Polypropylene (PP) | Hot-fill beverages and food containers | Higher temperature resistance | UV sensitivity and brittleness | Med |

| Stainless Steel | Industrial applications and premium products | Exceptional durability and corrosion resistance | Higher cost and weight | High |

| Glass | High-end beverages and specialty products | Chemical inertness and recyclability | Fragility and higher cost | High |

In-depth Look: Manufacturing Processes and Quality Assurance for water cap dimensions

What Are the Main Stages of Manufacturing Water Caps?

The manufacturing of water caps involves several critical stages, each aimed at ensuring precision in dimensions and quality. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Water Caps?

Material preparation is the foundational step in the manufacturing process. High-quality polymers, such as polypropylene or polyethylene, are commonly used for plastic caps, while metals like aluminum may be employed for more durable options. The materials are sourced from certified suppliers to ensure they meet industry standards for safety and performance. Before manufacturing, materials undergo rigorous testing for compliance with international regulations.

What Forming Techniques Are Used in Water Cap Production?

The forming process involves converting raw materials into the desired cap shapes. Techniques such as injection molding and blow molding are prevalent in producing plastic caps.

-

Injection Molding: This method involves injecting molten plastic into a mold, allowing for high precision in dimensions. It is particularly effective for producing caps with intricate designs and consistent quality.

-

Blow Molding: Often used for larger or hollow caps, this technique involves inflating a heated plastic tube inside a mold. It is suitable for creating lightweight and sturdy designs.

Each method has its advantages, and manufacturers often choose based on the cap design and required specifications.

How Are Water Caps Assembled and Finished?

After forming, caps undergo assembly, where additional components, such as liners or seals, are added to enhance functionality. This step ensures that the cap not only fits securely but also provides an effective barrier against contaminants.

The finishing stage involves surface treatments to improve aesthetics and functionality. This can include processes such as printing, coating, or adding textures for grip. Ensuring the caps are visually appealing while maintaining their functional integrity is crucial in competitive markets.

What Quality Assurance Practices Are Essential for Water Cap Dimensions?

Quality assurance (QA) is vital in ensuring that water caps meet specified dimensions and performance standards. This includes adherence to international standards like ISO 9001, which outlines the requirements for a quality management system.

Which International Standards Should B2B Buyers Be Aware Of?

B2B buyers should be aware of several international and industry-specific quality standards:

- ISO 9001: Focuses on ensuring consistent quality and improvement in manufacturing processes.

- CE Marking: Indicates compliance with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API (American Petroleum Institute): Relevant for caps used in applications involving chemicals or oils, ensuring safety and performance.

Understanding these standards helps buyers assess the credibility of manufacturers and the quality of their products.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This stage checks raw materials upon delivery, ensuring they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor dimensions and detect defects early in the process.

-

Final Quality Control (FQC): Once the caps are produced, they undergo rigorous testing against specifications to confirm they meet all requirements before shipment.

Each checkpoint serves as a critical measure to maintain quality throughout the production lifecycle.

What Common Testing Methods Are Used for Water Caps?

Testing methods are essential for validating the performance and safety of water caps. Common methods include:

-

Dimensional Inspection: Utilizing calipers and gauges to measure dimensions accurately, ensuring that caps meet the specified tolerances.

-

Seal Integrity Testing: This assesses the ability of the cap to maintain a secure seal under various conditions, simulating real-world use.

-

Material Testing: Analyzing the physical and chemical properties of materials to confirm they meet safety and regulatory standards.

-

Environmental Testing: Caps may also undergo tests to evaluate their performance under extreme temperatures or humidity levels.

These testing methods not only ensure compliance with industry standards but also enhance customer confidence in the product’s reliability.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to verify the quality control practices of their suppliers. Here are some effective strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall operational efficiency of suppliers.

-

Quality Reports: Requesting documentation detailing quality control processes, inspection results, and compliance with industry standards provides transparency and assurance.

-

Third-Party Inspections: Engaging independent inspection agencies can offer an objective evaluation of the supplier’s quality control systems and product quality.

-

Certification Verification: Buyers should verify suppliers’ certifications against international standards, ensuring they are up-to-date and relevant.

These measures empower buyers to make informed decisions and mitigate risks associated with sourcing.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate additional challenges when dealing with suppliers across different regions. Key nuances include:

-

Cultural Differences: Understanding local manufacturing practices and quality expectations can vary significantly, requiring buyers to adapt their approaches accordingly.

-

Regulatory Compliance: Different regions have unique regulations governing product safety and quality. Buyers must ensure that suppliers comply with both local and international standards.

-

Communication Barriers: Language differences may complicate the exchange of quality-related information. Clear communication channels are essential for addressing concerns promptly.

-

Logistical Challenges: International shipping introduces risks related to product damage or delays. Ensuring robust packaging and a reliable shipping partner is crucial.

By considering these factors, buyers can enhance their sourcing strategies and ensure the quality of water caps aligns with their expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘water cap dimensions’

To effectively procure water caps that meet your specific requirements, it’s essential to follow a structured checklist. This guide will help you navigate the complexities of water cap dimensions, ensuring that you make informed decisions during the sourcing process.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical specifications of the water caps you need. This includes the neck finish, thread size, and dimensions that correspond to your water bottles. Understanding these details will help you avoid compatibility issues later on and ensure that the caps provide a secure seal.

- Key Measurements to Note: The “T” dimension (outer diameter of the thread), “E” dimension (outer diameter of the neck), and “I” dimension (inner diameter) are critical to achieving a proper fit.

Step 2: Identify Industry Standards

Familiarize yourself with industry standards related to bottle neck finishes and thread sizes. Standards set by organizations like the Society of Plastics Industry (SPI) and the Glass Packaging Institute (GPI) ensure that you are sourcing caps that comply with accepted practices.

- Why It Matters: Adhering to these standards reduces the risk of sourcing caps that may not perform reliably in your market, especially in diverse regions like Africa, South America, and Europe.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request detailed company profiles, product samples, and references from clients in similar industries or regions.

- What to Look For: Assess their manufacturing capabilities, quality control processes, and experience with international shipping and regulations. This ensures that the supplier can meet your volume and quality expectations.

Step 4: Verify Material Compatibility

Ensure that the materials used for the caps are compatible with the contents of your water bottles. Consider factors such as chemical resistance, durability, and potential for leaching.

- Material Types: Common materials include plastics (like PET and HDPE) and metals. Each has unique properties that may affect the product’s performance and safety.

Step 5: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples for testing. This step is crucial for evaluating the fit, sealing ability, and overall quality of the caps.

- Testing Parameters: Conduct tests under various conditions to assess factors like seal integrity, ease of use, and resistance to environmental factors. Feedback from your team can provide insights into usability.

Step 6: Negotiate Terms and Conditions

After confirming the quality of the samples, engage in negotiations regarding pricing, delivery timelines, and payment terms. Be clear about your expectations to avoid misunderstandings later.

- Important Aspects: Discuss minimum order quantities, lead times, and any potential for bulk discounts. Ensure that both parties have a clear understanding of the terms before finalizing the agreement.

Step 7: Plan for Ongoing Quality Assurance

Once you begin sourcing caps, establish a system for ongoing quality assurance. Regular inspections and audits of the supplier’s production processes will help maintain the integrity of your supply chain.

- Continuous Improvement: Keep the lines of communication open with your supplier. Regular feedback can lead to improvements in product quality and service, ultimately benefiting both parties.

By following these steps, you can ensure that your sourcing process for water cap dimensions is efficient and effective, leading to successful procurement and satisfied end-users.

Comprehensive Cost and Pricing Analysis for water cap dimensions Sourcing

What Are the Key Cost Components in Sourcing Water Cap Dimensions?

When sourcing water cap dimensions, understanding the cost structure is crucial for B2B buyers to make informed decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Common materials for water caps include plastics like PET, polypropylene, and various metal alloys. The price of these materials fluctuates based on global market trends and availability.

-

Labor: Labor costs can vary widely depending on the production location. In regions with lower labor costs, such as parts of South America or Africa, buyers may find more competitive pricing. However, labor quality and expertise are equally important.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce these overheads, allowing suppliers to offer more competitive pricing.

-

Tooling: Custom molds and tooling for specific cap designs can entail significant upfront costs. While these costs are amortized over large production runs, smaller orders may face higher per-unit costs.

-

Quality Control (QC): Ensuring the caps meet industry standards and specifications is vital. Investing in QC processes can lead to higher upfront costs but can save money in the long run by reducing defects and returns.

-

Logistics: Shipping and handling costs are particularly relevant for international buyers. Factors such as distance, shipping method, and Incoterms can significantly influence total logistics costs.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the supplier’s business model and market position can provide insights into how much room there is for negotiation.

How Do Price Influencers Affect Water Cap Dimensions Sourcing?

Several factors influence pricing in the sourcing of water caps:

-

Volume/MOQ: Minimum Order Quantities (MOQs) play a critical role in pricing. Suppliers often provide discounts for larger orders, which can significantly lower the cost per unit.

-

Specifications and Customization: Customized designs and specifications, such as unique thread sizes or specific materials, can raise costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials Quality and Certifications: Higher quality materials or those that meet specific certifications (e.g., FDA compliance for food safety) can increase costs but are essential for product integrity and compliance.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can affect pricing. Established suppliers may charge more but offer better quality assurance and reliability.

-

Incoterms: Understanding the terms of shipping (such as FOB or CIF) is crucial, as they dictate who is responsible for shipping costs and risks, impacting the total landed cost.

What Tips Can Help Buyers Negotiate Better Prices for Water Caps?

-

Negotiation Strategies: Buyers should come prepared with data on market rates and competitor pricing. Building a strong relationship with suppliers can also facilitate better terms and pricing.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership rather than just the initial purchase price. This includes considering logistics, potential defects, and long-term supplier reliability.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and trade tariffs that can affect pricing. Engaging with local suppliers or distributors may help mitigate some of these costs.

-

Leverage Market Trends: Keeping abreast of market trends in material costs and supply chain dynamics can provide leverage during negotiations. Buyers should be proactive in seeking alternative suppliers if market conditions change.

Disclaimer on Indicative Prices

Pricing for water caps can vary widely based on the aforementioned factors. It is advisable for buyers to request quotes from multiple suppliers and conduct thorough market research to obtain the most accurate and competitive pricing.

Alternatives Analysis: Comparing water cap dimensions With Other Solutions

Understanding Alternatives in Water Cap Solutions

When it comes to selecting packaging solutions, understanding the alternatives to water cap dimensions is crucial for B2B buyers. The water cap’s dimensions play a significant role in ensuring product integrity, user convenience, and compatibility with various closures. However, there are alternative methods and technologies available that may offer different advantages based on specific needs and applications. In this analysis, we will compare traditional water cap dimensions against alternative closure systems and innovative sealing methods.

Comparison Table

| Comparison Aspect | Water Cap Dimensions | Alternative 1: Snap-On Caps | Alternative 2: Vacuum Sealing |

|---|---|---|---|

| Performance | Reliable and secure seal with standardized dimensions | Quick application, less secure | Excellent for preserving freshness and extending shelf life |

| Cost | Moderate production cost | Generally lower than threaded caps | Higher initial investment due to equipment |

| Ease of Implementation | Requires precise manufacturing standards | Simple and quick to apply | Requires specialized equipment for sealing |

| Maintenance | Minimal maintenance; inspect for wear | Low maintenance; replace as needed | Moderate maintenance; equipment upkeep necessary |

| Best Use Case | Ideal for bottled beverages, compliant with standards | Suitable for quick-service products like sauces or dressings | Best for perishable goods requiring extended freshness |

Analyzing Alternatives to Water Cap Dimensions

Snap-On Caps

Snap-on caps offer a straightforward closure method that eliminates the need for threading. These caps are designed to simply snap onto the container, providing a quick and efficient sealing solution. One of the main advantages of snap-on caps is their ease of use, which can significantly speed up the packaging process. However, they may not provide the same level of security as traditional threaded caps, potentially compromising product integrity in transport or storage. Snap-on caps are best used for products that are not sensitive to exposure, such as sauces or condiments.

Vacuum Sealing

Vacuum sealing is an innovative method that removes air from the packaging, creating an airtight environment. This technology is particularly beneficial for preserving the freshness of perishable goods, extending shelf life significantly. While vacuum sealing can be more expensive due to the required machinery and initial setup costs, it offers unparalleled protection against spoilage. However, it requires ongoing maintenance of the sealing equipment, which could be a drawback for some manufacturers. This method is ideal for food and beverage industries where maintaining product quality is paramount.

Making the Right Choice for Your Business Needs

When evaluating whether to use water cap dimensions or explore alternative closure solutions, B2B buyers should consider several factors. Assess the nature of the product, target market, and distribution channels. Water cap dimensions provide reliability and compliance with industry standards, making them suitable for many beverage applications. Conversely, snap-on caps and vacuum sealing may offer advantages in speed and freshness preservation, respectively. Ultimately, selecting the right solution will depend on balancing cost, performance, and the specific requirements of the product being packaged.

Essential Technical Properties and Trade Terminology for water cap dimensions

What Are the Key Technical Properties of Water Cap Dimensions?

Understanding the technical specifications of water cap dimensions is crucial for B2B buyers involved in packaging and manufacturing. These properties ensure compatibility, functionality, and quality across products. Here are several critical specifications:

1. Neck Finish Dimensions

The neck finish is defined by two key measurements: the neck width (T dimension) and the thread finish (e.g., 400). The neck width indicates the outer diameter of the neck in millimeters, while the thread finish specifies the number of complete turns of the thread. For example, a 60/400 neck finish means the neck diameter is 60mm, and there is one complete thread turn. Accurate neck finish dimensions are vital for ensuring a secure fit between the bottle and cap, preventing leaks and maintaining product integrity.

2. Material Grade

The material used for caps can significantly affect performance. Common materials include polypropylene, polyethylene, and various grades of stainless steel. Each material has unique properties, such as resistance to chemical interactions, temperature variations, and durability. Choosing the right material grade is essential for ensuring that the cap meets the specific requirements of the product being packaged, especially in regions with varying climates.

3. Tolerance Levels

Tolerance refers to the allowable deviation from specified dimensions. For water cap dimensions, maintaining tight tolerances is crucial to ensure a proper fit. For instance, a tolerance of ±0.2mm can be the difference between a secure seal and a leaky cap. In B2B transactions, specifying tolerance levels helps manufacturers maintain quality control and minimizes the risk of product failures.

4. Thread Type

There are primarily two types of threads: continuous and non-continuous. Continuous threads are unbroken spirals around the neck, while non-continuous threads may have gaps. The choice of thread type impacts how the cap engages with the bottle, affecting ease of use and sealing effectiveness. Understanding these differences helps buyers select the right closure system for their products.

5. Cap Height

Cap height is another important measurement that affects how the cap fits onto the bottle and its overall functionality. A well-defined cap height ensures that the cap aligns correctly with the neck of the bottle, which is crucial for applications that require specific dispensing mechanisms or features.

6. Seal Type

Different seal types, such as linerless closures or those with a foam or plastic liner, serve various purposes, including enhancing seal integrity and preventing contamination. The choice of seal type can affect the shelf life of the product and its usability, making it an important consideration for buyers.

What Are Common Trade Terms Related to Water Cap Dimensions?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are several essential terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products or components that are used in another company’s end products. In the context of water caps, buyers often work with OEMs to ensure that the caps meet specific design and quality standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for buyers to manage inventory effectively and maintain cost efficiency, especially when sourcing caps in bulk.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It typically outlines specific requirements, such as dimensions, materials, and quantities. Submitting a well-defined RFQ can lead to better pricing and more accurate proposals.

4. Incoterms (International Commercial Terms)

Incoterms are international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand the logistics involved in importing caps from different regions, affecting overall costs and delivery timelines.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. In the context of water caps, understanding lead times is essential for planning production schedules and meeting market demands.

6. Custom Specifications

This term refers to unique requirements set by buyers that may differ from standard offerings. Custom specifications might include specific dimensions, colors, or materials. Clearly defining these specifications is crucial for successful product development and fulfillment.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance product quality and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the water cap dimensions Sector

What Are the Current Market Dynamics and Key Trends Impacting Water Cap Dimensions?

The global market for water cap dimensions is experiencing notable shifts driven by increasing consumer demand for sustainable packaging solutions and innovative designs. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, navigate these market dynamics, understanding key trends becomes essential. The rise of e-commerce is significantly influencing sourcing strategies, with digital platforms enabling easier access to suppliers and manufacturers worldwide. Additionally, advancements in manufacturing technology, such as automation and 3D printing, are facilitating more efficient production processes, allowing for rapid prototyping and customization of water cap designs.

Furthermore, there is a growing emphasis on compliance with international standards, such as those set by the Society of Plastics Industry (SPI) and the Glass Packaging Institute (GPI). These guidelines ensure consistency in thread sizes and neck finishes, which are crucial for achieving secure closures. Buyers are increasingly prioritizing suppliers who can demonstrate adherence to these standards, thus enhancing product compatibility and reducing operational risks.

Emerging markets, particularly in Africa and South America, are witnessing a surge in bottled water consumption, prompting manufacturers to innovate their cap designs to improve functionality and user experience. This trend highlights the need for international buyers to stay informed about regional preferences and regulatory requirements that could impact their sourcing decisions.

How Is Sustainability Shaping the B2B Landscape for Water Cap Dimensions?

Sustainability has become a critical factor in the sourcing of water cap dimensions, as environmental concerns continue to grow. The packaging industry is under pressure to minimize its ecological footprint, leading to increased demand for caps made from recycled or biodegradable materials. B2B buyers are now prioritizing suppliers who offer sustainable options and have transparent supply chains, as consumers increasingly favor brands that demonstrate environmental responsibility.

Moreover, ethical sourcing practices are gaining traction among B2B buyers. Companies are expected to ensure that their suppliers adhere to fair labor practices and minimize environmental impacts throughout the production process. Certifications such as FSC (Forest Stewardship Council) and ISO 14001 (Environmental Management) are becoming essential in evaluating potential suppliers. These certifications not only validate a supplier’s commitment to sustainability but also enhance a buyer’s brand image in the eyes of environmentally conscious consumers.

As buyers look to align with sustainable practices, the introduction of innovative materials, such as plant-based plastics and reusable designs, is transforming the market. By investing in sustainable water cap dimensions, companies can reduce waste and appeal to an increasingly eco-aware customer base, thereby securing a competitive edge in the marketplace.

What Is the Historical Context of Water Cap Dimensions and Their Evolution in B2B Markets?

The evolution of water cap dimensions has been shaped by advancements in material science and changing consumer preferences over the decades. Initially, caps were primarily made from metal, but the shift towards lightweight and cost-effective plastic materials began in the late 20th century. This transition allowed for greater design flexibility and a reduction in production costs, which is particularly beneficial for B2B buyers looking to optimize their supply chains.

As health and safety regulations evolved, manufacturers began to focus on creating tamper-evident and child-resistant closures to enhance consumer safety. This led to the development of standardized neck finishes and thread sizes, ensuring compatibility across different bottle types. Today, the market is characterized by a blend of traditional manufacturing methods and cutting-edge technologies, making it essential for B2B buyers to stay updated on both historical trends and current innovations to make informed sourcing decisions.

In conclusion, understanding the dynamics of the water cap dimensions sector, including market trends, sustainability practices, and historical evolution, equips international B2B buyers with the insights needed to navigate this complex landscape effectively. By prioritizing innovative, sustainable solutions, buyers can not only enhance their product offerings but also align with the growing demand for responsible business practices in the global market.

Frequently Asked Questions (FAQs) for B2B Buyers of water cap dimensions

-

How do I choose the right water cap dimensions for my product?

Selecting the right water cap dimensions begins with understanding your bottle’s neck specifications. Focus on the “T” dimension (outer diameter of the thread) and the thread finish (e.g., 60/400). Ensure that your cap size matches these specifications for a secure fit. Additionally, consider the intended use of your product; for instance, products requiring enhanced sealing may benefit from deeper threads or higher neck finishes. Always communicate your requirements clearly with suppliers to avoid compatibility issues. -

What are the most common neck finishes for water bottles?

The most common neck finishes for water bottles include 400, 410, and 415 finishes. The 400 neck finish features one complete thread turn, ideal for standard bottles. The 410 offers one and a half thread turns for a tighter seal, while the 415 has two complete turns, providing even more stability. Depending on your product’s needs—such as dispensing requirements or sealing strength—select the neck finish that best matches your specifications. -

What should I look for when vetting a supplier for water bottle caps?

When vetting a supplier for water bottle caps, assess their manufacturing capabilities, quality control processes, and compliance with international standards. Check for certifications such as ISO or FDA approval, which indicate adherence to safety and quality regulations. Additionally, inquire about their experience in producing caps for your specific market and product type. Request samples to evaluate the fit and quality of their products before committing to a larger order. -

What is the minimum order quantity (MOQ) for customized water caps?

Minimum order quantities (MOQs) for customized water caps can vary significantly based on the supplier and the complexity of the design. Typically, MOQs may range from 1,000 to 10,000 units. It is crucial to discuss your requirements with potential suppliers to negotiate a suitable MOQ that aligns with your production needs. Smaller businesses may also seek suppliers willing to offer lower MOQs for initial testing or pilot runs. -

How can I ensure the quality of water bottle caps during production?

To ensure the quality of water bottle caps, implement a rigorous quality assurance (QA) process that includes regular inspections and testing. Collaborate with your supplier to establish quality benchmarks and testing protocols for dimensions, material strength, and sealing effectiveness. Consider third-party audits or inspections if necessary, especially for international shipments, to validate the supplier’s compliance with your quality standards. -

What payment terms are typically offered by suppliers for water caps?

Payment terms can vary widely among suppliers, but common practices include a 30% deposit upfront with the remaining balance due upon delivery or before shipment. Some suppliers may offer letter of credit options for larger orders, which can provide additional security for both parties. Always clarify payment terms upfront and consider negotiating for more favorable terms based on your purchasing volume or relationship with the supplier. -

What logistics considerations should I keep in mind when sourcing water caps internationally?

When sourcing water caps internationally, consider logistics factors such as shipping costs, customs duties, and lead times. Ensure your supplier can provide accurate shipping estimates and delivery timelines. Familiarize yourself with the import regulations of your country to avoid delays. Additionally, consider partnering with a logistics provider experienced in international trade to streamline the shipping process and manage any potential challenges. -

How do I customize water cap dimensions for my specific needs?

Customizing water cap dimensions involves collaboration with your supplier to define your specific requirements, such as neck finish, thread size, and material. Provide detailed specifications and any design prototypes if available. It’s also beneficial to discuss the intended application of your caps, as this can influence material choice and design features. Ensure that the supplier can accommodate your customization needs and has the technical expertise to deliver high-quality products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Water Cap Dimensions Manufacturers & Suppliers List

1. Paramount Global – Key Product Details

Domain: paramountglobal.com

Registered: 1999 (26 years)

Introduction: Key product details include: 1. Bottle Neck: The narrowest part of the bottle, providing control and allowing various closures. 2. Bottle Neck Finish: The connection point of the outer threads to the cap, commonly referred to as neck finish for bottles and thread finish for wide-mouth containers. 3. Measurements: – Neck width (T dimension) in mm – Thread finish (three-digit number) – Other dimensi…

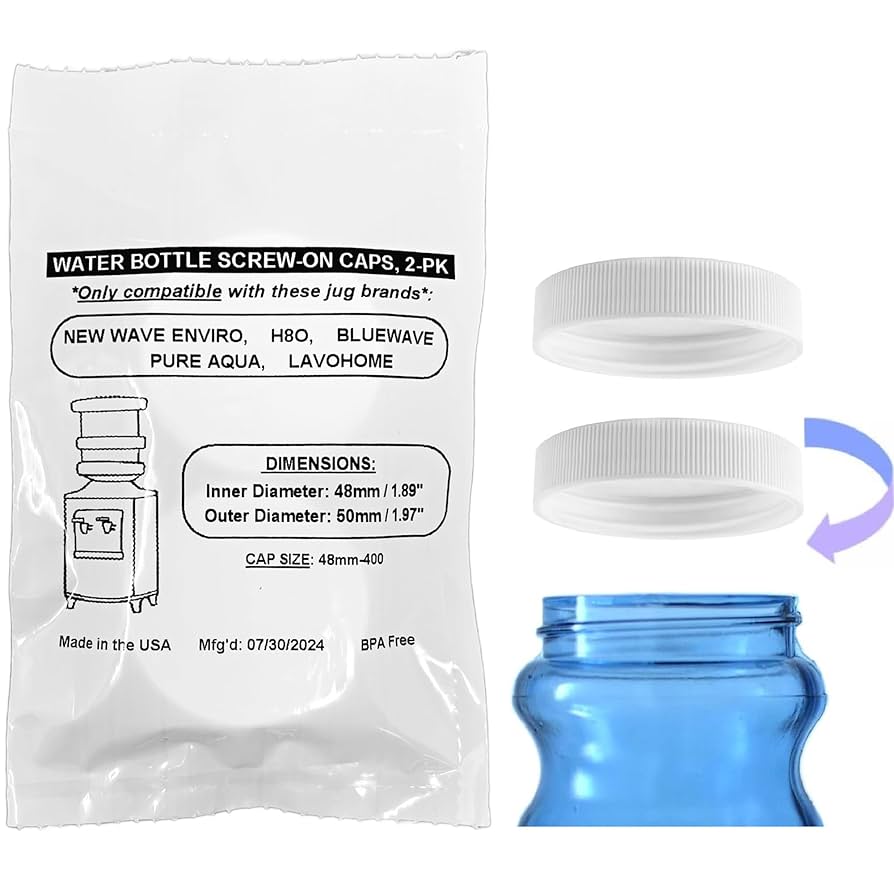

2. US Plastic – 55mm U-5 Universal Water Jug Cap

Domain: usplastic.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “55mm U-5 Universal White Water Jug Cap with Polyethylene Foam Liner”, “Item Number”: “82645”, “Color”: “White”, “Style”: “Cap”, “Mouth Size”: “55mm”, “Material”: “Polyethylene”, “Weight”: “0.029 lbs”, “Features”: [“Designed to accommodate various cooler probes used in the bottled water market”, “Avoids breaking probes”, “Incorporates a foam flap punctured by the probe upon insert…

3. MeasureTake – Crown and Screw Caps

Domain: measuretake.com

Registered: 2025 (0 years)

Introduction: Standard crown caps measure approximately 26.7mm in diameter, with an inner diameter of about 21.5mm and a height of roughly 6mm. They weigh 2.2 grams and can withstand over 80 pounds of pressure. Plastic screw caps range from 28mm to 38mm in diameter, with heights of 15-20mm. Sports drinks use 42-48mm caps. Twist-off metal caps measure 26-27mm in diameter and approximately 7.5mm in height, weighi…

4. Walmart – 3pk Screw-On Lids for Water Jugs

Domain: walmart.com

Registered: 1995 (30 years)

Introduction: This company, Walmart – 3pk Screw-On Lids for Water Jugs, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Briowt – Replacement Caps for Water Bottles

Domain: briowt.com

Registered: 2020 (5 years)

Introduction: Replacement Caps include various types designed for different water bottles. Key products include: 1. 48MM White Screw Cap for 1g, 2g, 3g, and 5g Water Bottles – standard replacement cap. 2. Safe-Guard Caps for 3g and 5g Crown Top Bottles – traditional push caps, 55mm size. 3. 55MM Push Cap for Crown Top Water Bottles – universal fit, 55mm size. 4. 48MM Blue Safe-Guard Screw Cap for 1g, 2g, 3g, an…

6. Geartrade – Water Bottle with Sport Cap

7. New Wave – 48mm Replacement Cap

Domain: thewaterbottlestore.com

Registered: 2005 (20 years)

Introduction: {“Product Name”: “New Wave Enviro 48mm Replacement Cap”, “Compatible Sizes”: “1, 3, and 5 Gallon Bottles”, “Material”: “BPA Free Plastic”, “Cap Size”: “48-400 screw cap”, “Price”: “$0.50”, “Product Code”: “NW8”}

8. Garage Grown Gear – Water Bottle Sport Cap

Domain: garagegrowngear.com

Registered: 2012 (13 years)

Introduction: {“name”: “Water Bottle Sport Cap”, “price”: “$1.10”, “quantity_options”: “1, 2, 3, 4, 5, 6, 7, 8, 9, 10+”, “shipping_info”: “Ships in 1-2 business days”, “description”: “Sip without breaking stride with these water bottle sport caps! Simply designed to provide splash-free, drip-free hydration. Featuring a divided spout to help control the flow of water and is conveniently made to fit most conventi…

9. Litesmith – Water Bottle Sport Caps

Domain: litesmith.com

Registered: 2014 (11 years)

Introduction: {“name”:”Water Bottle Sport Caps”,”price_range”:”$0.99 – $2.82″,”description”:”Flip open to drink, flip closed to seal. Snap top keeps spout clean. Clicks when closed. Quick on-the-go convenience. Fits any narrow-mouth water/soda bottle with a 28 mm thread. Compatible with various brands including Smartwater, LIFEWTR, Essentia, Aquafina, Desani, Coke/Pepsi, CNOC, Platypus, Evernew, and Sawyer.”,”s…

Strategic Sourcing Conclusion and Outlook for water cap dimensions

What Are the Key Takeaways for Strategic Sourcing of Water Cap Dimensions?

As we conclude this guide on water cap dimensions, it’s essential to emphasize the critical role that precise measurements and specifications play in the strategic sourcing process. Understanding the intricacies of neck finishes and thread sizes—such as the significance of the “T” and “E” dimensions—ensures compatibility between bottles and closures, minimizing production errors and enhancing product integrity. For B2B buyers, particularly in diverse regions such as Africa, South America, the Middle East, and Europe, this knowledge is invaluable in securing reliable suppliers and optimizing inventory management.

How Can Strategic Sourcing Lead to Improved Business Outcomes?

Strategic sourcing, when applied to water cap dimensions, not only streamlines procurement processes but also fosters innovation in product design. By aligning with manufacturers who adhere to recognized standards, businesses can improve quality control and reduce time-to-market. As global demand for sustainable and efficient packaging solutions continues to rise, now is the opportune moment for international buyers to invest in partnerships that prioritize precision and quality.

What Is the Next Step for International B2B Buyers?

Looking ahead, we encourage you to leverage this guide as a foundation for informed decision-making. Engage with suppliers who can provide detailed specifications and innovative solutions tailored to your market needs. By prioritizing strategic sourcing of water cap dimensions, you position your business for long-term success and sustainability in an increasingly competitive landscape.