Wpc Wall Panel Guide: Type,Cost,Material…

Introduction: Navigating the Global Market for wpc wall panel

In today’s dynamic construction and interior design landscape, sourcing WPC wall panels presents a unique challenge for international B2B buyers. These innovative materials, a blend of wood fiber and recycled plastic, are not just eco-friendly; they also offer aesthetic versatility and durability. As markets in Africa, South America, the Middle East, and Europe increasingly embrace sustainable building solutions, understanding the intricacies of WPC wall panels becomes crucial for making informed purchasing decisions.

This comprehensive guide delves into the multifaceted world of WPC wall panels, exploring various types, applications, and the benefits they offer across different sectors. From residential to commercial settings, these panels are redefining interior spaces while addressing critical concerns around sustainability and design flexibility. Additionally, we will provide actionable insights on supplier vetting processes, pricing strategies, and installation considerations to empower buyers in their procurement journey.

By equipping B2B buyers with the knowledge needed to navigate the global market for WPC wall panels, this guide aims to facilitate smarter purchasing decisions. Whether you’re operating in the burgeoning markets of Vietnam or the established sectors in Germany, understanding these materials can enhance your project outcomes and foster long-term business success. Explore how WPC wall panels can elevate your offerings and meet the growing demand for sustainable construction solutions.

Understanding wpc wall panel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Modern WPC Slat Panels | Made from a blend of recycled plastic and wood fibers; offers aesthetic appeal and versatility. | Interior design in residential and commercial spaces. | Pros: Eco-friendly, easy installation; Cons: May require careful handling during installation. |

| Acoustic WPC Panels | Designed to reduce sound transmission; often laminated with sound-absorbing materials. | Offices, conference rooms, and residential spaces needing sound control. | Pros: Effective sound insulation; Cons: Higher cost compared to standard panels. |

| Outdoor WPC Composite Panels | Weather-resistant, durable against UV rays and moisture; often textured for slip resistance. | Outdoor applications like patios, pool areas, and exterior walls. | Pros: Long-lasting, low maintenance; Cons: Can be heavier, requiring robust support structures. |

| Decorative 3D WPC Panels | Features three-dimensional designs for enhanced visual impact; available in various textures. | Retail environments, showrooms, and feature walls in hospitality. | Pros: Unique aesthetics, enhances branding; Cons: Installation can be more complex. |

| PVC Core WPC Panels | Lightweight with a PVC core; offers moisture resistance and ease of cutting. | Bathrooms, kitchens, and humid environments. | Pros: Cost-effective, easy to handle; Cons: Less durable than solid wood or composite options. |

What Are the Characteristics of Modern WPC Slat Panels?

Modern WPC Slat Panels are a popular choice for B2B buyers due to their combination of sustainability and aesthetic versatility. Made from a blend of recycled plastic and wood fibers, these panels are ideal for a variety of applications, including residential and commercial interiors. Their lightweight design allows for easy installation, making them a preferred option for contractors and interior designers. However, care must be taken during handling to avoid damage.

How Do Acoustic WPC Panels Enhance Sound Control?

Acoustic WPC Panels are specifically engineered to minimize sound transmission, making them essential for environments where noise control is critical. These panels often feature a laminated design that incorporates sound-absorbing materials, making them suitable for offices, conference rooms, and residential areas. While they provide effective sound insulation, their higher price point may require careful budget consideration for B2B buyers.

Why Choose Outdoor WPC Composite Panels for Exterior Projects?

Outdoor WPC Composite Panels are designed to withstand the elements, offering durability against UV rays and moisture. Their textured surfaces provide additional slip resistance, making them ideal for patios, pool areas, and exterior walls. B2B buyers appreciate their long-lasting nature and low maintenance requirements, although the weight of these panels may necessitate stronger support structures during installation.

What Are the Benefits of Decorative 3D WPC Panels?

Decorative 3D WPC Panels stand out for their striking three-dimensional designs, which add visual depth to any space. They are particularly effective in retail environments, showrooms, and hospitality settings where creating an impactful atmosphere is crucial. While these panels can significantly enhance branding and customer experience, their installation may require specialized skills, which should be factored into project planning.

How Do PVC Core WPC Panels Perform in Humid Environments?

PVC Core WPC Panels are lightweight and designed for moisture resistance, making them an excellent choice for areas prone to humidity, such as bathrooms and kitchens. Their ease of cutting and handling makes them a cost-effective option for contractors. However, buyers should be aware that while they offer affordability, their durability may not match that of solid wood or higher-end composite materials.

Key Industrial Applications of wpc wall panel

| Industry/Sector | Specific Application of wpc wall panel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Renovation | Interior wall cladding in residential and commercial spaces | Enhances aesthetic appeal while providing durability and ease of maintenance | Ensure compliance with local building codes and certifications |

| Hospitality | Wall paneling in hotels and resorts | Creates a luxurious ambiance, improving guest experience | Look for moisture-resistant options for high-humidity areas |

| Retail & Showrooms | Display walls for product showcases | Attracts customers and enhances brand presentation | Consider customizable designs to align with brand identity |

| Healthcare | Wall coverings in clinics and hospitals | Promotes hygiene and easy cleaning, crucial for health facilities | Verify antimicrobial properties and fire safety ratings |

| Education | Classrooms and hallways wall treatment | Provides sound insulation and a conducive learning environment | Ensure panels meet acoustic performance standards |

How are WPC Wall Panels Used in Construction and Renovation Projects?

In the construction and renovation sector, WPC wall panels are employed as a stylish and functional interior wall cladding solution for both residential and commercial projects. They address common issues like moisture resistance and durability, making them suitable for high-traffic areas. Buyers in this sector should prioritize sourcing panels that comply with local building regulations and certifications to ensure safety and reliability.

What Role Do WPC Wall Panels Play in the Hospitality Industry?

In hotels and resorts, WPC wall panels are used to create inviting and luxurious environments. Their aesthetic versatility allows for creative designs that enhance the overall guest experience. For international buyers, especially in regions with high humidity, it is essential to select moisture-resistant panels to maintain the integrity and appearance of the installations over time.

How Can Retailers Utilize WPC Wall Panels for Product Displays?

Retailers leverage WPC wall panels for creating eye-catching display walls that highlight their products. These panels not only serve as a backdrop but also enhance the overall shopping experience by providing a modern and clean aesthetic. Buyers should consider customizable options that align with their brand identity to maximize visual impact and customer engagement.

Why Are WPC Wall Panels Important for Healthcare Facilities?

In healthcare settings, WPC wall panels are increasingly used due to their hygiene benefits and ease of maintenance. They can be easily cleaned and are often designed with antimicrobial properties, making them ideal for clinics and hospitals. Buyers must ensure that the panels meet stringent fire safety ratings and hygiene standards to comply with healthcare regulations.

How Do WPC Wall Panels Improve Educational Environments?

WPC wall panels are utilized in educational institutions for wall treatments in classrooms and hallways, providing sound insulation and enhancing the learning atmosphere. This application addresses the need for quiet environments conducive to education. Buyers in this sector should ensure that the panels meet acoustic performance standards to effectively reduce noise levels and improve student focus.

3 Common User Pain Points for ‘wpc wall panel’ & Their Solutions

Scenario 1: Navigating Sourcing Quality WPC Wall Panels

The Problem: B2B buyers often face challenges in sourcing high-quality WPC wall panels that meet their specific project requirements. With an increasing number of suppliers in the market, distinguishing between genuine quality and subpar products can be daunting. Buyers may encounter panels that warp, fade, or show signs of wear much sooner than expected, leading to costly replacements and project delays. This is particularly concerning for businesses in sectors like hospitality or retail, where aesthetics and durability are paramount.

The Solution: To mitigate this issue, buyers should prioritize sourcing from reputable manufacturers with proven track records. Conducting thorough background checks, including reviewing customer testimonials and case studies, can provide insights into product performance. Additionally, it’s beneficial to request samples before making bulk purchases, allowing buyers to assess texture, finish, and overall quality firsthand. Collaborating with suppliers that offer warranties or guarantees can also provide added security, ensuring that buyers are protected in case of defects.

Scenario 2: Overcoming Installation Challenges with WPC Wall Panels

The Problem: Installation of WPC wall panels can be a complex process, particularly for businesses that lack specialized construction expertise. Buyers may struggle with aligning panels properly, ensuring a secure fit, or managing wall imperfections that could affect the final look. These challenges can lead to wasted materials, increased labor costs, and extended project timelines, frustrating both contractors and clients.

The Solution: To streamline the installation process, B2B buyers should invest in comprehensive training or support from their suppliers. Many reputable manufacturers provide installation guides, video tutorials, or on-site training sessions for their products. Furthermore, using adjustable clips or adhesive systems designed for WPC panels can help accommodate wall irregularities and ensure a more forgiving installation process. Buyers should also consider hiring skilled labor with experience in WPC products to ensure a professional finish and avoid common pitfalls.

Scenario 3: Addressing Sustainability Concerns with WPC Wall Panels

The Problem: As global awareness of environmental issues increases, B2B buyers are increasingly concerned about the sustainability of the materials they use in their projects. There may be skepticism regarding the eco-friendliness of WPC wall panels, particularly if they are perceived to contain harmful chemicals or if the sourcing practices are not transparent. This concern can complicate purchasing decisions, especially for businesses looking to align with green building standards or certifications.

The Solution: Buyers can address sustainability concerns by seeking out manufacturers that prioritize eco-friendly practices, such as using recycled materials and adhering to strict environmental regulations. Transparency in sourcing and production processes is critical; therefore, buyers should inquire about certifications, such as FSC (Forest Stewardship Council) or GREENGUARD, which indicate environmentally responsible practices. Additionally, highlighting the long-term benefits of WPC panels, such as their durability and low maintenance requirements, can further support sustainability narratives. Engaging in discussions about lifecycle assessments with suppliers can also provide insight into the overall environmental impact of WPC wall panels, enabling buyers to make informed decisions that align with their corporate social responsibility goals.

Strategic Material Selection Guide for wpc wall panel

What Are the Key Materials Used in WPC Wall Panels?

When selecting materials for WPC (Wood Plastic Composite) wall panels, understanding the properties, advantages, and limitations of common materials is crucial for B2B buyers. Here, we analyze four prevalent materials used in WPC wall panels, focusing on their performance, suitability for various applications, and considerations for international markets.

1. Recycled Plastic

Key Properties: Recycled plastic is often used as a primary component in WPC wall panels. It exhibits excellent resistance to moisture, UV radiation, and temperature fluctuations, making it suitable for diverse climates.

Pros & Cons: The durability of recycled plastic is a significant advantage, as it does not warp or rot like traditional wood. However, it can be more expensive than virgin plastic, and its manufacturing process can be complex, requiring specialized equipment.

Impact on Application: Recycled plastic is compatible with various media, including paint and adhesives, allowing for customization in design. However, it may not have the same aesthetic appeal as natural wood.

Considerations for International Buyers: Compliance with environmental regulations is crucial, particularly in regions with stringent recycling laws. Buyers should ensure that the products meet local standards such as ASTM for the U.S. or DIN for Germany.

2. Wood Fiber

Key Properties: Wood fiber provides structural integrity and aesthetic appeal to WPC wall panels. It offers good thermal insulation and sound absorption properties.

Pros & Cons: The natural look of wood fiber is a major selling point, as it can mimic the appearance of solid wood. However, it may be susceptible to moisture and pests if not treated properly, which can limit its durability in humid environments.

Impact on Application: Wood fiber is particularly effective in applications where appearance is essential, such as residential interiors. Its compatibility with various finishes allows for versatile design options.

Considerations for International Buyers: Buyers should verify that wood fiber products comply with international standards like JIS in Japan or ISO for general quality assurance. Additionally, sourcing sustainably harvested wood fiber is increasingly important in many markets.

3. PVC (Polyvinyl Chloride)

Key Properties: PVC is known for its high resistance to chemicals and moisture, making it ideal for environments prone to spills or humidity.

Pros & Cons: The low maintenance requirement and long lifespan of PVC wall panels are significant advantages. However, the material can be less environmentally friendly compared to other options, and its aesthetic may not appeal to all buyers.

Impact on Application: PVC’s durability makes it suitable for commercial applications, including retail spaces and restaurants. It is also compatible with various surface treatments.

Considerations for International Buyers: Compliance with local regulations regarding the use of PVC is essential, especially in regions focused on sustainability. Buyers should look for certifications that indicate low VOC emissions.

4. Composite Materials

Key Properties: Composite materials combine various elements, such as wood fibers and plastics, to enhance performance. They offer improved strength and flexibility.

Pros & Cons: The versatility of composite materials allows for innovative designs and applications. However, the manufacturing process can be complex and may lead to higher costs.

Impact on Application: These materials are suitable for high-traffic areas due to their durability and resistance to wear. They can be used in both indoor and outdoor settings.

Considerations for International Buyers: Buyers should ensure that composite materials meet the necessary international standards and certifications. Understanding the local market demand for composite products can also influence purchasing decisions.

Summary Table of Material Selection for WPC Wall Panels

| Material | Typical Use Case for wpc wall panel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Recycled Plastic | Outdoor installations | Excellent moisture and UV resistance | Higher cost compared to virgin plastic | Medium |

| Wood Fiber | Residential interiors | Natural aesthetic appeal | Susceptible to moisture and pests | Medium |

| PVC | Commercial applications | Low maintenance and durability | Less environmentally friendly | Low |

| Composite Materials | High-traffic areas | Enhanced strength and flexibility | Complex manufacturing process | High |

This strategic material selection guide aims to empower B2B buyers with the insights needed to make informed purchasing decisions regarding WPC wall panels. By understanding the properties and implications of each material, buyers can align their choices with market demands and regulatory requirements across diverse regions.

In-depth Look: Manufacturing Processes and Quality Assurance for wpc wall panel

What Are the Key Stages in the Manufacturing Process of WPC Wall Panels?

The manufacturing of Wood Plastic Composite (WPC) wall panels involves several critical stages, each contributing to the final product’s durability, aesthetics, and performance.

Material Preparation

The process begins with the careful selection and preparation of raw materials. WPC is typically made from a combination of recycled wood fibers and thermoplastics, such as polyethylene or polypropylene. The wood fibers are sourced from various wood processing industries, while the plastics can be obtained from post-consumer waste. The materials undergo drying and grinding to achieve the desired consistency and moisture content, ensuring optimal binding during the subsequent stages.

Forming

Once the materials are prepared, they are mixed in precise ratios to form a composite blend. This mixture is then subjected to various forming techniques. One common method is extrusion, where the blend is heated and forced through a die to create continuous panels. Another technique is injection molding, which allows for more complex shapes and profiles. The choice of forming method may vary based on the desired thickness, texture, and application of the wall panel.

Assembly

After forming, the panels undergo an assembly process, which may involve laminating additional layers for enhanced properties, such as moisture resistance and aesthetic appeal. This could include the application of decorative films or coatings. Some manufacturers also incorporate acoustic properties into their WPC panels, making them suitable for environments requiring sound dampening.

Finishing

The final stage of manufacturing involves finishing processes that enhance the appearance and performance of the panels. This can include surface treatments like sanding, painting, or applying a protective sealant. The finishing process not only improves the visual appeal but also extends the lifespan of the panels by providing resistance to wear and moisture.

How is Quality Assurance Implemented in WPC Wall Panel Production?

Quality assurance (QA) is a fundamental aspect of WPC wall panel manufacturing, ensuring that products meet international standards and customer expectations.

What International Standards Guide WPC Wall Panel Quality?

Manufacturers often adhere to international standards such as ISO 9001, which provides a framework for quality management systems. Compliance with ISO standards demonstrates a commitment to continuous improvement and customer satisfaction. Additionally, specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, depending on the intended market and application of the panels.

What Are the Key Quality Control Checkpoints in WPC Panel Production?

Quality control is typically integrated at various stages of production through checkpoints known as:

-

Incoming Quality Control (IQC): This stage involves the inspection of raw materials before they enter the production line. Ensuring the quality of inputs is crucial for minimizing defects in the final product.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to monitor the production parameters. This helps in identifying and correcting any deviations from the specified standards in real-time.

-

Final Quality Control (FQC): After the panels are manufactured, a thorough inspection is performed to ensure that they meet all specifications. This includes checks for dimensional accuracy, surface finish, and overall quality.

What Common Testing Methods Are Used to Ensure WPC Panel Quality?

Manufacturers utilize various testing methods to assess the quality of WPC wall panels, including:

-

Mechanical Testing: This involves assessing the strength, flexibility, and durability of the panels under different loads.

-

Moisture Resistance Testing: Given that WPC is often used in humid environments, testing for water absorption and swelling is critical.

-

Fire Resistance Testing: Panels are subjected to fire tests to ensure they meet safety standards for flammability.

-

Acoustic Testing: For panels designed for sound insulation, manufacturers conduct tests to measure sound absorption and transmission loss.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must conduct due diligence to verify the quality control practices of their suppliers. Here are several strategies:

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting supplier audits is an effective way to assess a manufacturer’s quality control practices. Buyers can request access to the supplier’s quality management system documentation, including audit reports, certifications, and compliance records. On-site audits can provide deeper insights into manufacturing processes, equipment, and overall operational standards.

How Can Buyers Review Quality Control Reports?

Buyers should request detailed quality control reports from their suppliers, which should outline the results of IQC, IPQC, and FQC activities. These reports can help assess the reliability of the supplier’s quality assurance processes and identify any recurring issues that may affect product quality.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can add an additional layer of assurance for buyers. Independent inspections provide unbiased evaluations of the manufacturing process, product specifications, and adherence to industry standards. This is particularly important for international buyers who may not have the capacity to conduct on-site audits.

What Are the Quality Control Nuances for International Buyers from Diverse Regions?

For international buyers, understanding regional quality control standards and practices is crucial. Buyers from Africa, South America, the Middle East, and Europe may encounter varying regulations and expectations regarding WPC wall panel quality.

How Do Regional Standards Affect Quality Expectations?

For instance, European buyers may prioritize CE certification, while buyers in the Middle East may focus on compliance with local building codes. Buyers should familiarize themselves with these standards to ensure that the products they source will meet local regulations and market expectations.

What Considerations Should Buyers Keep in Mind Regarding Supply Chain Transparency?

Supply chain transparency is increasingly important for B2B buyers. Understanding the source of materials, manufacturing processes, and the overall sustainability practices of a supplier can influence purchasing decisions. Buyers should inquire about the supplier’s supply chain practices and any certifications related to sustainability and ethical sourcing.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for WPC wall panels is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions that align with their quality expectations and market requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wpc wall panel’

This practical sourcing guide is designed to assist B2B buyers in navigating the procurement process for WPC wall panels. With the increasing demand for sustainable and versatile building materials, understanding the key steps in sourcing these panels can significantly streamline your purchasing decision and ensure you find the right supplier for your needs.

Step 1: Define Your Technical Specifications

Clearly outline the specifications you require for the WPC wall panels. Consider factors such as size, thickness, color, and intended application (e.g., indoor vs. outdoor use). Defining these parameters upfront helps in narrowing down suppliers that can meet your specific needs and reduces the chances of miscommunication later in the procurement process.

Step 2: Research Market Trends and Prices

Stay informed about current market trends and pricing for WPC wall panels. This knowledge allows you to understand the price range and helps you identify competitive offers. Look for reports or industry publications that focus on WPC materials to gauge the best options available in your target regions, especially in diverse markets like Africa and Europe.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request detailed company profiles, product catalogs, and references from other businesses in your industry. Pay attention to their experience level, especially in dealing with international clients, as this can influence their understanding of your requirements and shipping logistics.

Step 4: Verify Certifications and Compliance

Ensure that the suppliers you consider have the necessary certifications for WPC wall panels. Look for compliance with international standards for quality, safety, and environmental impact. Certifications such as FSC (Forest Stewardship Council) can indicate sustainable sourcing practices, which are increasingly important to eco-conscious buyers.

Step 5: Request Samples for Quality Assessment

Before finalizing any orders, request samples of the WPC wall panels. This step allows you to assess the material quality, durability, and aesthetics firsthand. Evaluate how the panels perform under conditions similar to their intended use, such as exposure to moisture or varying temperatures, to confirm their suitability.

Step 6: Discuss Terms and Conditions

Engage in discussions regarding payment terms, lead times, and delivery logistics with your chosen supplier. Clear communication about these terms is crucial to prevent misunderstandings later. Ensure that you also discuss return policies and warranties, as these can protect your investment in the event of product defects or issues.

Step 7: Establish a Long-term Relationship

Once you find a reliable supplier, consider building a long-term partnership. Regular communication and feedback can lead to better pricing, priority service, and tailored solutions for your specific needs. A strong supplier relationship can also facilitate future projects and enhance your overall sourcing strategy.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing WPC wall panels, ensuring they make informed decisions that align with their business objectives and sustainability goals.

Comprehensive Cost and Pricing Analysis for wpc wall panel Sourcing

What are the Key Cost Components in WPC Wall Panel Production?

When sourcing WPC (Wood Plastic Composite) wall panels, understanding the cost structure is critical for international B2B buyers. The primary cost components include:

-

Materials: The raw materials for WPC panels typically consist of recycled wood fibers and plastic. The quality and source of these materials can significantly influence costs. Higher-quality or certified materials may come at a premium, but they also enhance durability and aesthetic appeal.

-

Labor: Labor costs vary by region and can be a substantial part of the overall cost. In regions with lower labor costs, such as parts of Asia, the manufacturing price may be more competitive. Conversely, labor-intensive processes can lead to higher costs in regions with stricter labor laws and higher wages.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, equipment maintenance, and facility depreciation. Efficient manufacturing processes can help reduce these costs, affecting the final price of the panels.

-

Tooling: Custom tooling for specific panel designs or sizes can be a significant upfront investment. Buyers looking for unique designs should consider these costs as they can impact the overall pricing structure.

-

Quality Control (QC): Ensuring high quality in production often requires dedicated QC personnel and equipment. This adds to the manufacturing cost but is crucial for maintaining standards, especially when exporting to regions with strict quality regulations.

-

Logistics: Shipping costs can vary widely based on distance, mode of transport, and regional tariffs. Import duties and taxes may also apply, particularly for buyers in Africa and South America. Understanding Incoterms is essential to clarify responsibilities for shipping costs and risks.

-

Margin: Supplier margins can fluctuate based on competition, market demand, and the value-add provided by the supplier. Buyers should be aware of these margins when negotiating prices.

How Do Price Influencers Affect WPC Wall Panel Sourcing?

Several factors influence the pricing of WPC wall panels:

-

Volume/MOQ: Ordering in bulk usually leads to lower per-unit costs. Buyers should assess their needs and negotiate minimum order quantities (MOQ) to optimize pricing.

-

Specifications/Customization: Custom designs or specific specifications can increase costs. Understanding the balance between desired features and budget constraints is vital.

-

Materials: The choice of material impacts pricing. Sustainable or premium materials may be more expensive but can provide long-term value.

-

Quality and Certifications: Panels that meet international quality standards or possess certifications (e.g., eco-labels) may command higher prices but can assure buyers of product reliability.

-

Supplier Factors: Supplier reputation, experience, and reliability can influence costs. Established suppliers may charge more due to their proven track record.

-

Incoterms: Different shipping terms can significantly affect costs. Buyers should clearly understand the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) when negotiating prices.

What Buyer Tips Can Help Negotiate Better Prices for WPC Wall Panels?

To maximize cost-efficiency in sourcing WPC wall panels, consider the following strategies:

-

Negotiate Pricing: Leverage bulk orders or long-term contracts to negotiate better prices. Building a relationship with suppliers can also lead to favorable terms.

-

Understand Total Cost of Ownership (TCO): Beyond the purchase price, consider logistics, installation, maintenance, and longevity when evaluating costs. A higher upfront cost may yield savings over time through durability and reduced maintenance.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations, import tariffs, and regional pricing differences. Researching market conditions in target regions can provide leverage during negotiations.

-

Request Multiple Quotes: Obtaining quotes from various suppliers can create competitive pressure, potentially lowering prices.

-

Factor in Local Regulations: Understand the legal requirements and standards in your region, as compliance can affect overall costs.

Conclusion

Sourcing WPC wall panels requires a comprehensive understanding of cost components and pricing influencers. By applying strategic negotiation techniques and considering the Total Cost of Ownership, international buyers can make informed decisions that enhance value while optimizing costs. Always remember to consider the implications of Incoterms and local market dynamics for a successful sourcing experience.

Alternatives Analysis: Comparing wpc wall panel With Other Solutions

Introduction: Exploring Alternatives to WPC Wall Panels

When considering wall panel solutions, businesses often seek materials that balance performance, cost, and ease of installation. WPC (Wood Plastic Composite) wall panels are gaining popularity due to their sustainability and aesthetic appeal. However, it’s prudent to evaluate other viable alternatives that may align better with specific project requirements. This analysis compares WPC wall panels against two prominent alternatives: traditional wood paneling and PVC wall panels, providing insights into their respective advantages and drawbacks.

Comparison Table

| Comparison Aspect | WPC Wall Panel | Traditional Wood Panel | PVC Wall Panel |

|---|---|---|---|

| Performance | Highly durable, moisture-resistant | Prone to warping and rotting | Waterproof, but less durable than WPC |

| Cost | Moderate ($5-$9/sq.ft.) | Higher ($8-$15/sq.ft.) | Lower ($3-$6/sq.ft.) |

| Ease of Implementation | Requires specialized tools | Easy to install with basic tools | Quick installation, often interlocking |

| Maintenance | Low maintenance, easy to clean | Requires regular maintenance and sealing | Low maintenance, easy to wipe down |

| Best Use Case | Interior/exterior applications, high humidity areas | Residential interiors, aesthetic features | Wet areas like bathrooms and kitchens |

Detailed Breakdown of Alternatives

Traditional Wood Paneling

Traditional wood paneling offers a classic aesthetic that appeals to many buyers. It provides natural beauty and warmth, making it suitable for high-end residential and commercial projects. However, wood can be susceptible to moisture, leading to warping or rotting over time. Maintenance is also a consideration, as wood panels require regular sealing and refinishing to maintain their appearance and structural integrity. This can increase long-term costs and labor.

PVC Wall Panels

PVC wall panels are an economical alternative that offers excellent waterproofing capabilities, making them ideal for areas exposed to high moisture, such as bathrooms and kitchens. Their interlocking design allows for straightforward installation, reducing labor costs and time. However, while PVC panels are cost-effective, they may lack the durability and aesthetic appeal of WPC or wood panels. Over time, they can become discolored or brittle, leading to a shorter lifespan compared to WPC products.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate wall panel solution depends on various factors, including the specific environment, budget constraints, and desired aesthetics. WPC wall panels provide a balanced option, combining durability, moisture resistance, and low maintenance, making them suitable for diverse applications. Traditional wood panels excel in aesthetics but demand more upkeep, while PVC panels offer affordability and ease of installation, albeit with potential longevity concerns. B2B buyers should assess their unique project requirements and long-term goals to determine the best fit among these alternatives, ensuring that their investment aligns with their operational needs and design vision.

Essential Technical Properties and Trade Terminology for wpc wall panel

What Are the Essential Technical Properties of WPC Wall Panels?

When evaluating WPC (Wood Plastic Composite) wall panels for B2B procurement, understanding their technical properties is crucial for making informed purchasing decisions. Here are some key specifications to consider:

-

Material Composition

WPC panels are made from a blend of wood fibers and recycled plastic, which contributes to their durability and sustainability. This composition allows for a variety of finishes and textures, making them suitable for both aesthetic and functional applications. Buyers should consider the ratio of wood to plastic, as this can affect the panel’s strength, weight, and environmental impact. -

Density and Weight

The density of WPC panels typically ranges from 600 to 800 kg/m³. This specification is vital as it influences the panel’s sturdiness, ease of installation, and overall performance. Higher density panels tend to be more robust and resistant to damage, making them ideal for high-traffic areas. -

Thermal Conductivity

WPC panels generally have low thermal conductivity, making them effective insulators. This property is particularly important for buyers in regions with extreme temperatures, as it can enhance energy efficiency in buildings. Understanding thermal performance can help businesses reduce heating and cooling costs. -

Water Resistance and Durability

One of the standout features of WPC wall panels is their resistance to moisture, rot, and pests. Many manufacturers provide panels with a waterproof rating, ensuring longevity in humid or outdoor environments. This durability reduces maintenance costs and extends the lifespan of the installation, which is a significant consideration for B2B buyers looking for long-term solutions. -

Fire Rating

Depending on the formulation, WPC panels can achieve various fire ratings. Buyers should look for panels that meet specific fire safety standards relevant to their region or application. This is especially critical in commercial settings where safety regulations are stringent. -

Surface Finish Options

WPC panels come with various surface finishes, including textured, smooth, and wood-grain appearances. These options allow businesses to choose panels that match their design vision while also considering factors like ease of cleaning and maintenance.

What Are Common Trade Terms Associated with WPC Wall Panels?

Understanding industry jargon is essential for navigating the procurement process efficiently. Here are some common terms related to WPC wall panels:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces products that are marketed by another company under its brand name. In the context of WPC panels, understanding OEM relationships can help buyers ensure quality and consistency in their product sourcing. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. Knowing the MOQ is critical for buyers to plan their inventory and budget effectively. It can also influence purchasing strategies, especially for smaller businesses. -

RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer solicits price quotes from suppliers for specific products. This process is essential for comparing costs and ensuring competitive pricing for WPC wall panels. -

Incoterms (International Commercial Terms)

These are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping responsibilities, risk management, and delivery obligations. -

Lead Time

Lead time refers to the period between placing an order and receiving the goods. Understanding lead times is crucial for project planning and ensuring timely completion of construction or renovation projects involving WPC wall panels. -

Sustainability Certification

This term refers to certifications that indicate a product meets certain environmental standards, such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification). For B2B buyers focused on sustainability, these certifications can be a deciding factor in product selection.

By familiarizing yourself with these technical properties and trade terms, you can enhance your procurement strategies and make informed decisions that align with your business objectives.

Navigating Market Dynamics and Sourcing Trends in the wpc wall panel Sector

What Are the Current Market Dynamics and Key Trends Affecting the WPC Wall Panel Sector?

The global WPC wall panel market is experiencing notable growth, driven by rising demand for sustainable building materials and the increasing popularity of eco-friendly construction practices. Key markets in Africa, South America, the Middle East, and Europe are witnessing a surge in investments, particularly as urbanization accelerates. In regions like Vietnam, manufacturers are leveraging advanced technologies to optimize production processes, which enhances both product quality and cost-effectiveness. In Europe, particularly Germany, regulatory frameworks are pushing for greener building solutions, further driving the adoption of WPC panels.

Emerging trends include the integration of smart technology into wall panels, allowing for features such as sound insulation and temperature regulation. This is particularly appealing to B2B buyers looking for multifunctional products that enhance building performance. Additionally, the customization capabilities of WPC panels are becoming a key selling point, enabling businesses to cater to specific aesthetic and functional requirements of their clientele. The rise of e-commerce platforms is also reshaping sourcing strategies, allowing buyers to access a broader range of suppliers and products with ease.

How Is Sustainability and Ethical Sourcing Influencing the WPC Wall Panel Market?

Sustainability is a cornerstone of the WPC wall panel sector, with environmental considerations influencing purchasing decisions among B2B buyers. WPC panels, made from a composite of recycled wood fibers and plastic, significantly reduce the demand for virgin materials and minimize waste. This aligns with the growing emphasis on sustainable building practices across various industries, particularly in regions like Europe and the Middle East, where stringent environmental regulations are in place.

Ethical sourcing is also gaining traction, with buyers increasingly scrutinizing their supply chains. Companies are prioritizing suppliers who demonstrate transparency and commitment to sustainable practices. Certifications such as FSC (Forest Stewardship Council) and PEFC (Programme for the Endorsement of Forest Certification) are becoming essential for suppliers to differentiate themselves in a competitive market. By ensuring their products are sourced from responsibly managed forests, manufacturers can enhance their marketability while addressing the concerns of environmentally-conscious buyers.

What Is the Historical Context of WPC Wall Panels in B2B Markets?

The WPC wall panel industry has evolved significantly over the past few decades. Initially developed in the 1990s as an alternative to traditional wood products, WPC panels gained popularity due to their durability, low maintenance, and resistance to moisture and pests. As sustainability became a focal point in construction, the demand for WPC materials surged, leading to innovations in manufacturing processes and product design.

Today, WPC wall panels are recognized not only for their practical benefits but also for their aesthetic versatility. They have become a favored choice in various applications, from residential interiors to commercial spaces. As the market continues to mature, the focus on sustainable practices and technological advancements will likely shape the future trajectory of the WPC wall panel sector.

Frequently Asked Questions (FAQs) for B2B Buyers of wpc wall panel

-

How do I ensure the quality of WPC wall panels when sourcing?

To ensure the quality of WPC wall panels, conduct thorough supplier vetting by requesting samples before placing larger orders. Look for suppliers with ISO certifications and positive customer reviews. Additionally, inquire about their production processes, including the materials used, to confirm they meet international standards. Establish a quality assurance protocol, including third-party inspections at the factory or upon delivery, to ensure the panels meet your specifications and standards. -

What is the best type of WPC wall panel for outdoor use?

For outdoor applications, select WPC wall panels specifically designed for exterior use, as they are engineered to withstand weather elements. Look for panels with enhanced UV resistance and water-repellent features to prevent warping and fading. Products that incorporate a higher percentage of wood fibers and are treated for durability will provide better performance. Always confirm that the panels come with a warranty that covers outdoor usage to safeguard your investment. -

How can I customize WPC wall panels to fit my project needs?

Most manufacturers offer customization options for WPC wall panels, including variations in size, color, and texture. When discussing your project with suppliers, clearly outline your requirements, such as specific dimensions or finishes. Some suppliers may also provide bespoke designs or branding options. Ensure to ask about minimum order quantities for customized products, as these may vary between manufacturers. -

What are the minimum order quantities (MOQ) for WPC wall panels?

Minimum order quantities for WPC wall panels can vary significantly based on the manufacturer and the specific product line. Generally, MOQs range from 100 to 1,000 square feet, depending on the panel type and customization requirements. Always clarify MOQs with potential suppliers during the negotiation phase. If your project requires a smaller quantity, discuss the possibility of combined orders with other buyers or check if the supplier offers pre-packaged options. -

What payment terms should I expect when sourcing internationally?

Payment terms for international sourcing can vary widely among suppliers. Common practices include a 30% deposit upon order confirmation, with the balance due before shipment or upon delivery. Some suppliers may offer letters of credit or payment through escrow services for added security. It’s essential to negotiate favorable terms that protect your interests while also considering the supplier’s requirements to build a mutually beneficial relationship. -

How do I manage logistics and shipping for imported WPC wall panels?

Managing logistics for importing WPC wall panels involves coordinating with freight forwarders to handle shipping, customs clearance, and delivery. Always confirm shipping costs, estimated delivery times, and insurance coverage for your order. It’s advisable to choose suppliers with experience in international shipping to navigate customs regulations effectively. Consider using Incoterms (International Commercial Terms) to clarify responsibilities for transportation, risk, and costs between you and the supplier. -

What should I know about the environmental impact of WPC wall panels?

WPC wall panels are generally considered eco-friendly due to their composite material made from recycled wood and plastic. When sourcing, inquire about the sustainability practices of the manufacturer, including sourcing of raw materials and recycling processes. Look for certifications like FSC (Forest Stewardship Council) or similar, which indicate responsible forestry practices. Understanding the environmental impact can enhance your brand’s sustainability profile and appeal to eco-conscious clients. -

What are the common applications for WPC wall panels in various industries?

WPC wall panels are versatile and can be used across various industries, including residential, commercial, and industrial settings. Common applications include interior wall cladding in homes and offices, soundproofing in studios, and weather-resistant paneling for outdoor spaces. In hospitality, they can enhance aesthetics while providing durability. Understanding the diverse applications can help you target your market effectively and propose tailored solutions to potential clients.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Wpc Wall Panel Manufacturers & Suppliers List

1. Art3D – Modern WPC Slat Panel

Domain: art3d.com

Registered: 1998 (27 years)

Introduction: Modern WPC Slat Panel, made from wood-plastic composite, suitable for indoor and outdoor use, available in various colors and finishes, resistant to moisture, insects, and decay, easy to install and maintain, ideal for wall decoration, fencing, and privacy screens.

2. Slat Solution – WPC Fluted Slat Wall Panels

Domain: slatsolution.com

Registered: 2023 (2 years)

Introduction: WPC Fluted Slat Wall Panels are designed for interior decor, suitable for high-traffic areas such as commercial buildings, apartments, property management, schools, and homes. Made from Wood-Plastic Composite (WPC) with a durable wood veneer-like finish, they mimic the look and feel of real wood at a lower cost. Available in four finishes: Antique Maple, Antique Oak, Light Oak, and Ultra Black. Pr…

3. WPC Wall Panels – Acoustic Panel/Wood Veneer

Domain: laminatefloorsmiami.com

Registered: 2007 (18 years)

Introduction: {“WPC Wall Panels”: {“Acoustic Panel/Wood Veneer”: {“Sizes”: [“12″ x 118”, “11.2” x 118″], “Price”: {“Regular”: “$49.99”, “Sale”: “$39.99”}}, “Polystyrene Panel/Paper Film”: {“Size”: “4.8” x 106″}, “Outdoor Panel WPC Composite”: {“Size”: “8.5” x 114″, “Price”: “$35.00”}}, “Laminwall”: [{“Type”: “Wall Panel”, “Core”: “PVC”, “Film”: “Paper”, “Color”: “Pale Yellow”, “Price”: “$16.99”}, {“Type”: “Wall…

4. New Gen Depot – WPC Fluted Wall Panels

Domain: newgendepot.com

Registered: 2024 (1 years)

Introduction: WPC Fluted Wall Panels – Stylish & Durable Interior Panels. Available in various colors and wood-like textures. Sizes include 95 x 6.5 inches and 108 x 6.5 inches. Each box contains either 10 or 14 panels, covering approximately 42.9 sq. ft. per box. Key benefits include wholesale pricing, low maintenance, eco-friendly materials, and quick installation. Prices range from $13.90 to $210.00 dependin…

5. George Panel – Outdoor WPC Wall Panels

Domain: georgepanel.com

Registered: 2022 (3 years)

Introduction: Outdoor WPC Wall Panels combine the advantages of wood and plastic, offering a natural wood texture while being waterproof and anti-corrosion. They are easy to install, customizable, and available in various designs, colors, textures, and finishes. Made from recyclable materials, they are environmentally friendly and sustainable. The panels are durable, resistant to harsh outdoor conditions, and s…

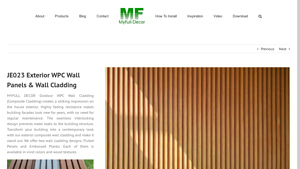

6. MyFullDecor – Exterior WPC Fluted Wall Panels

Domain: myfulldecor.com

Registered: 2018 (7 years)

Introduction: Exterior WPC Fluted Wall Panels

– Type: Outdoor Wall Panel / Wall Cladding

– Material: WPC (Wood Plastic Composite)

– Design: Fluted Panels and Embossed Planks

– Size: 219x26mm

– Weight: 2.86 kgs/m

– Profile Code: JE-23

– Colors Available: Maple Wood, Silver Grey, Ancient Wood, Light Grey, Teak A, Rosewood, Teak B

– Features:

– Highly fade resistant

– Seamless interlocking design to prevent w…

7. Wayfair – Outdoor WPC Wall Panels

Domain: wayfair.com

Registered: 2004 (21 years)

Introduction: {“keyword”:”outdoor wpc wall panels”,”product_count”:14020,”categories”:[{“name”:”Wall Paneling”,”filter_string”:”masterClID~7279″},{“name”:”Privacy Screens”,”filter_string”:”masterClID~7552″},{“name”:”All Fencing”,”filter_string”:”masterClID~3361″},{“name”:”Ceiling Tiles”,”filter_string”:”masterClID~7160″},{“name”:”Floor Tiles & Wall Tiles”,”filter_string”:”masterClID~2970″},{“name”:”Arbors & Tre…

Strategic Sourcing Conclusion and Outlook for wpc wall panel

In the rapidly evolving landscape of interior design and construction, WPC wall panels emerge as a versatile and eco-friendly solution that aligns with sustainability goals while enhancing aesthetic appeal. For B2B buyers, understanding the nuances of strategic sourcing for WPC products is crucial. This includes identifying reliable suppliers who offer quality materials, assessing pricing structures that reflect market trends, and evaluating product versatility for various applications—ranging from residential to commercial projects.

The integration of WPC wall panels not only provides functional benefits, such as sound insulation and moisture resistance, but also caters to the growing demand for sustainable building materials. As international markets, particularly in Africa, South America, the Middle East, and Europe, increasingly prioritize eco-friendly options, the opportunity for businesses to capitalize on WPC products is significant.

Looking ahead, we encourage B2B buyers to engage with suppliers who share their commitment to sustainability and innovation. Establishing strong partnerships and staying informed about emerging trends will be vital in navigating the competitive landscape. Embrace the potential of WPC wall panels to transform spaces while contributing to a greener future.